Patents

Literature

35results about How to "Provides productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

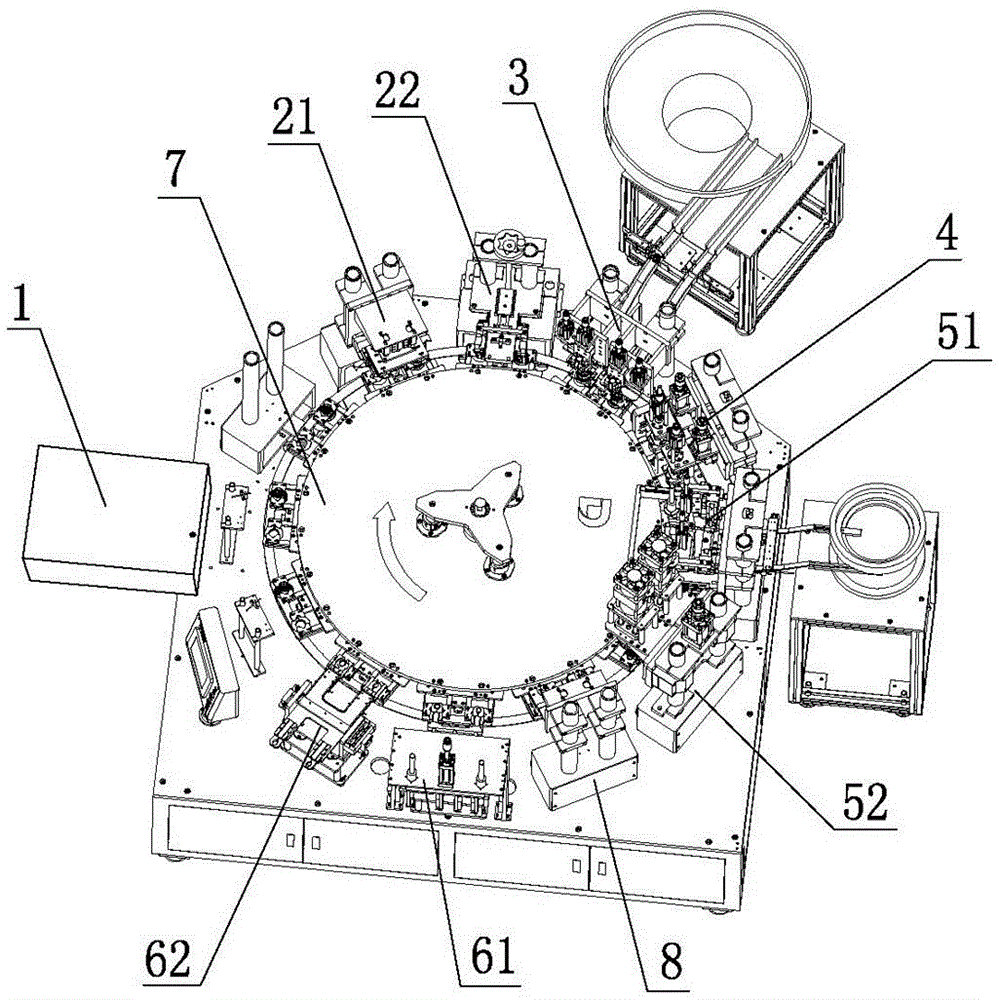

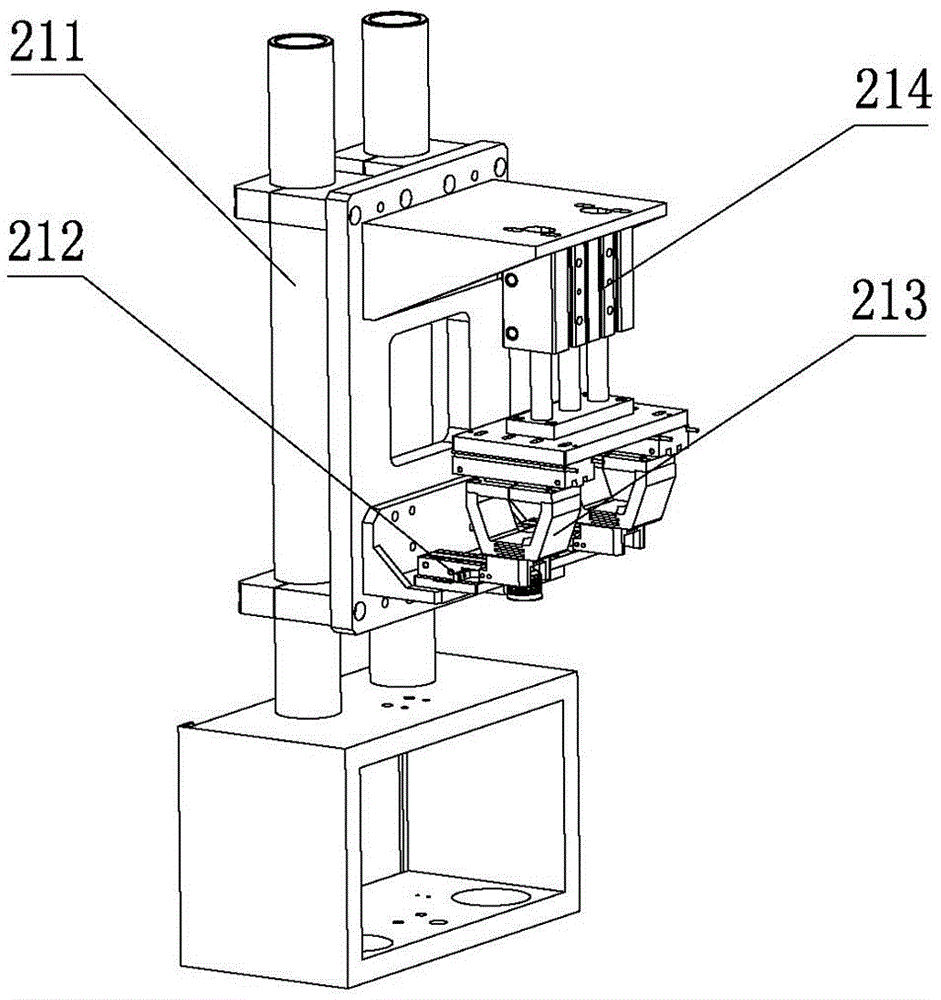

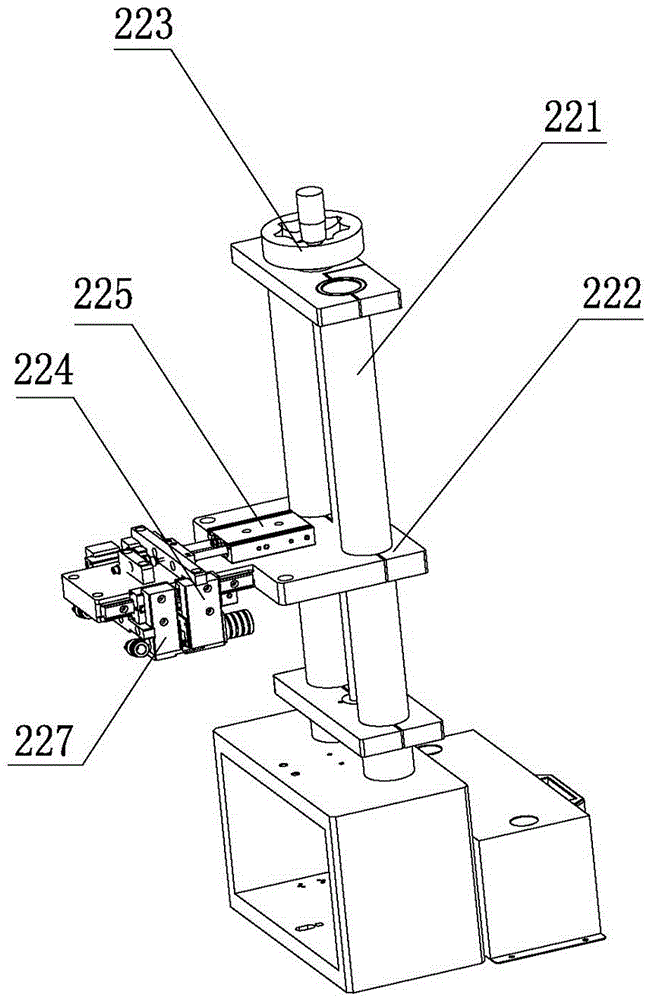

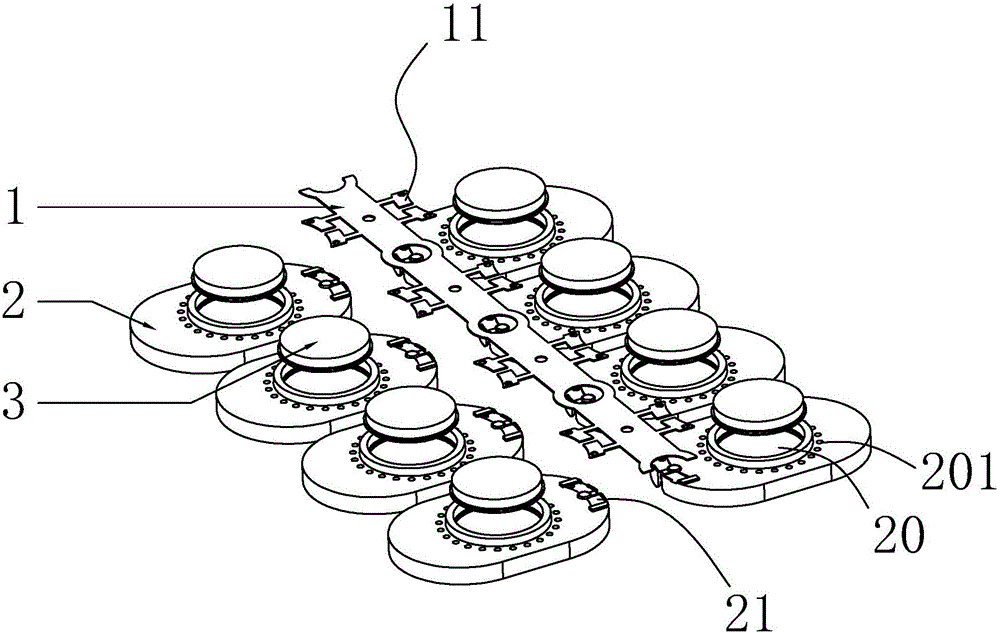

Automatic assembly equipment for LED (Light-Emitting Diode) bulb lamp

ActiveCN106425460AProvides productivityImprove product qualityAssembly machinesWaste productEngineering

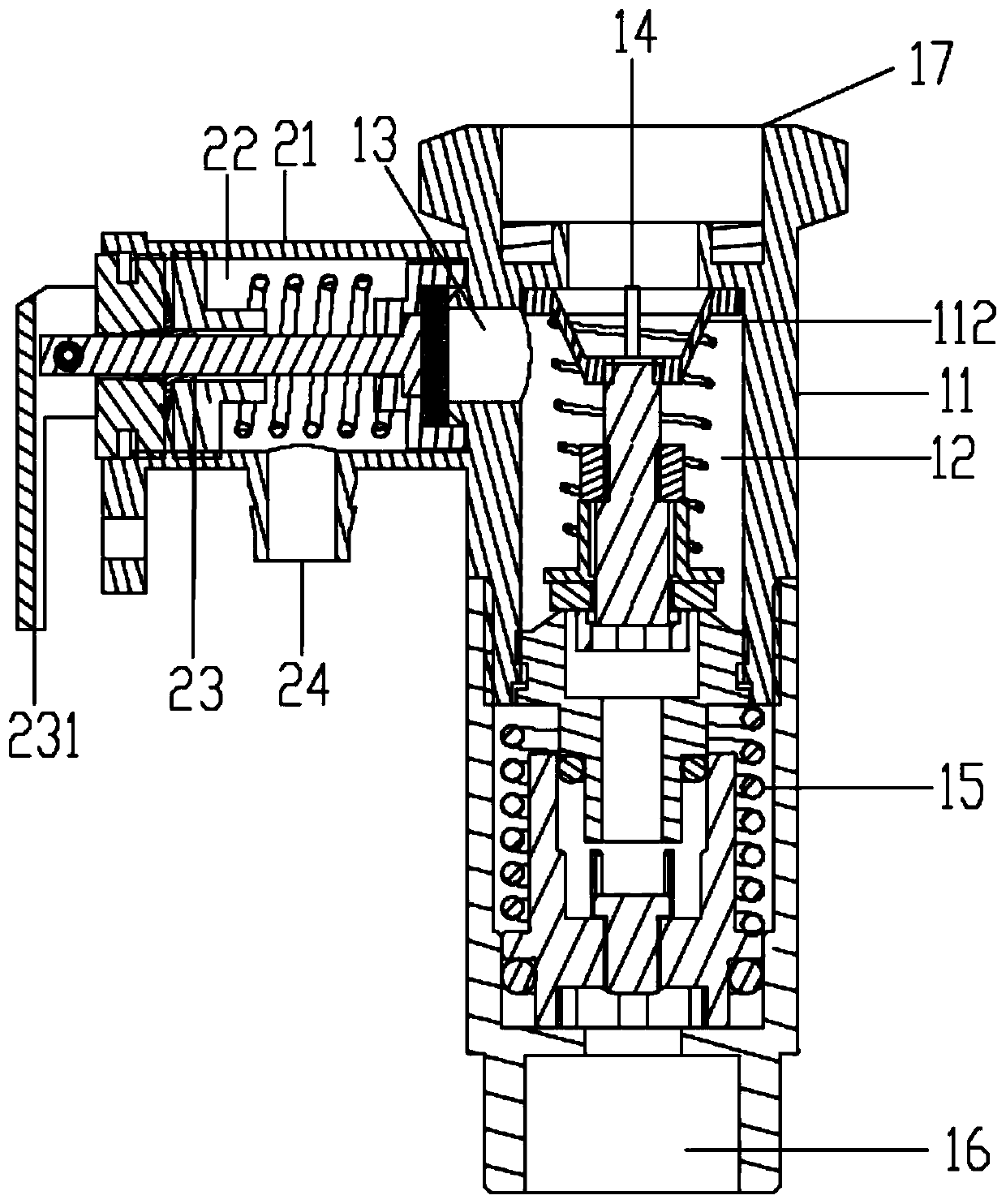

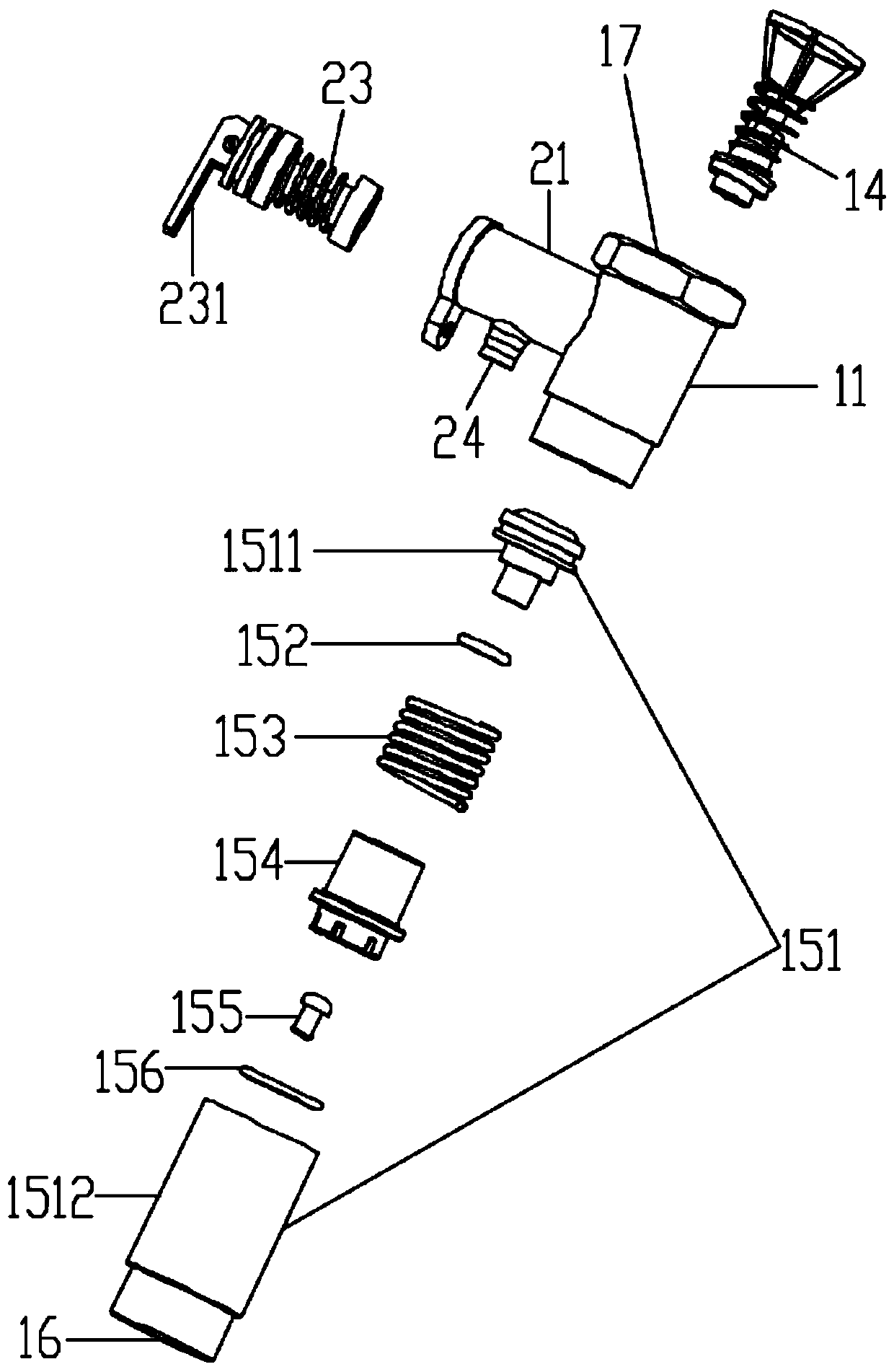

The invention relates to the technical field of manufacturing of an LED lamp and particularly relates to automatic assembly equipment for an LED bulb lamp. The automatic assembly equipment comprises a lamp holder feeding device, a wire embedding device, a lamp cap mounting device, a wire bending device, a lamp nail mounting device, a blanking device and a conveying device, wherein the wire embedding device is used for settling wires on a lamp holder; the lamp cap mounting device is used for mounting a lamp cap on the lamp holder; the wire bending device is used for bending the wires; the lamp nail mounting device is used for mounting a lamp nail at the upper end of the lamp cap; the conveying device is used for conveying the lamp holder among all devices; the wire embedding device comprises a wire embedding mechanism and a wire shearing mechanism; the lamp nail mounting device comprises a lamp nail feeding mechanism and a riveting mechanism, wherein the riveting mechanism is used for fixedly connecting the lamp nail with the lamp holder. By the structure, the automatic assembly equipment provided by the invention has the advantages of realizing automatic assembly of the lamp cap and the lamp holder of the LED bulb lamp, improving the production efficiency, improving the product quality, reducing generation rate of waste products and realizing automatic large-scale production.

Owner:广东立迪智能科技有限公司

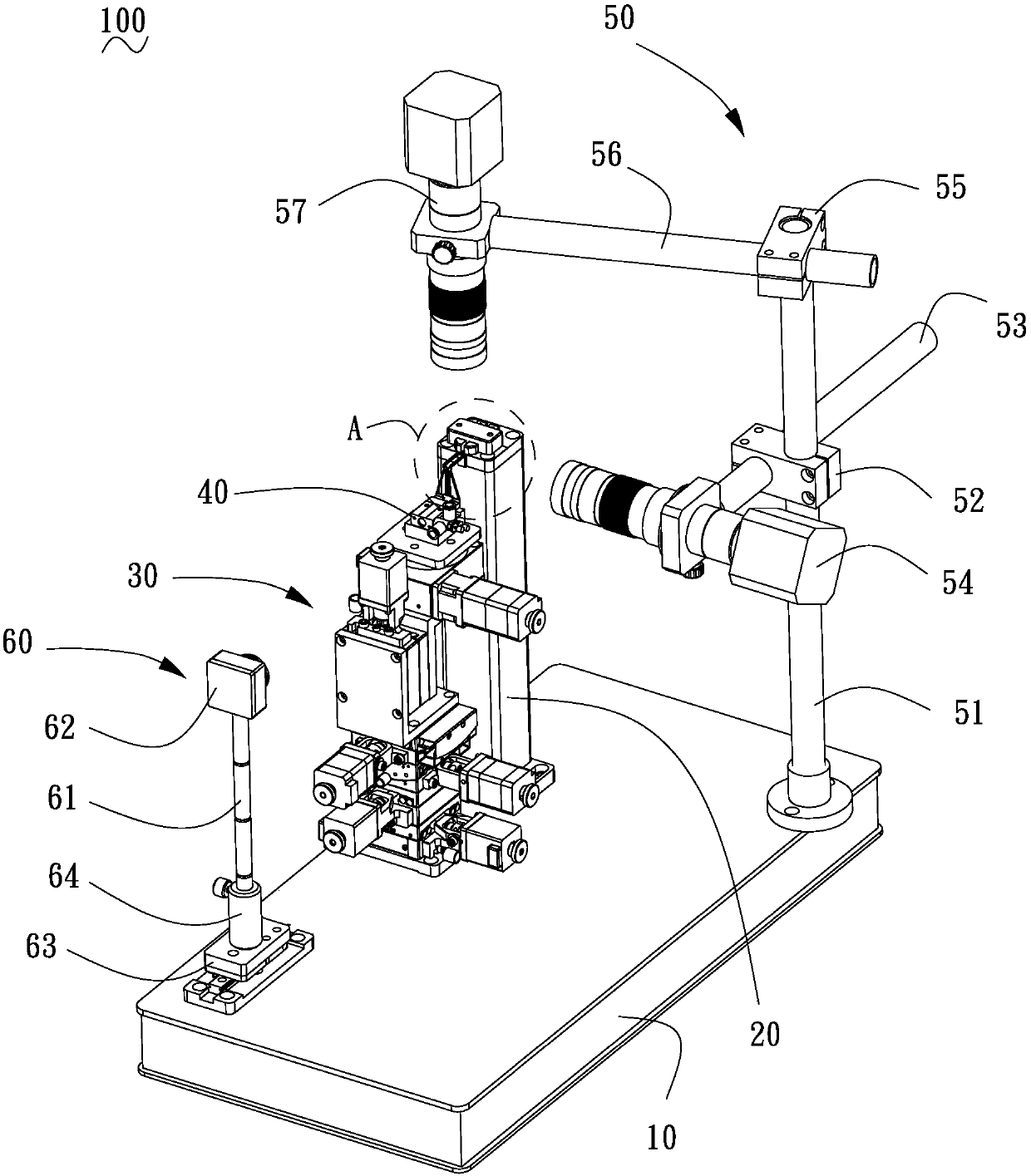

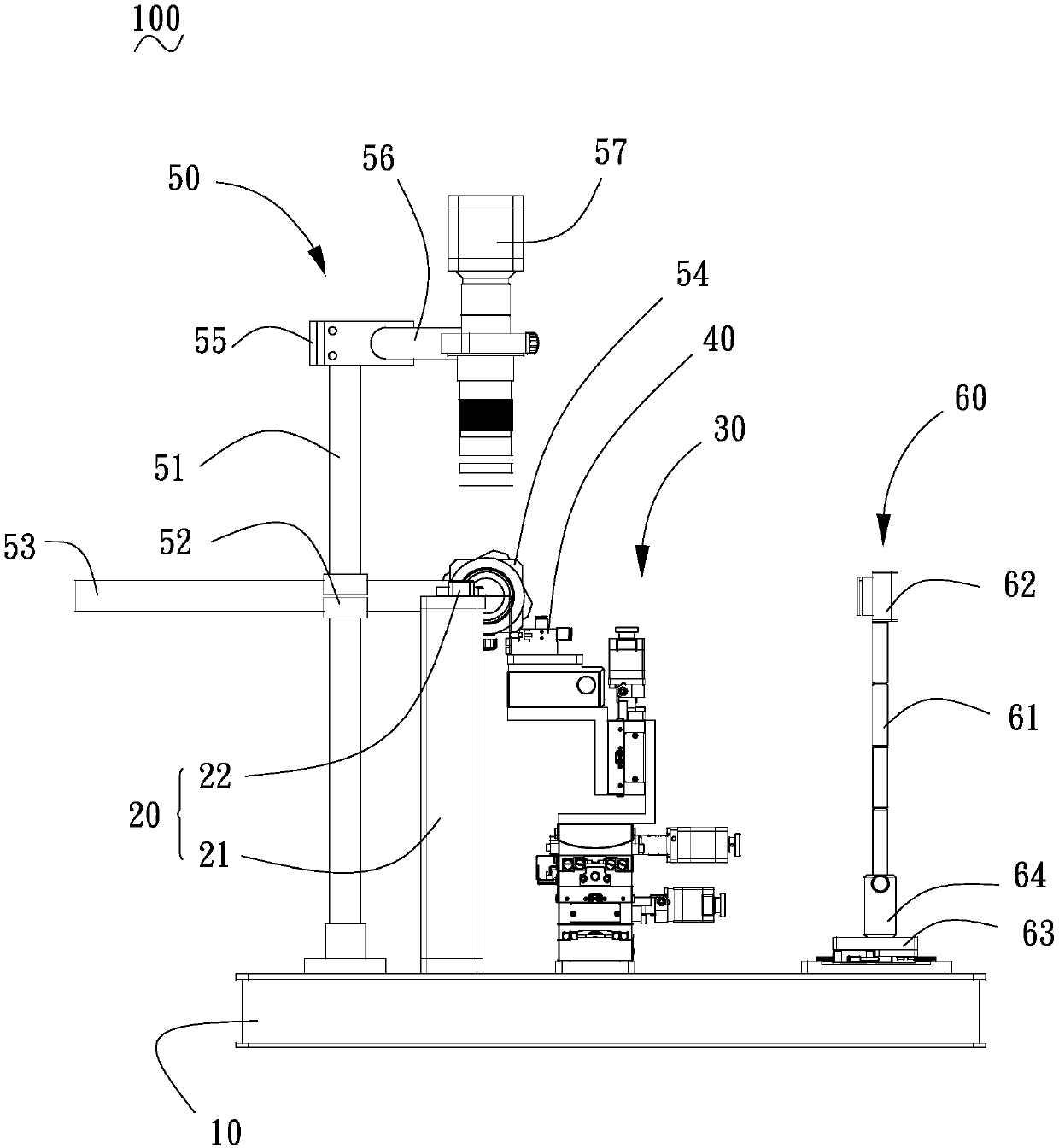

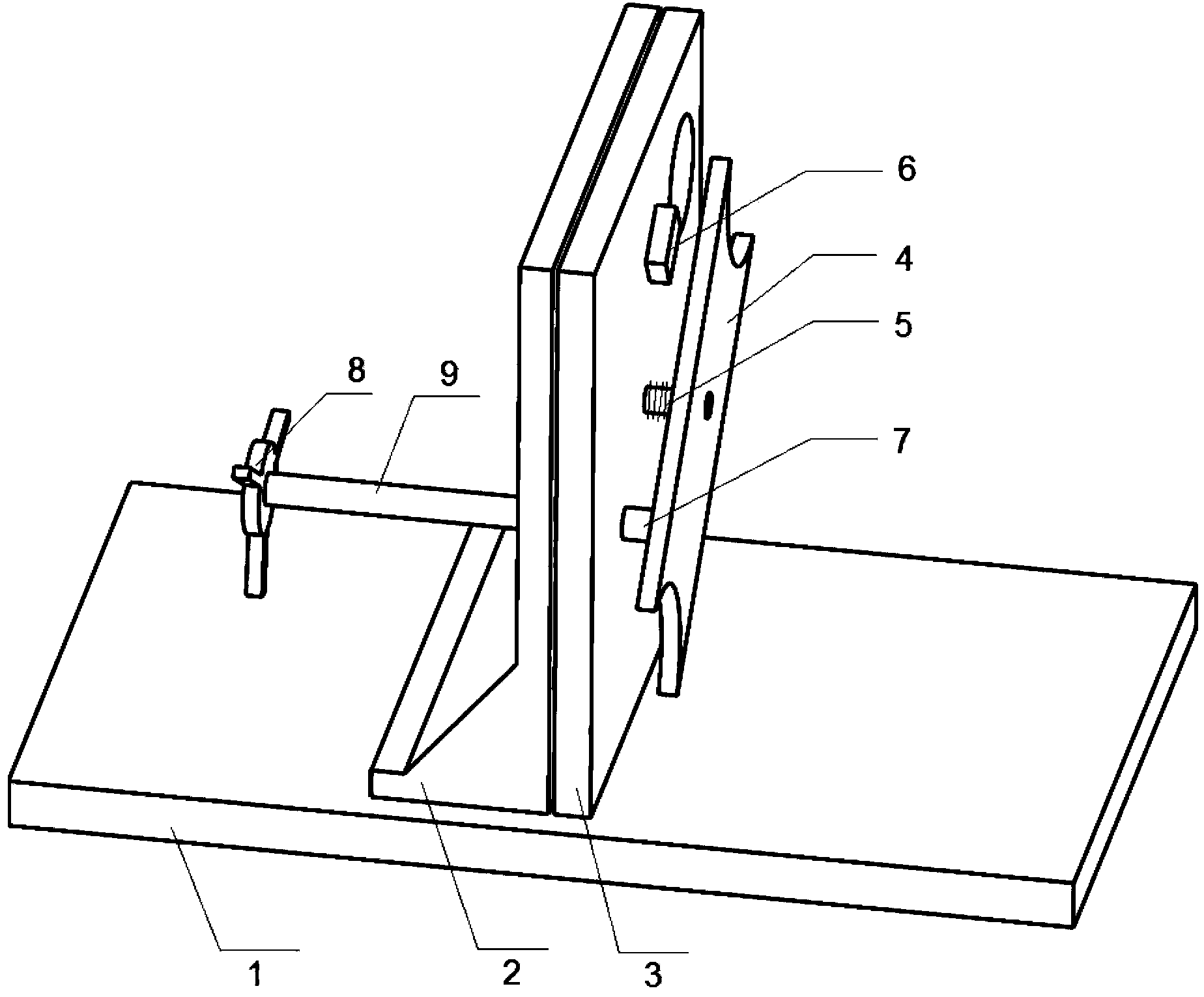

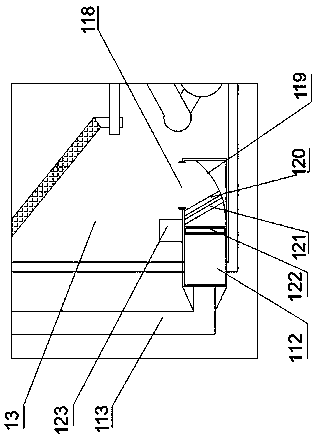

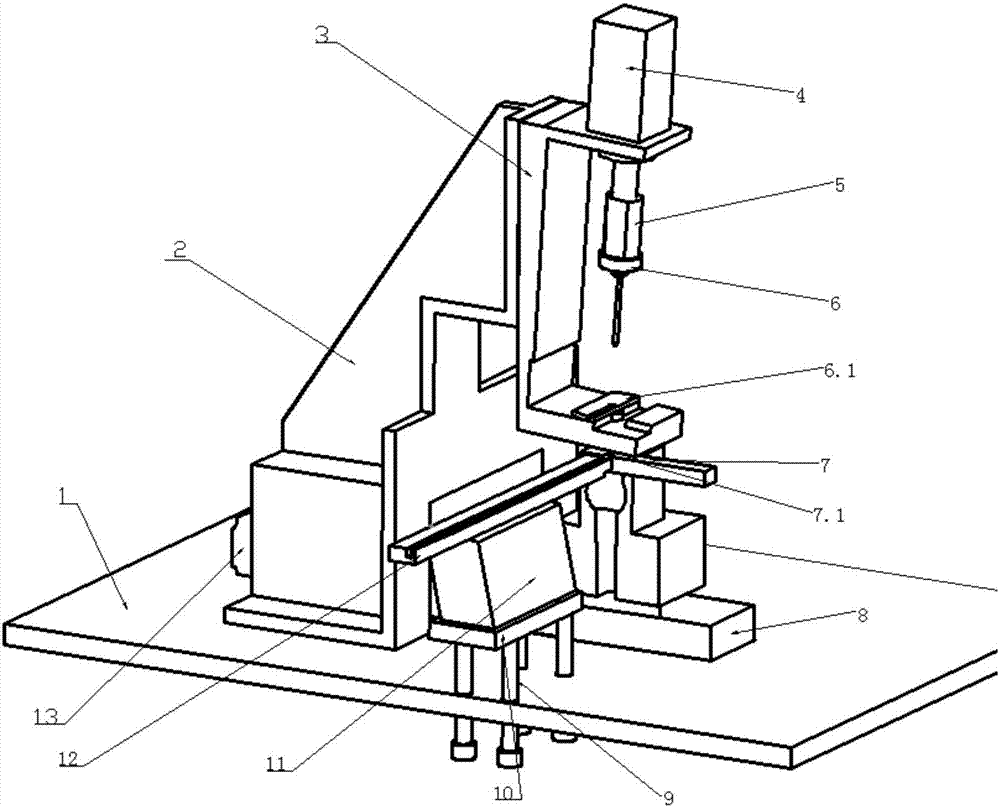

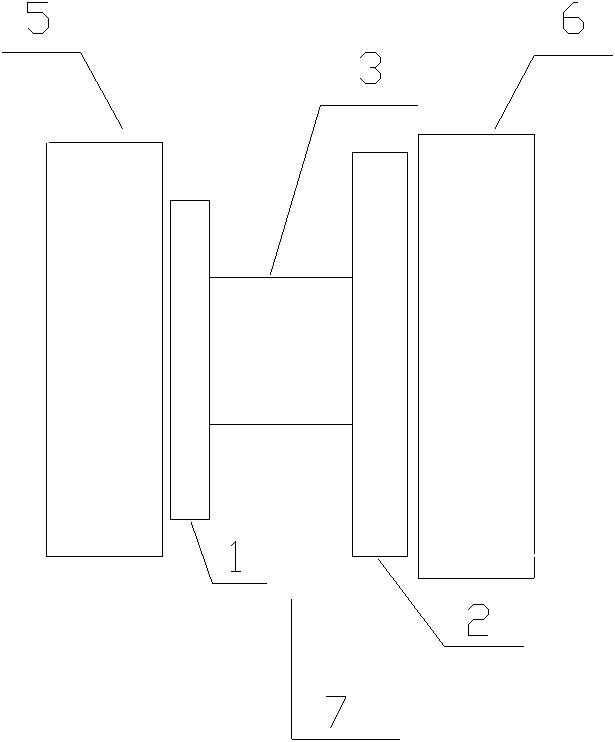

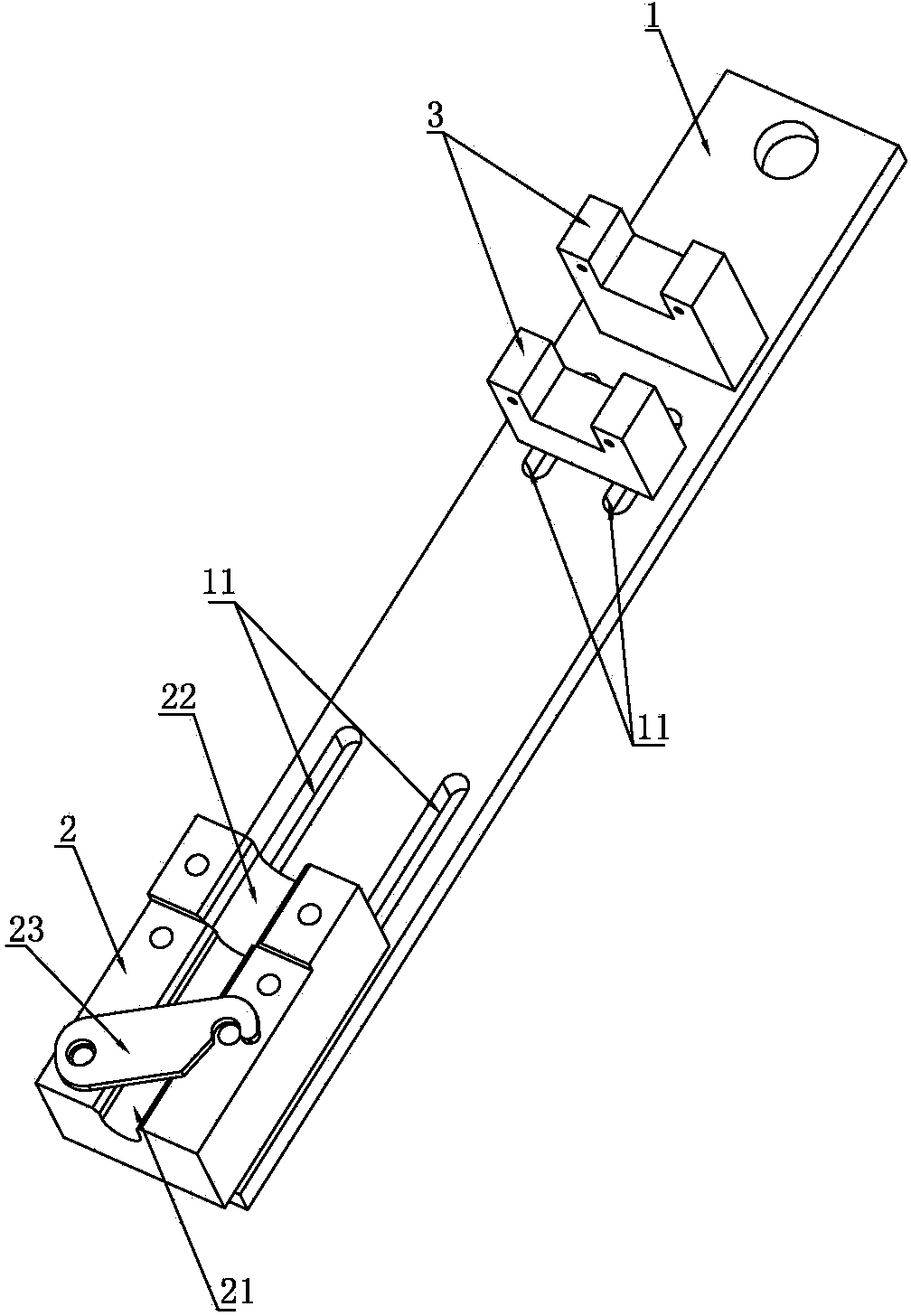

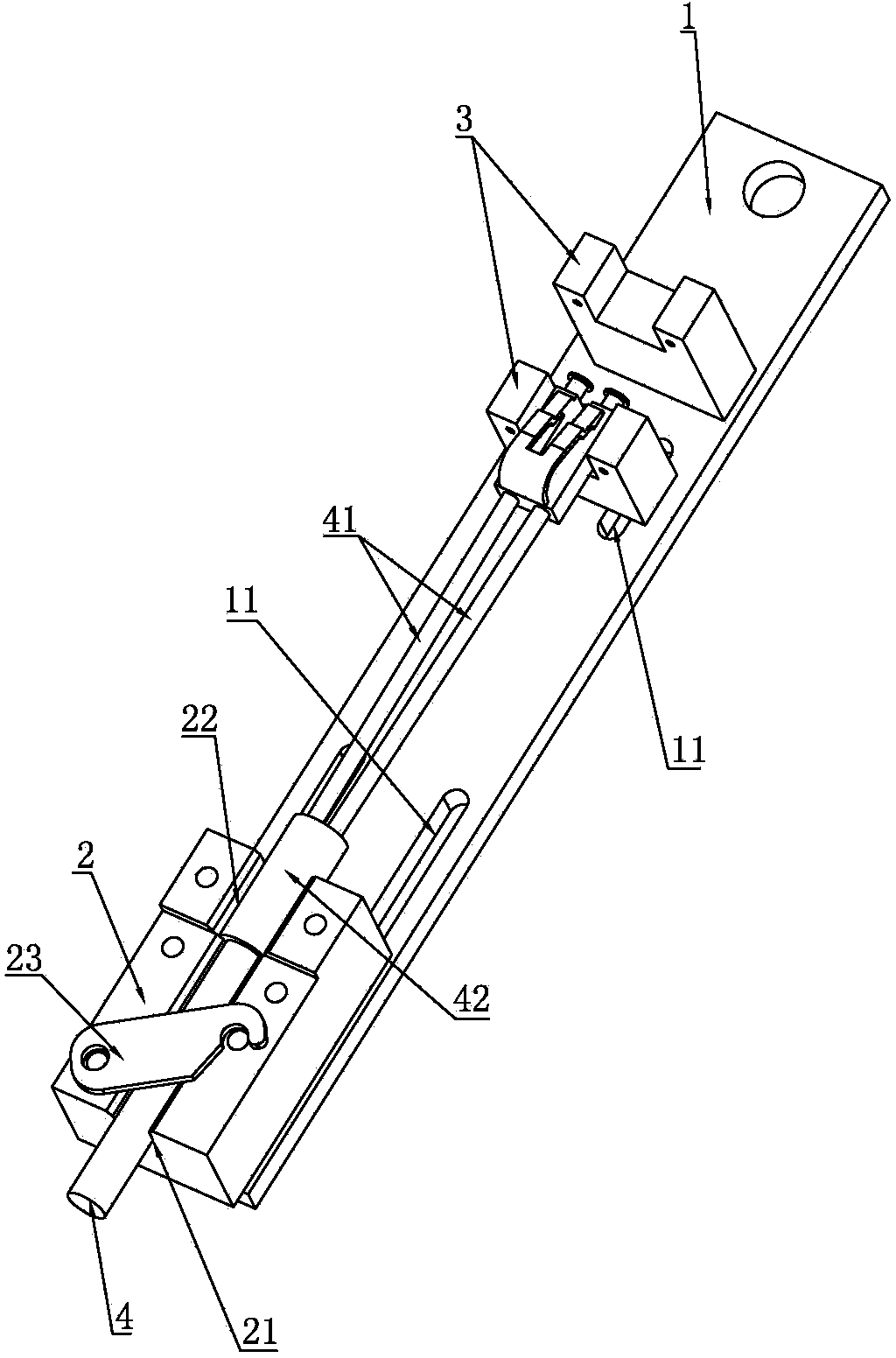

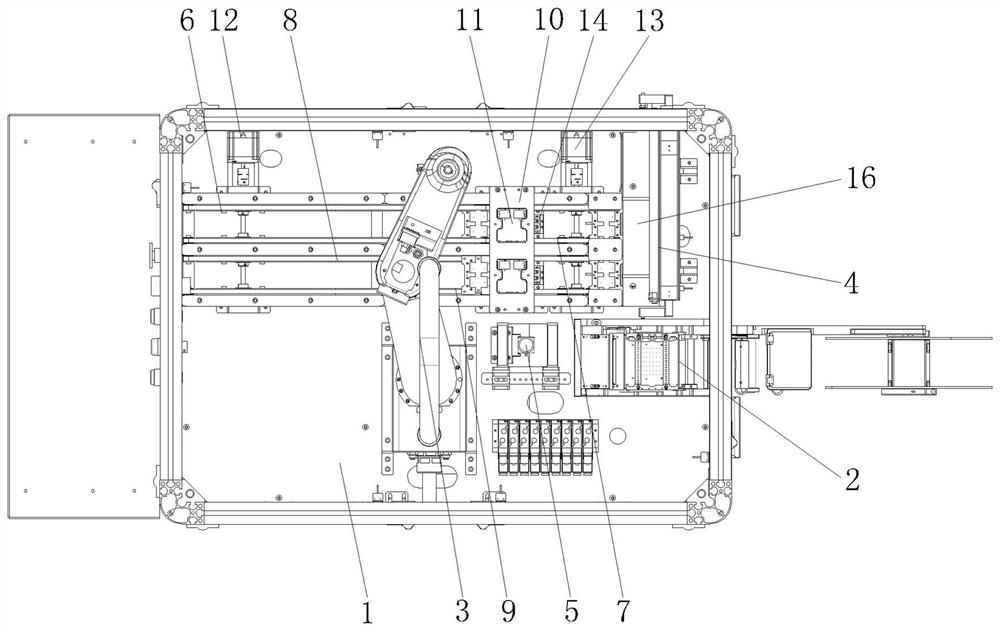

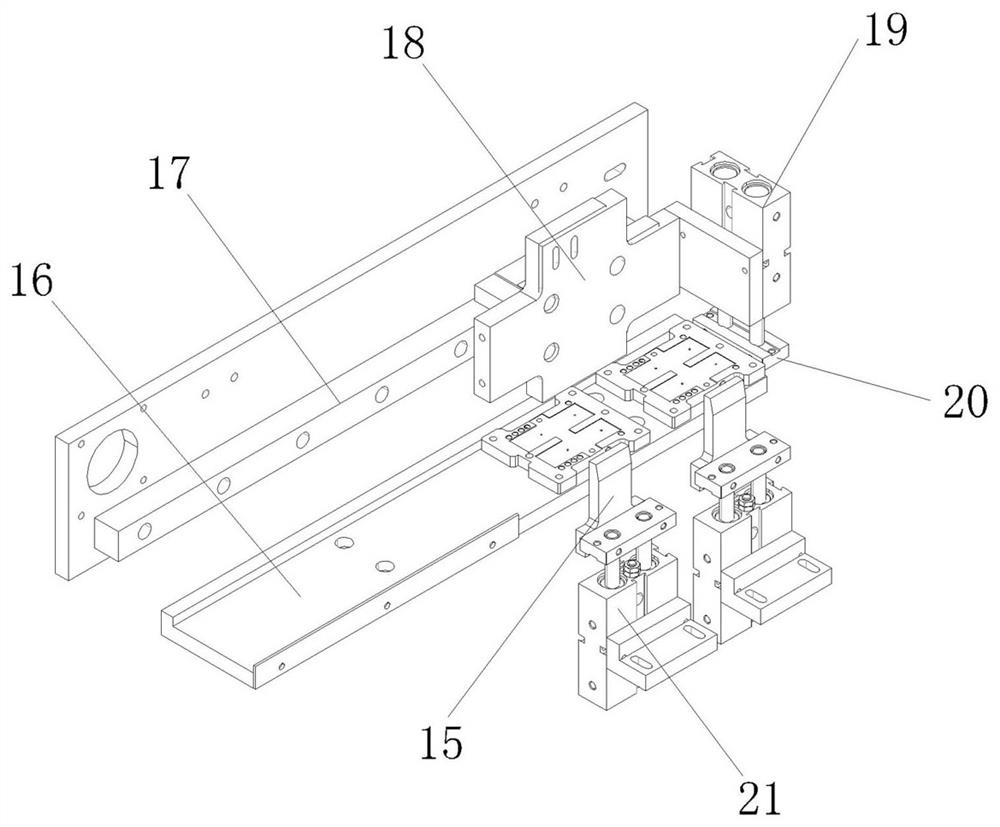

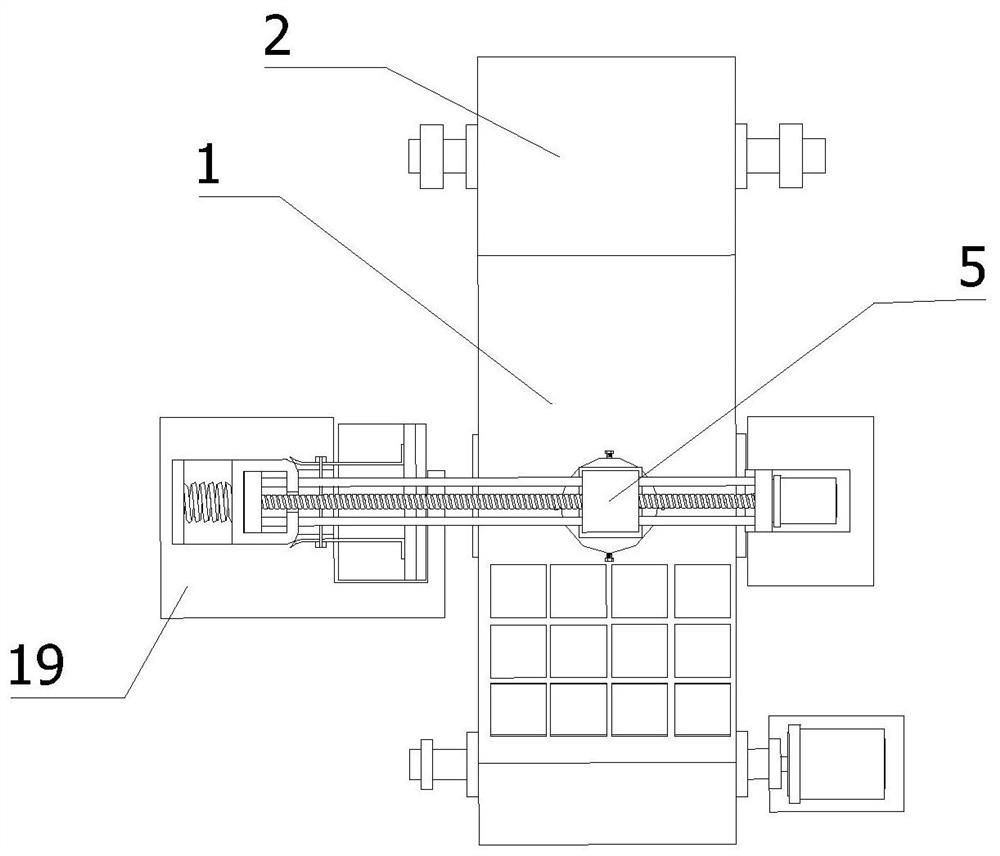

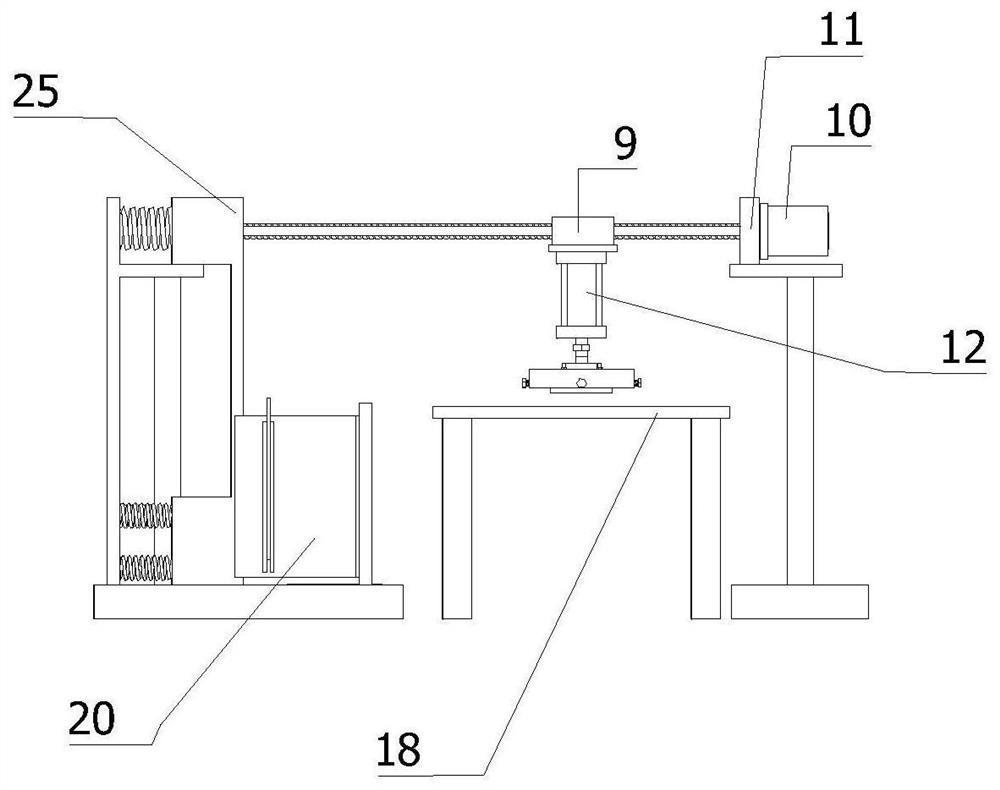

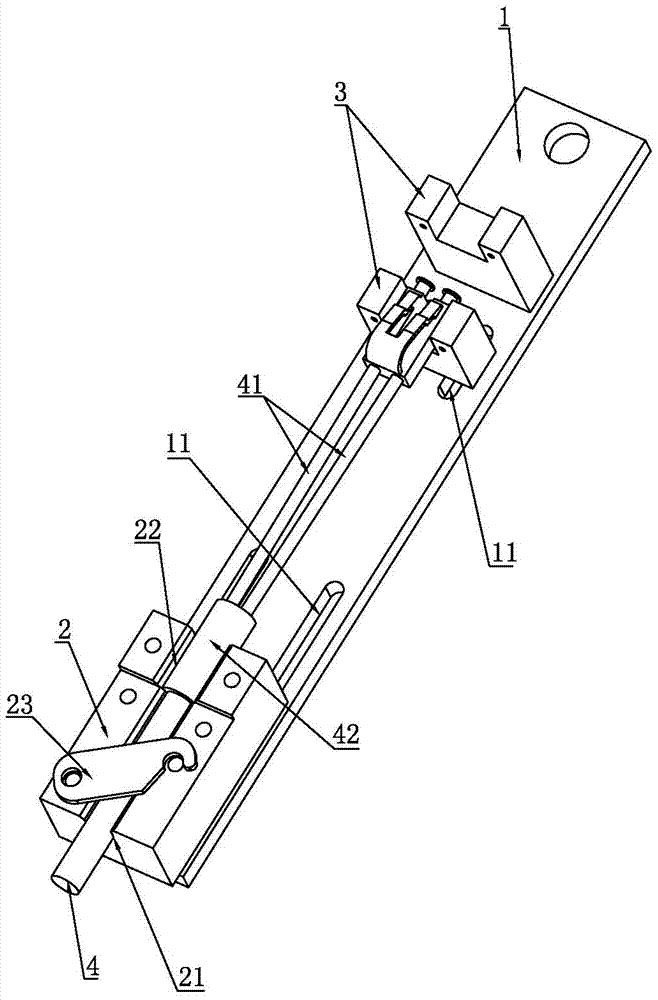

Semiconductor laser fast-axis collimation equipment

PendingCN107706736AAvoid frequent operationsProvides productivityLaser detailsSemiconductor laser optical deviceSemiconductor laser theoryCollimator

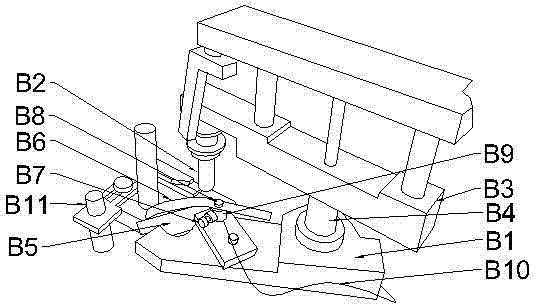

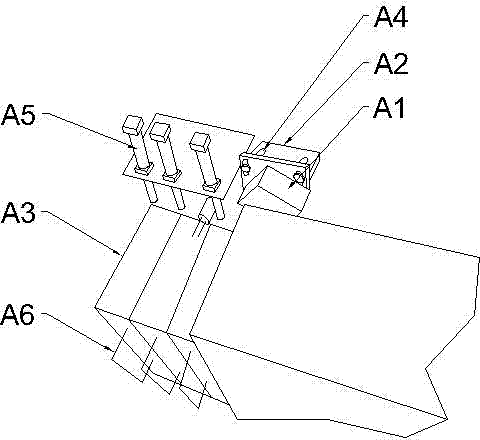

The invention discloses semiconductor laser fast-axis collimation equipment used for adjusting the position and angle of a fast-axis lens so as to perform fast-axis collimation on light beams emittedfrom a semiconductor laser light emitting chip. The semiconductor laser fast-axis collimation equipment comprises a substrate, a chip bearing frame mounted on the substrate, an adjustment fame mountedon the substrate, a lens clamp mounted on the adjustment frame, an image collection assembly mounted on the substrate, and an optical detection assembly mounted on the substrate; the image collectionassembly is used for identifying the position of the fast-axis lens through image detection; and the adjustment frame is used for adjusting the position and the angle of the lens clamp to enable thelaser light beams to form light spots on the optical detection assembly. The semiconductor laser fast-axis collimation equipment, by virtue of detection and analysis of the image detection assembly orthe optical detection assembly, controls the action of the adjustment frame, so that automation of the semiconductor laser fast-axis collimation can be realized, frequent manual operation is avoided,and production efficiency of the semiconductor laser is improved.

Owner:SHENZHEN JPT OPTO ELECTRONICS CO LTD

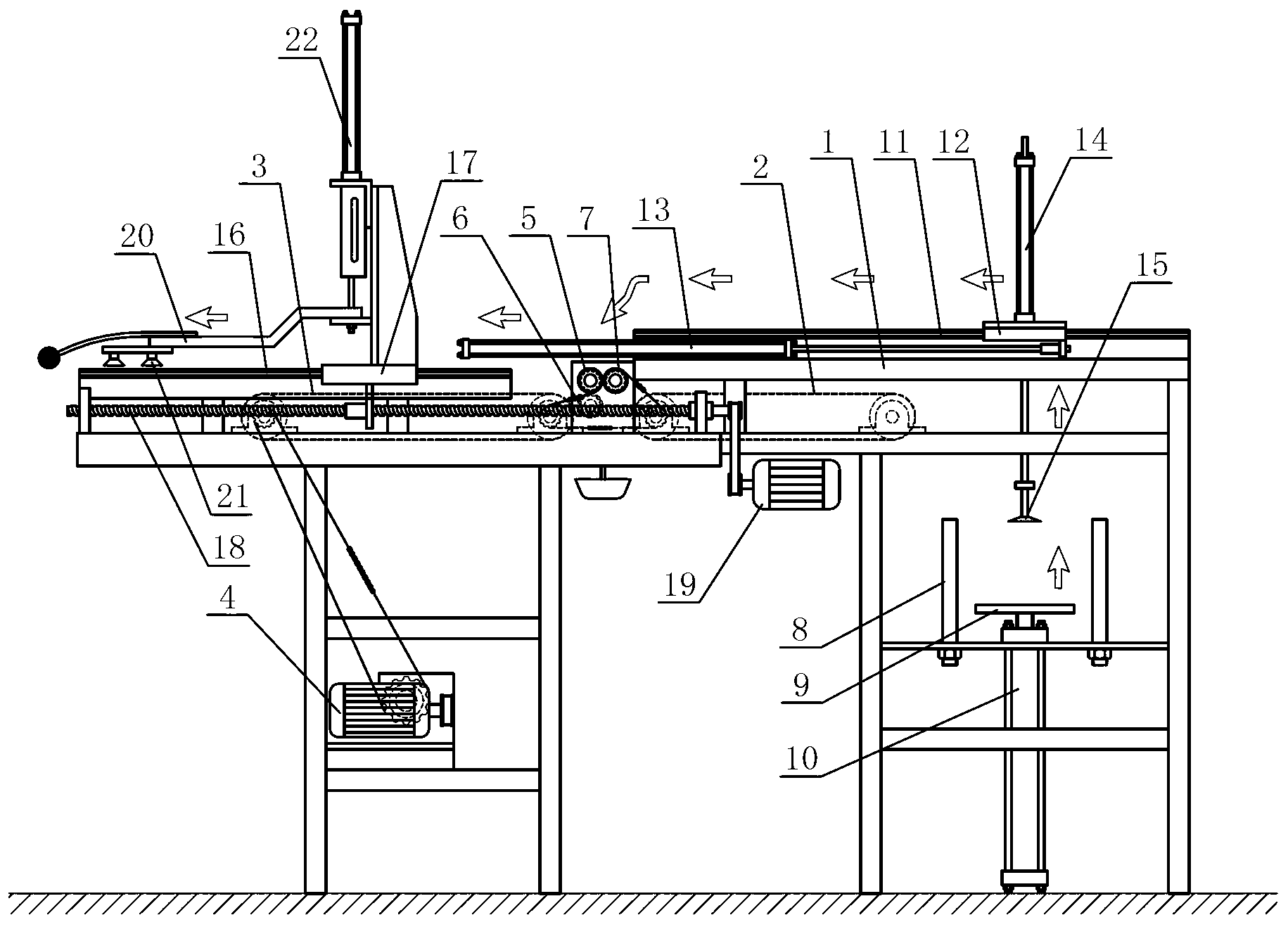

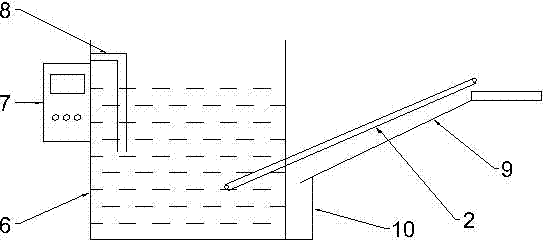

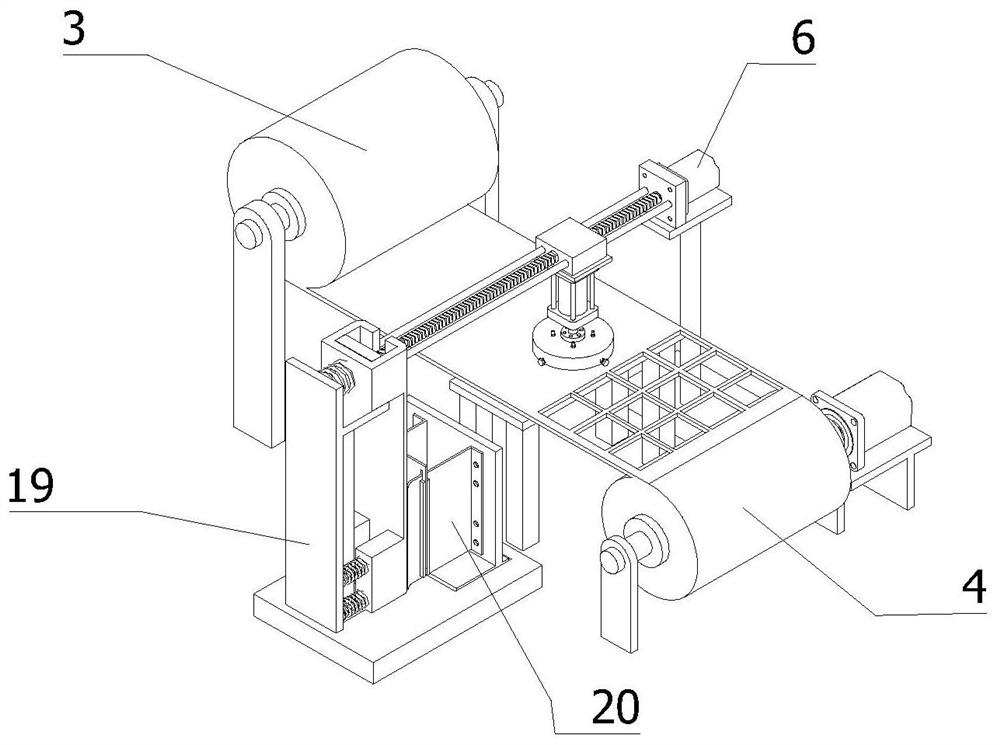

Automatic oil coating feeding device before sheet stamping forming

ActiveCN103302197AReduce labor intensityProvides productivityShaping toolsLiquid surface applicatorsElectric machineryCoating

The invention discloses an automatic oil coating feeding device before sheet stamping forming. The automatic oil coating feeding device comprises a machine frame, wherein two conveying belts distributed at front end and rear end in a conveying direction are mounted on the machine frame and driven by a motor to synchronously rotate; an oil coating roller set comprising an oil coating roller, a bearing roller and an oil applying roller is arranged between the two conveying belts; a storage rack is arranged below the input side of the front conveying belt; a top plate and a first air cylinder capable of driving the top plate to lift up and down are mounted at the bottom of the storage rack; a loading mechanism is arranged above the storage rack; and a feeding mechanism is arranged above the rear conveying belt. As the automatic oil coating feeding device is equipped with the oil coating roller set, a sheet can be coated with oil while the sheet is conveyed, the mechanical automatic oil coating feeding is achieved, the labor intensity of a staff is reduced, the production efficiency is improved, and the potential safety hazard in production is reduced.

Owner:GUANGDONG SUNRISE HOUSEWARE

Method for batch manufacturing lacquer picture

InactiveCN101234579AProvides productivitySpecial ornamental structuresSpecial artistic techniquesLacquerSeparation pattern

The invention relates to a method for manufacturing lacquer pictures in batch, which is characterized by including the following steps: 1) a drawing board for manufacturing the lacquer picture is prepared and a lacquer layer consistent with the basic background color of the designed pictures and conforming to designed thickness is manufactured on the drawing board; 2) according to design and process requirements for patterns of the lacquer pictures to be manufactured, color separation is carried out and corresponding color separation patterns are manufactured; how many colors are set for the manufactured lacquer pictures, how many corresponding color separation patterns are manufactured; 3) convex indentations are engraved on the drawing board according to the color separation patterns by an intelligent and automatic engraving machine; the lacquer is filled on the indentations and corresponding decorative material is inlayed or corresponding chromogenic lacquer is filled; after the lacquer is dry, the convex indentations are wore down and transparent lacquer is coated; the manufacture method is carried out according to the sequence to finish color inlaying on each color separation patterns; 4) after the lacquer on the drawing board is dry, the material, of which the color is deeper than the background color on the drawing board is wore down to present the patterns consistent with the required lacquer pictures; then, the transparent lacquer is coated to finish a delicate lacquer picture. The method for manufacturing the lacquer pictures in batch can greatly reduce manufacture cost as well as accelerate manufacture speed of the lacquer pictures so as to increase market supply.

Owner:吴善宝

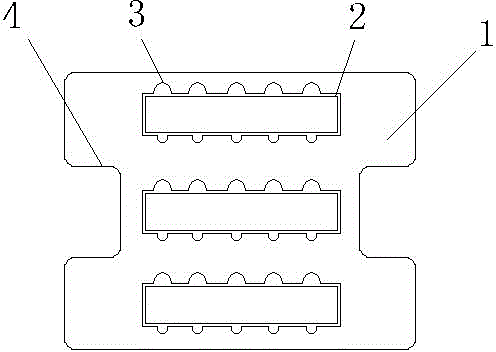

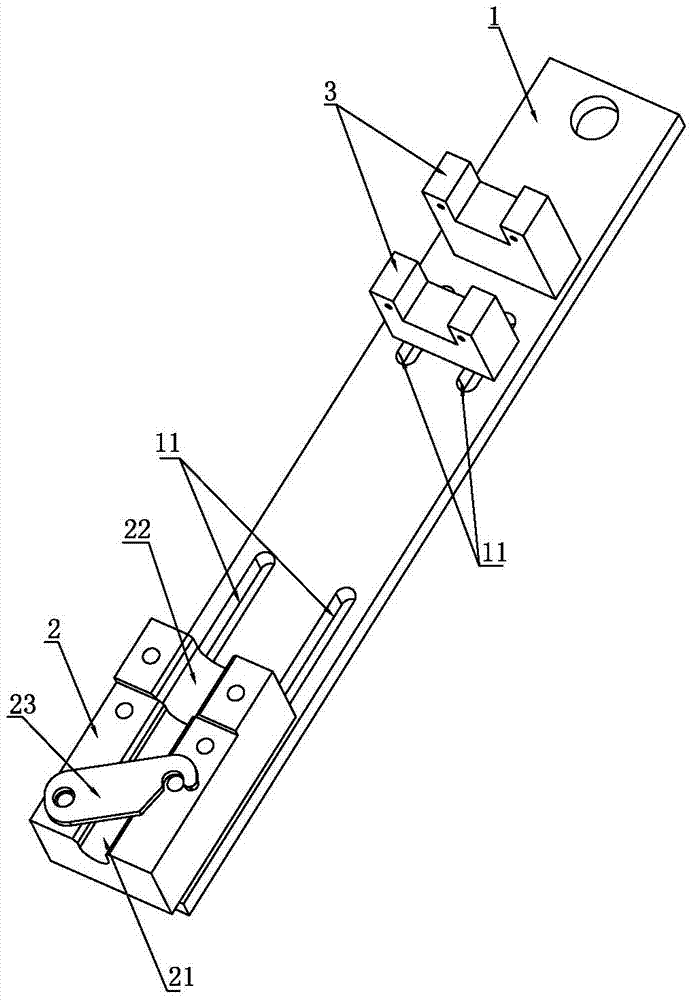

Connecting rod big end hole fine boring fixture

ActiveCN103358150AImprove clamping efficiencyProvides productivityPositioning apparatusMetal-working holdersCanis lupus familiarisMechanical engineering

Owner:WUHU HANGTIAN AUTOMOBILE CONNECTING ROD

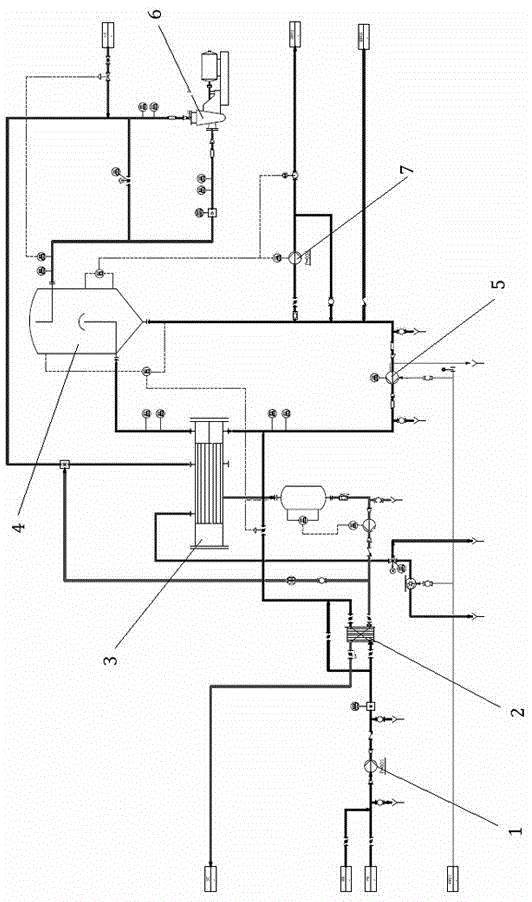

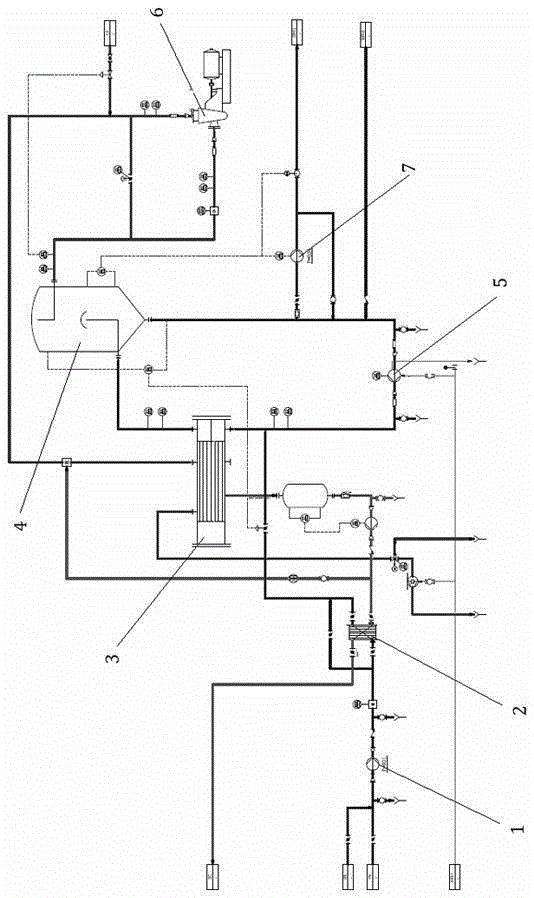

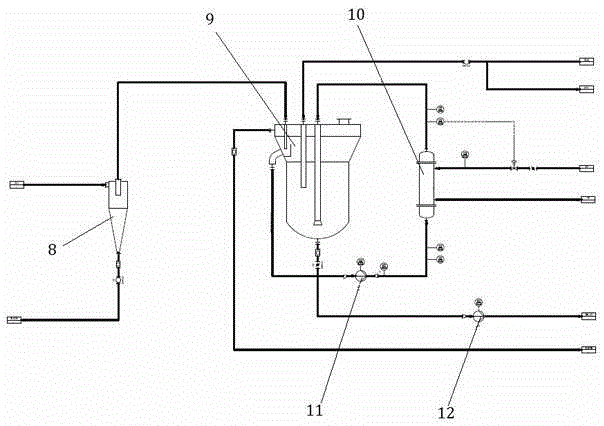

Continuous sodium acetate evaporation crystallization system and continuous sodium acetate evaporation crystallization method

ActiveCN104529743ASmooth feedingStable discharge operationSolution crystallizationCrystallization by component evaporationSodium acetateCyclone

The present invention relates to a continuous sodium acetate evaporation crystallization system, which comprises an evaporation system and a crystallization system, wherein the outlet of the evaporation system material inlet pump is respectively connected with an evaporation heater and a pre-heater, the material outlet of the pre-heater is communicated with the evaporation heater, the material outlet of the evaporation heater is connected with the material inlet of an evaporation separation chamber, the material outlet of the evaporation separation chamber is respectively connected with the inlets of a first circulation pump and a material outlet pump, the first circulation pump is communicated with the evaporation heater, the outlet of the material outlet pump is connected with the material inlet of a cyclone, the material outlet on the top portion of the cyclone is connected with the material inlet of a crystallization separation chamber, the material outlet on the top portion of the crystallization separation chamber is connected with the inlet of a second circulation pump, the outlet of the second circulation pump is connected with the material inlet of a cooler, the material outlet of the cooler is connected with the material inlet of the crystallization separation chamber, and the material outlet on the bottom portion of the crystallization separation chamber is connected with a slurry pump. According to the present invention, the continuous production way of the sodium acetate evaporation crystallization is achieved, such that the product quality is easily stabilized, the production efficiency is easily increased, and the energy source consumption of the whole production process can be reduced.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

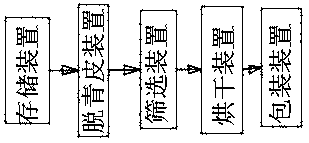

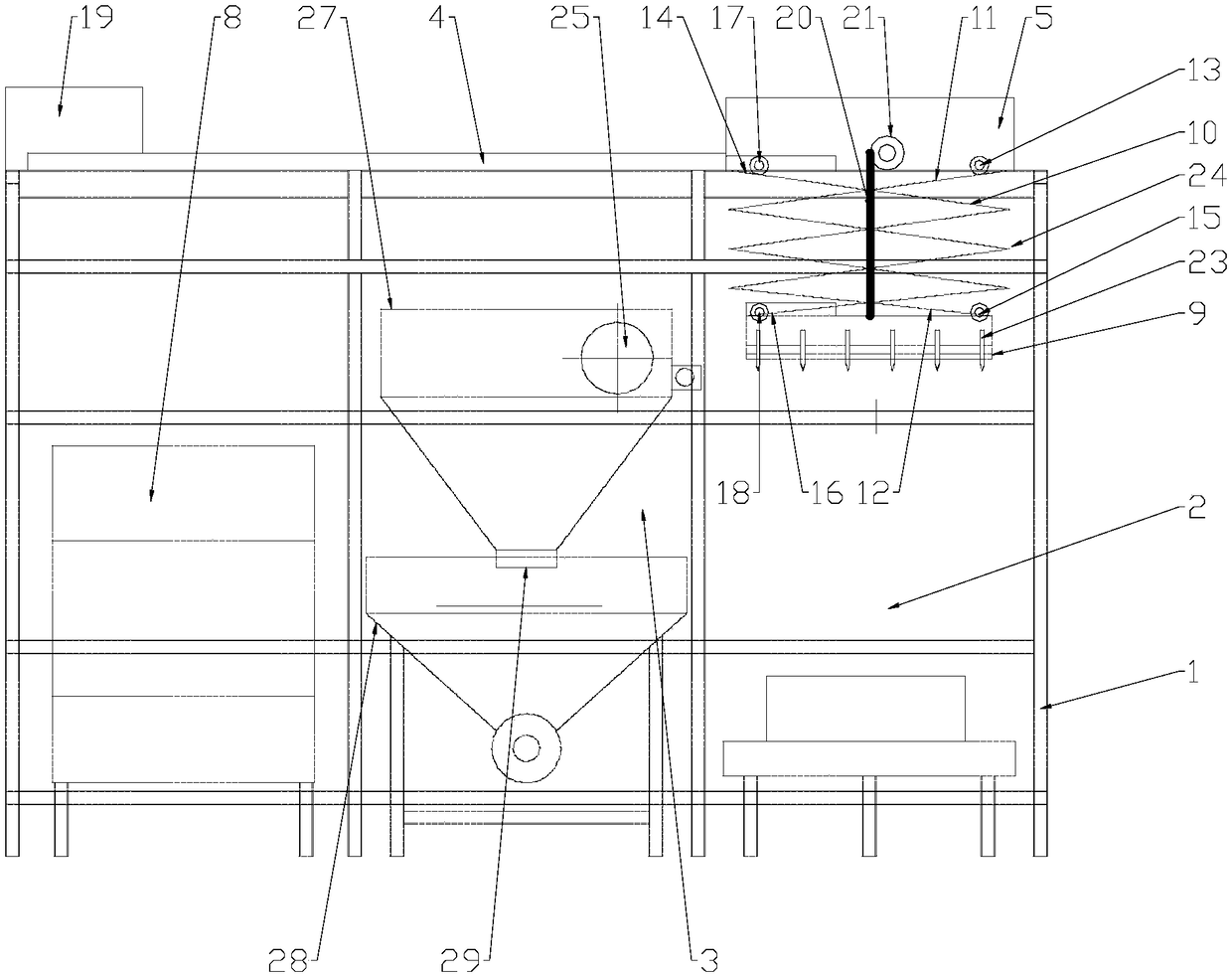

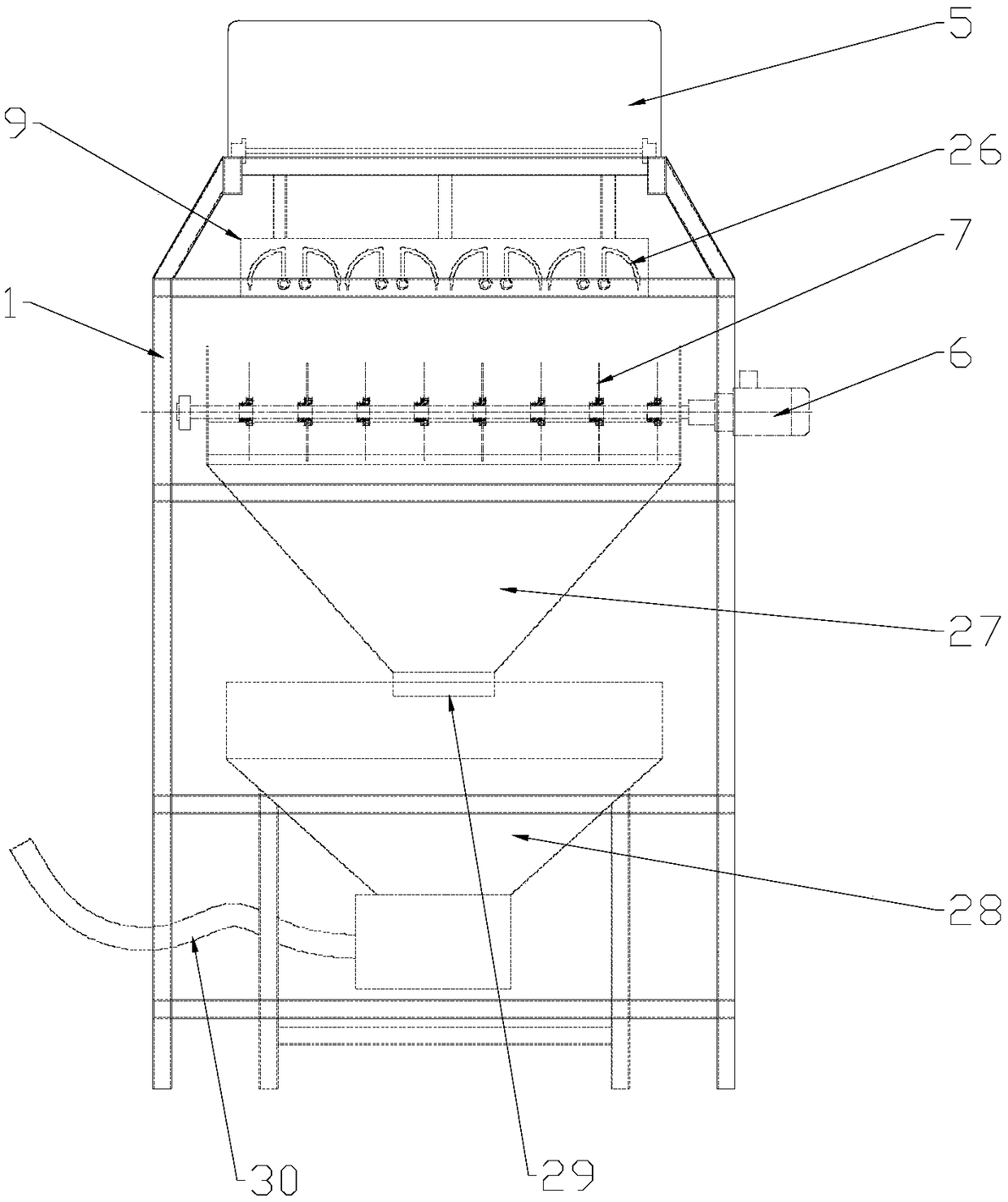

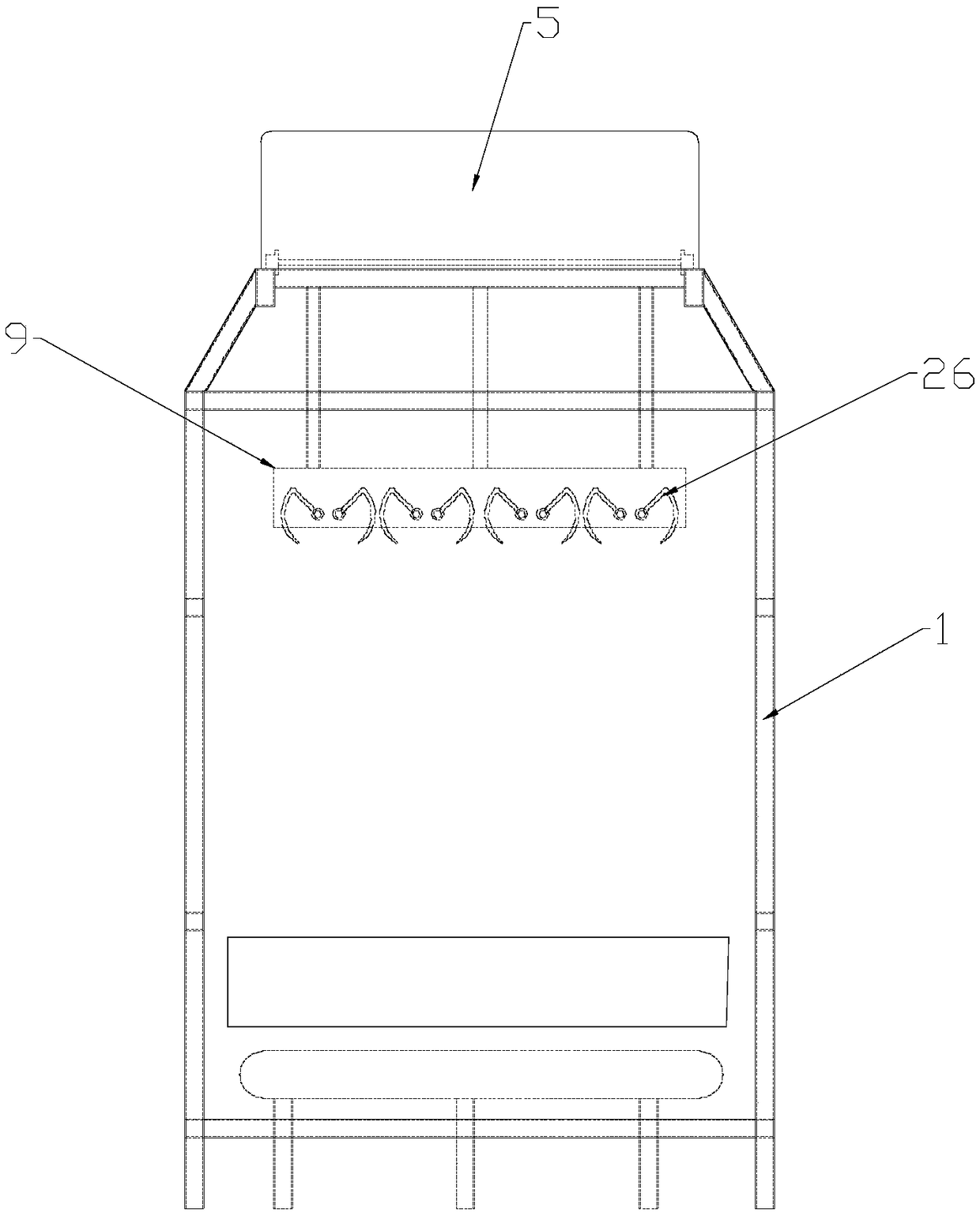

Processing production line for improving macadimia nut quality

PendingCN111280460AProvides productivityImprove production environmentSievingGas current separationProcess engineeringManufacturing engineering

The invention discloses a processing production line for improving the quality of macadimia nuts. The production line comprises a storage device, a green seedcase removing device, a screening device,a drying device and a packaging device; the storage device is connected with the green seedcase removing device through an elevator, a discharging port of the green seedcase removing device is connected with the screening device through a sliding way, and the screening device is connected with the drying device through a conveying belt; the drying device is connected with the packaging device through a conveying belt. According to the production line, the storage device, the green seedcase removing device, the screening device, the drying device and the packaging device are connected and automatically transformed, macadimia nuts are finally graded through different selection of all the steps, and finished products with good quality are obtained.

Owner:云南迪思企业集团坚果有限公司

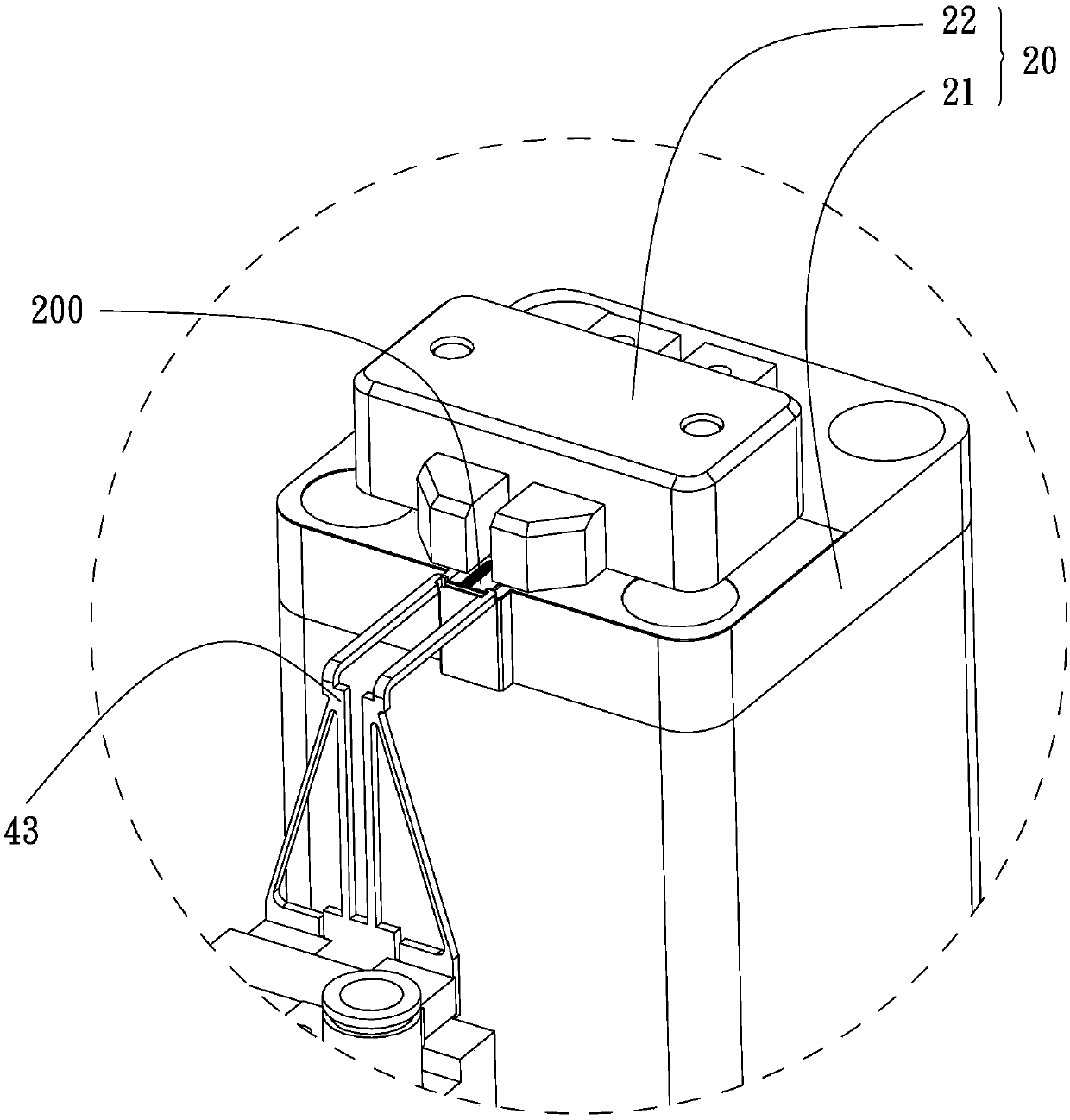

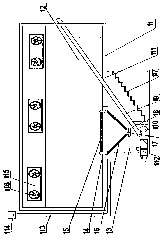

Full-automatic press fit device of sleeve and insert core

PendingCN106891140AEasy to operateProvides productivityMetal working apparatusButt jointControl system

The invention discloses a full-automatic press fit device of a sleeve and an insert core. The full-automatic press fit device comprises a rack, and a sleeve feeding device, an insert core feeding device, a press fit part and a control system which are arranged on the rack, wherein the control system is connected with the sleeve feeding device, the insert core feeding device and the press fit part; the sleeve feeding device and the insert core feeding device are in butt joint with the press fit part; the sleeve feeding device and the insert core feeding device separately provide the sleeve and the insert core for the press fit part; and the insert core is inserted in the sleeve through the press fit part. According to the full-automatic press fit device, automatic transportation, locating, supply and press fit of the sleeve and the insert core are formed, manual press fit is completely replaced, operation is convenient, and production efficiency is improved.

Owner:WUHAN YUSHENG OPTICAL DEVICES

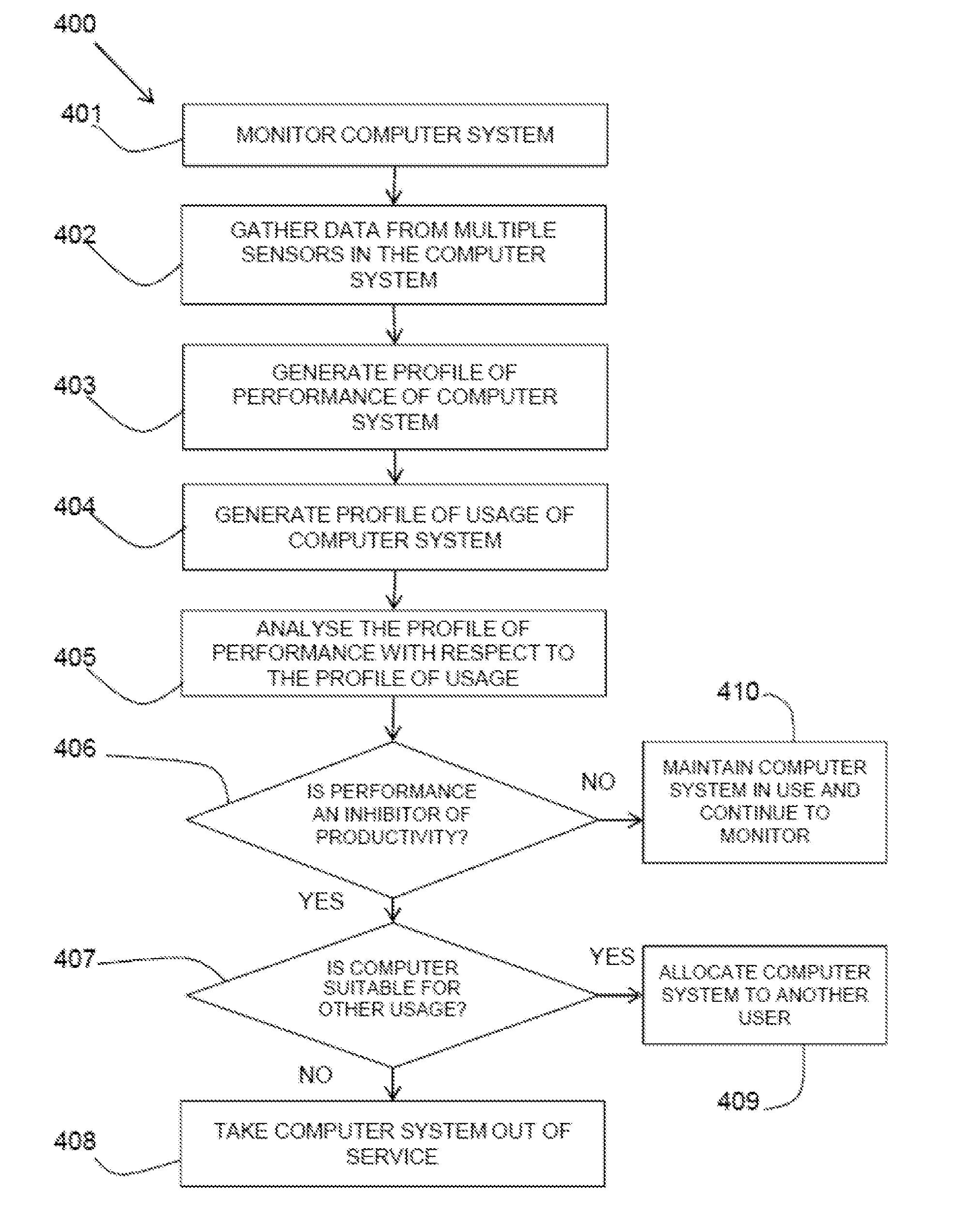

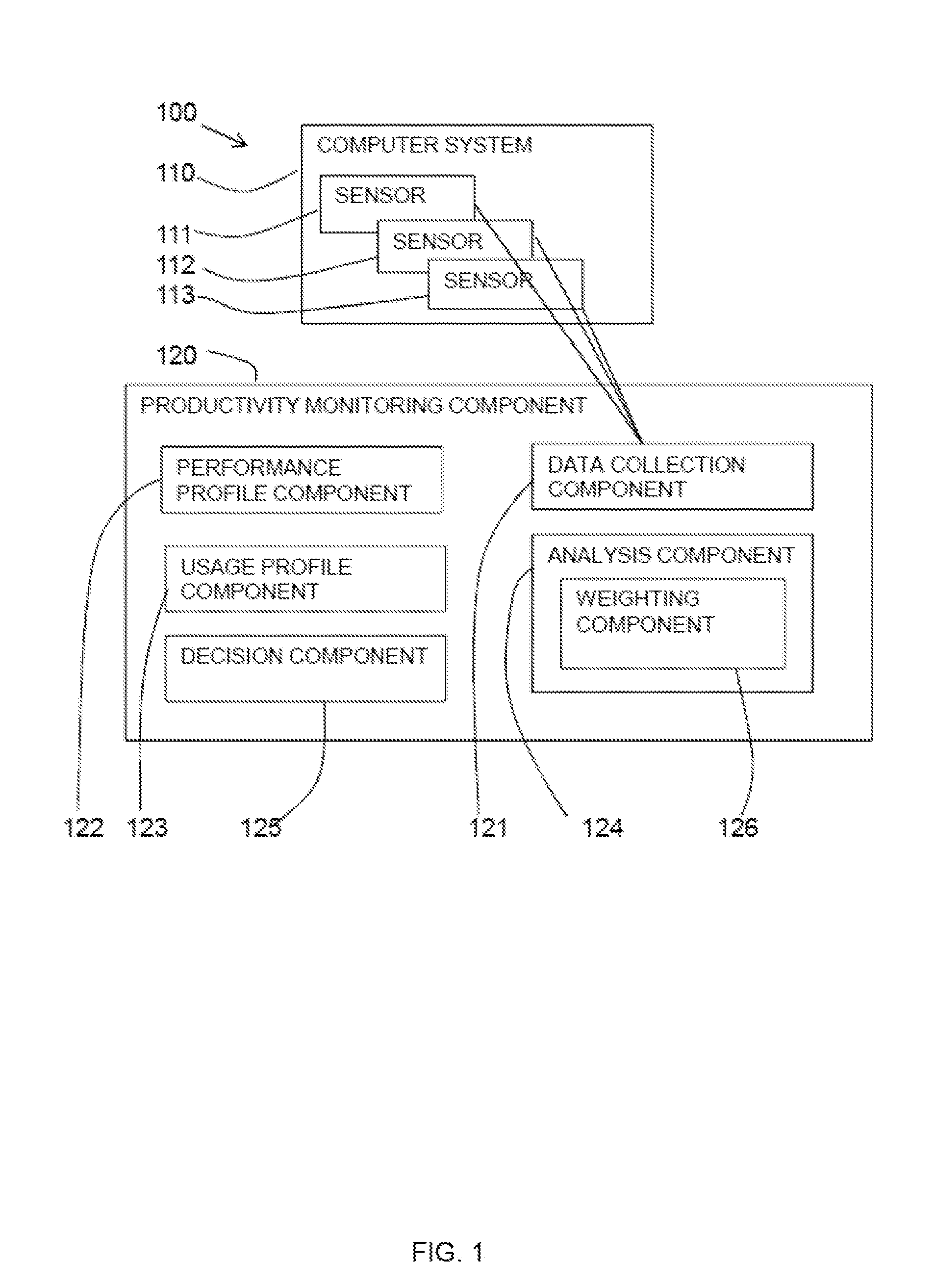

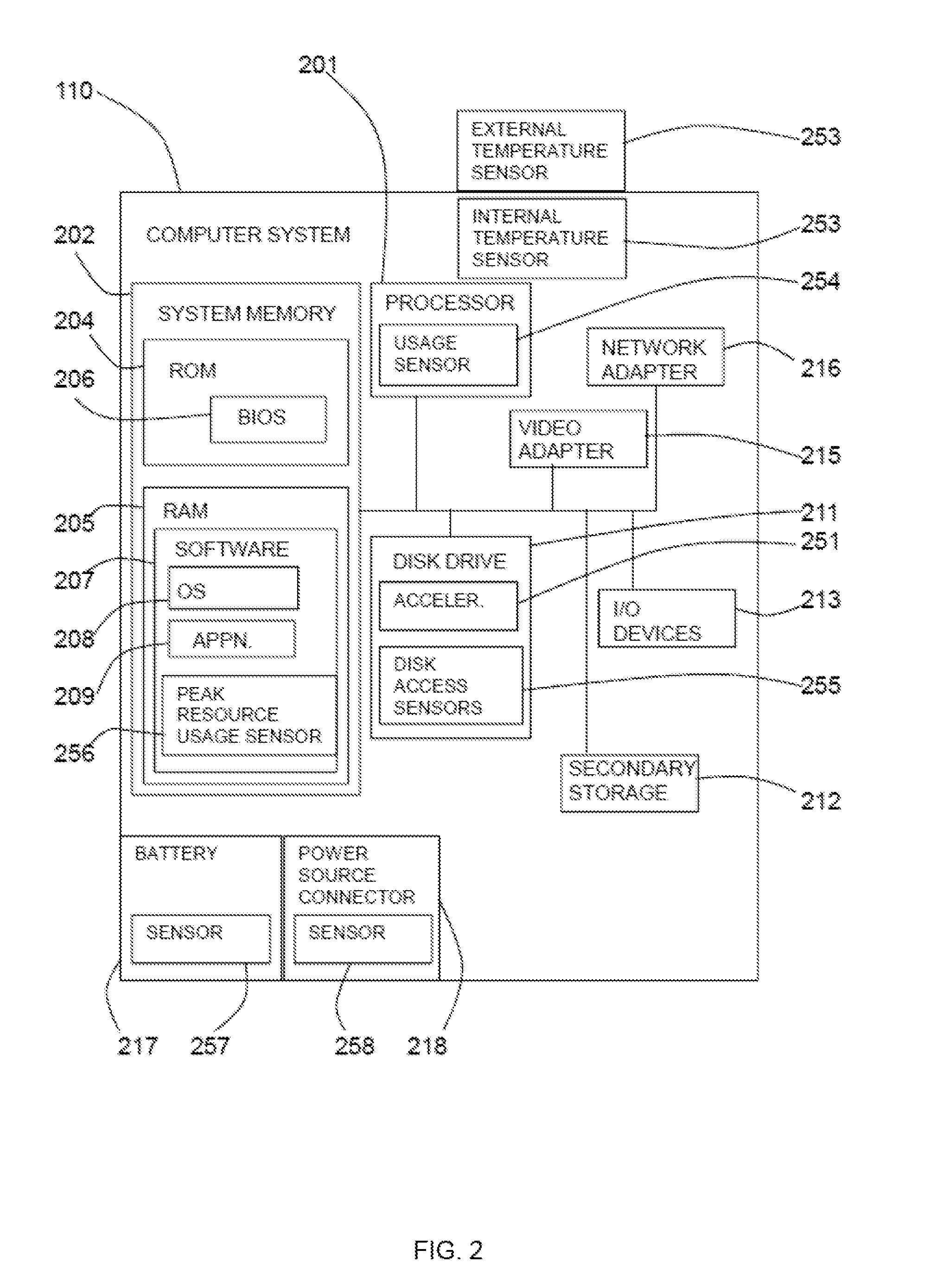

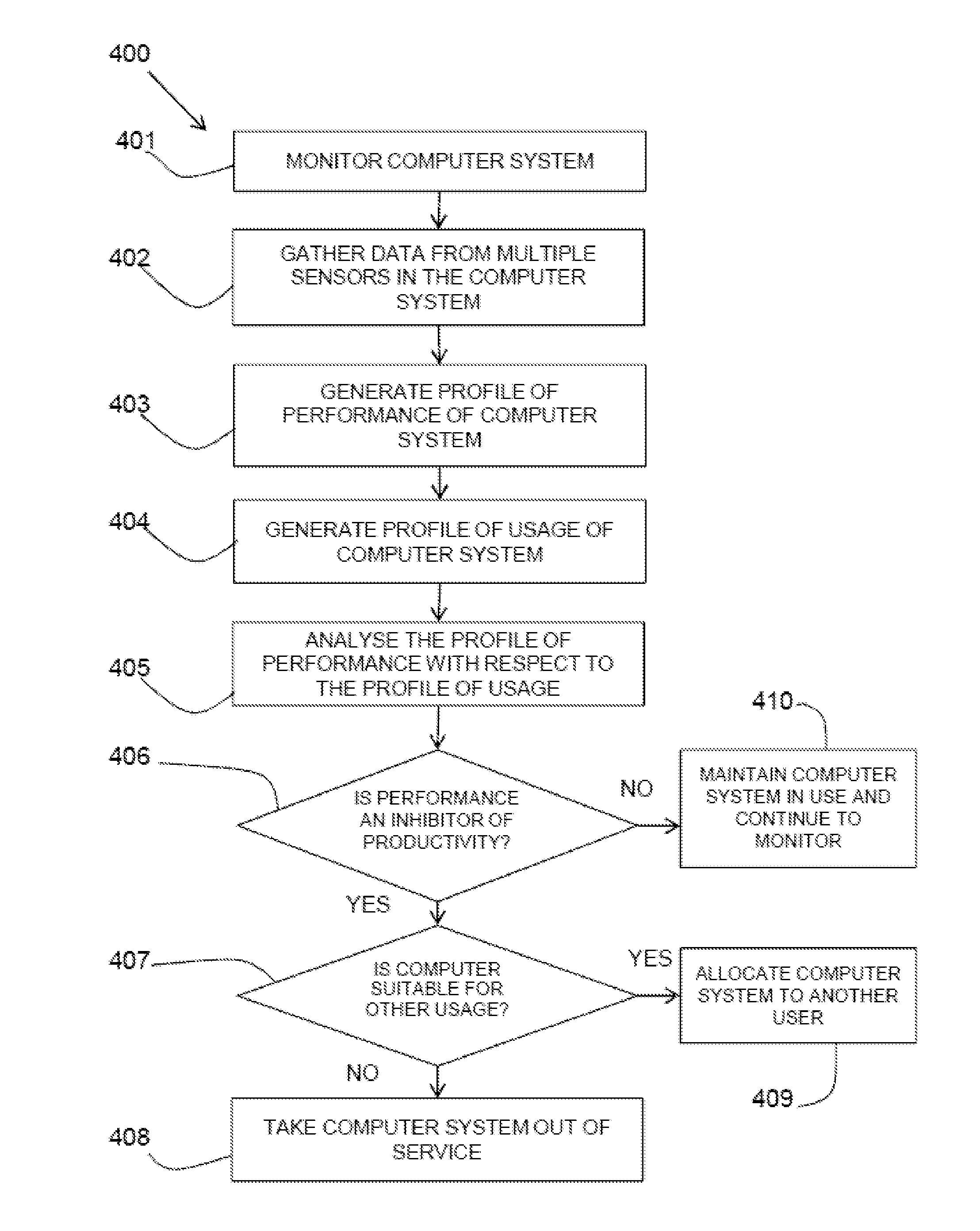

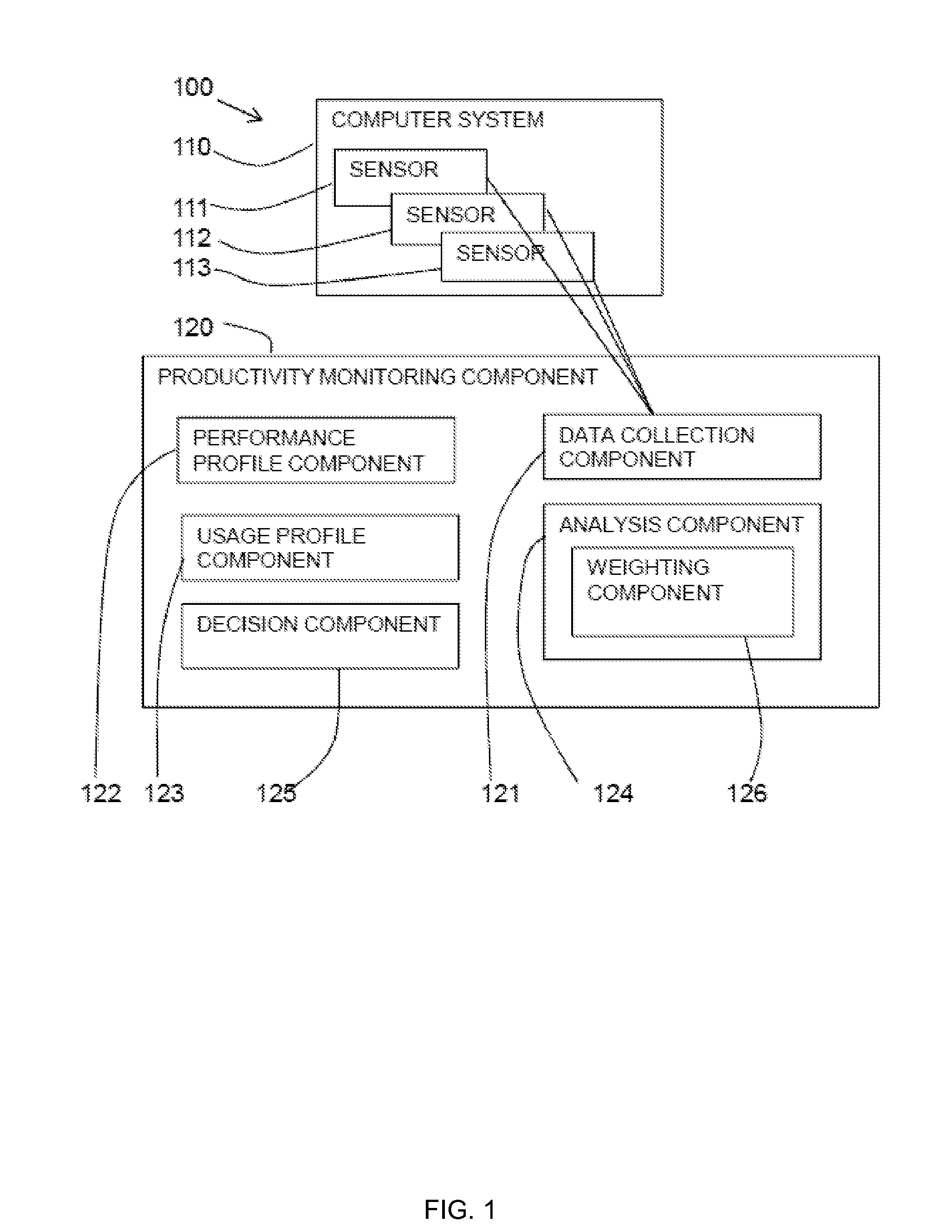

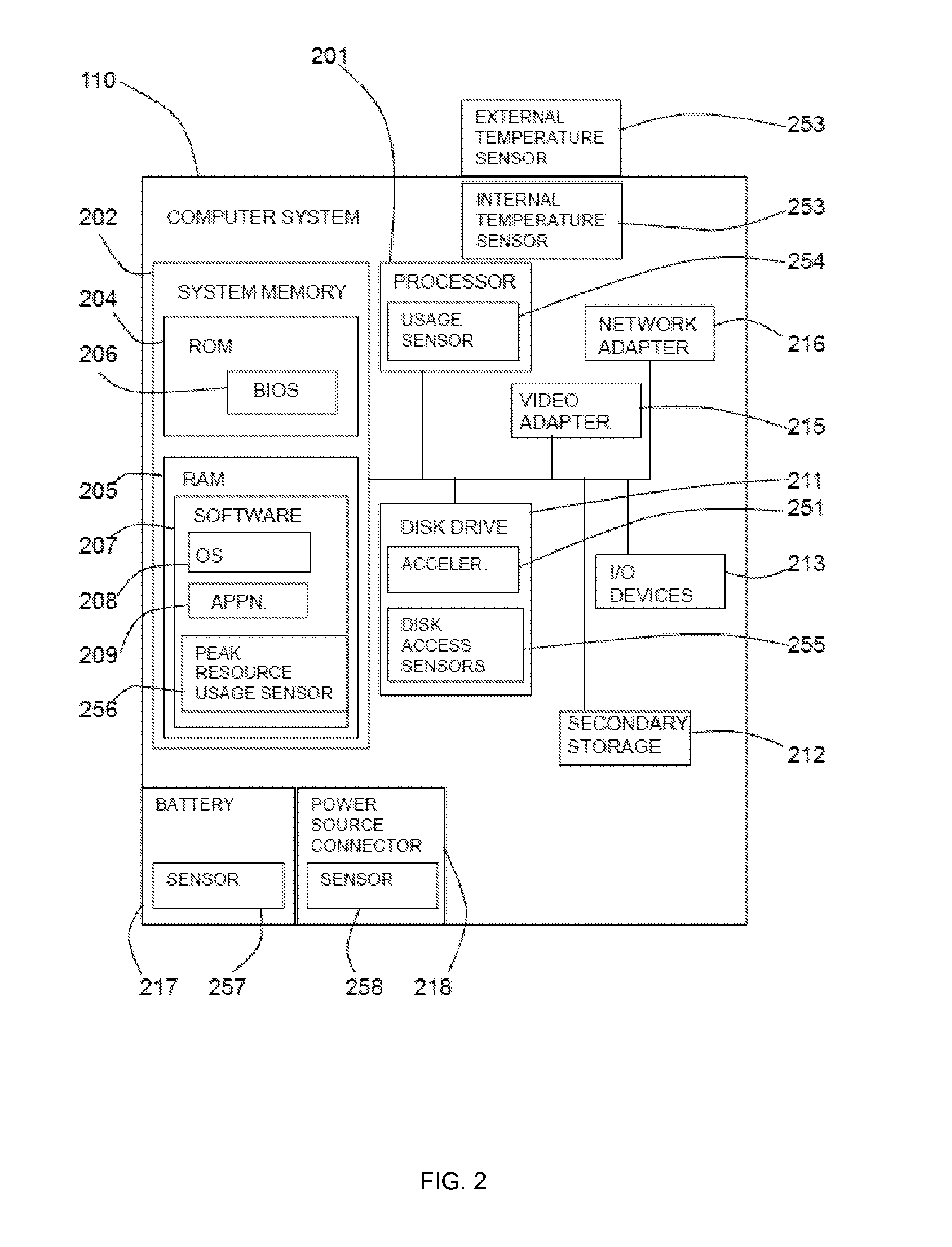

Computer system productivity monitoring

InactiveUS20150052241A1Avoid unnecessary system replacementAvoid inefficiencyError detection/correctionDigital computer detailsSoftware engineeringSubject matter

Embodiments of the inventive subject matter include an apparatus comprising a processor and a computer readable storage medium having computer usable code. The computer usable code can be configured to gather information about a computer system. The computer usable code can be further configured to generate a profile of performance of the computer system based on the information about the computer system. The computer usable code can be further configured to generate a profile of usage of the computer system based on the information about the computer system. The computer usable code can be further configured to analyze the profile of performance of the computer system against the profile of usage of the computer system. The computer usable code can be further configured to determine that productivity of the computer system is inhibited based on the analysis of the profile of performance against the profile of usage.

Owner:IBM CORP

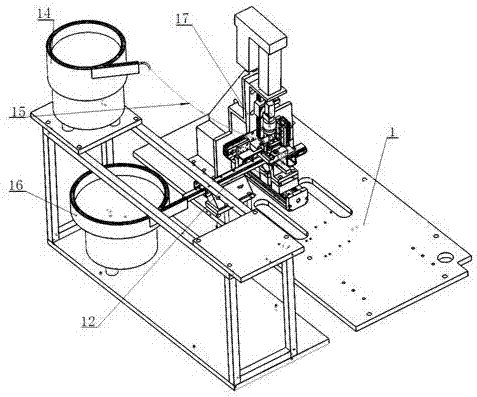

Feeding device used for full-automatic tapping machine

InactiveCN104526080AAvoid errorsProvides productivityThread cutting feeding devicesThread cutting machinesMechanical engineering

The invention discloses a feeding device used for a full-automatic tapping machine. The feeding device comprises a vibration disc, a linear guide rail, a chuck, a chuck driving device, a vertical driving device and a front and back driving device. The chuck driving device drives the chuck to clamp parts, the vertical driving device and the front and back driving device drive the chuck to move vertically and horizontally, one end of the linear guide rail is connected with the vibration disc, and the other end of the linear guide rail is arranged below the chuck. The parts to be tapped can be continuously provided for the full-automatic tapping machine and automatically assembled inside a die without shutdown for manually assembling the parts, in this way, errors caused by manual operation are avoided, a machine table can continuously operate, production efficiency can be effectively improved, and the labor cost can be effectively lowered.

Owner:SUZHOU JINYIKANG AUTOMATION EQUIP

Transmission read-write device and method for intelligent IC cards

InactiveCN103854033AProvides productivityLess investment in equipmentCo-operative working arrangementsConveyor partsComputer moduleComputer hardware

Owner:BEIJING WATCH DATA SYST

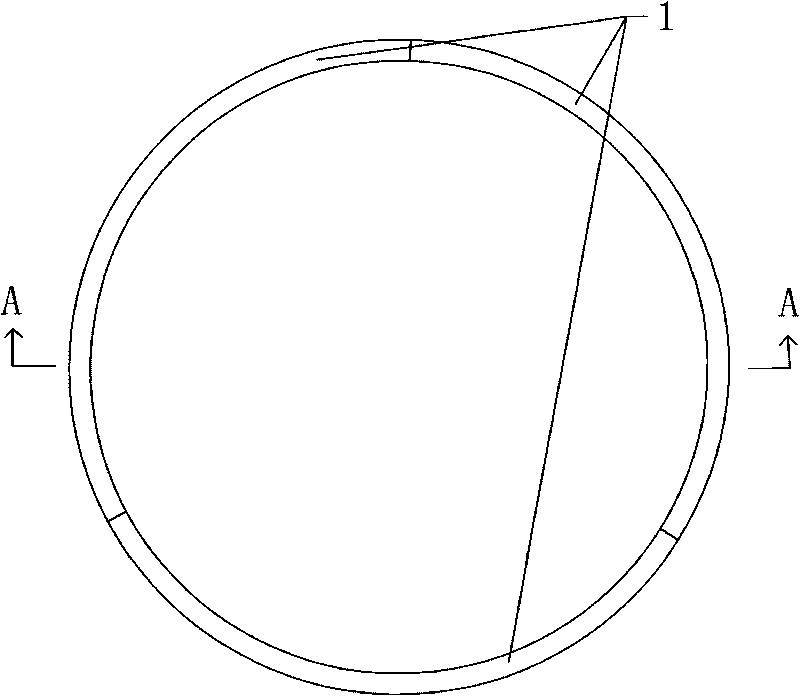

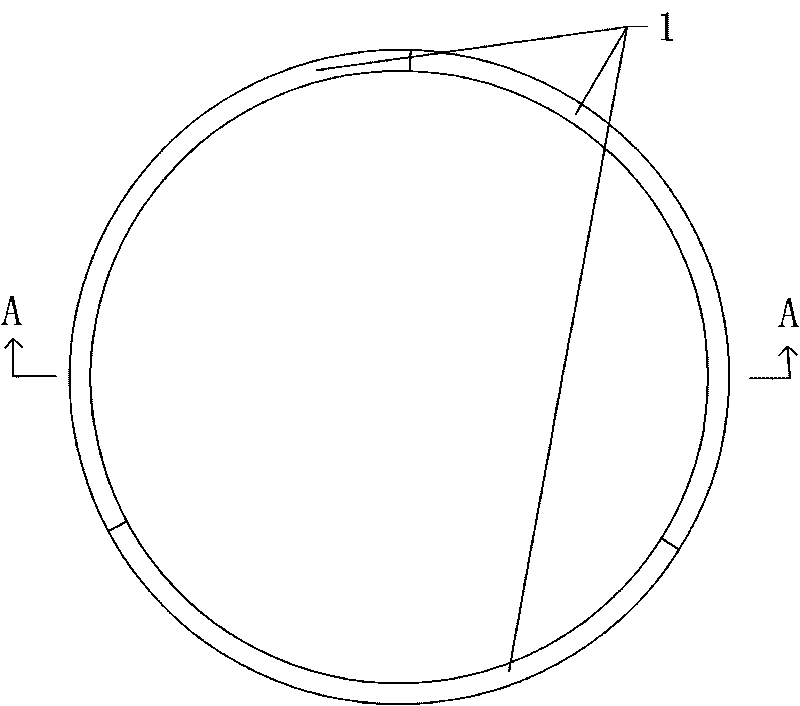

Bearing cage

The invention discloses a bearing cage, which at least comprises three arc retaining sheets. The inside of each retaining sheet is provided with a window opening. A plurality of retaining sheets are connected end to end to form the bearing cage, thus, only the operation of processing the retaining sheets needs to be carried out in the production process, and the retaining sheets have simple and convenient processing so as to simplify the production process of the bearing cage and greatly improve the production efficiency. The bearing cage is of a separated structure so as to have very convenient use.

Owner:潘冬东

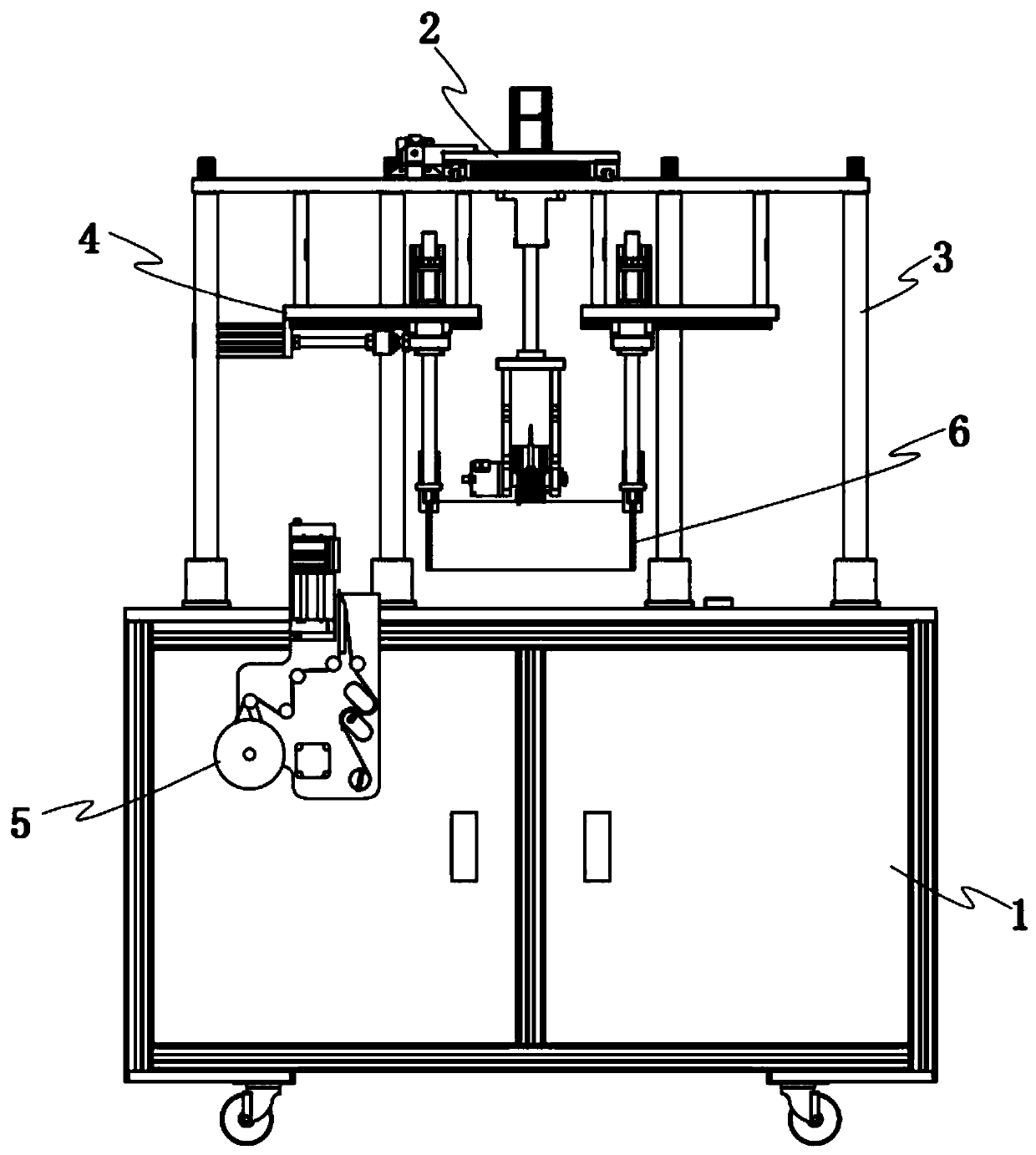

Grinding-drilling-labelling all-in-one machine for large-diameter metal pipe fitting

ActiveCN111300069AProvides productivityStandardize the production methodOther manufacturing equipments/toolsPositioning apparatusPhysicsLabelling machine

The invention relates to a grinding-drilling-labelling all-in-one machine for a large-diameter metal pipe fitting. The grinding-drilling-labelling all-in-one machine for the large-diameter metal pipefitting comprises an installation machine body as well as a vertical frame body and a labelling mechanism which are arranged on the installation machine body, wherein a grinding-drilling mechanism isarranged at the middle part of the vertical frame body, and the vertical frame body is symmetrically provided with clamping displacement mechanisms for the pipe fitting at the two sides of the grinding-drilling mechanism. The grinding-drilling-labelling all-in-one machine for the large-diameter metal pipe fitting realizes automatic pipe wall grinding and drilling, and pipe body surface labelling for the metal pipe fitting on the same equipment, realizes grinding-drilling-labelling all-in-one operation for the pipe fitting, replaces the previous manner of independently carrying out pipe fittingmachining by working personnel with different tools, increases the production efficiency for the pipe fitting, and normalizes the production manner; and moreover, the grinding-drilling mechanism is ingenious and compact in structural design, and drilling and grinding for the metal pipe fitting can be completed on the same mechanism.

Owner:佛山市鸿迪铝业有限公司

Temperature reducing device for air cylinder and oil cylinder

InactiveCN102734265AProvides productivityExtended service lifeFluid-pressure actuator componentsEngineeringPiston rod

The invention discloses a temperature reducing device for an air cylinder and an oil cylinder. The temperature reducing device is a connecting device arranged between the air cylinder and high temperature equipment in contact with the air cylinder or between the oil cylinder and high temperature equipment in contact with the oil cylinder; the connecting device comprises a connecting block, a base and a connecting column; and the connecting block is connected with the base through the connecting column, wherein at least one installing hole is arranged on the connecting block. The temperature reducing device provided by the invention is used between the air cylinder or oil cylinder and a die, so as to reduce high temperature of the air cylinder or the oil cylinder due to direct contact with the die during the production process; after the temperature reducing device is applied, the temperature at a piston rod of the air cylinder is reduced to around 120 DEG C, the temperature at an oil seal for a shaft of the air cylinder is reduced to around 115 DEG C, the temperature at the a piston rod of the oil cylinder is reduced to 135 DEG C and the temperature at an oil seal for a shaft of the oil cylinder is reduced to 115 DEG C; therefore, the problems of short production time or production failure of the air cylinder and oil leakage of the oil cylinder due to the high temperature are solved, the production efficiency is improved, the production cost is saved, and the service life of the air cylinder or the oil cylinder is prolonged.

Owner:TAICANG HAIJIA VEHICLE FITTINGS

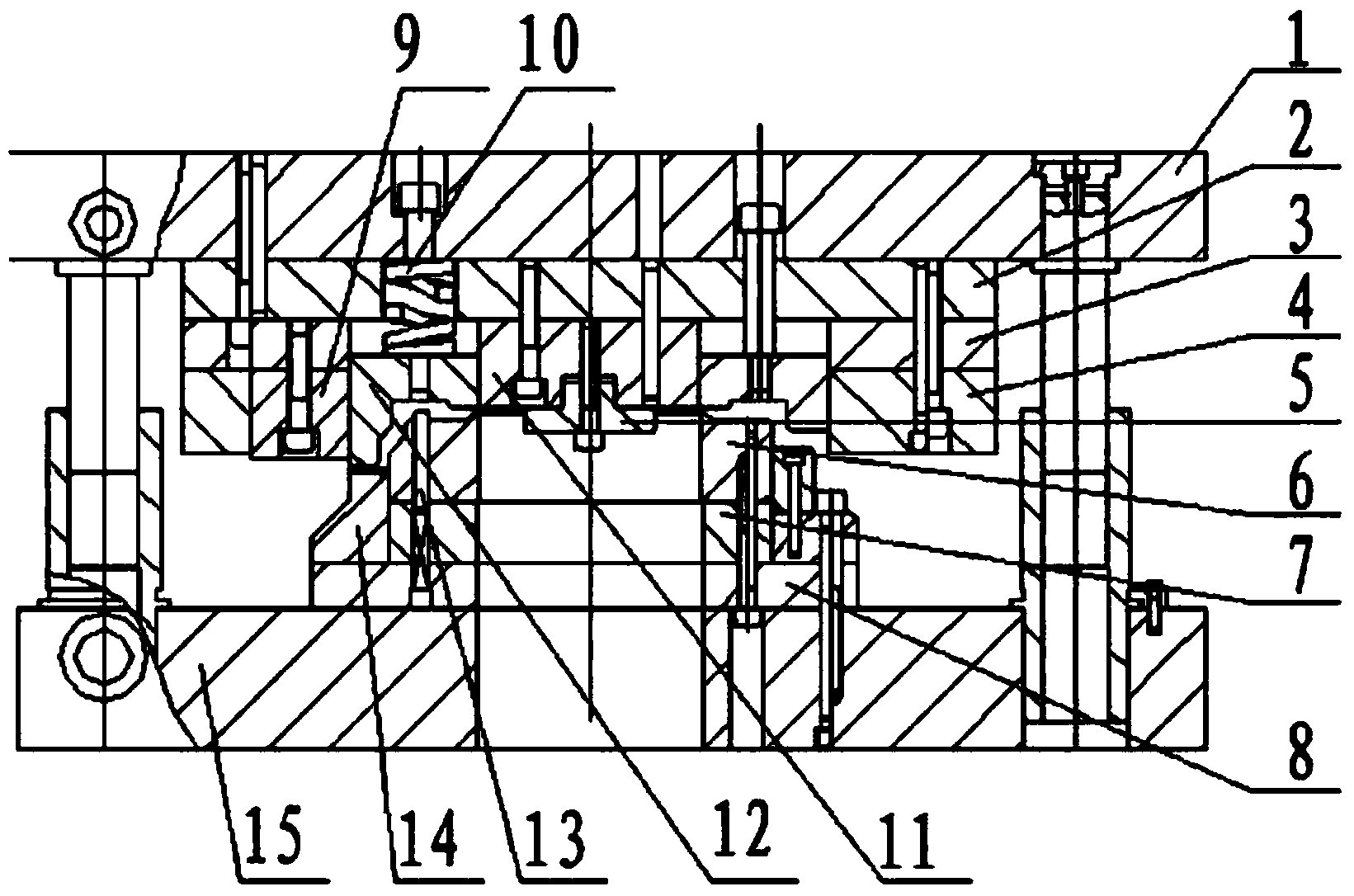

Vehicle clutch cover pressing side cutting and center hole punching composite die

InactiveCN103861951AShorten the processing cycleProvides productivityShaping toolsClutchWork in process

The invention discloses a vehicle clutch cover pressing side cutting and center hole punching composite die which comprises an upper die frame plate, a lower die frame plate and a discharging plate. The lower end face of an upper die cushion plate is connected with a hole punching protruding die. A lower die cushion plate is provided with a hole punching concave die which is placed below the hole punching protruding die and is matched with the hole punching protruding die when the hole punching protruding die is pressed down. The discharging plate is connected to the hole punching protruding die in a sleeved mode. The discharging plate is connected with the upper die frame plate through a spring. A side cutting protruding die which is placed below the discharging plate and is matched with a side cutting concave die insert is connected to the outside of the hole punching concave die in a sleeved mode. The vehicle clutch cover pressing side cutting and center hole punching composite die has the advantages that the two procedures of cover side cutting and center hole punching are completed in a concentrating mode, so that a machining cycle is greatly shortened, production efficiency is improved, half-finished product turnover is lowered, and the labor intensity of workers is lowered; and the accuracy and the concentricity of products can be guaranteed, and then product quality is improved.

Owner:WUHU DAJIE CLUTCH

Computer system productivity monitoring

ActiveUS20150134815A1Avoid unnecessary system replacementAvoid inefficiencyError detection/correctionDigital computer detailsProduction rateSubject matter

Embodiments of the inventive subject matter include gathering, from a plurality of sensors of a computer system, information about the computer system. Embodiments further include generating a profile of performance of the computer system indicating a state of components of the computer system during use. Embodiments further include generating a profile of usage of the computer system indicating current activities and usage of the computer system. Embodiments further include analyzing the profile of performance of the computer system against the profile of usage of the computer system to determine if the state of the components of the computer system during use is acceptable for the current activities and usage of the computer system. Embodiments further include determining that productivity of the computer system is inhibited based, at least in part, on the analyzing the profile of performance of the computer system against the profile of usage of the computer system.

Owner:INT BUSINESS MASCH CORP

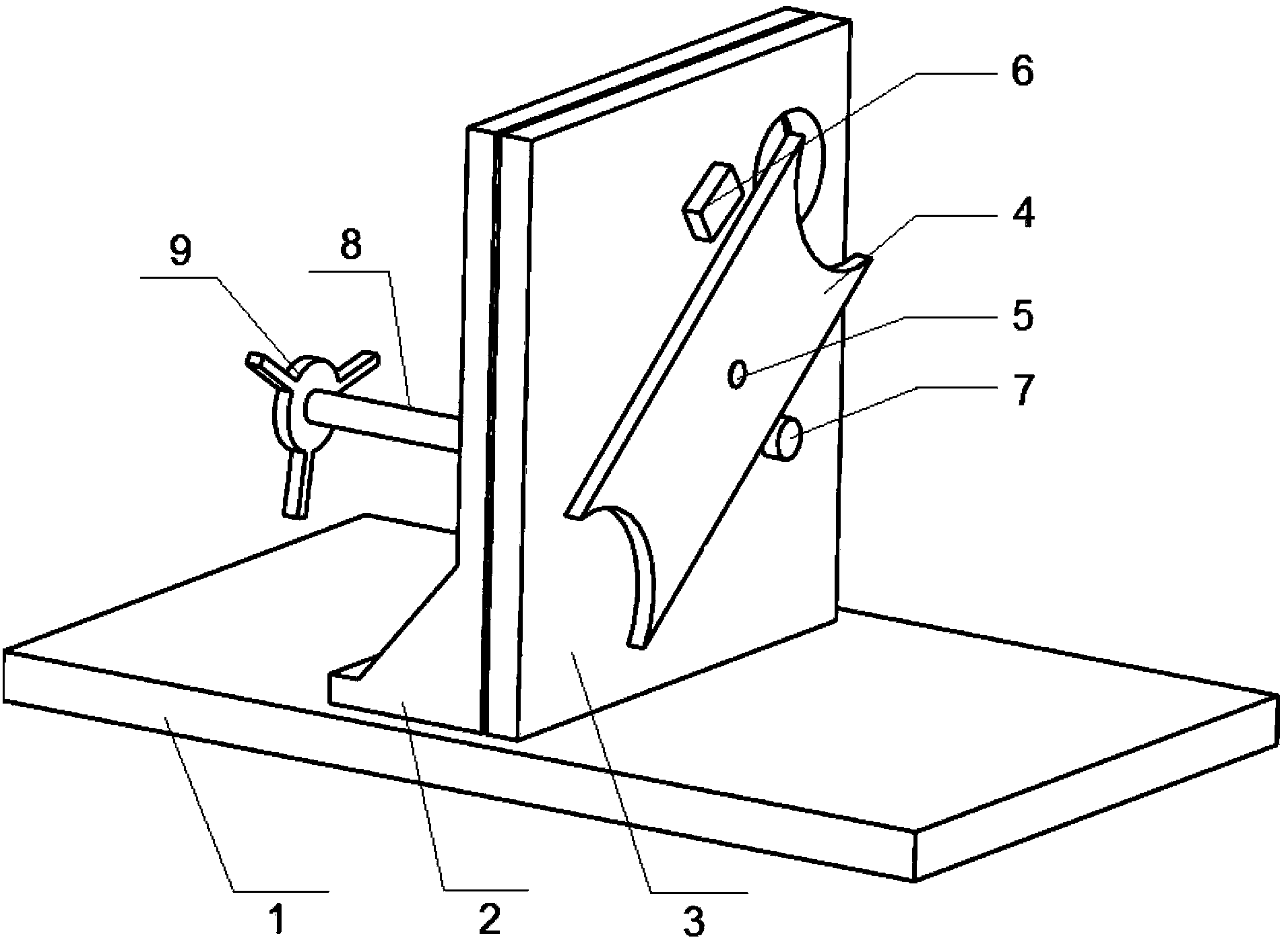

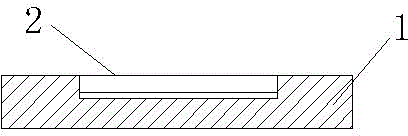

Cable outer mold glue injection frame

ActiveCN104252923AGuaranteed qualityProvides productivityInsulating conductors/cablesEngineeringMechanical engineering

The invention provides a cable outer mold glue injection frame, and relates to the technical field of cable processing. The cable outer mold glue injection frame comprises a bottom plate, an outer mold fixing frame and at least one cable end fixing frame, wherein the outer mold fixing frame is used for fixing an outer mold, the cable end fixing frame is used for fixing the end part of a core wire of a cable, the outer mold fixing frame and the at least one cable end fixing frame are connected onto the bottom plate in a side by side way at the left side and the right side, each cable end fixing frame has a preset distance from the outer mold fixing frame, the outer mold fixing frame and the cable end fixing frame are adopted for respectively fixing the positions of the outer mold and the end part of the core wire, the outer mold can be positioned in a correct position only through setting the distance between the outer mold fixing frame and the cable end fixing frame to be the preset distance in advance and directly and respectively fixing the outer mold and the end part of the core wire onto the outer mold fixing frame and the cable end fixing frame before the outer mold glue injection, then, glue materials are injected into the outer mold, and the outer mold glue injection work procedure is completed, convenience and high speed are realized, the production efficiency is improved, and meanwhile, the outer mold position cannot easily generate the deviation, so the cable quality is also ensured.

Owner:GUANGDONG ZHONGDE CABLE

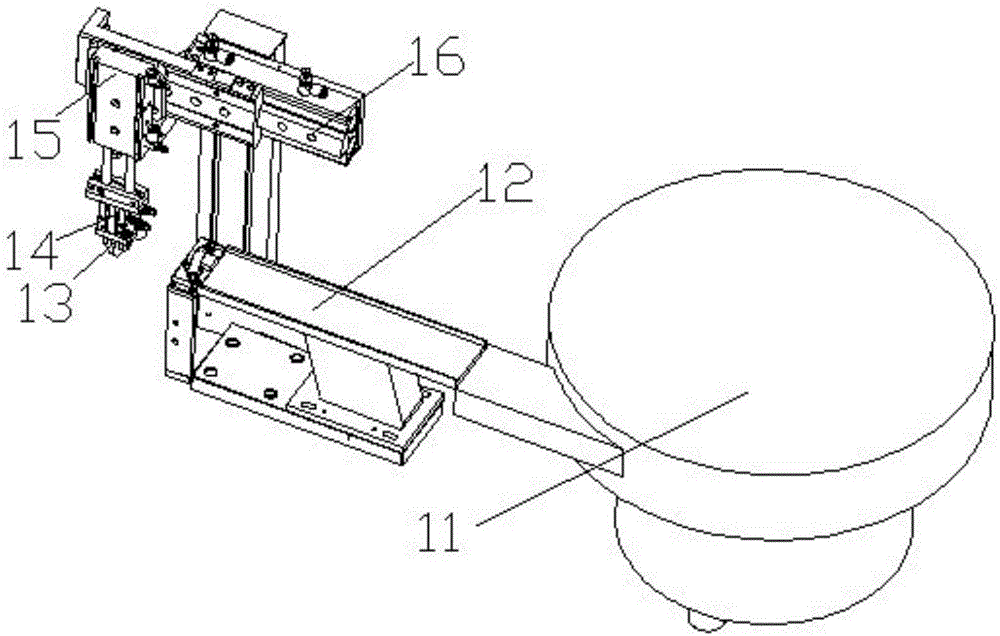

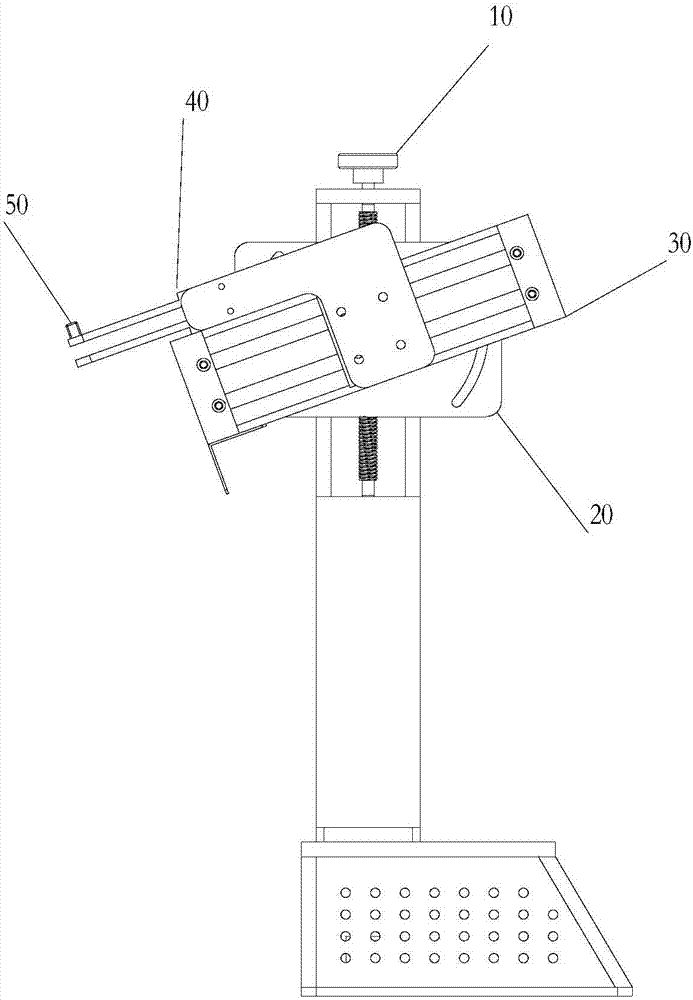

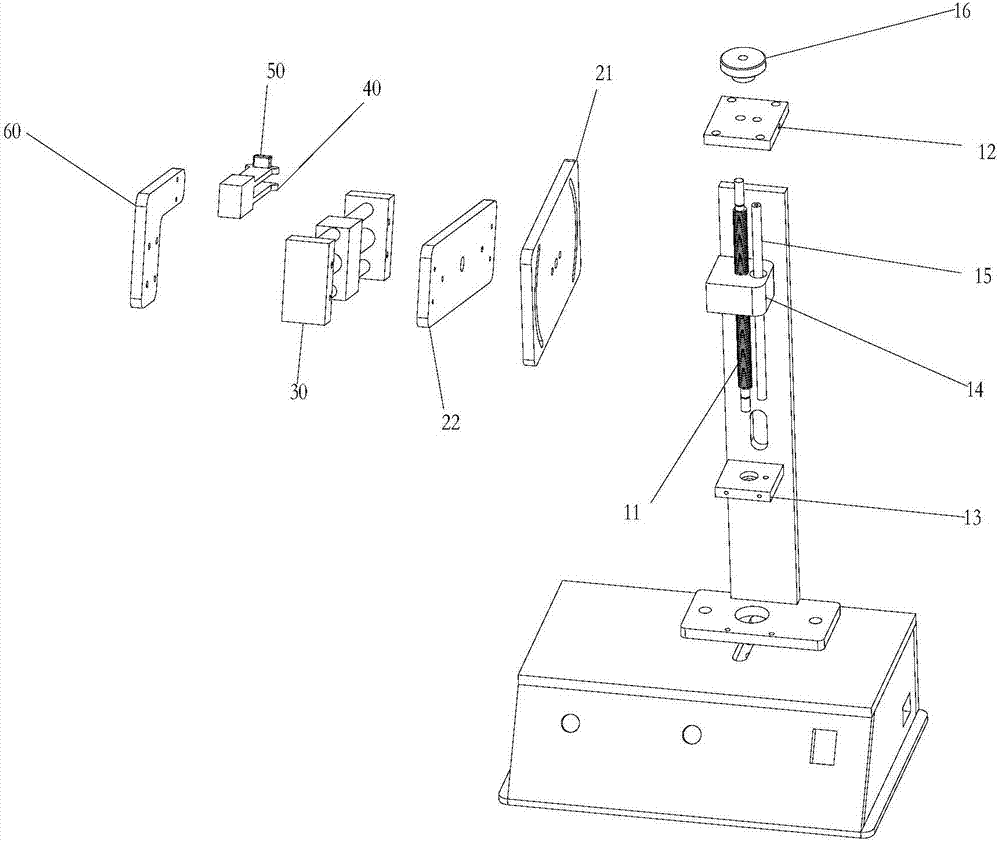

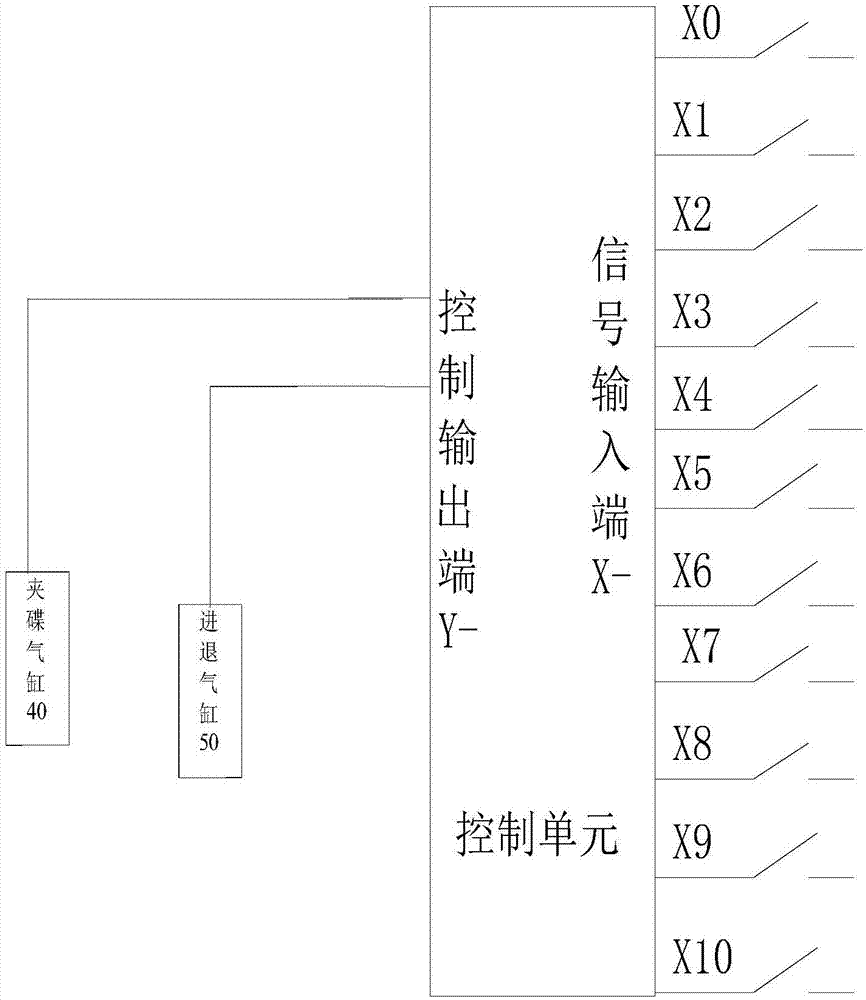

Automatic disc placing and taking device and control system and method thereof

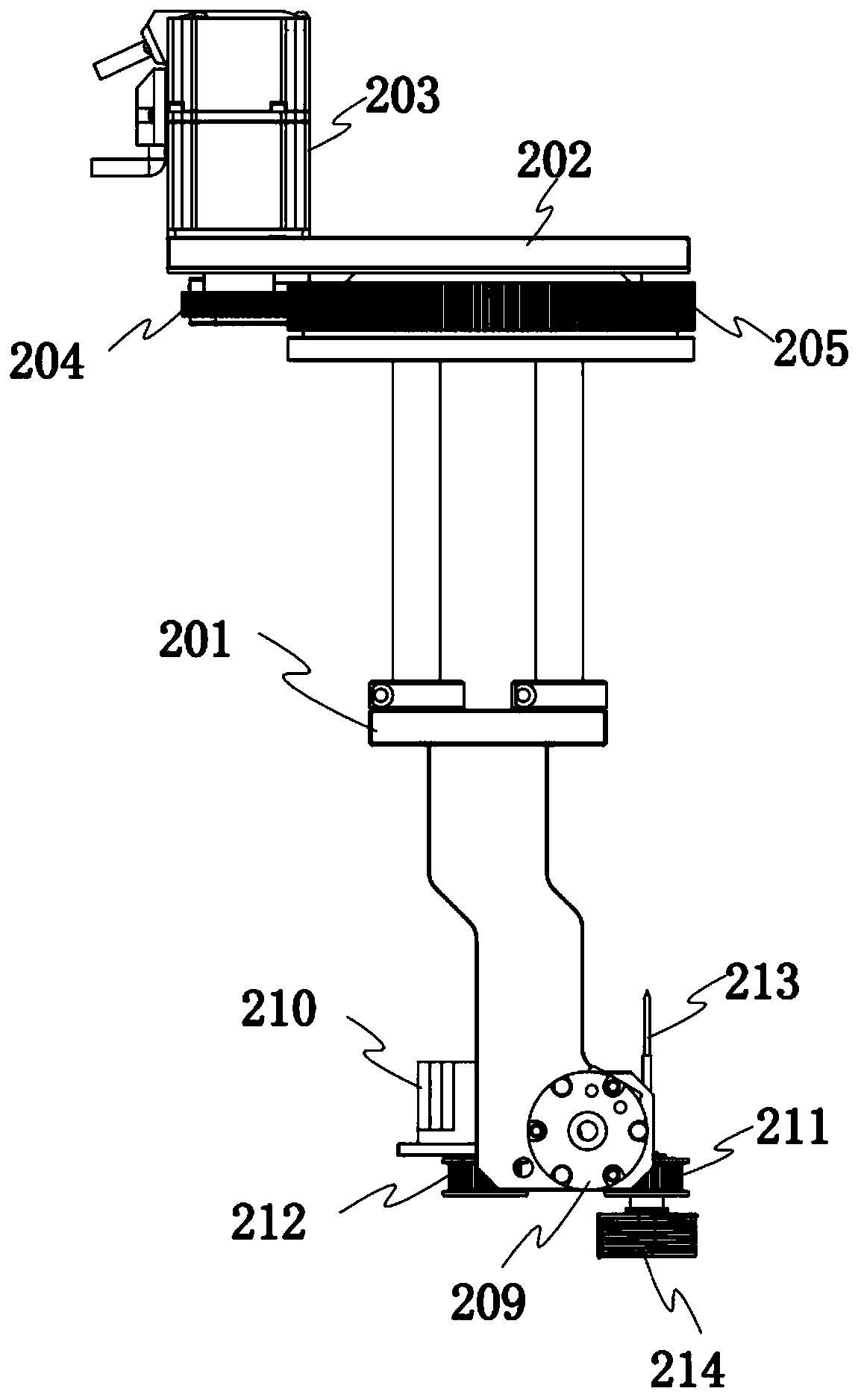

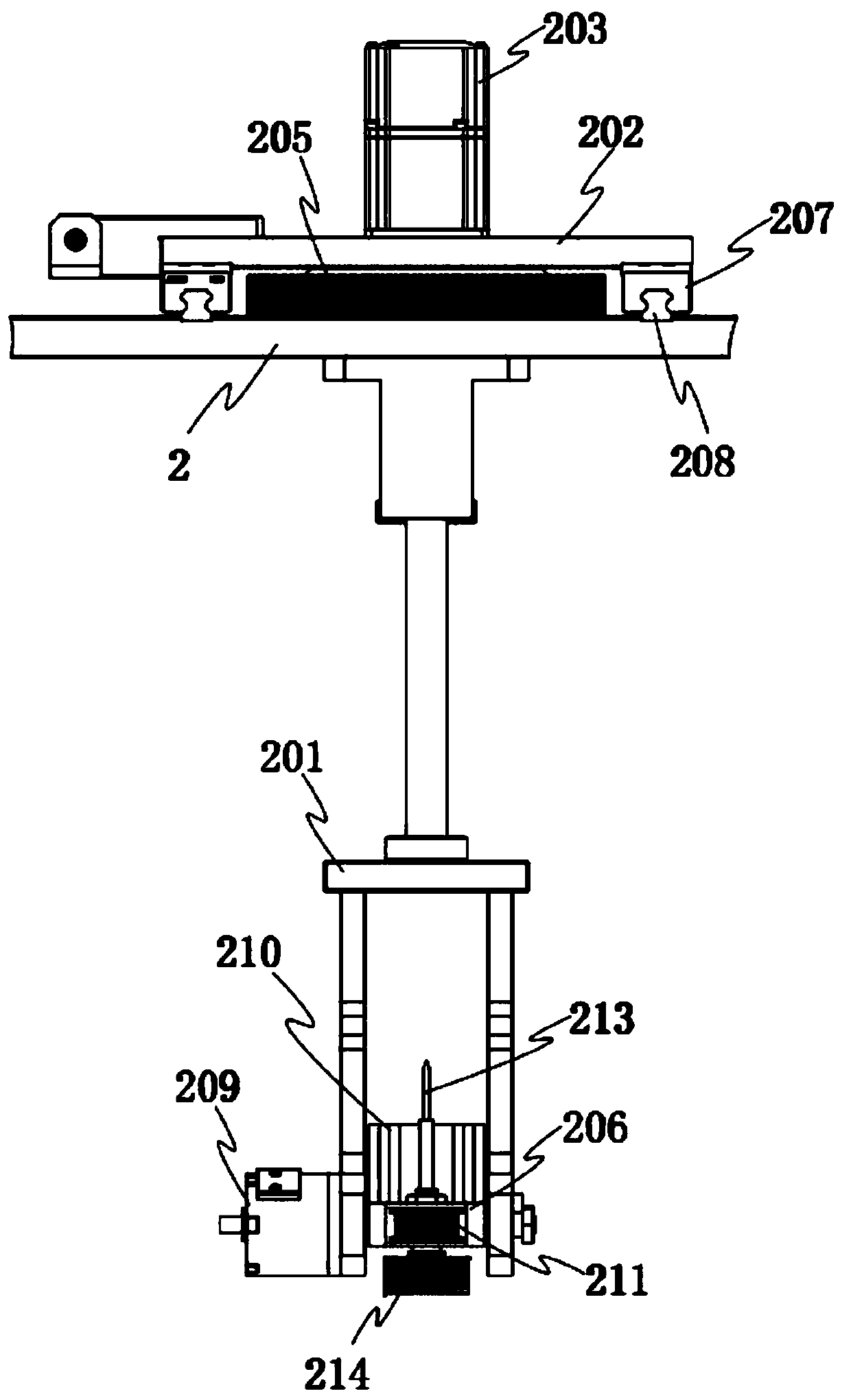

PendingCN107139175AProvides productivityReduce manufacturing costProgramme-controlled manipulatorRecord information storageEngineeringComputer hardware

The invention relates to the field of automation, and discloses an automatic disc placing and taking device. The automatic disc placing and taking device comprises a height adjusting grab handle, an angle rotating table, an advance and retreat cylinder, a disc clamping cylinder and a photoelectric sensor, wherein the angle rotating table is connected with the height adjusting grab handle; the height adjusting grab handle is used for achieving height adjusting of the angle rotating table; the advance and retreat cylinder is connected with the angle rotating table; the angle rotating table is used for adjusting the rotating angle of the advance and retreat cylinder; the disc clamping cylinder is connected with the advance and retreat cylinder; the photoelectric sensor is fixed to the disc clamping cylinder; and automatic placing and taking actions of a disc are achieved through electrical matching. By adopting the technical scheme, automatic operation of placing and taking of the disc can be achieved, the production efficiency is improved, and the cost is reduced.

Owner:FORYOU GENERAL ELECTRONICS

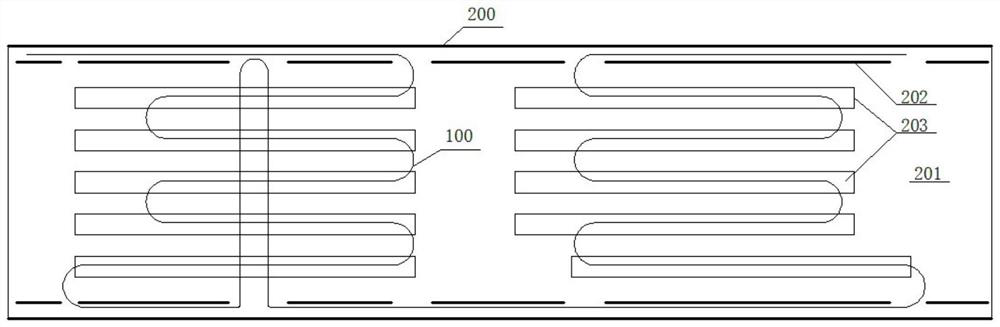

Automatic feeding equipment for mylar

PendingCN113148638AReduce labor intensityProvides productivityConveyorsConveyor partsMagnetAssembly line

The invention belongs to the technical field of mylar feeding, and particularly relates to automatic feeding equipment for mylar. The equipment comprises a bottom plate. A feeder, a mechanical arm transferring mechanism, a first feeding assembly line, a second feeding assembly line and a carrying module are arranged on the upper portion of the bottom plate, the first feeding assembly line and the second feeding assembly line are used for supplying jigs and are arranged in parallel, and the carrying module is used for pushing the jigs to magnet assembling equipment. A camera is arranged at the feeding tail end of the feeder. The first feeding assembly line comprises a first left conveying belt mechanism and a first right conveying belt mechanism, and the second feeding assembly line comprises a second left conveying belt mechanism and a second right conveying belt mechanism. A positioning frame is fixedly installed on the upper portion of the first right conveying belt mechanism and the upper portion of the second right conveying belt mechanism. The positioning frame comprises two discharging positions corresponding to the first right conveying belt mechanism and the second right conveying belt mechanism respectively. When in use, the automatic feeding equipment for mylar has the advantages that the labor intensity of workers can be greatly reduced, and the production efficiency is improved.

Owner:信阳圆创磁电科技有限公司

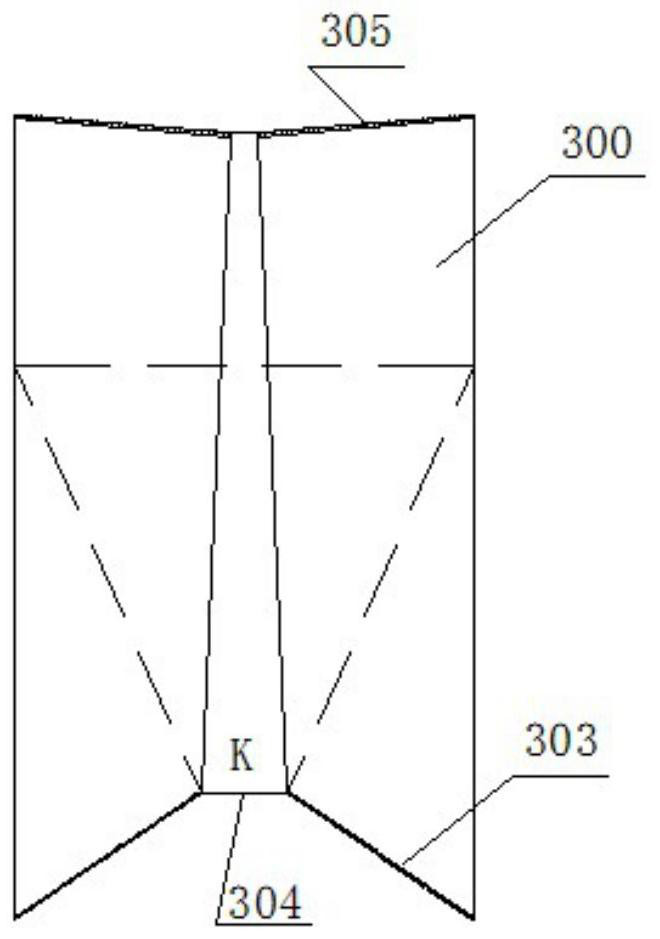

Automatic medicinal material unpacking device and method

PendingCN109383892AReduce labor intensityProvides productivityUnpacking by cuttingEngineeringMaterial storage

The invention relates to the technical field of separation of medicinal materials, in particular to an automatic medicinal material unpacking device. The device comprises a supporting mechanism, a gripping mechanism, a lifting mechanism, a walking mechanism and a cutting mechanism; the supporting mechanism comprises a bracket, a first material storage bin and a second material storage bin which are formed by the bracket in sequence, wherein the first material storage bin is used for storing bundled medicinal materials, the second material storage bin is used for storing unfastened medicinal materials, and the first material storage bin is communicated with the second material storage bin; the walking mechanism comprises a slide rail and a driving vehicle, and the driving vehicle is slidably connected to the slide rail; the cutting mechanism comprises cutters; the cutting mechanism is arranged in the second material storage bin, the slide rail extends into the second material storage bin from the first material storage bin and is fixedly connected to the upper portion of the bracket, one end of the lifting mechanism is connected with the driving vehicle, and the other end of the lifting mechanism is connected with the gripping mechanism. Through the arrangement of the gripping mechanism, the lifting mechanism, the walking mechanism and the cutting mechanism, cutting of medicinalmaterial packages is automatically completed at a time, the labor intensity of workers is greatly reduced, and the production efficiency of the whole production line is improved.

Owner:江苏国瑞特环保工程技术有限公司

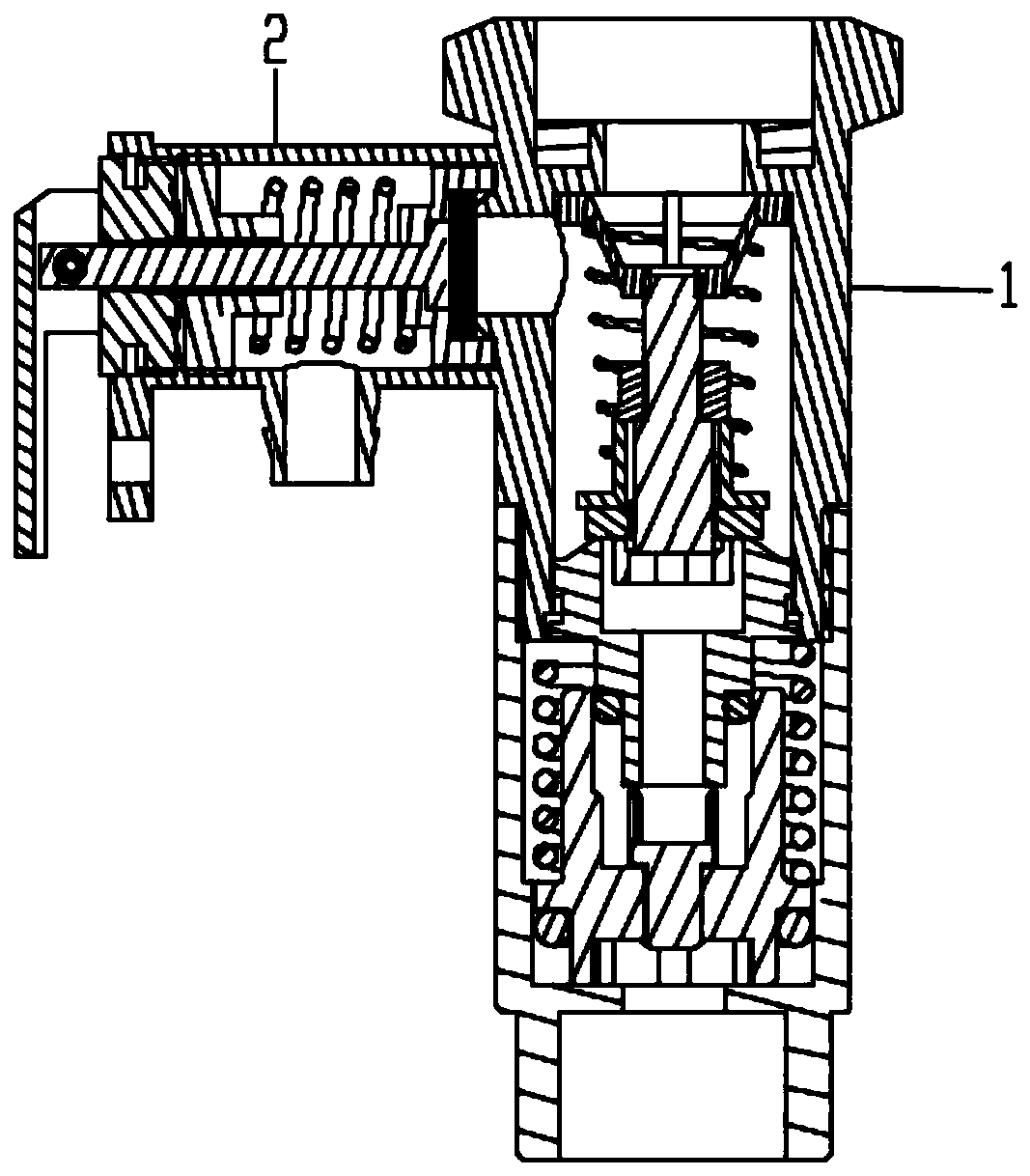

One-way safety valve provided with decompression component and water heater applying same

PendingCN111396609AReduced assembly stepsProvides productivityOperating means/releasing devices for valvesEqualizing valvesStructural engineeringSafety valve

The invention discloses a one-way safety valve provided with a decompression component and a water heater applying the same. The one-way safety valve comprises a main valve body module with the internal leakage function and a branched valve body module with the external leakage function; the branched valve body module is detachably connected with the upper side wall of the main valve body module;and the main valve body module comprises the decompression component for decompression. According to the one-way safety valve provided with the decompression component, the safety valve and the decompression component are integrated, so that safe pressure limiting and decompression can be simultaneously obtained through mounting the one-way safety valve provided with the decompression component onthe water heater at one time, the assembling step is reduced, the production efficiency is improved, the production cost is reduced and the user experience degree is increased.

Owner:VATTI CORP LTD

Aging manufacturing technology for aluminum electrolytic capacitor and detecting device

ActiveCN104779081AShorten aging timeProvides productivityCapacitor manufactureCapacitanceAluminum electrolytic capacitor

Owner:YIYANG HETIAN ELECTRONICS

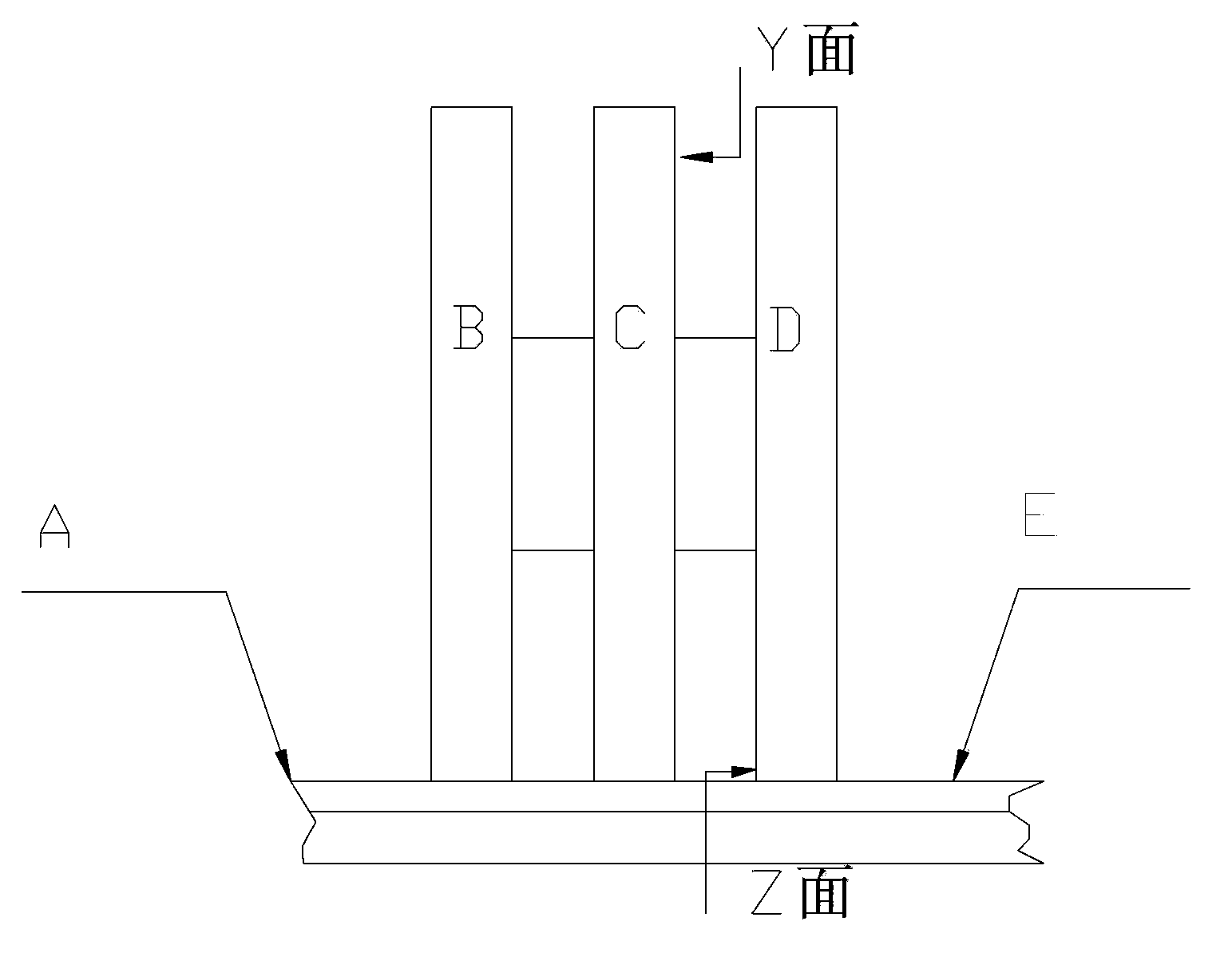

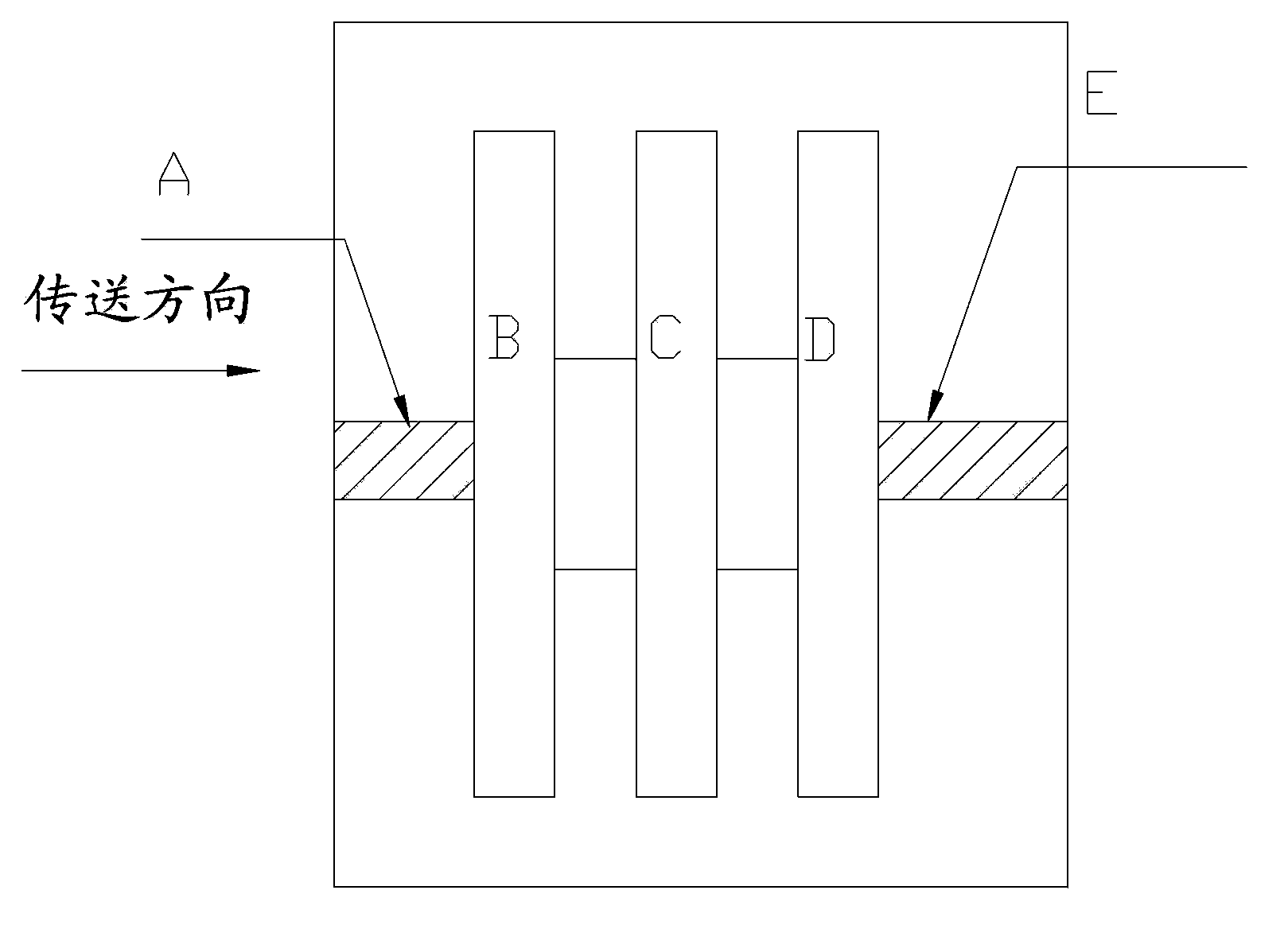

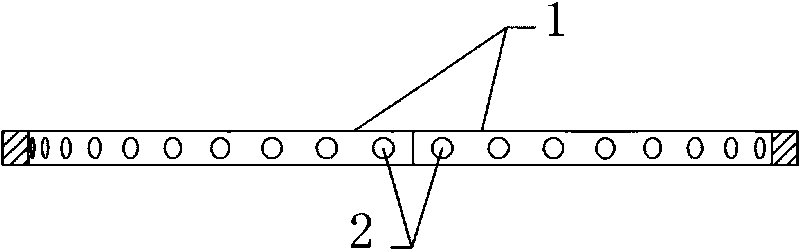

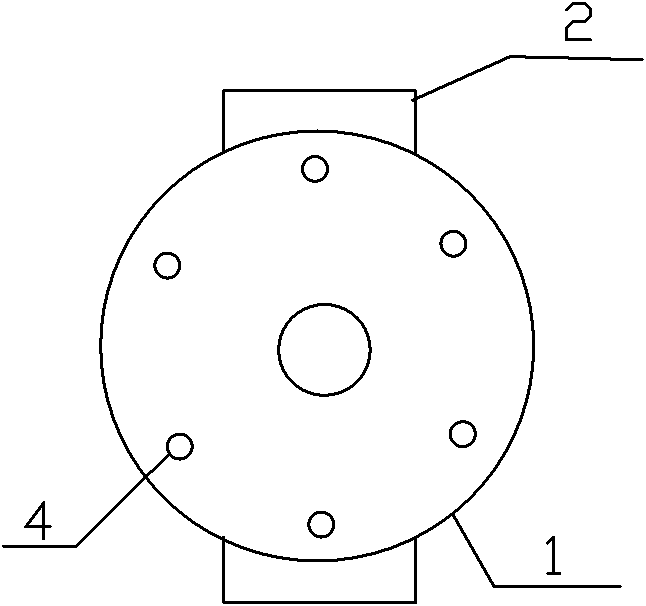

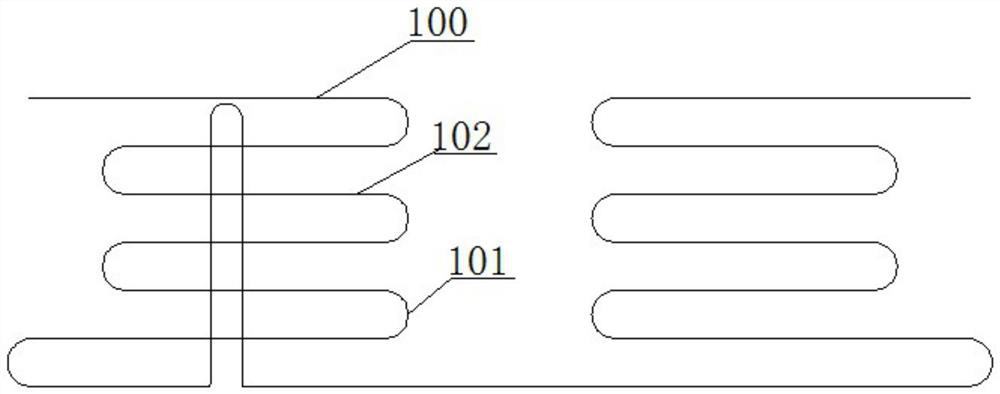

Pallets for Conveyor Belts

PendingCN106144113AProvides productivityReduce waste of resourcesTray containersAutomotive engineeringProcess engineering

The invention discloses a tray for a connecting rod conveyor belt, which includes a chassis placed on the conveyor belt, a plurality of oil grooves are arranged on the chassis, and a plurality of component grooves matching the connecting rod are arranged in each oil groove. The depth of the oil groove is greater than the depth of the part groove. The present invention adopts a tray placed on the conveyor belt, and the connecting rod is placed in the tray, which is convenient for the manipulator of the automatic feeding device to grab and place. At the same time, the oil groove on the tray can make the connecting rod After processing, the excess oil on the parts is filtered out, which not only plays the role of cleaning the parts, but also the oil in the oil tank can be added to the honing machine for recycling, which improves production efficiency and reduces waste of resources.

Owner:熊宝华

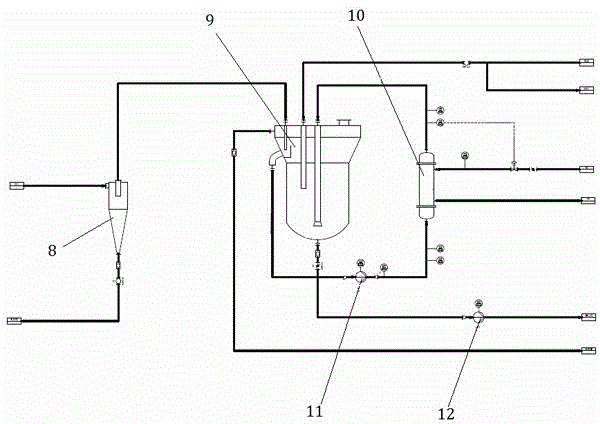

A kind of sodium acetate continuous evaporation crystallization method

ActiveCN104529743BSmooth feedingStable discharge operationSolution crystallizationCrystallization by component evaporationSodium acetateCyclone

The present invention relates to a continuous sodium acetate evaporation crystallization system, which comprises an evaporation system and a crystallization system, wherein the outlet of the evaporation system material inlet pump is respectively connected with an evaporation heater and a pre-heater, the material outlet of the pre-heater is communicated with the evaporation heater, the material outlet of the evaporation heater is connected with the material inlet of an evaporation separation chamber, the material outlet of the evaporation separation chamber is respectively connected with the inlets of a first circulation pump and a material outlet pump, the first circulation pump is communicated with the evaporation heater, the outlet of the material outlet pump is connected with the material inlet of a cyclone, the material outlet on the top portion of the cyclone is connected with the material inlet of a crystallization separation chamber, the material outlet on the top portion of the crystallization separation chamber is connected with the inlet of a second circulation pump, the outlet of the second circulation pump is connected with the material inlet of a cooler, the material outlet of the cooler is connected with the material inlet of the crystallization separation chamber, and the material outlet on the bottom portion of the crystallization separation chamber is connected with a slurry pump. According to the present invention, the continuous production way of the sodium acetate evaporation crystallization is achieved, such that the product quality is easily stabilized, the production efficiency is easily increased, and the energy source consumption of the whole production process can be reduced.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Method for manufacturing medical NTC temperature sensor structure

PendingCN112277241AAutomateProvides productivityDomestic articlesCoatingsManufacturing efficiencyManufacturing engineering

The invention provides a method for manufacturing a medical NTC temperature sensor structure. The method comprises the following steps that stamping is carried out to form metal sheet bodies, metal pins are formed on the formed metal sheet bodies, the two metal sheet bodies are symmetrically arranged in an injection mold, a set distance is reserved between the two metal pins, a sensing element isprovided, a packaging material is injected into the injection mold so as to form packaging pieces for supporting the metal sheet bodies and wrapping the metal pins and the sensing element, so that manufacturing of the sensor structure is completed. The method is simple in step and convenient to operate, and can greatly improve the manufacturing efficiency and the quality of the manufactured product.

Owner:江苏易感素智能科技有限公司

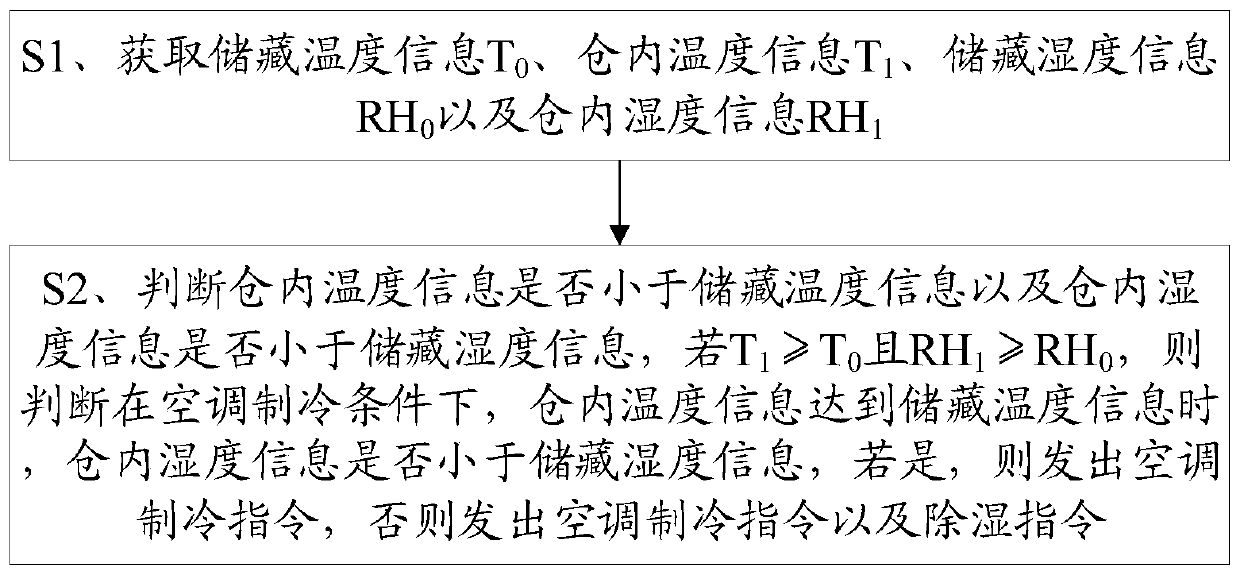

Control method for intelligent granary and terminal

ActiveCN110096085AProvides productivityReduce labor costsSimultaneous control of multiple variablesRefrigerationComputer science

The invention discloses a control method for an intelligent granary. The method includes the following steps that: storage temperature information T0, in-granary temperature information T1, storage humidity information RH0 and in-granary humidity information RH1 are acquired; and whether the in-granary temperature information T1 is smaller than the storage temperature information is judged, and whether the in-granary humidity information is smaller than the storage humidity information is judged, if T1 is larger than or equal to T0, and RH1 is larger than or equal to RH0, whether the in-granary humidity information is smaller than the storage humidity information under an air conditioner refrigeration condition is judged when the in-granary temperature information reaches the storage temperature information, if the in-granary humidity information is smaller than the storage humidity information, an air conditioner refrigeration instruction is emitted, otherwise, an air conditioner refrigeration instruction and a dehumidification instruction are sent out. With the control method for the intelligent granary of the invention adopted, real-time and accurate temperature and humidity control over the intelligent granary can be realized; production efficiency is improved; labor cost is reduced; and misoperation caused by manual intervention and possible harm to a human body are avoided, and meanwhile, energy-saving and energy-saving effects are achieved while the requirements of storage temperature information and storage humidity information are satisfied.

Owner:FUJIAN REIDA PRECISION

Automatic processing equipment for leather blanking and stacking

InactiveCN112193878AReduce security risksProvides productivityPile receiversArticle deliveryAutomatic processingEngineering

The invention relates to the field of leather processing, in particular to automatic processing equipment for leather blanking and stacking which comprises a leather unwinding device, a leather blanking device and a leather stacking device. Leather is drawn out by an unwinding device and then is wound by a winding device in a horizontal state, and when the leather passes through a pressure-bearingtable, a stamping head is driven by a translation mechanism to carrying out blanking on the unwound leather, the blanked leather is sucked by a sucker arranged in the stamping head, then the sucked leather is moved to the upper end of a material collecting vehicle through the translation mechanism and falls onto the material collecting vehicle, and a material stacking plate and the material collecting vehicle push the leather to be flush with each other. Leather is automatically processed and stacked through the leather unwinding device, the leather blanking device and the leather stacking device, and compared with the prior art, potential safety hazards are reduced, the production efficiency is improved, and the labor cost is reduced.

Owner:诸暨市更新工业设计工作室

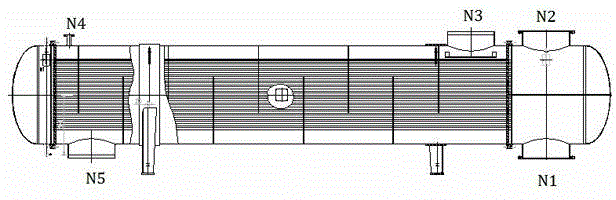

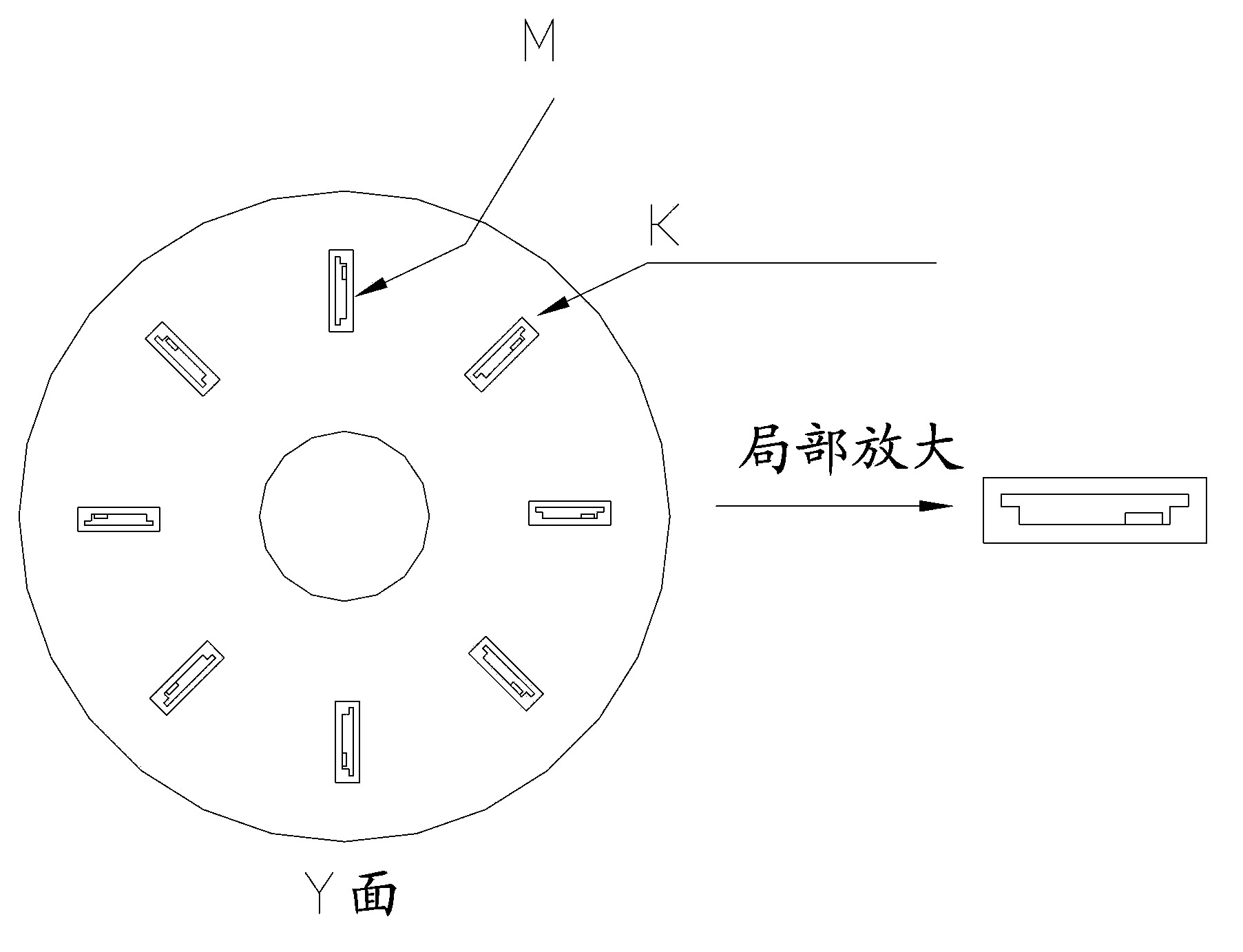

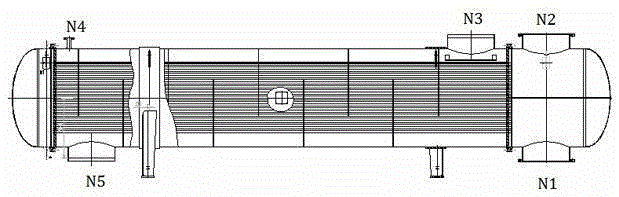

Heat exchange tube positioning adjusting roller and method

PendingCN114192691AShape and Position SpecificationsProvides productivityMaterial gluingHeat exchange apparatusPhysicsEngineering

The invention discloses a heat exchange tube positioning adjusting roller and method, and belongs to the technical field of refrigerator heat exchange tubes. The heat exchange tube positioning adjusting roller comprises a cylindrical roller body, adjusting channels are arranged on the circumferential face of the roller body, the adjusting channels are annularly arranged in the circumferential direction of the roller body, and the adjusting channels are connected end to end to form an annular groove; a bottom face is arranged at the bottom of the adjusting channel, the width of the bottom face is the adjusting width of the adjusting channel, the adjusting width tends to be gradually reduced from the head section to the tail section of the adjusting channel, the adjusting width of the head section is larger than the outer diameter of the heat exchange tube, and the adjusting width of the tail section of the adjusting channel is larger than or equal to the outer diameter of the heat exchange tube. The method is used for pasting the refrigerator heat exchange tube on the back plate in the production and manufacturing process of the refrigerator heat exchange tube.

Owner:柳州津晶电器有限公司

Miniature loudspeaker and preparation method of miniature loudspeaker

InactiveCN105828261AProvides productivityEase of mass productionElectrical transducersLoudspeakersLoudspeakerSoldering

The invention discloses a micro-speaker and a preparation method of the micro-speaker. Tin-plated steel sheets are embedded in the PCB of the bracket to replace the externally pasted PCB. No matter whether tin welding or machine spot welding is used, the welding effect can be improved. And efficiency are more than external PCB. It can effectively improve the welding performance of the product, which is beneficial to the mass production of the product and improves the production efficiency.

Owner:DONGGUAN HUAMING COMM EQUIP

Cable outer mold glue rack

ActiveCN104252923BGuaranteed qualityProvides productivityInsulating conductors/cablesFixed frameEngineering

Owner:GUANGDONG ZHONGDE CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com