Cable outer mold glue injection frame

A cable and glue filling technology, which is applied in the direction of insulating conductors/cables, can solve the problems of low production efficiency, long time consumption, deviation of the outer mold position, etc., and achieve the effect of ensuring quality and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in detail below with reference to the drawings and specific embodiments.

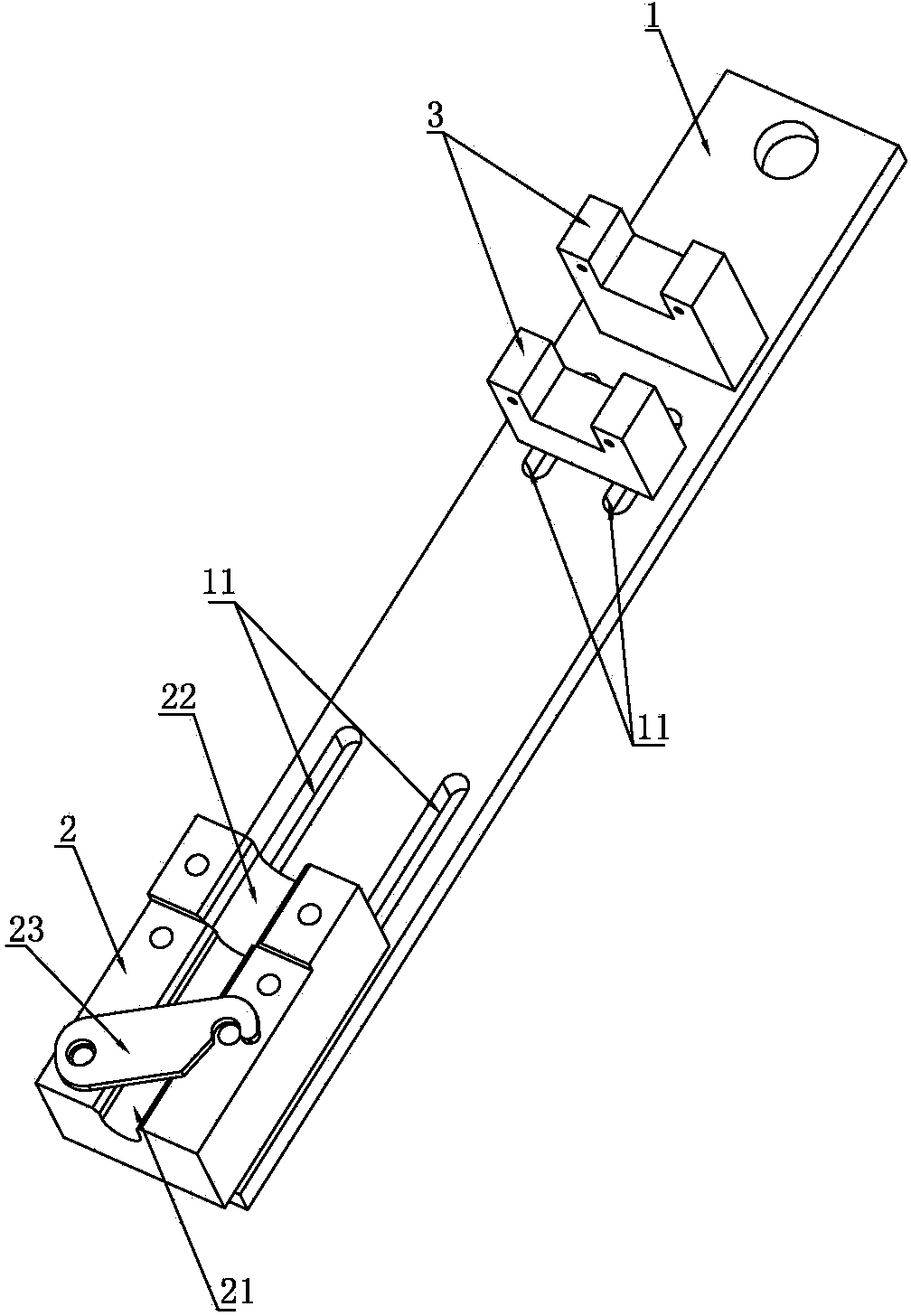

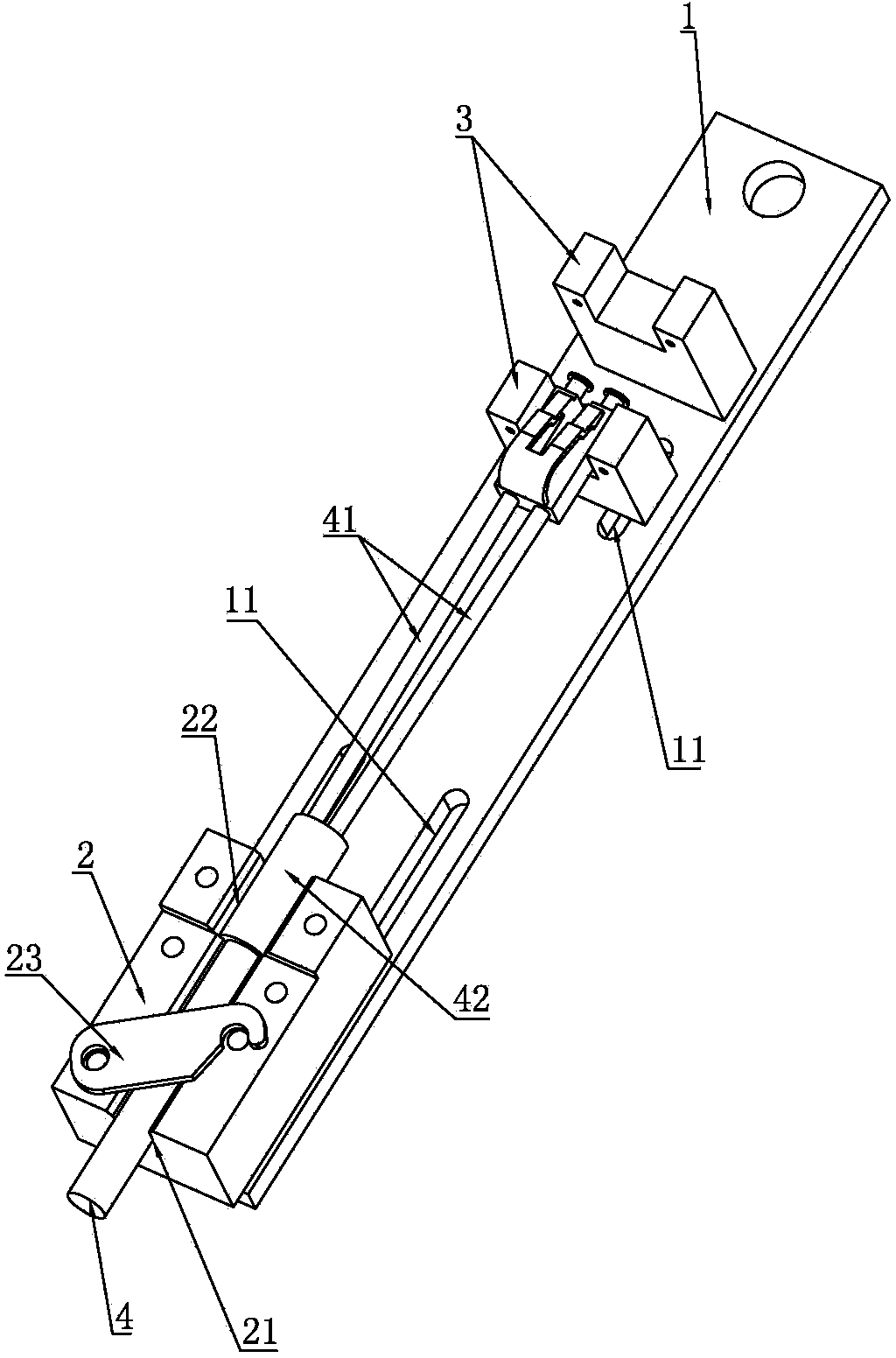

[0016] Such as figure 1 As shown, the cable outer mold potting frame of this embodiment includes a bottom plate 1, an outer mold fixing frame 2, and two wire end fixing frames 3. The outer mold fixing frame 2 and the two wire end fixing frames 3 are connected side by side to The bottom plate 1 and the outer mold fixing frame 2 are provided with a wire groove 21 for positioning the cable 4, an outer mold groove 22 for positioning the outer mold 42 and an outer mold groove 22 for fastening the cable positioned by the wire groove 21 4 of the fastener 23, the wire groove 21 and the outer mold groove 22 are opened in the left and right direction, the left end of the outer mold groove 22 is connected with the right end of the wire groove 21, such as figure 2 As shown, before using the cable outer mold potting rack of this embodiment to pot the outer mold 42 of the cable 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com