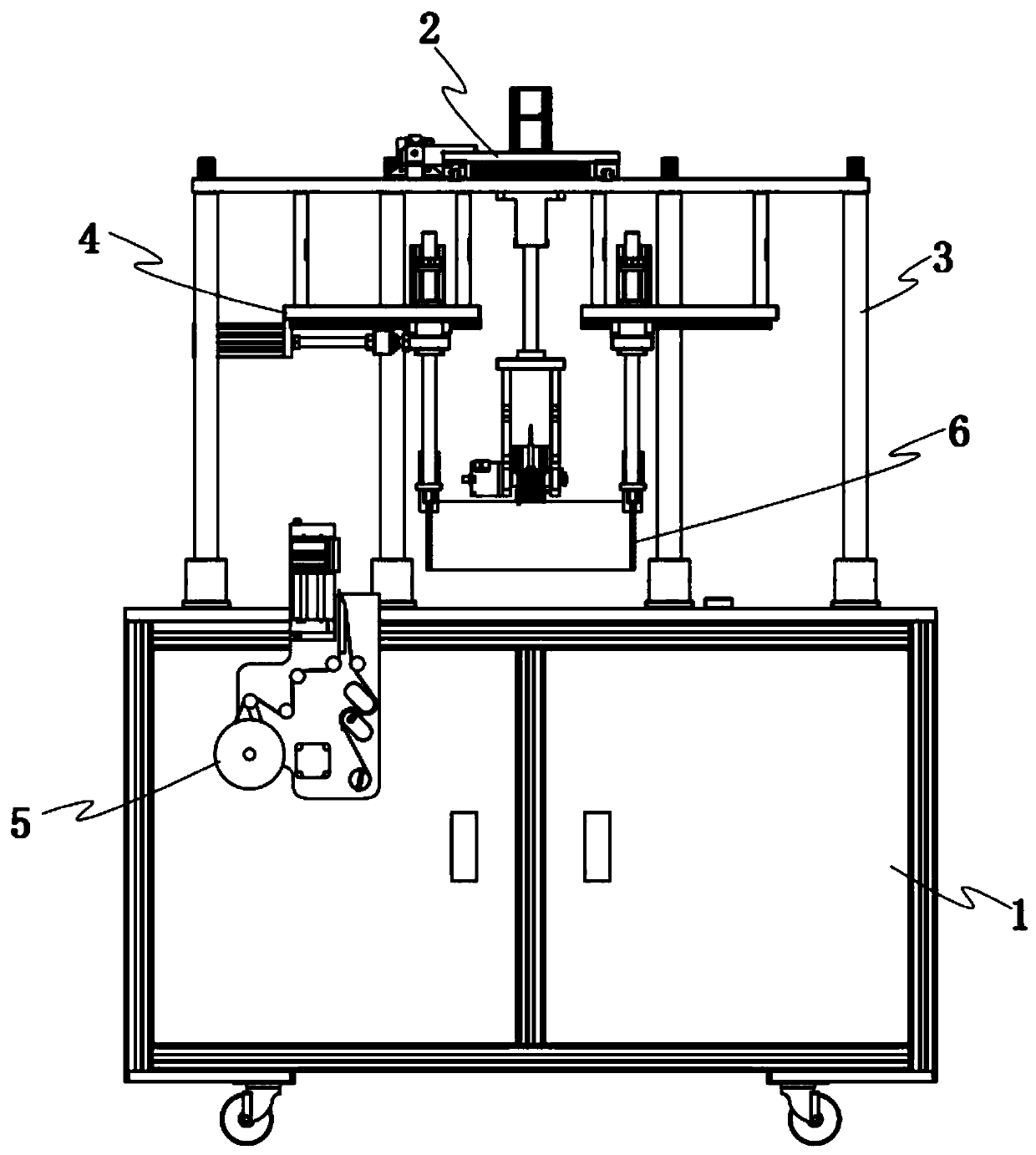

Grinding-drilling-labelling all-in-one machine for large-diameter metal pipe fitting

A metal pipe fitting and large-diameter technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, irregular production, lack of production, etc., and achieve high production efficiency, ingenious and compact structural design, The effect of standardized production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

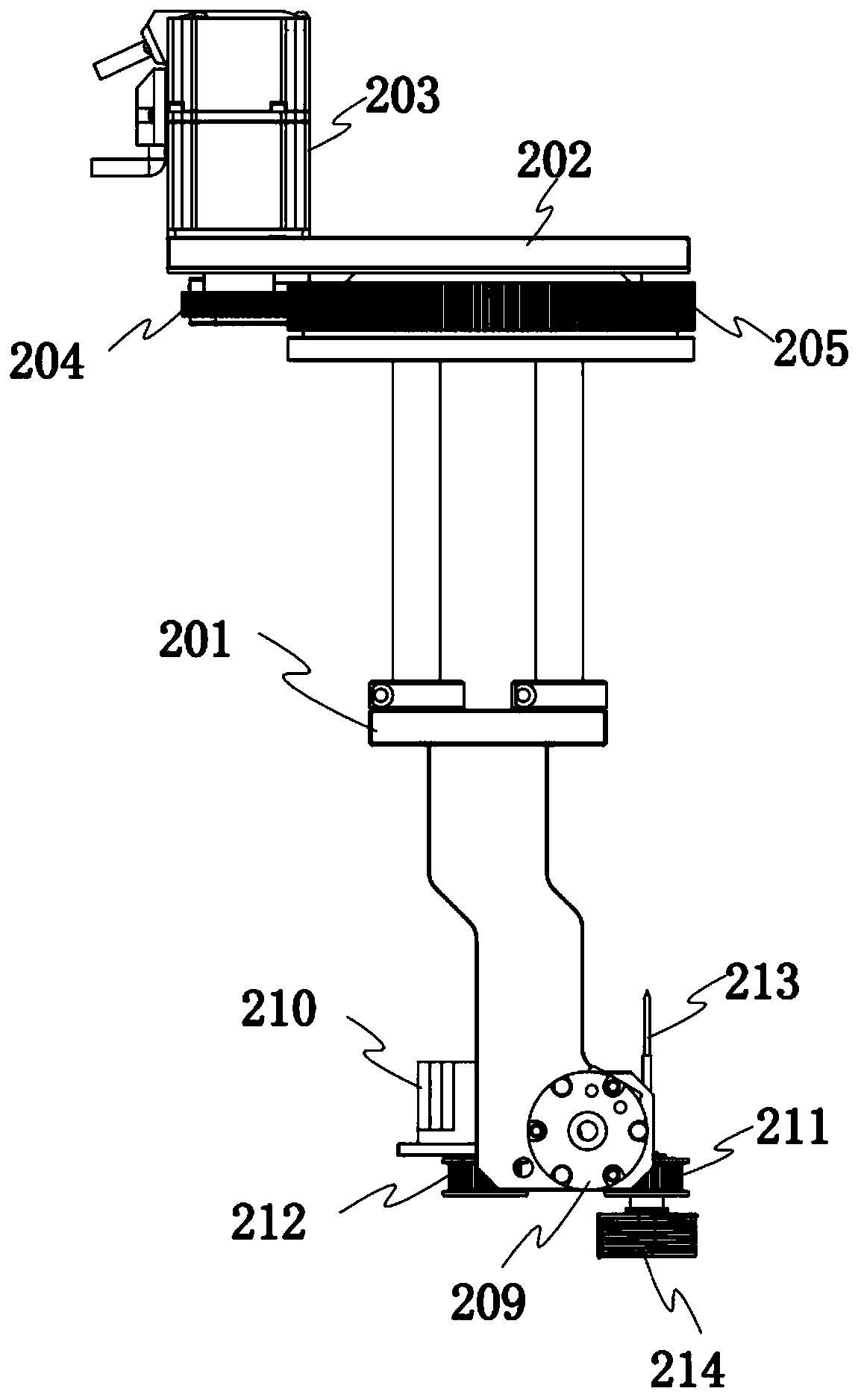

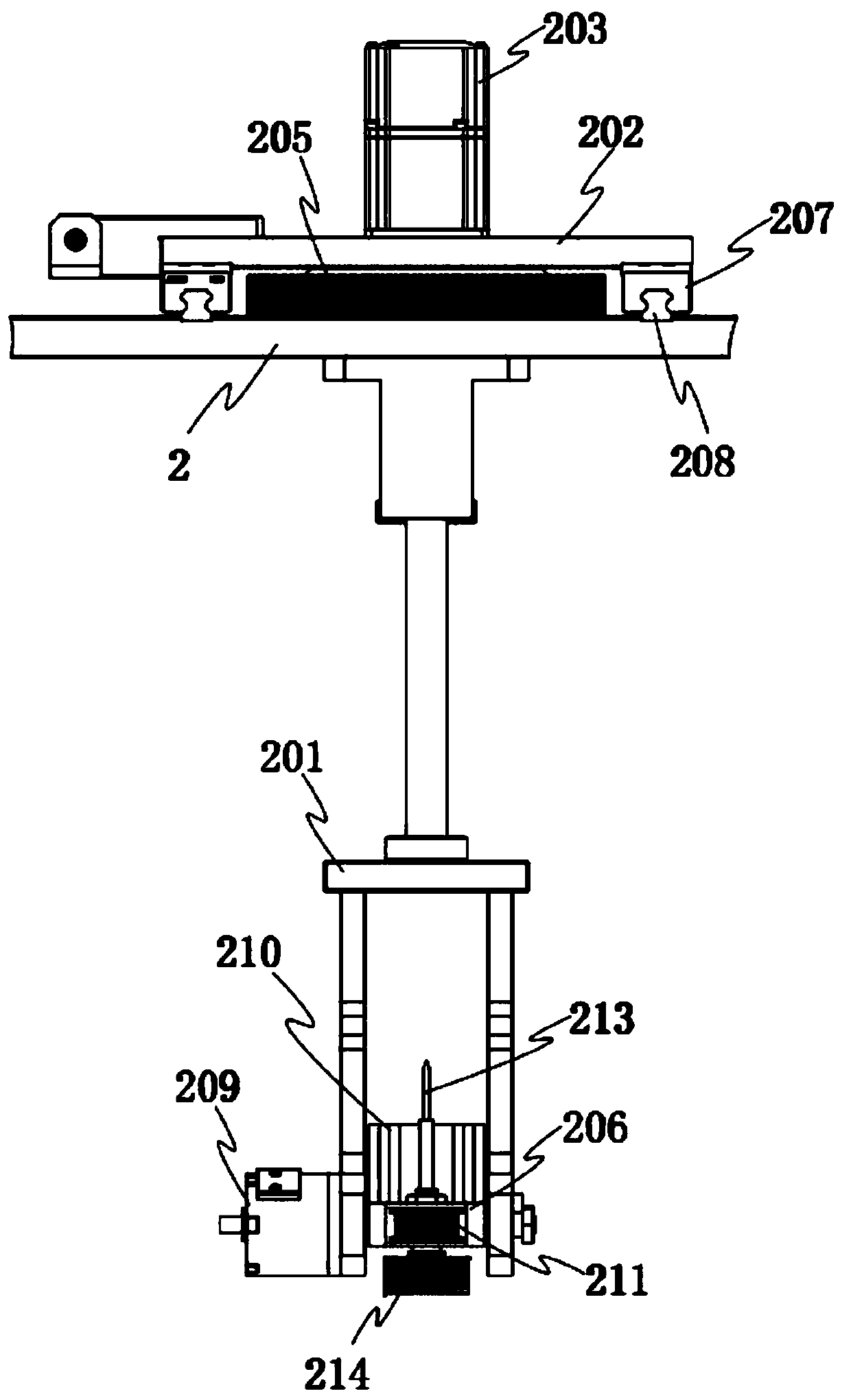

[0026] When the equipment is working, firstly clamp the pipe walls on both sides of the metal pipe 6 with the fixed clamping jaws 408 of the pipe clamping displacement mechanism 4, and the clamping cylinder 407 drives the fixed clamping jaws 408 to clamp the pipe walls on both sides of the metal pipe 6 Fixed, then the grinding and drilling motor 210 of the grinding and drilling mechanism 2 is belt-driven through the driving pulley 212 and the rotating pulley 211, driving the grinding wheel 214 and the drilling tool 213 at the center of the rotating pulley 211 to rotate, and then the pipe clamping displacement mechanism The longitudinal displacement driving cylinder 406 of 4 drives the longitudinal displacement block 403 to slide along the horizontal parallel slide rail 402, and at the same time, the lifting cylinder 404 drives the clamping cylinder 407 to move up and down along the vertical guide rod 405, thereby driving the clamped metal pipe 6 along the horizontal and Move in ...

Embodiment 2

[0028] After the pipe wall of the metal pipe 6 is polished and drilled, the pipe clamping displacement mechanism 4 transfers the metal pipe 6 to the side of the labeling mechanism 5, and at the same time, the labeling drive motor 502 of the labeling mechanism 5 passes through the linkage pulley 510 And belt drive, the collection reel 509 and the drive reel 508 are driven to rotate, the collection reel 509 is wound in the collected watchband, and the drive reel 508 drives the label pulley 503 to rotate and output the labeling tape, and the labeling is along the guide pulley 504 It is guided to the horizontal support block 511, and then the surface and labeling cylinder 506 is driven by the horizontal displacement cylinder 505 to move to the upper part of the horizontal support block 511, and then the surface and labeling cylinder 506 drives the labeling block 507 to move closer to the horizontal support block 511 and Pick up the label on the labeling tape, and then the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com