Temperature reducing device for air cylinder and oil cylinder

A technology for high-temperature equipment and oil cylinders, applied in mechanical equipment, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problems of reducing the service life of the cylinder, increasing the production cost, reducing the production efficiency, and extending the service life. , Save production costs and provide the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

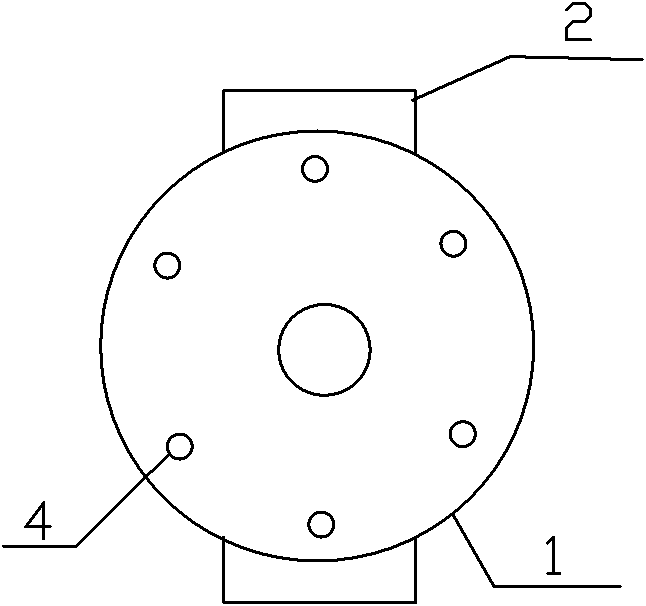

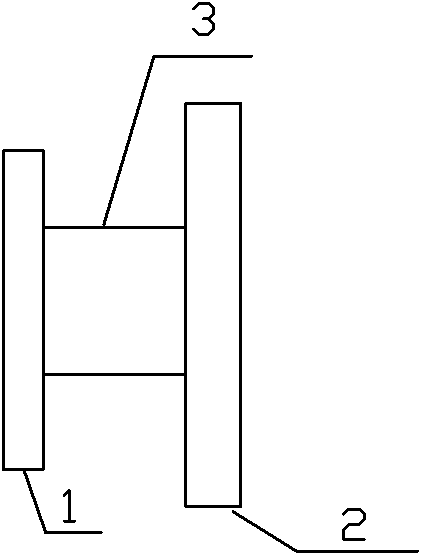

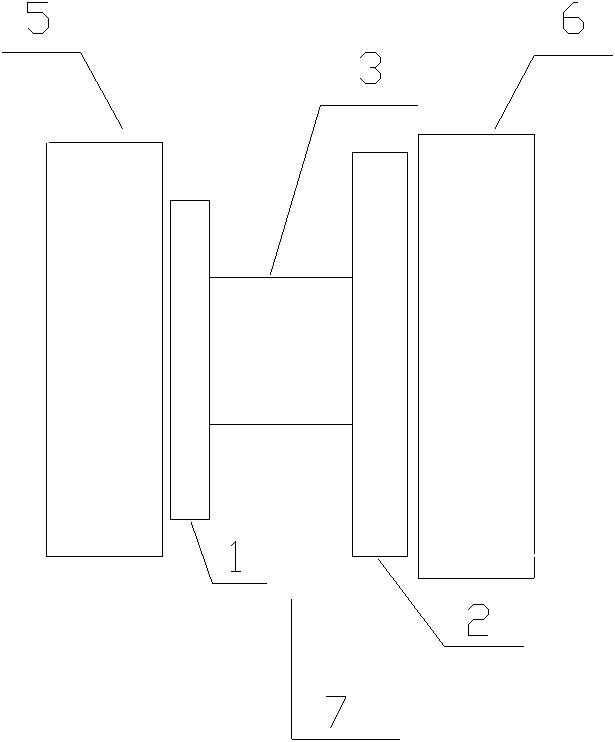

[0014] Such as figure 1 , figure 2 , image 3 As shown, the cooling device is a connection device 7 provided between the cylinder, the oil cylinder 5 and the high-temperature device 6 in contact with it, that is, the mold end. The connection device 7 includes a connection block 1, a base 2 and a connection column 3 , the connecting block 1 and the base 2 are connected through the connecting column 3 . The connecting block 1 is provided with six mounting holes 4 .

[0015] When the present invention is in use, the cooling device, that is, the connecting block 1 of the connecting device 7, is connected to the cylinder or oil cylinder 5, and the base 2 is connected to the high-temperature device 6, that is, the mold end, and the heat of the mold is first transferred to the cooling device, and then to the cylinder Or oil cylinder, the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com