Suspension

A suspension and leaf spring technology, applied in the field of side-mounted leaf spring type independent suspension, can solve the problems of poor durability, high component cost, and many assembly steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention shown in the drawings are described below.

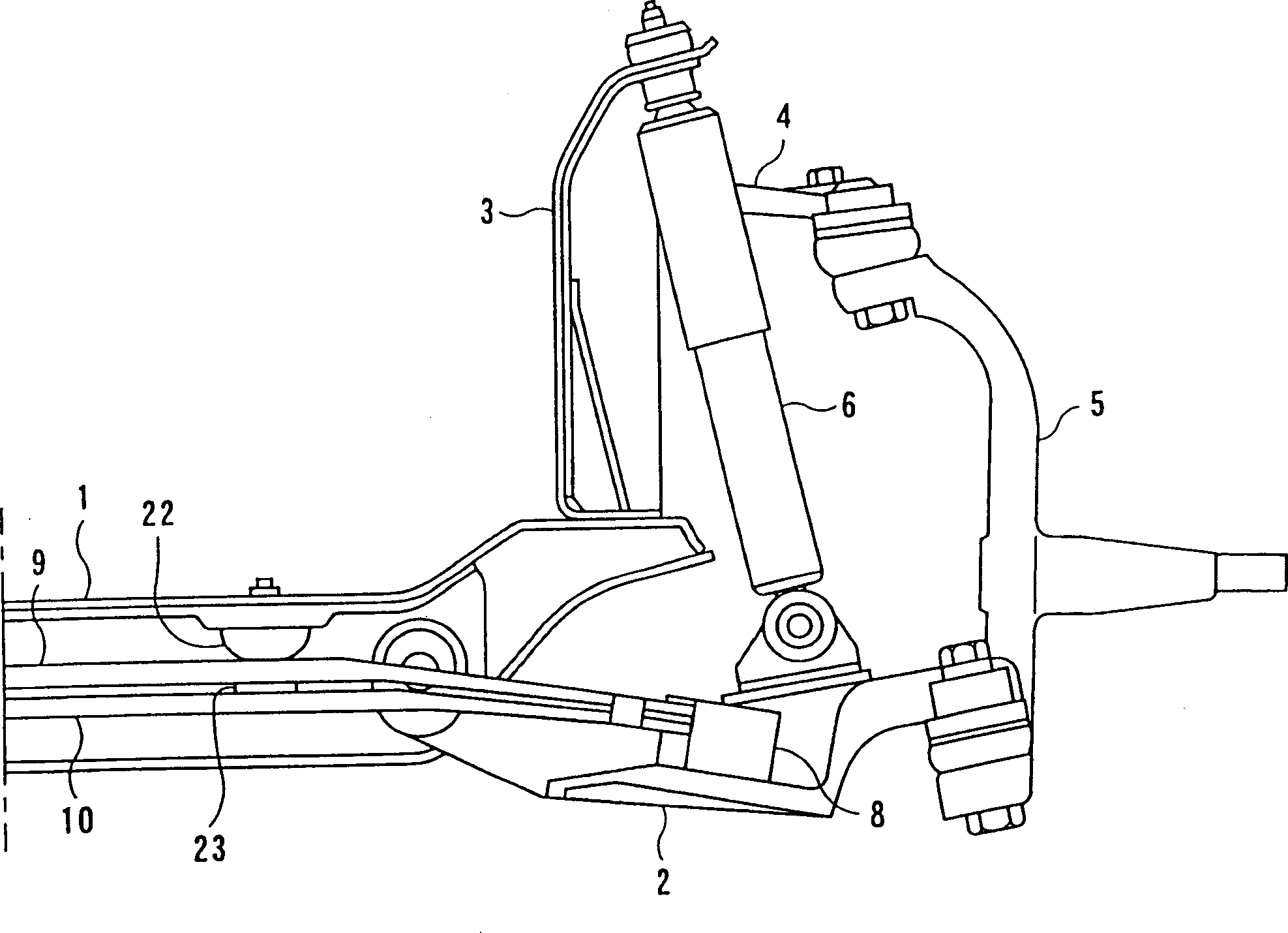

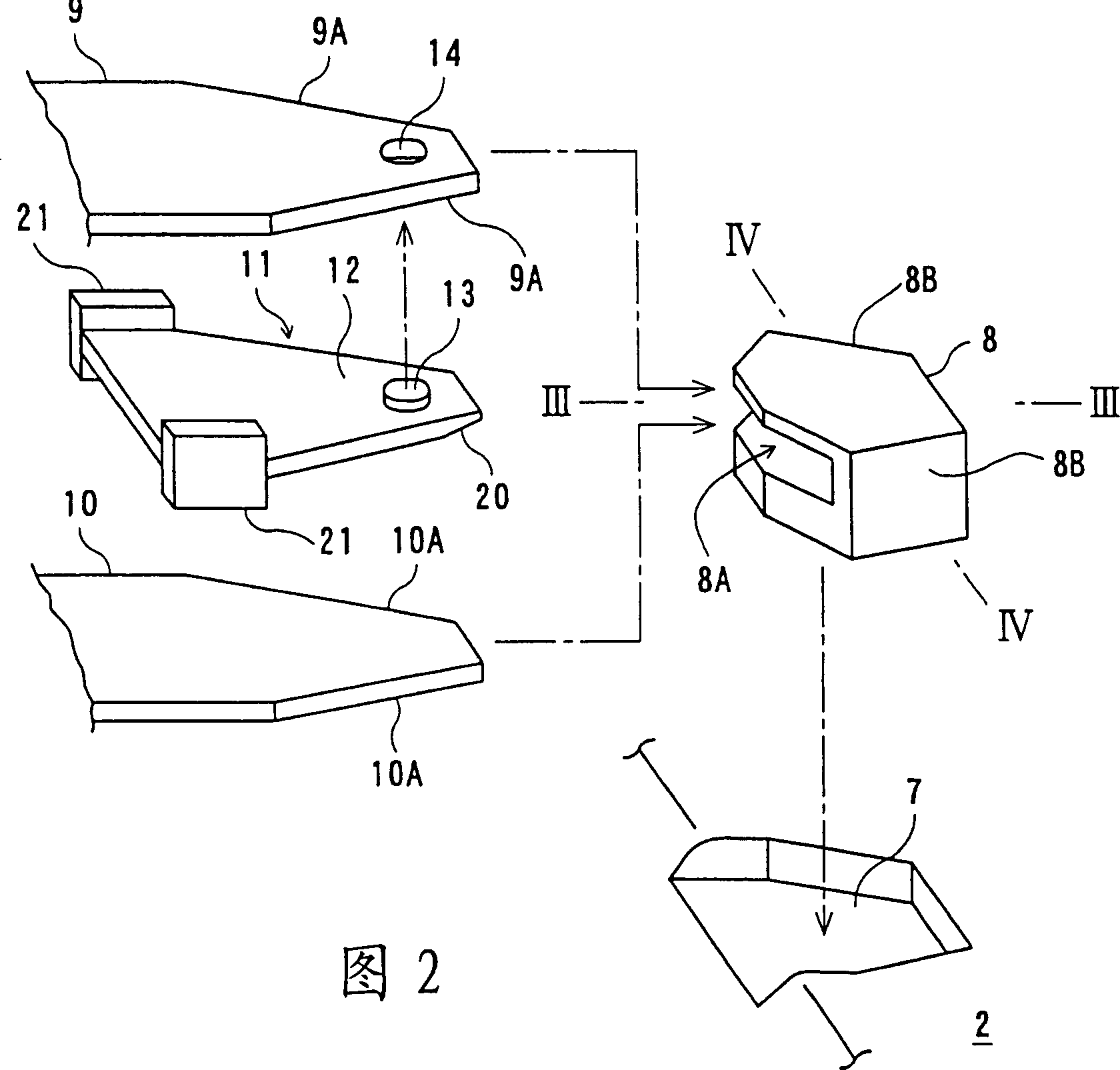

[0024] A cross member 1 extending in the vehicle width direction is connected to a vehicle body (not shown). The left and right ends of the beam 1 are respectively connected to one end of the suspension lower arm 2 and one end of the suspension upper arm 4 through the tower 3 in a pivoting manner. The wheels, not shown, are mounted on a steering knuckle 5 that spans between the two arms 2 and 4 . The shock absorber 6 is connected so as to straddle the suspension lower arm 2 and the tower 3 . According to this embodiment, the wheel support comprises two arms 2 and 4 and a steering knuckle 5 .

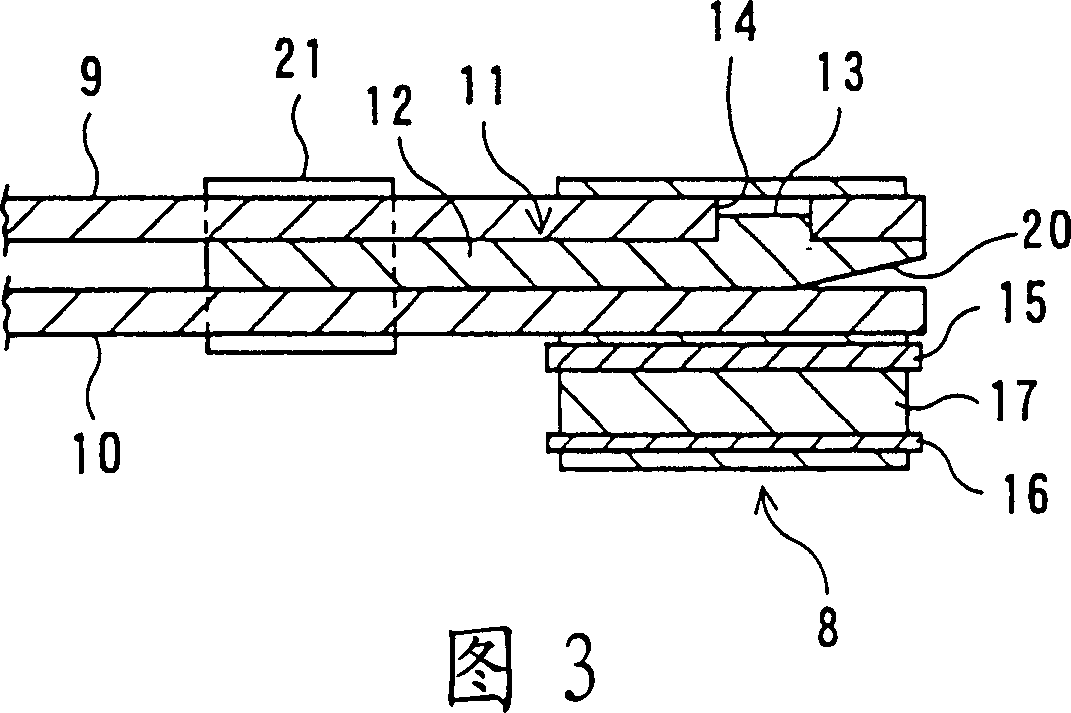

[0025] Further, a receiver 8 is mounted on a substantially trapezoidal groove portion 7 on each of the right and left suspension lower arms 2 . Two leaf springs 9 and 10 made of spring steel are stacked and arranged along the cross member 1 so as to extend in the vehicle width direction. The left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com