One-way safety valve provided with decompression component and water heater applying same

A safety valve and water heater technology, applied in safety valves, valve details, balance valves, etc., can solve problems such as affecting production efficiency and cost, dripping water, and cumbersome assembly steps for water heaters, so as to improve production efficiency, reduce production costs, and improve users. The effect of experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

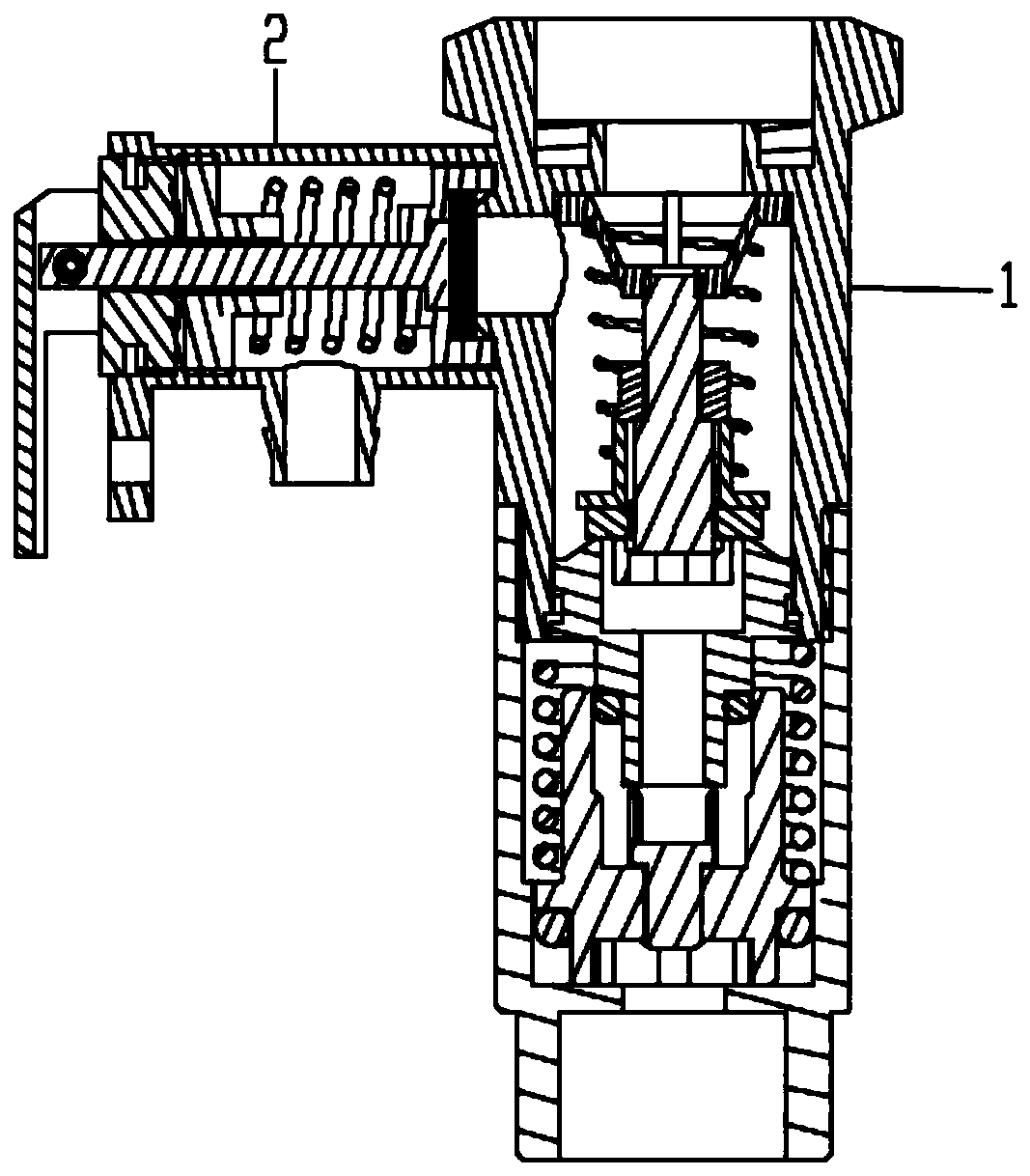

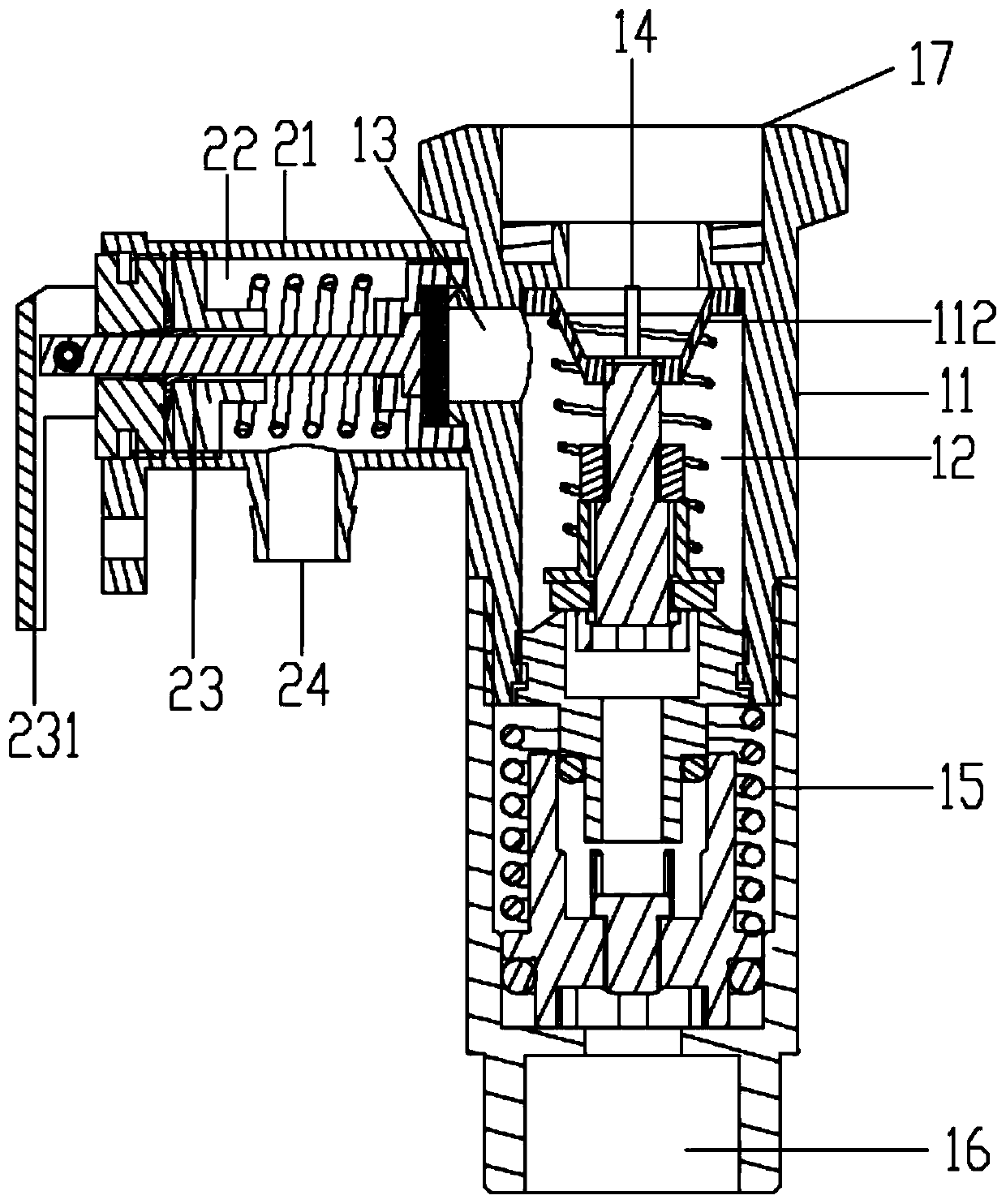

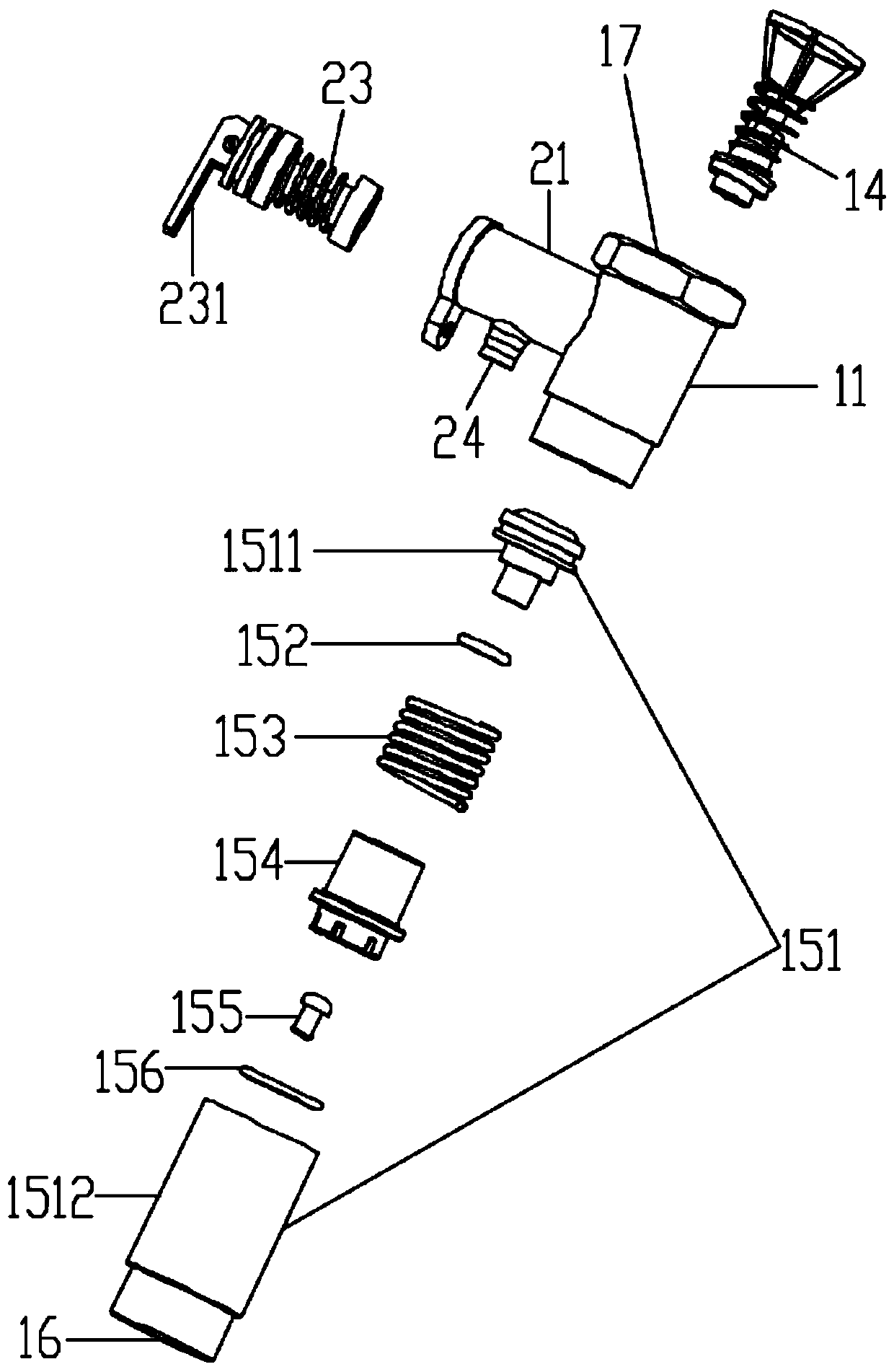

[0029] Embodiment 1 of the present invention provides a one-way safety valve with a decompression assembly, such as figure 1 As shown, it includes a main valve body module 1 with an internal leakage function and a branch valve body module 2 with an external leakage function. The upper side wall of the main valve body module 1 is detachably connected to the branch valve body module 2. The valve body module 1 includes a decompression assembly 15 for decompression.

[0030] In this way, with the above-mentioned structure, the one-way safety valve with a decompression assembly of the present invention includes a main valve body module 1 with an internal leakage function and a branch valve body module 2 with an external leakage function. The upper side wall is threadedly connected to the branch valve body module 2, and the main valve body module 1 includes a decompression assembly 15 for decompression, and the decompression assembly 15 is integrally installed in the main valve body...

Embodiment 2

[0049] Embodiment 2 of the present invention provides a water heater, which includes the one-way safety valve with a decompression assembly and a water heater body, and the one-way safety valve with a decompression assembly is installed at the water inlet end of the water heater body.

[0050] Like this, the water heater of the present invention, even when the secondary water supply pressure of the high floor exceeds the predetermined pressure, it can also be decompressed through the one-way safety valve with the decompression assembly in the water heater of the present invention, thereby solving the problem of existing water heaters. The one-way safety valve is easy to drip when the pressure is released. At the same time, the one-way safety valve with the decompression component is installed on the water heater at the same time, and the two functions of safety pressure limitation and decompression can be obtained at the same time, which reduces the assembly cost. Steps, improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com