Paste preparing method of soybean milk machine

A soymilk maker and mechanism technology, applied in the field of paste making, can solve problems such as burnt paste and overflow, and achieve the effects of solving burnt paste, improving reliability, reducing costs and assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

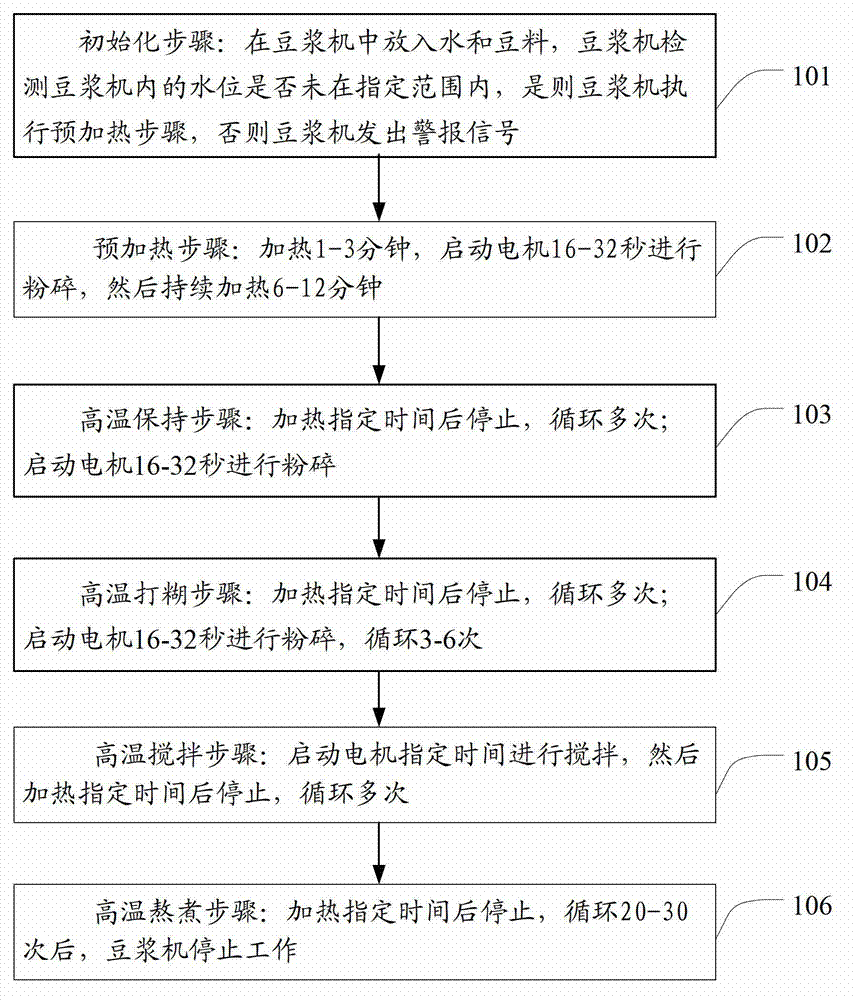

[0027] figure 1 It is the flow chart of a kind of soybean milk machine paste in the present invention; figure 1 shown,

[0028] Step 101, initialization step: put water and soybean material in the soymilk machine, and the soymilk machine detects whether the water level in the soymilk machine is not within the specified range. In step 101, the soymilk maker stops working while sending out an alarm signal;

[0029] Step 102, preheating step: heating for 1-3 minutes, starting the motor for 16-32 seconds to pulverize, and then continuing to heat for 6-12 minutes;

[0030] Step 103, the step of maintaining high temperature: stop after heating for a specified time, and cycle for many times; start the motor for 16-32 seconds to pulverize;

[0031] Step 104, the step of high-temperature beating: stop after heating for a specified time, and cycle for many times; start the motor for 16-32 seconds to pulverize, and cycle 3-6 times;

[0032] Step 105, the high temperature stirring ste...

Embodiment 2

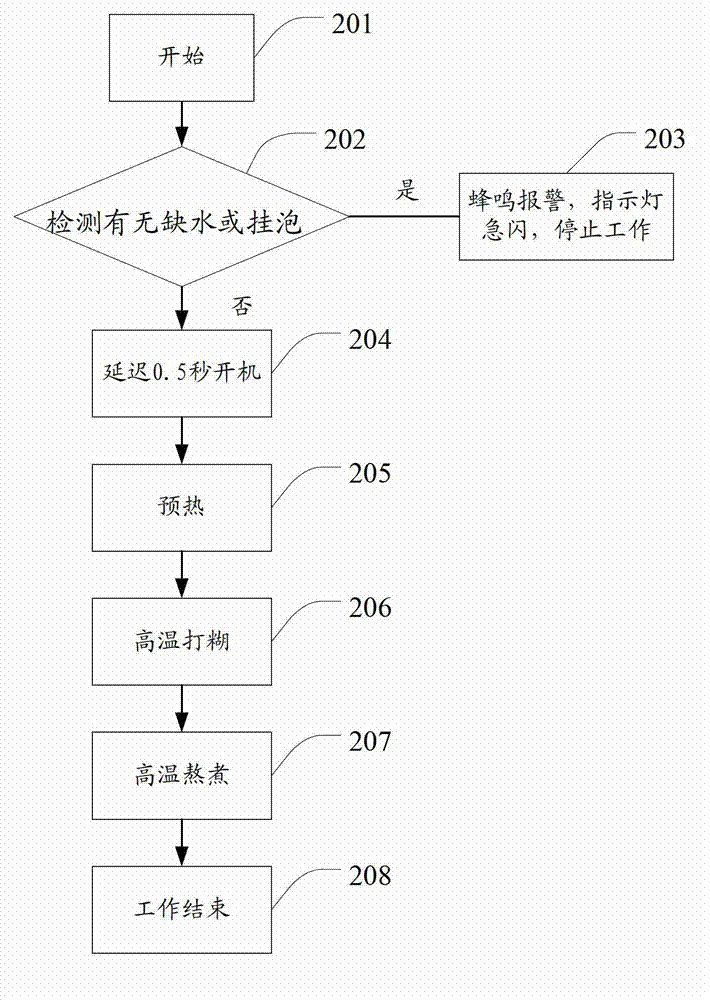

[0036] This embodiment is the same as the first embodiment except for the following features

[0037] In this embodiment, before the soymilk machine performs the paste making work, in order to prevent the soymilk machine from being damaged by soaking or dry burning, the water level in the soymilk machine needs to be detected in advance. That is, in the initialization step, the soymilk maker detects whether the water level in the soymilk maker is not within the specified range. Specifically:

[0038] The anti-overflow probe of the soymilk machine detects whether the water level in the soymilk machine is higher than the maximum water level line and touches the anti-overflow electrode. Anti-dry probe;

[0039] Among them, when the anti-overflow probe detects that the water level in the soymilk machine is higher than the highest water level line and touches the anti-overflow electrode, or when the anti-dry-burning probe of the soymilk machine detects that the water level in the ...

Embodiment 3

[0044] This embodiment is the same as the second embodiment except for the following features

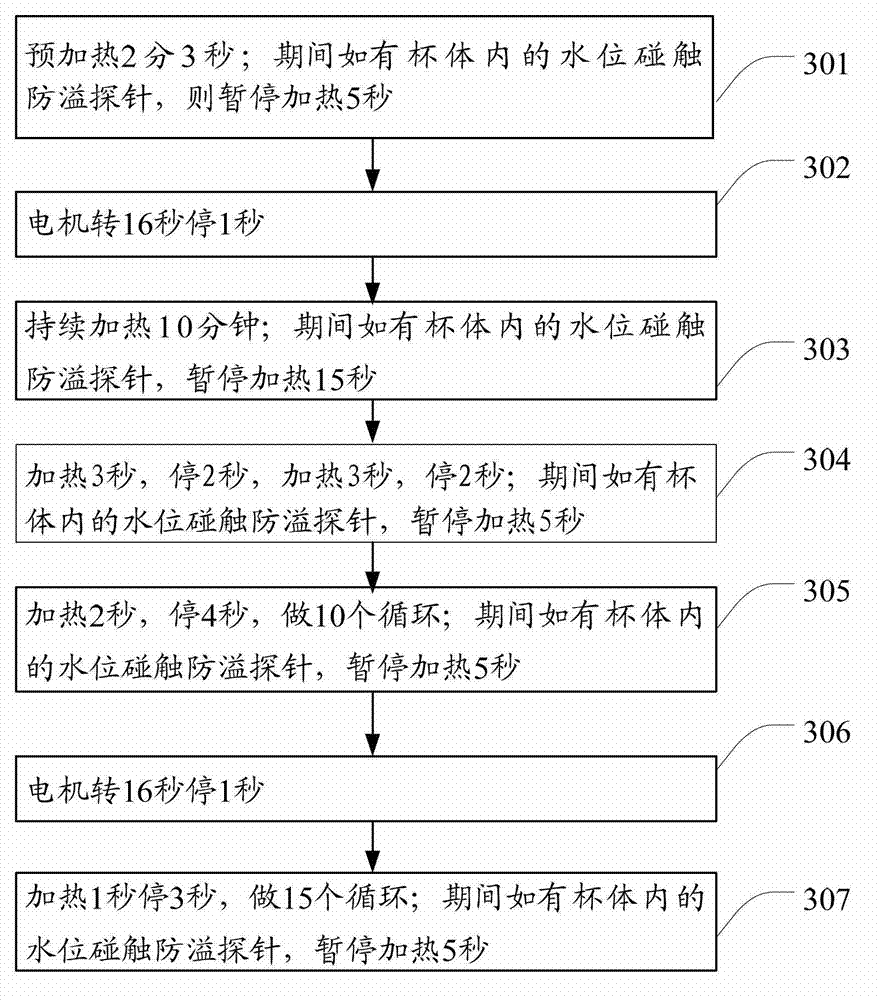

[0045] In this embodiment, after the initialization step is completed, the preheating step is entered.

[0046] In the preheating step, heating is performed for 1-3 minutes, the motor is started for 16-32 seconds to pulverize, and then the heating is continued for 6-12 minutes.

[0047] Specifically, the soymilk machine is heated for 2 minutes and 3 seconds, and then the motor is started to pulverize. The pulverization time is 16 seconds. After the pulverization is completed, it stops for 1 second. Heating was performed again, and the heating time was 10 minutes. That is, the first crushing operation is completed.

[0048]Since the liquid will expand and contract during heating, in order to prevent the water level in the cup from boiling or overflowing due to excessive heating. During the entire paste making process, the anti-spill probe will detect whether the water level in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com