Processing production line for improving macadimia nut quality

A production line and quality technology, applied in food processing, packaged food, packaged item types, etc., can solve problems such as waste of labor, mixed, and different tastes, and achieve the goal of improving dust removal effect, improving production efficiency, and optimizing production environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

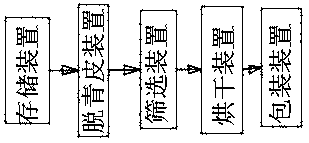

[0054] As shown in the figure, a processing line for improving the quality of macadamia nuts includes a storage device 1, a peeling device 2, a screening device 3, a drying device 4 and a packaging device 5. The storage device 1 and the peeling device 2 are lifted Machine connection, the discharge port of the green peeling device 2 is connected with the screening device 3 through a slideway, and the screening device 3 is connected with the drying device 4 through a conveyor belt; the drying device 4 is connected with the packaging device through a conveyor belt;

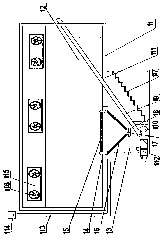

[0055] The upper part of the storage bin 11 of the storage device 1 is provided with a ventilation window 115; the ventilation window 115 is provided with two ventilation fans 116, the interior of the storage bin 11 is provided with a chamber 12, and the bottom of the chamber 12 is provided with The lower silo 13 is provided with a sealing cover 111 at the junction of the lower hopper 13 and the chamber 12, and the lo...

Embodiment 2

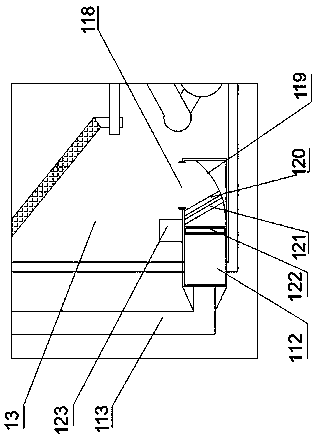

[0061] On the basis of the above embodiments, in this embodiment, the bottom of the lower bin 13 is provided with a dust collector 112, the dust collector 112 is arranged laterally at the bottom of the lower bin 13, and the bottom of the dust collector 112 is provided with a deflector 119, The deflector 119 is set in an arc shape, and the deflector 119 is set under the dust suction port 118. The top of the dust collector 112 is provided with a dust suction port 118, and the dust collector 112 is provided with a dust removal fan 122, and the dust removal fan 122 is connected to the dust collector. The dust removal motor 123 on the top of 112, the front section of the dust removal fan 122 are respectively provided with a first filter screen 120 and a second filter screen, the rear part of the dust collector 112 is connected with a dust discharge pipe 113, and the top of the dust discharge pipe 113 is provided with an exhaust port 114 for exhaust The port 114 is arranged on the to...

Embodiment 3

[0063] On the basis of the above embodiments, in this embodiment, a waste box 225 can be arranged below the squeeze roller 224; the waste box 225 is arranged at the bottom of the body 21, so that the green skins that can be squeezed off can fall into the waste box ; The chain fixing plate 213 is set in a trapezoidal structure; the two ends of the chain fixing plate 213 are provided with chain adjustment bolts 214; the chain adjustment bolts 214 are connected to the transmission chain 211 through a spring 226 to realize adjusting the height of the chain, controlling the pressure roller and the extrusion roller The distance between different batches of fruits of different sizes is suitable for different batches of fruits; the screen 221 is provided with an inclined structure, and a vibrator 222 is arranged on the screen 221 to improve the screening efficiency; the peeling roller A 27 , peeling roller B 28 , peeling roller C 29 and the peeling roller D 210 are provided with a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com