Patents

Literature

103results about How to "Reduce production safety hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing activated carbon by catalyzing and activating microorganism white-rot fungi or enzymes

InactiveCN102745689AReduce production safety hazardsShort manufacturing timeCarbon compoundsNicotiana tabacumBiological activation

The invention relates to a method for preparing activated carbon by catalyzing and activating microorganism white-rot fungi or enzymes, which belongs to the technical field of activated carbon preparation. According to the preparation method, tobacco solid waste is used as a raw material, and a product is obtained through simple processes of pretreating the raw material, preparing a tobacco activated base by microorganism white-rot fungi culture or enzyme catalysis and activation and preparing the activated carbon. The method has the characteristics of wide raw material source, low waste utilization cost, low energy consumption in the production process, no secondary pollution, benefit to environmental protection, good adsorptive property and wide application of the activated carbon production, and the like. The method can be widely applied to preparing the activated carbon by taking the tobacco solid waste as a raw material, and the activated carbon prepared by adopting the method provided by the invention can be widely applied to the fields of waste water treatment, removal of SO2 from smoke, adsorption of odors in food fresh keeping, and the like.

Owner:CHONGQING TECH & BUSINESS UNIV

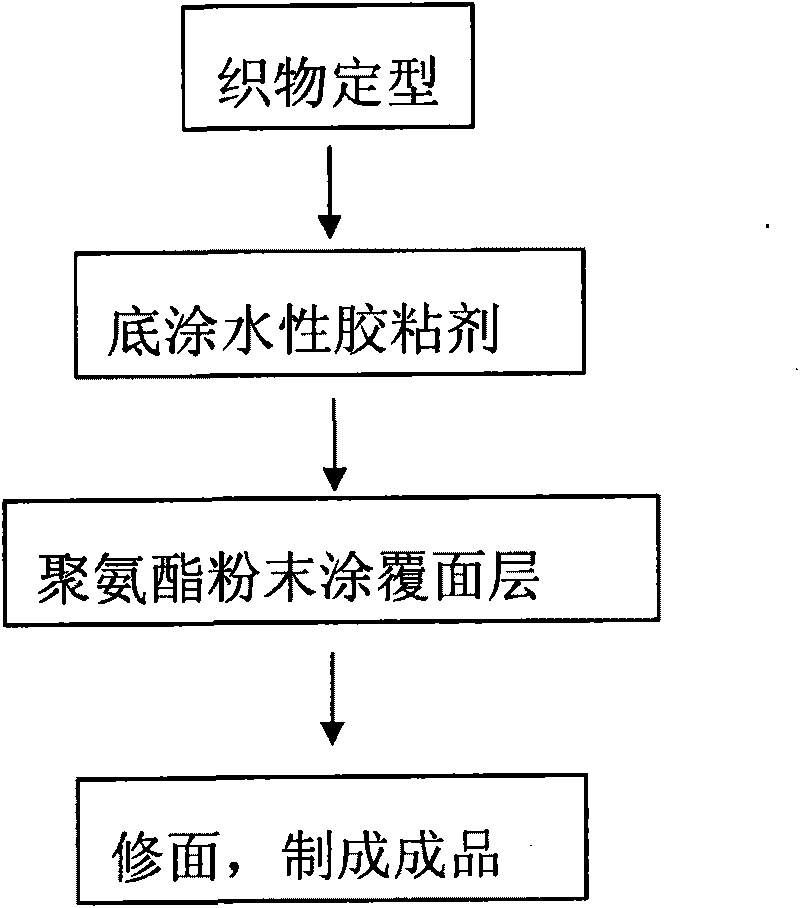

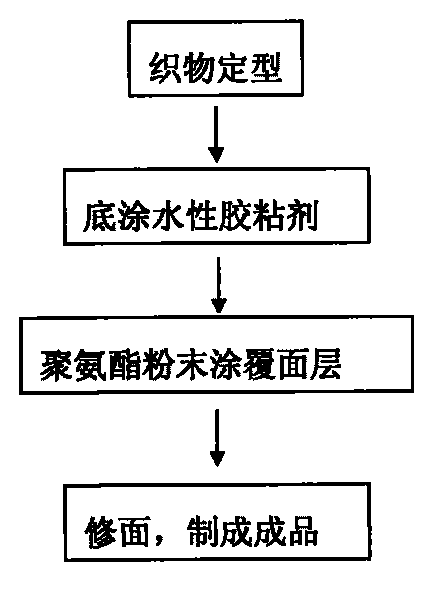

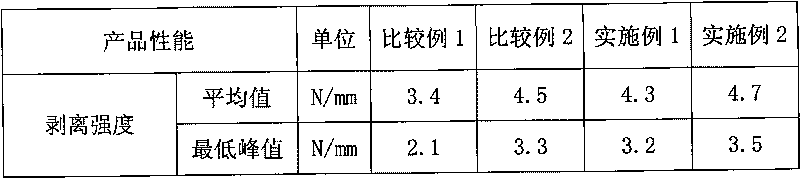

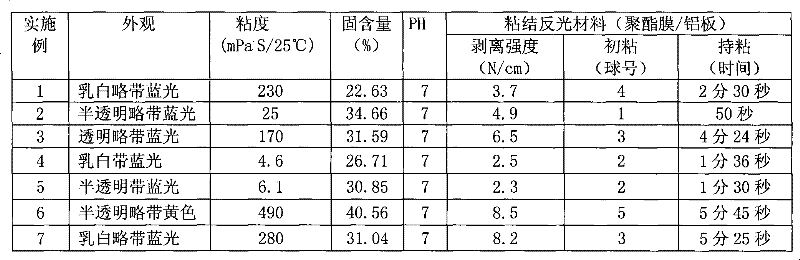

Method for manufacturing environmentally-friendly polyurethane elastomer conveying belt and aqueous adhesive therein

InactiveCN101736596ALittle flex fatigue damageExtended service lifeConveyorsPolyureas/polyurethane adhesivesFatigue damagePolyester

The invention relates to a method for manufacturing an environmentally-friendly polyurethane elastomer conveying belt and an aqueous adhesive therein. The method adopts a coating process, and comprises the following steps: heating and drying a polyester fabric core through a production line oven, and tentering the setting fabric; base-coating the aqueous adhesive to the setting fabric by a coating cutter of a coating machine, and drying the setting fabric in the oven; coating a surface layer by the coating cutter of the coating machine, and heating and melting the fabric in the oven; and feeding the conveying belt coated with the surface layer to the oven again for heating and finishing so as to form a finished product. The aqueous adhesive comprises the following components in part by weight: 100 parts of aqueous polyurethane, 1 to 5 parts of thickening agent, 0 to 2 parts of antifoaming agent and 1 to 10 parts of crosslinking agent, wherein the aqueous polyurethane is synthesized by polyester polyol and polyisocyanate. The method has the advantages that an organic adhesive solvent is replaced by the aqueous adhesive, so the polyurethane conveying belt is safe and sanitary, has no peculiar smell, meets the standard requirement and related regulations of organic volatile substances, and has good peeling strength for polyester fabrics and polyurethane elastomer, small flexure fatigue damage and long service life.

Owner:SHANGHAI YONGLI BELTING

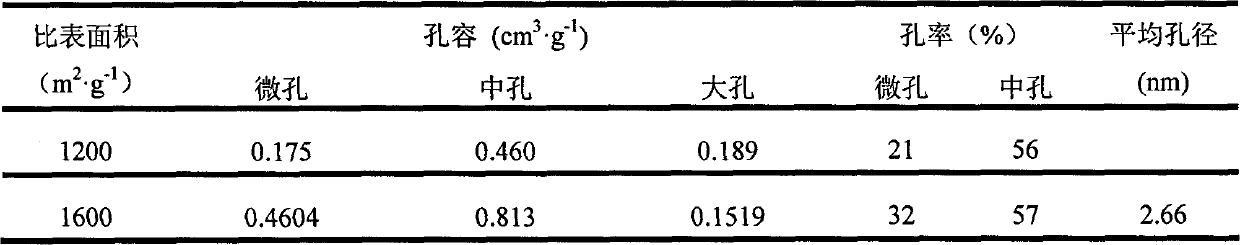

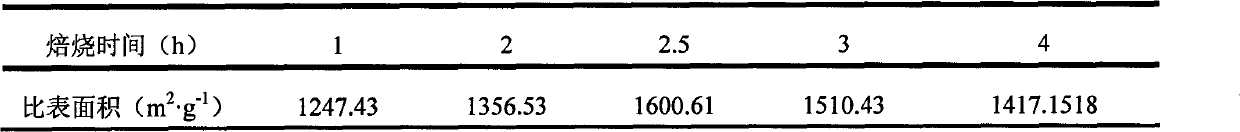

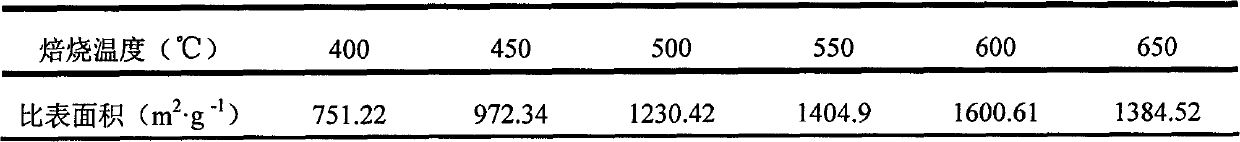

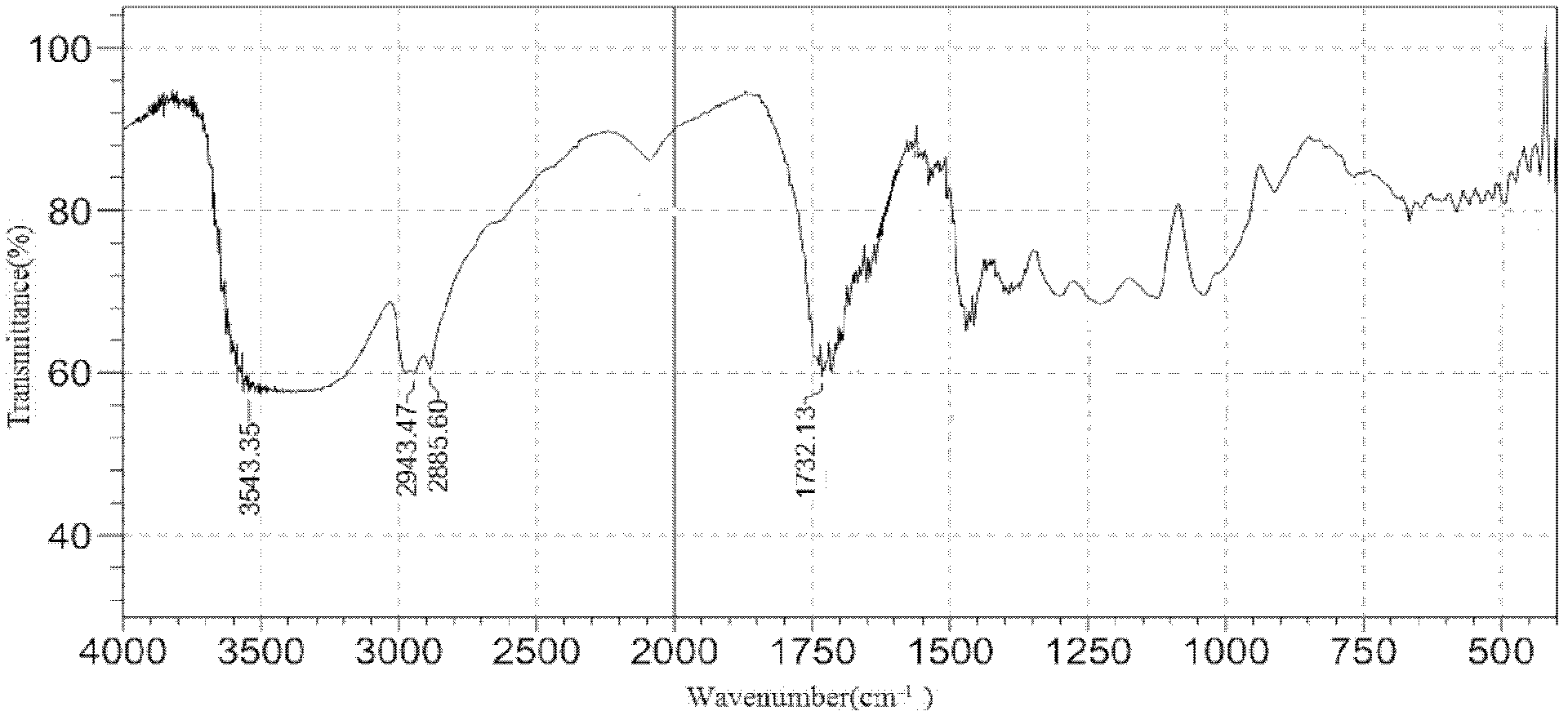

Method for preparing iron-based magnetic activated carbon by catalytic activation of radix puerariae waste residue with compound enzyme

InactiveCN103623776AImprove void structureReduce production safety hazardsOther chemical processesCarbon compoundsActivated carbonPectinase

The invention provides a method for preparing iron-based magnetic activated carbon from by catalytic activation of radix puerariae waste residue with compound enzyme, and belongs to the technical field of activated carbon. The method comprises the steps of by taking the radix puerariae waste residue as the raw material, carrying out raw material pretreatment, preparing a radix puerariae activated substrate through catalytic activation with compound enzymes (cellulase, ligninase and pectinase), and preparing the magnetic activated carbon by doping iron, thereby obtaining the product. The method provided by the invention has the characteristics of wide raw material source, low waste material utilization cost, few production steps and low process energy consumption and no secondary pollution, and is beneficial to environment protection; the activated carbon product are excellent in adsorptive property and the magnetic properties and wide in application, and secondary pollution caused by difficult activated carbon recovery is not generated, etc. The method can be widely applied to preparation of the magnetic activated carbon by using the radix puerariae residue solid wastes as raw materials and doping iron; the activated carbon prepared by the method can be widely applied to the fields of waste water treatment, oil fume desorption and odor adsorption in food preservation and the like.

Owner:CHONGQING TECH & BUSINESS UNIV

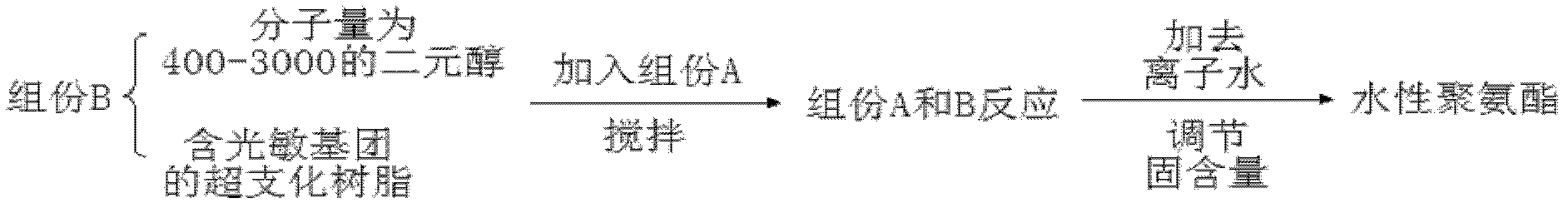

Water-based double-component light-cured polyurethane resin and preparation method thereof

ActiveCN102585158AReduce dosageEasy to preparePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolymer scienceSolid content

The invention discloses a water-based double-component light-cured polyurethane resin, which comprises the following components in part by mass: 10 to 60 parts of hydrophilic polyisocyanate serving as a component A, 5 to 40 parts of diol with the molecular weight of 400 to 3,000 and 10 to 50 parts of water-based hyperbranched resin containing photosensitive groups, wherein the diol and the water-based hyperbranched resin serve as components B. The resin is prepared by the following steps of: mixing the components B and the component A, adding deionized water, reacting completely with stirring, and thus obtaining the water-based double-component light-cured polyurethane resin of which solid content is 20 to 60 weight percent. The resin has a good environment-friendly effect, the preparation method is simple and facilitates industrialization, the ratio of soft and hard chain segments and the density of photosensitive groups of the prepared resin can be adjusted according to different performance requirements, and the resin has a broad application prospect in the fields of coating, adhesive and ink.

Owner:QINGDAO FUSILIN CHEM SCI & TECH

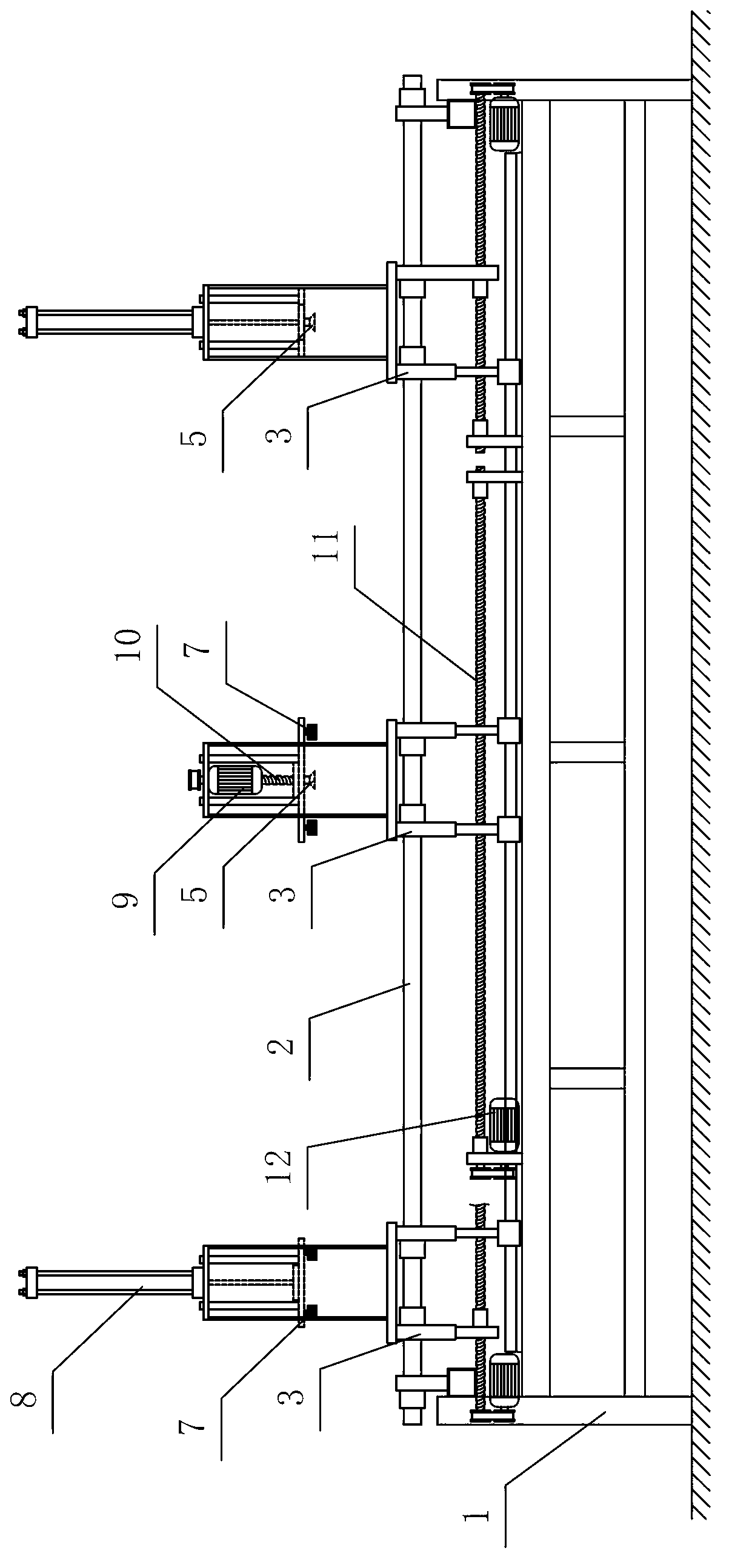

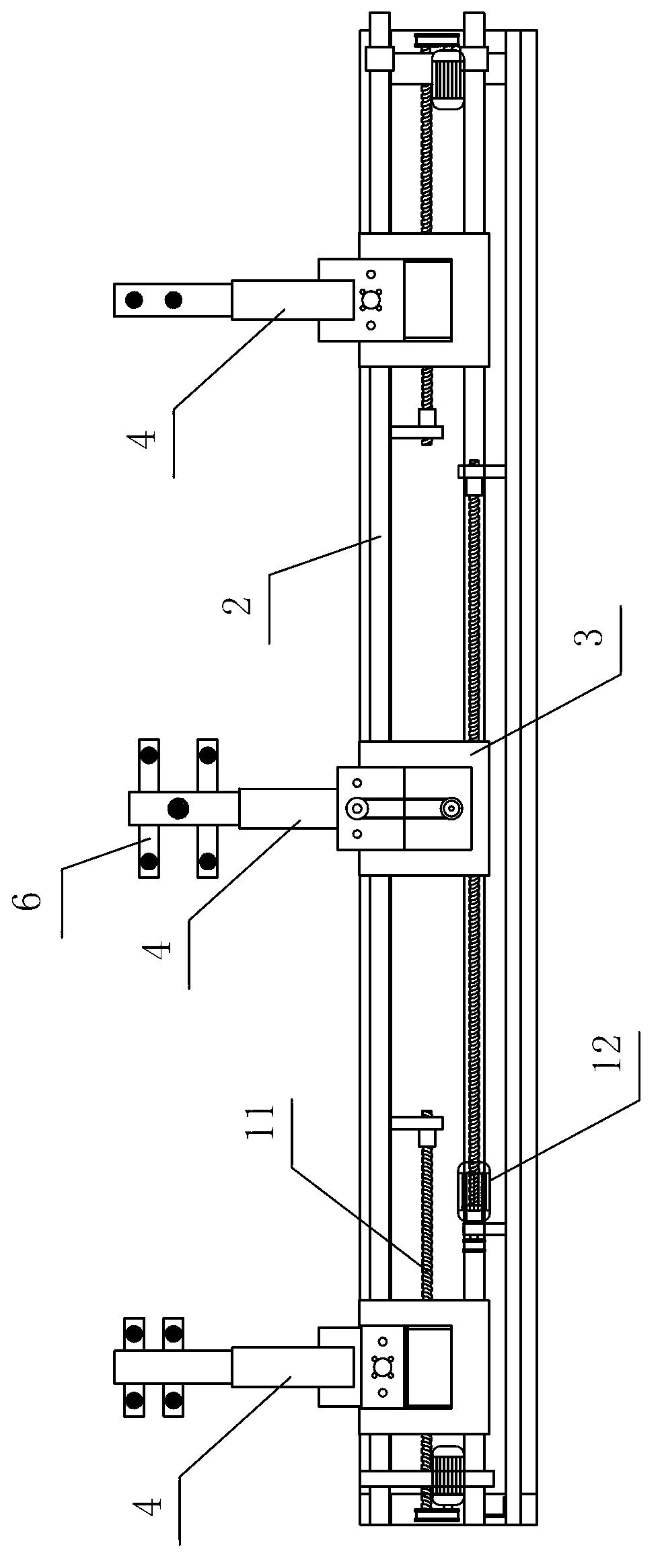

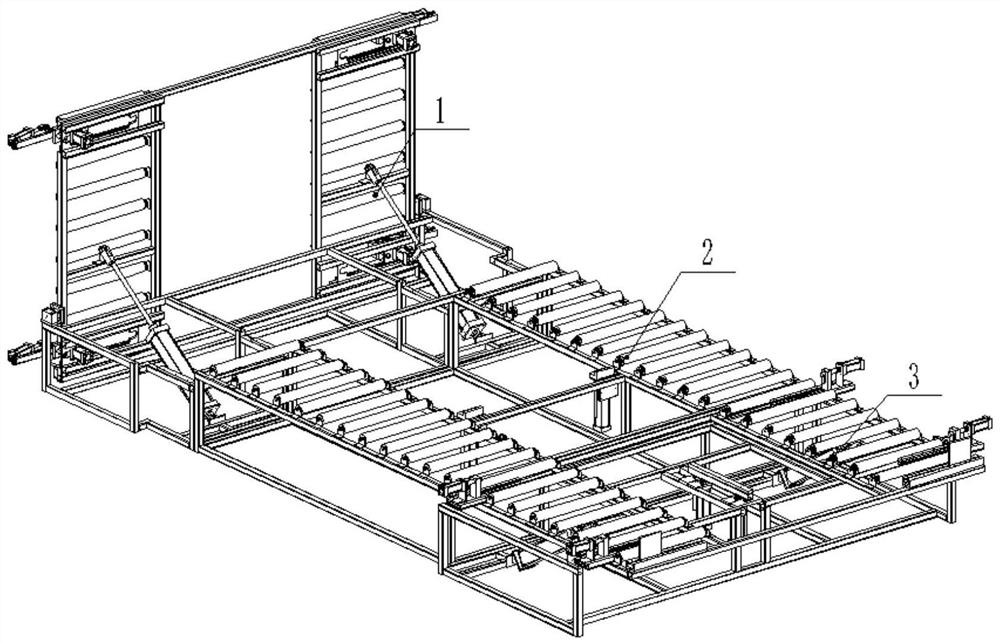

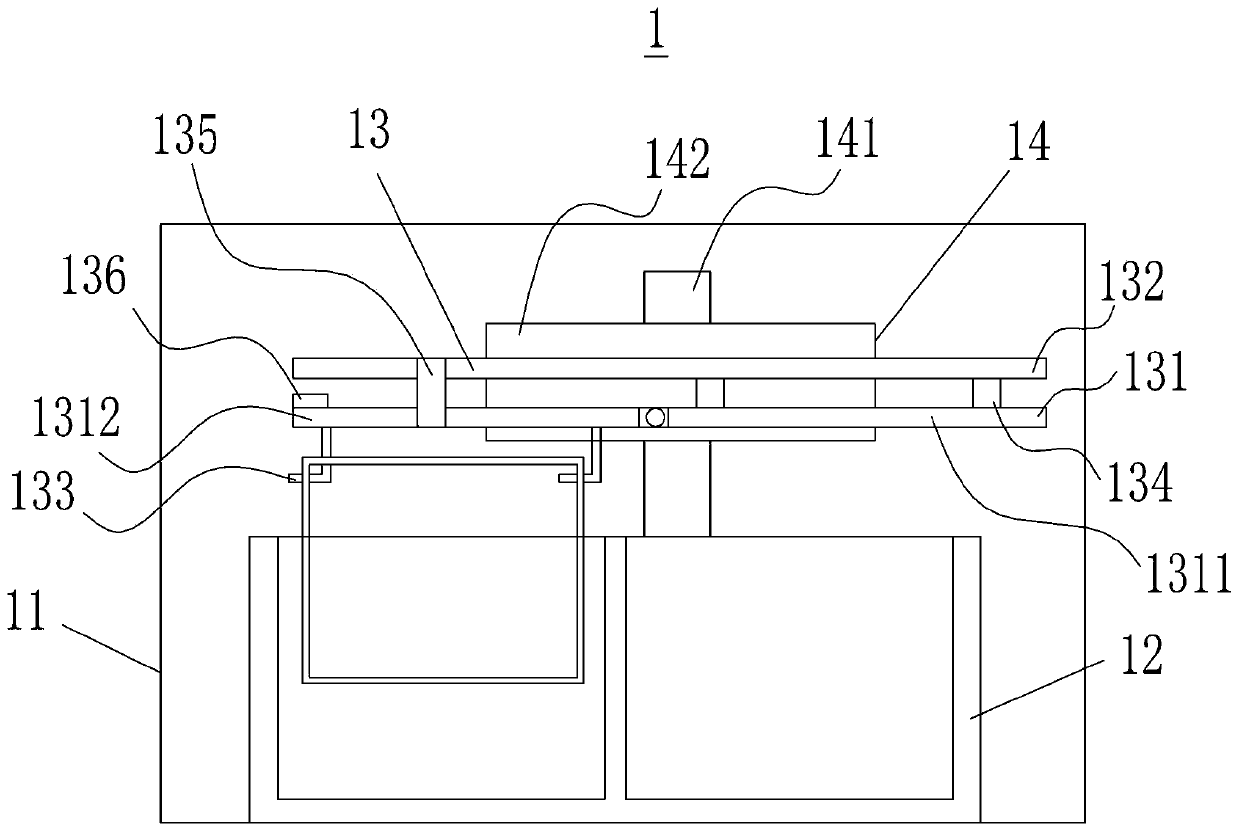

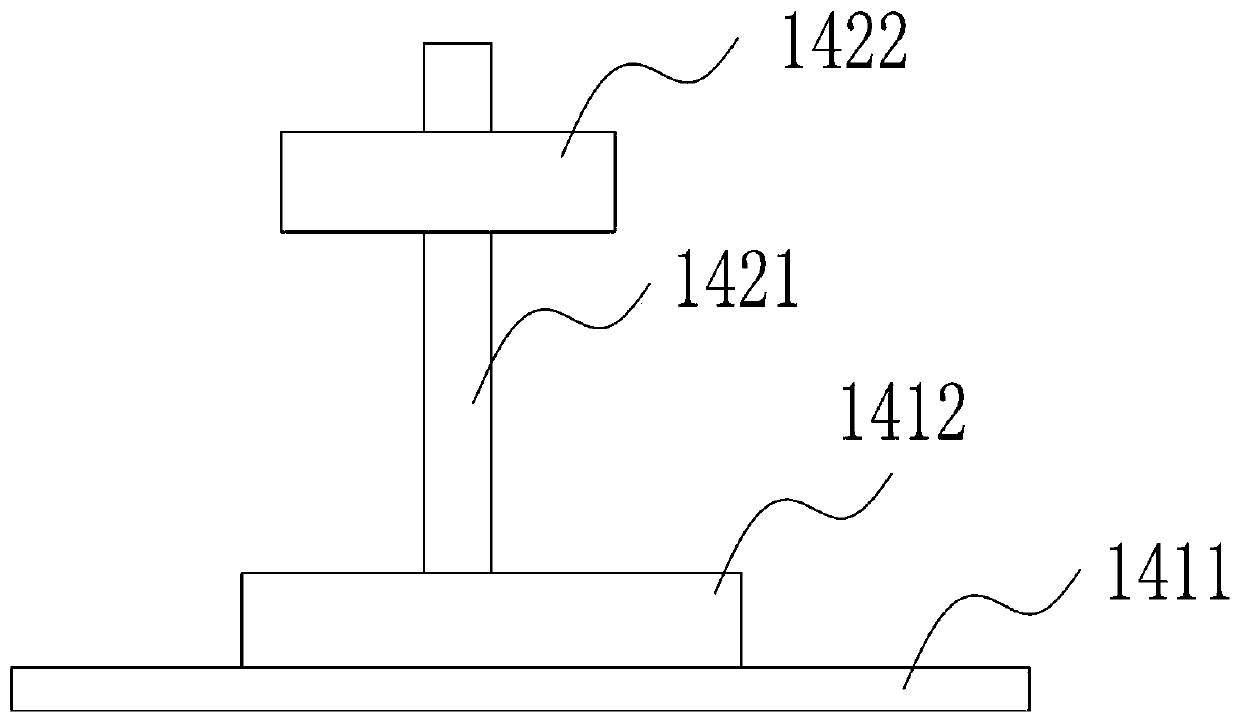

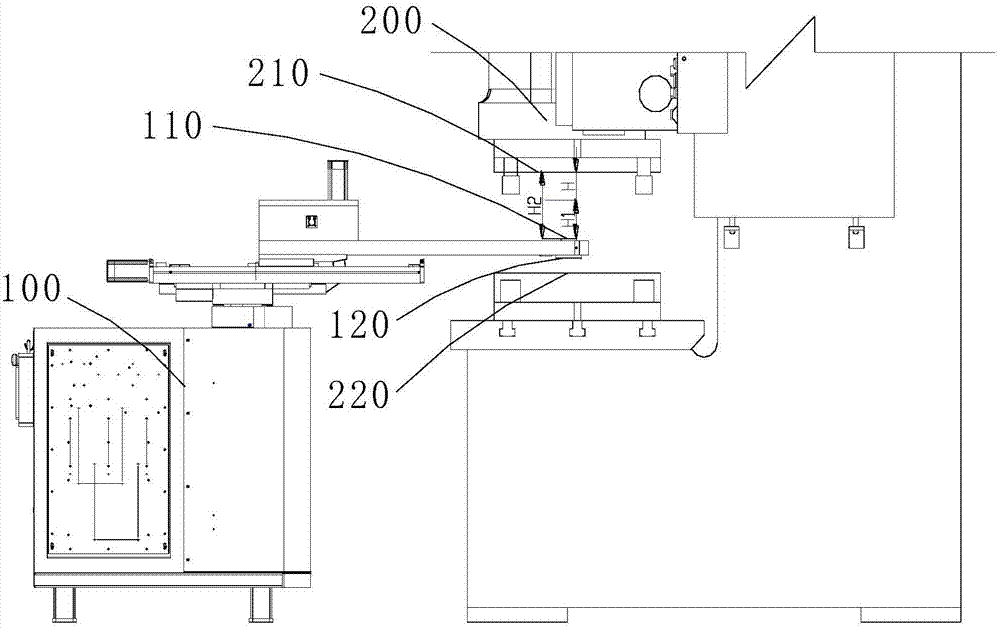

Multi-station automatic feeding device for sheet forming

InactiveCN103302199AReduce labor intensityRealize automatic feedingMetal-working feeding devicesPositioning devicesEngineeringUltimate tensile strength

The invention discloses a multi-station automatic feeding device for sheet forming. The multi-station automatic feeding device comprises a machine frame, wherein a guide rail is fixed to the machine frame; a suction disc mechanical hand capable of reciprocating is mounted in a position corresponding to each forming station on the guide rail; the suction disc mechanical hand comprises a sliding seat mounted on the guide rail in a sliding fit way, a transverse arm transversely extending to the forming station, a suction disc fixed on the lower side at the extension end of the transverse arm and a drive device fixed to the sliding seat and used for driving the transverse arm to lift up and down; each sliding seat is in threaded connection with a transmission screw rod fixed to the machine frame; and each transmission screw rod is in drive connection with a servo motor fixed to the machine frame. Each suction disc mechanical hand can be utilized by each forming station to suck a workpiece from a previous station and convey the workpiece to the next station, so that the mechanical automatic feeding can be achieved, the labor intensity of staff is reduced, the production efficiency is improved, and the potential safety hazard in production is reduced.

Owner:GUANGDONG SUNRISE HOUSEWARE

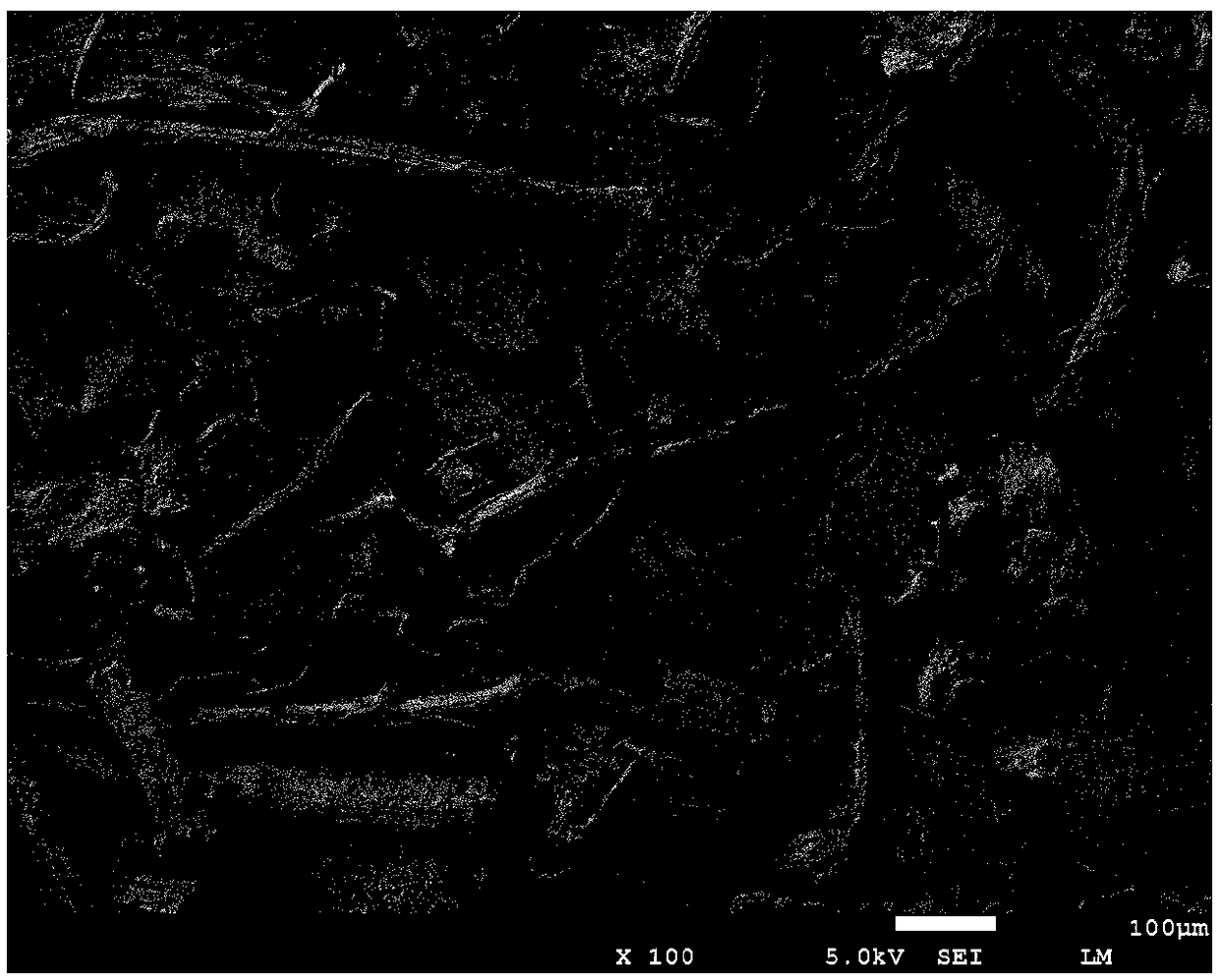

In-situ modified plant long fibers as well as preparation method and application thereof

The invention discloses a preparation method of in-situ modified plant long fibers. The preparation method comprises the following steps: after crushing woody fiber raw materials and washing with water, conveying the woody fiber raw materials and a modifying agent solution into a double-screw extrusion thread rolling machine; collecting the materials and carrying out heat-insulation reaction; after finishing the heat-insulation reaction, carrying out secondary water washing on a product to obtain the in-situ modified plant long fibers. Compared with the prior art, the preparation method can beused for effectively producing the surface modified plant long fibers in batches, and an enhanced wood-plastic composite material is prepared through the plant long fibers, so that the environment pollution in a production process is reduced and potential safety hazards of production are reduced; the compatibility of plant fibers and thermoplastic plastic is improved. The mechanical properties and weather resistance of the wood-plastic composite material are remarkably improved so that the preparation method has positive significance on a whole wood-plastic industry.

Owner:NANJING UNIV OF TECH

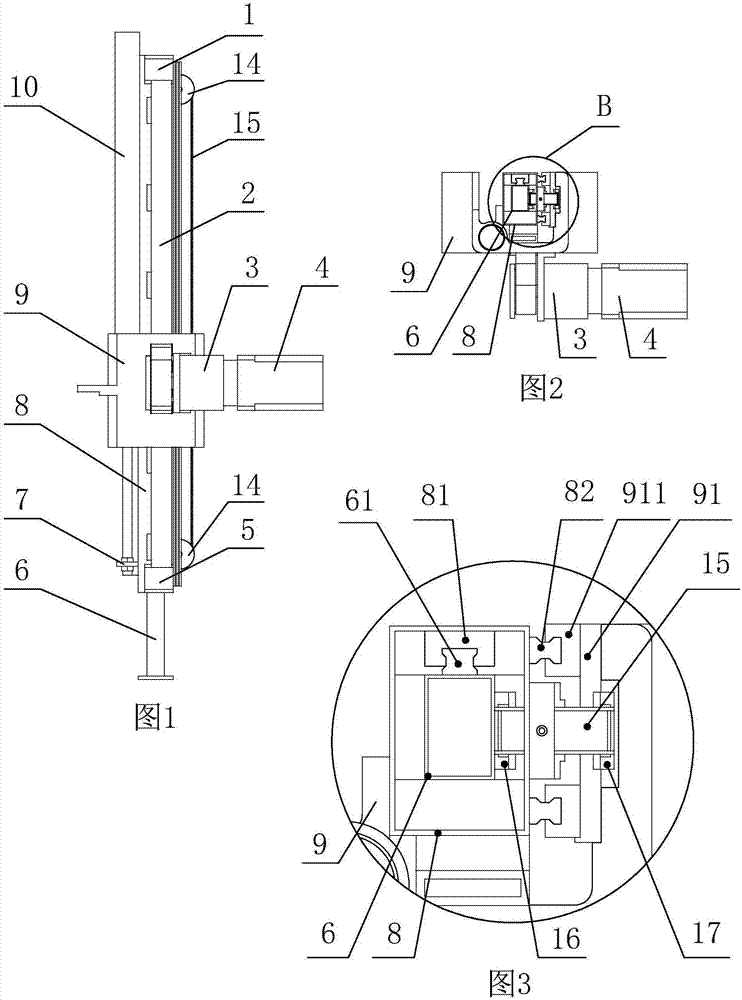

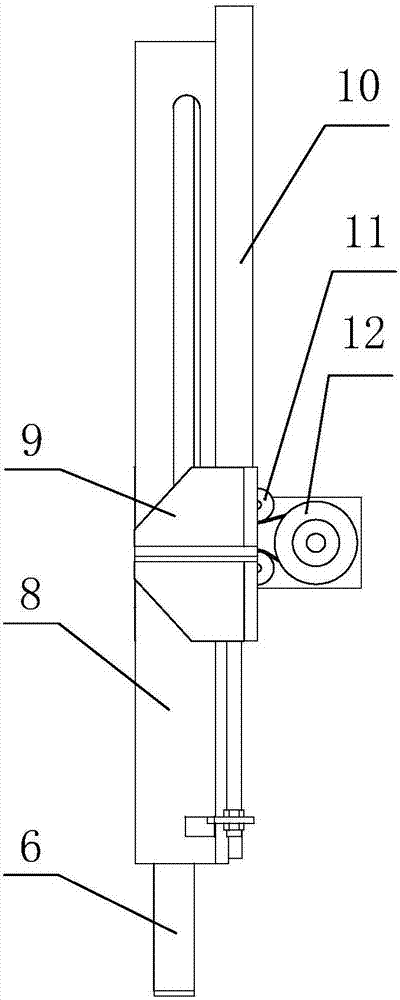

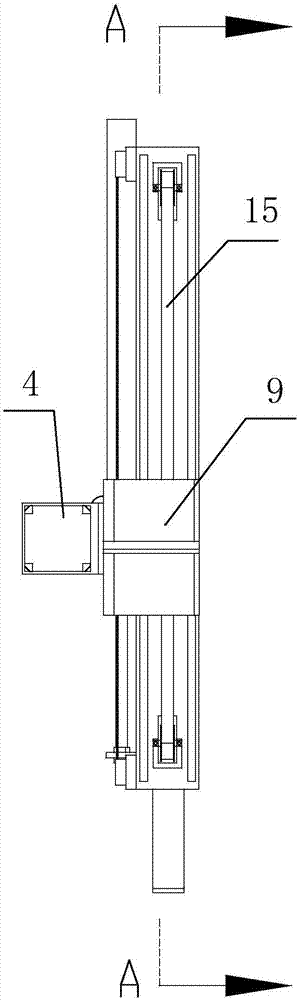

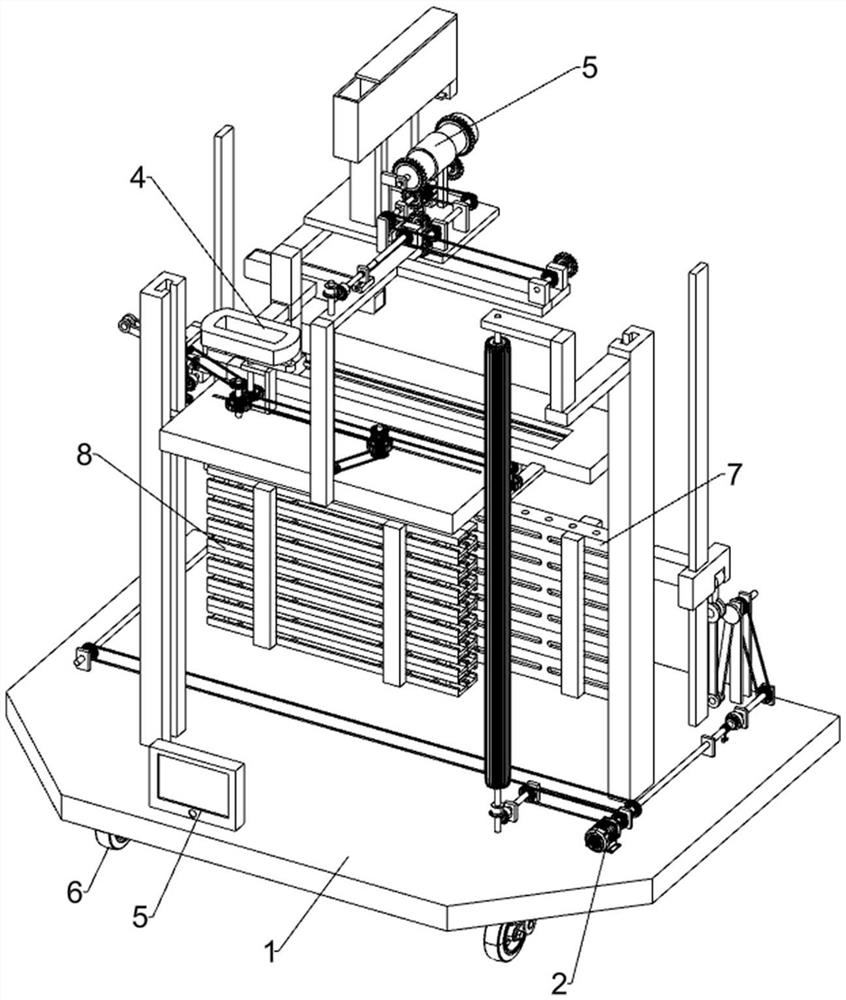

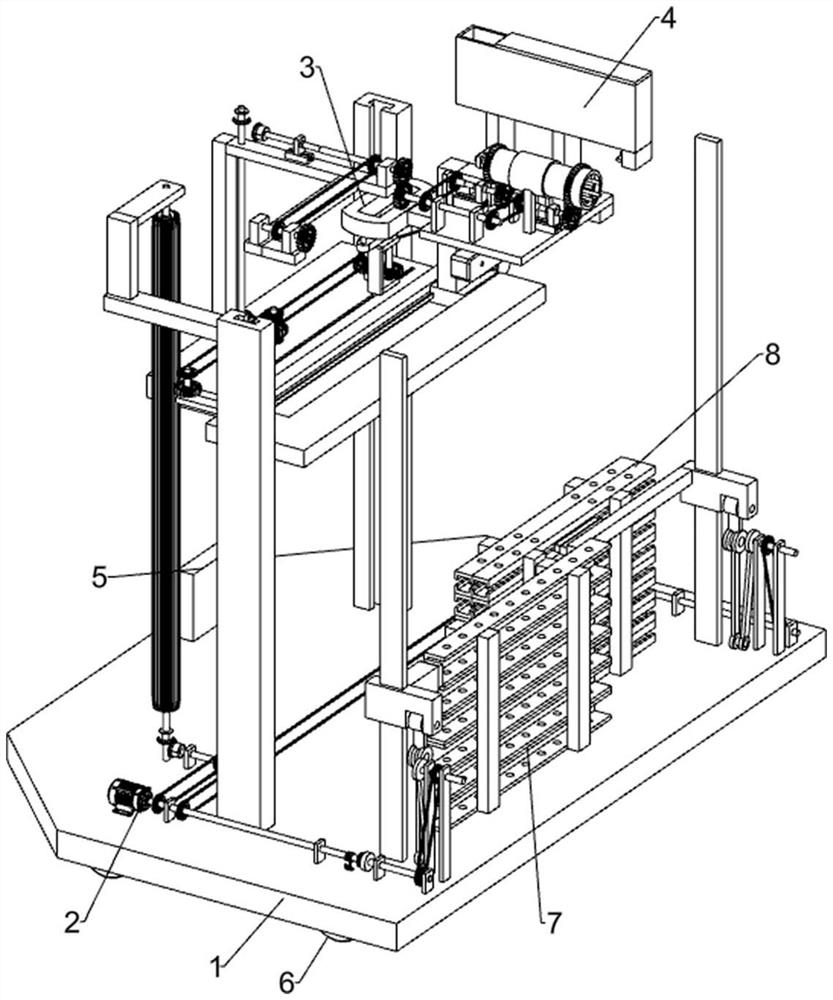

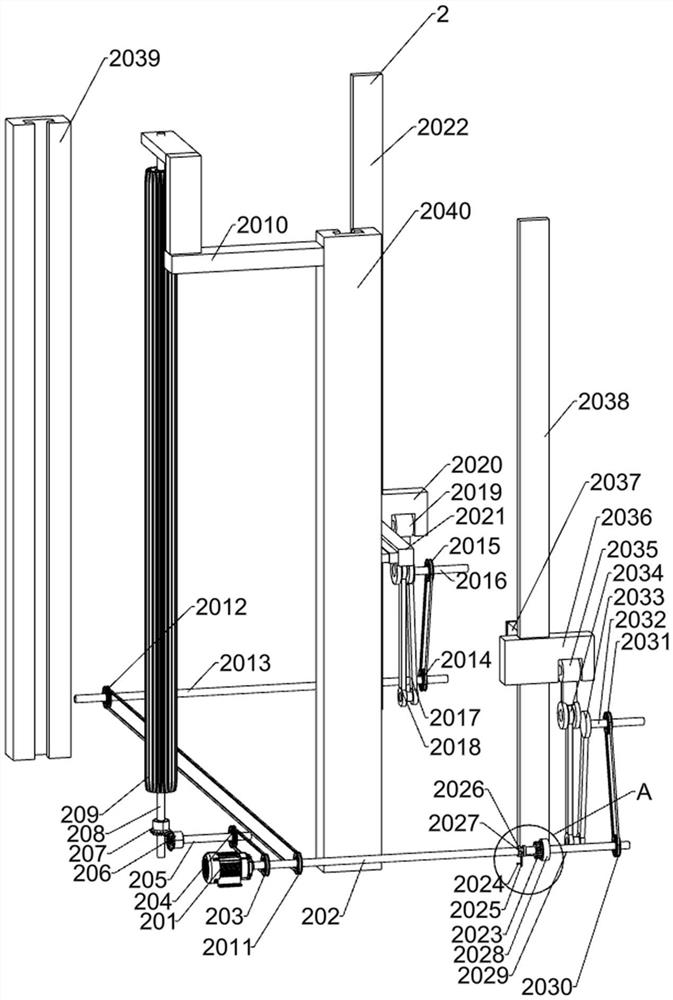

Mechanical arm driven in compound manner

PendingCN107030685ALarge travel rangeSave spaceProgramme-controlled manipulatorArmsRobotic armReduction drive

A mechanical arm driven in a compound manner comprises double slide arms and drive devices. The double slide arms include the outer slide arm and the inner slide arm embedded in the outer slide arm and connected with the outer slide arm in a sliding manner. The outer slide arm is connected with a slide rail base through slide rails in a sliding manner. The drive devices are installed on the slide rail base and include the first drive device and the second drive device. The first drive device comprises a servo motor, a speed reducer and a belt wheel I. The servo motor drives a conveyor belt I through the speed reducer and the belt wheel I so that an outer profile can be driven to slide up and down. The second drive device comprises a cylinder. A piston rod of the cylinder is connected with the outer profile and pushes the outer profile to slide. Two belt wheels II are arranged on the outer profile. A conveyor belt II is assembled between the belt wheels II. The inner side of the conveyor belt II is fixed to an inner profile, and the outer side of the conveyor belt II is fixed to the slide rail base. The outer profile moves up and down so as to drive the inner profile to move up and down at a double speed relative to the outer profile. By means of the mechanical arm, the stroke is increased, space is saved, the operation precision and efficiency are improved, the material mass range is widened, and safety is high.

Owner:柳州科瑞科技有限公司 +1

Auxiliary mounting device for building construction

InactiveCN111910933ALow efficiencyEasy to fixVehicle to carry long loadsLoad securingArchitectural engineeringElectric cars

The invention relates to the field of building construction, in particular to an auxiliary mounting device for building construction. The technical problem is to provide the auxiliary mounting devicefor building construction. .According to the technical scheme, the auxiliary mounting device for building construction comprises a bottom frame, a transverse beam lock conveying mechanism, a transverse bar lock mounting mechanism, a transverse beam fixing mechanism and the like; and electric wheels are arranged below the bottom frame. According to the device, during use, two transverse beams are automatically transported to the positions needing to be subjected to mounting, then the two transverse beams are automatically located on the same horizontal line and are in contact with each other tobe clamped into threaded steel bars of a form, a linear lock is automatically clamped into the upper portions of the two transverse beams, and nuts are automatically screwed into threaded steel barsof the linear lock and the two transverse beams, so that the two transverse beams are fixed through the linear lock, and during use, the structure is simple, the efficiency is high, workers do not need to work high above the ground, and potential production safety hazards are greatly reduced.

Owner:陈祥德

Automatic discharging die-cutting machine

InactiveCN102658567ARealize automatic unloadingSuction is safe and reliableMetal working apparatusEngineeringVacuum pump

The invention discloses an automatic discharging die-cutting machine and belongs to the field of machinery. The automatic discharging die-cutting machine comprises a frame, a motor assembly, a die-cutting table plate and a die-cutting assembly and is characterized by further comprising a discharging assembly. The discharging assembly comprises a discharging support, a discharging arm, a suction device, a discharging motor and a transmission device. The discharging support comprises a slide way and a rocker which are mounted on a support body, and the slide way has a certain radian. The discharging arm comprises a sucker holder and a discharging arm body, and the suction device comprises a vacuum pump, a position switch, an electromagnetic reversing valve, a sucker, an air storage device and a pipeline. The discharging motor is connected with the transmission device and a travelling end of the discharging arm body sequentially, a die-cutting limiting switch and a discharging trigger switch are arranged on the frame, the die-cutting limiting switch is in circuit connection with a motor, and the discharging trigger switch is in circuit connection with the discharging motor. Compared with the prior art, the automatic discharging die-cutting machine has the advantages that automatic discharging can be realized, labor intensity is relieved for workers, and labor is saved.

Owner:魏祥国

Novel curing agent

The invention discloses a novel curing agent, relating to the field of epoxy resin application technologies. The novel curing agent comprises the following ingredients in percentage by weight: 533.1g of diphenylmethane diisocyanate, 190.4g of ethyl acetate, 1.1g of an oxidant, 57.8g of trimethylol propane, and 217.6g of prepolymer. A preparation process comprises the steps of: 1) feeding three raw materials 1, 2 and 3 at a time, stirring in an opening mode, starting heating for raising the temperature to be 60 DEG C; 2) feeding about one fourth of a raw material4, observing the temperature change, and preparing cooling at any time; 3) after the raw material 4 is entirely fed and the reaction is complete and when the temperature has no obvious rise, keeping the temperature at about 70 DEG C, and feeding a part of a raw material 5; 4) after the five raw materials are entirely fed, keeping the temperature at about 70 DEG C; and 5) after two hours, sampling to detect NCO. With the novel curing agent, the toxicity to human bodies and the influence on the environment can be reduced, and the hidden safety hazard in the traditional production links can also be reduced.

Owner:王栋

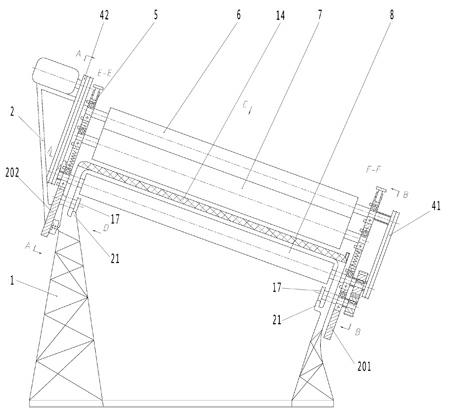

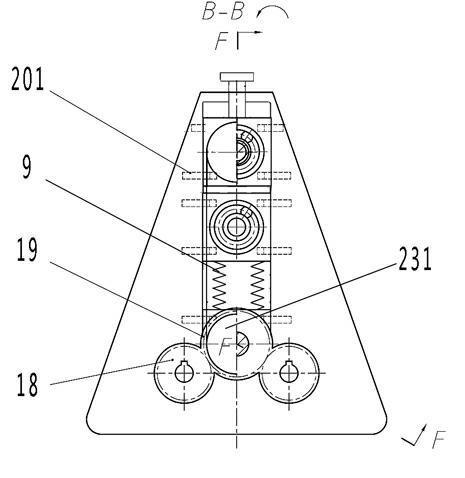

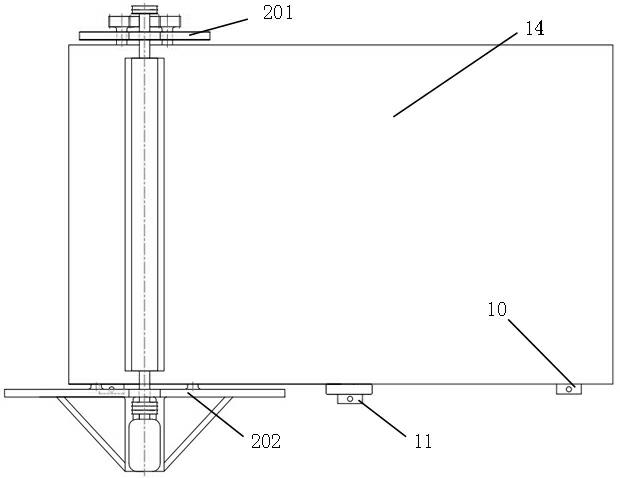

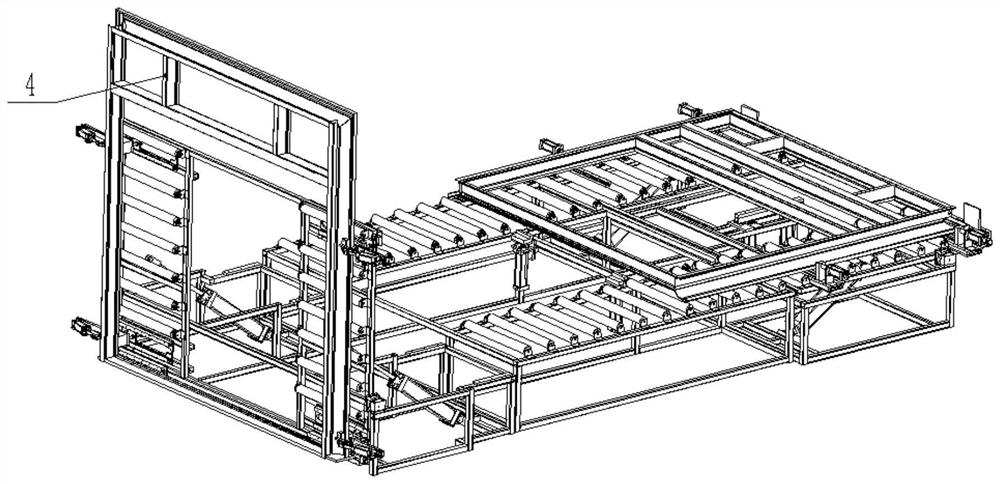

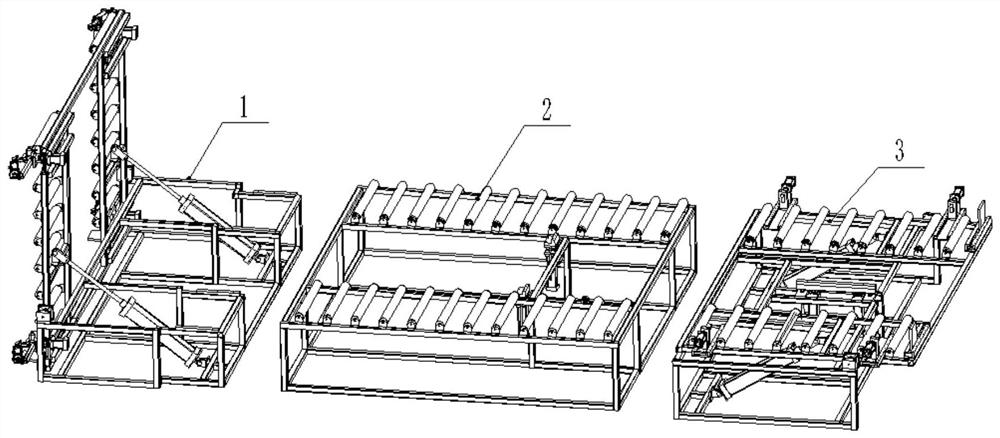

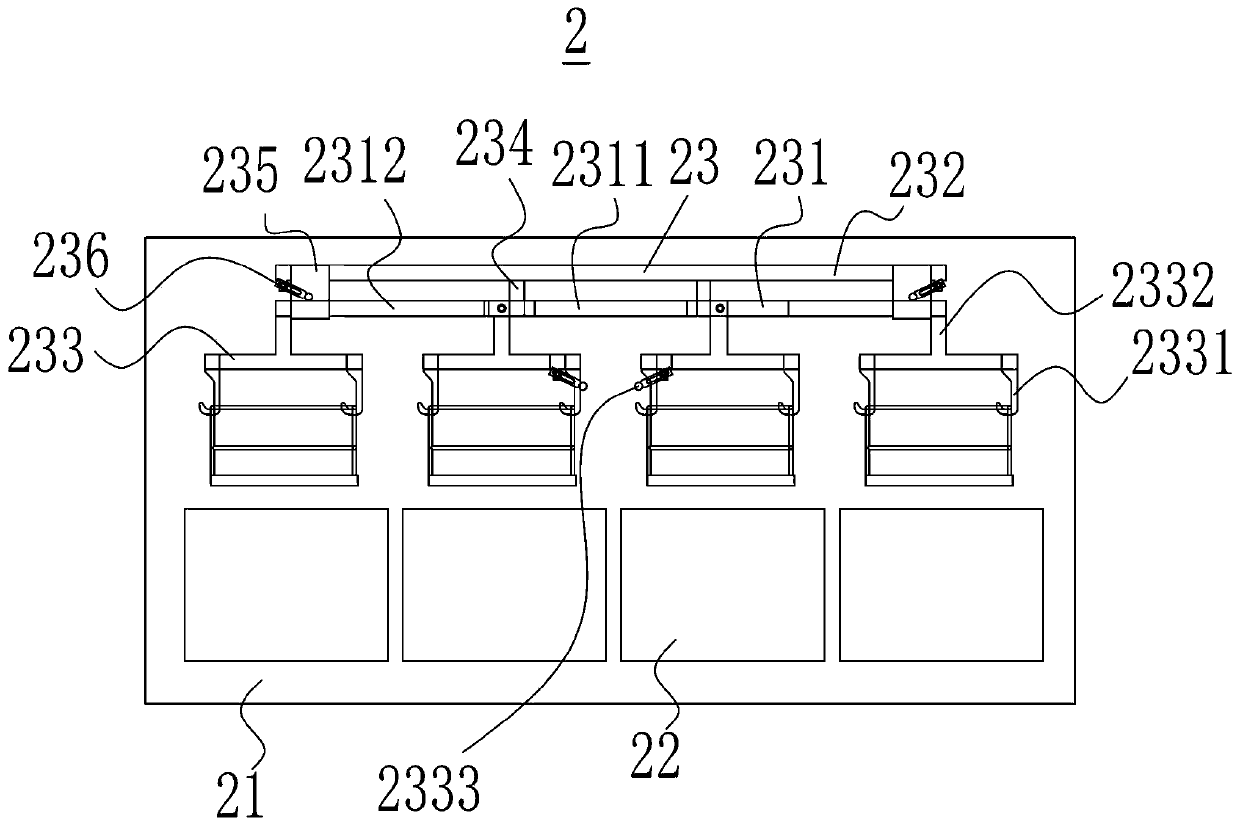

Non-standard door assembly packaging system

PendingCN111891511AReduce labor intensityIncrease productivityAssembly machinesPackaging machinesIndustrial engineeringChassis

The invention discloses a non-standard door assembly packaging system which belongs to the technical field of non-standard door assembly packaging. The non-standard door assembly packaging system comprises a rotary assembly device, a transition packaging frame and a rotary transportation device which are sequentially arranged, wherein the rotary assembly device comprises an assembly bottom frame,an assembly side frame which is rotatably connected to the assembly bottom frame and a first drive part for driving the assembly side frame to rotate on the assembly bottom frame; the lower part of the assembly side frame is equipped with a first door leaf supporting mechanism; the two side parts of the assembly side frame are equipped with first assembly clamping mechanisms; the transition packaging frame is used for transmitting door leaves on the rotary assembly device onto the rotary transportation device; and the rotary transportation device is used for limiting and turning over the transmitted door leaves. The non-standard door assembly packaging system mainly solves the problems such as low production efficiency, high labor intensity, great production site occupation, many potentialsafety hazards, and the like of current non-standard door assembly packaging.

Owner:CHENGDU HELE DOORS

Method for extracting lignin by using hydrothermal and alkali synchronous activation method

ActiveCN108752600AHigh extraction rateReduce production safety hazardsLignin derivativesActivation methodAlkalinity

The invention discloses a method for extracting lignin by using a hydrothermal and alkali synchronous activation method, and belongs to the technical field of biomass extraction from pretreated lignin. According to the method, a product is prepared by taking biomass such as ramulus mori (leaves) as raw materials, and carrying out simple process of biomass pretreatment, hydrothermal and alkali synchronous activation, acid-adjusting and precipitation of the lignin and lignin extraction. The method has the characteristics that raw materials are easily obtained and have low price; the prepared lignin product has high recovery rate and small chemical modification; the production process is simple; by the use of dilute acid, the lignin precipitates and the acidity and alkalinity of an activationsolution can be neutralized, environmental protection is facilitated and the like. The method disclosed by the invention can be widely applied to lignin extraction and also can be used for extractinghigh value natural products in the biomass; the high value transformation of the biomass is realized.

Owner:CHONGQING TECH & BUSINESS UNIV

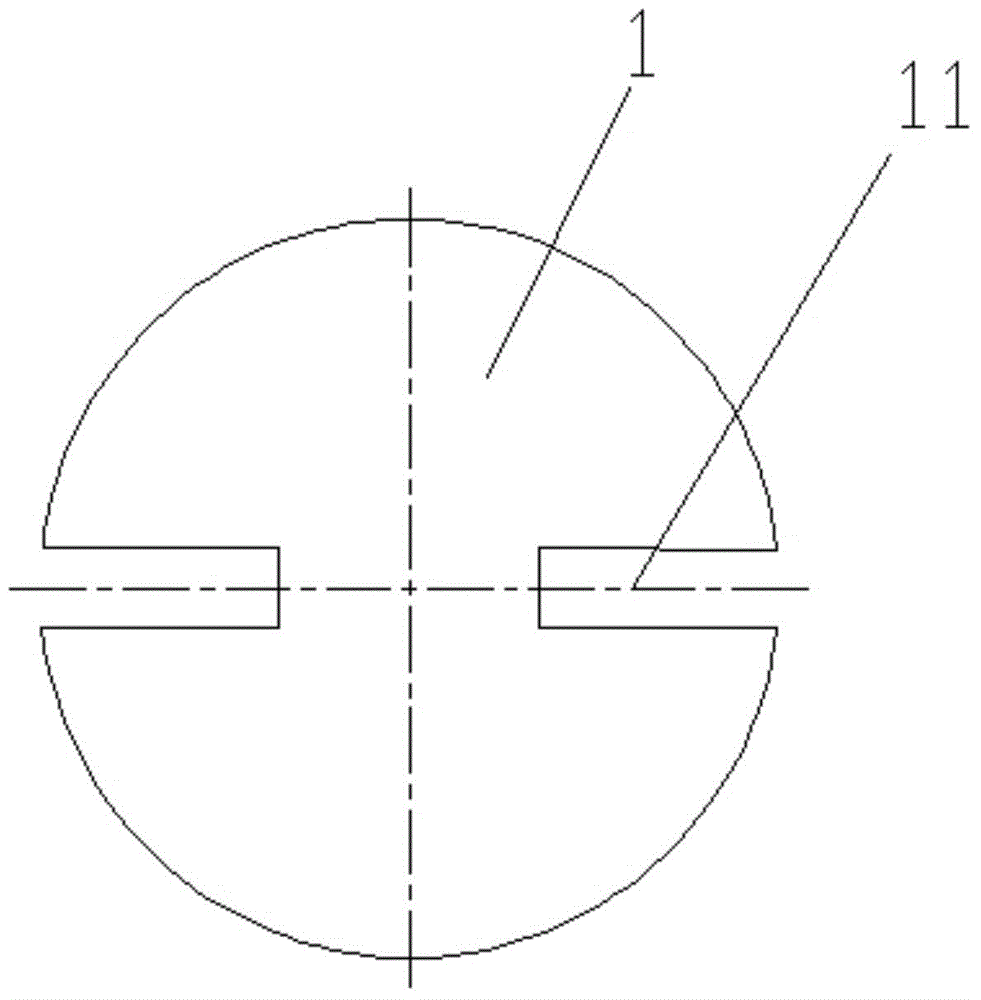

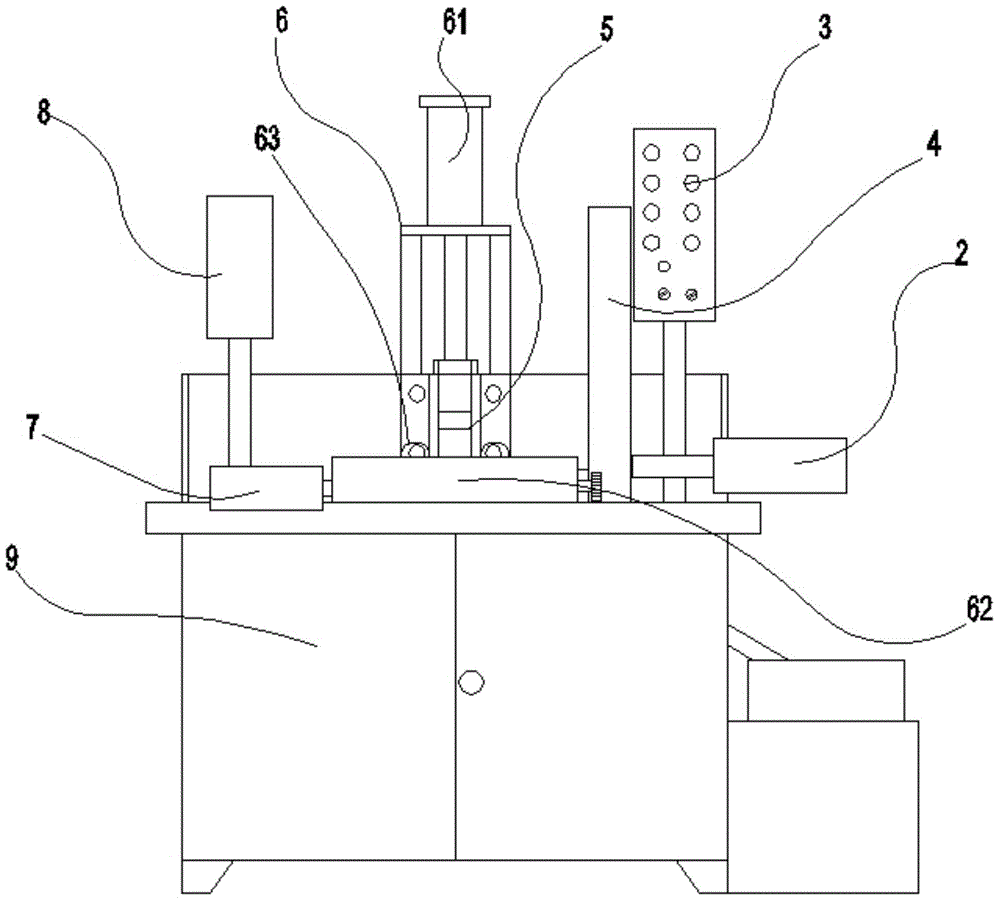

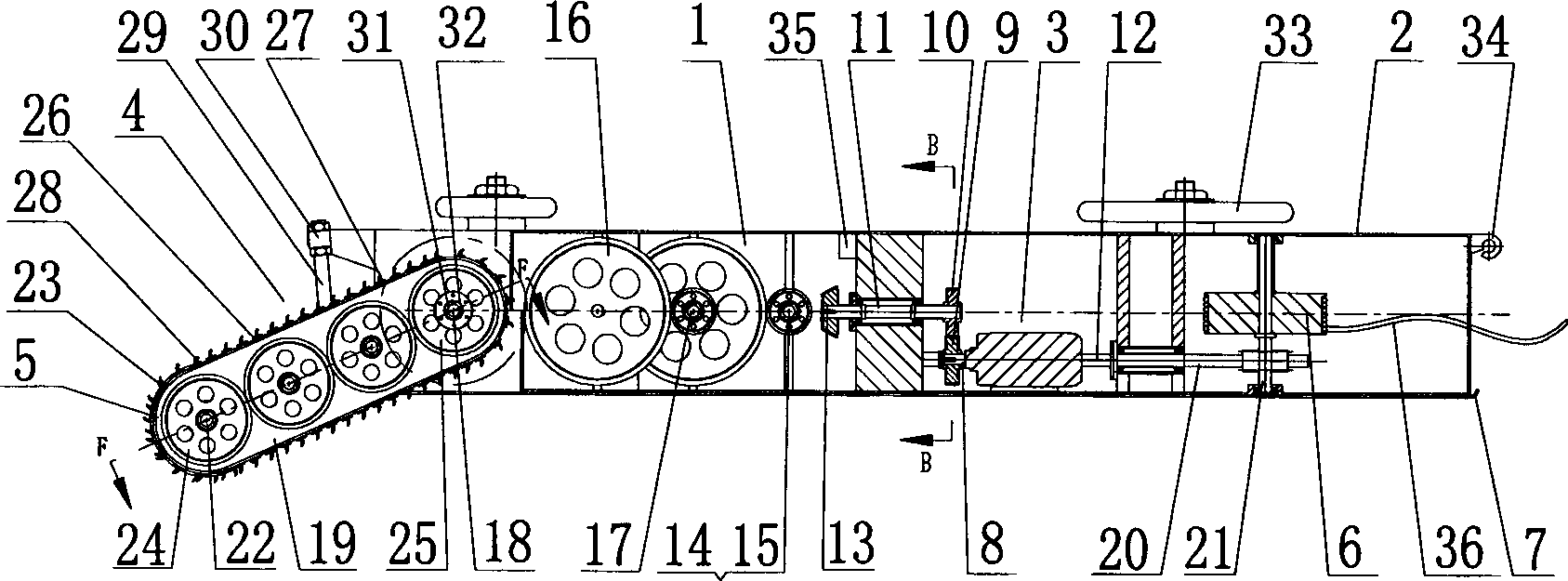

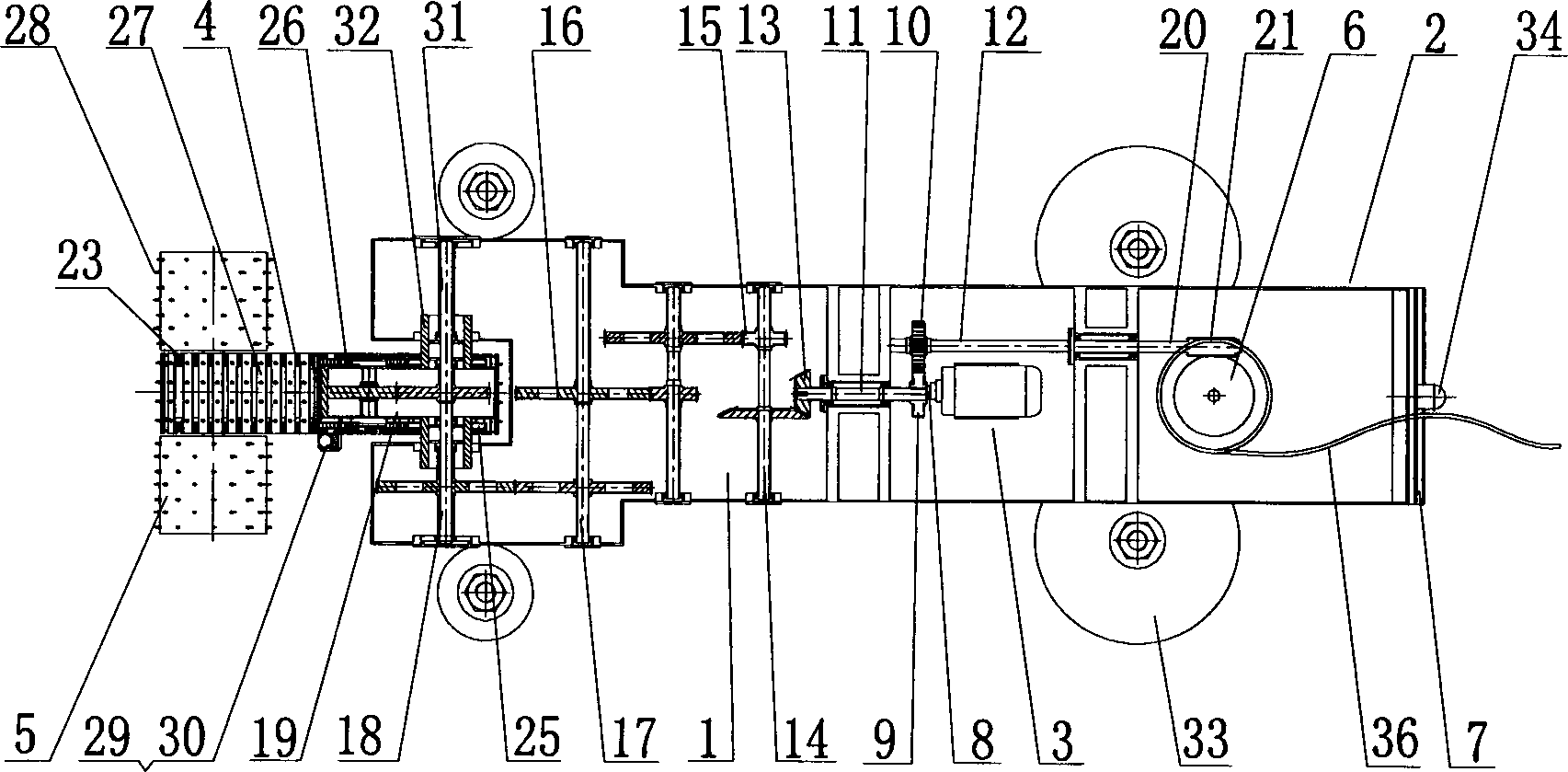

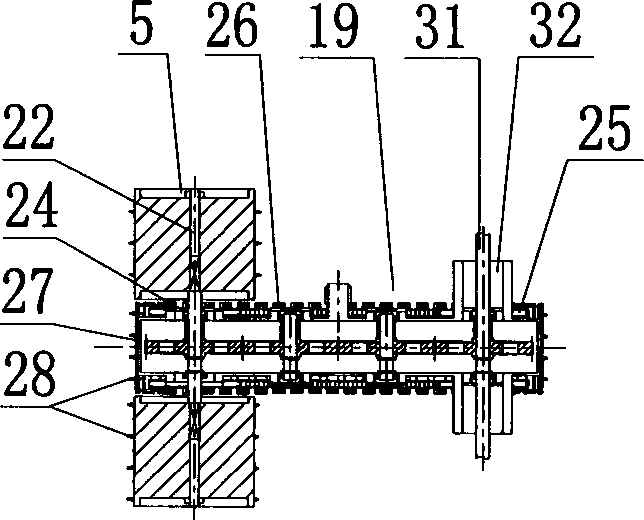

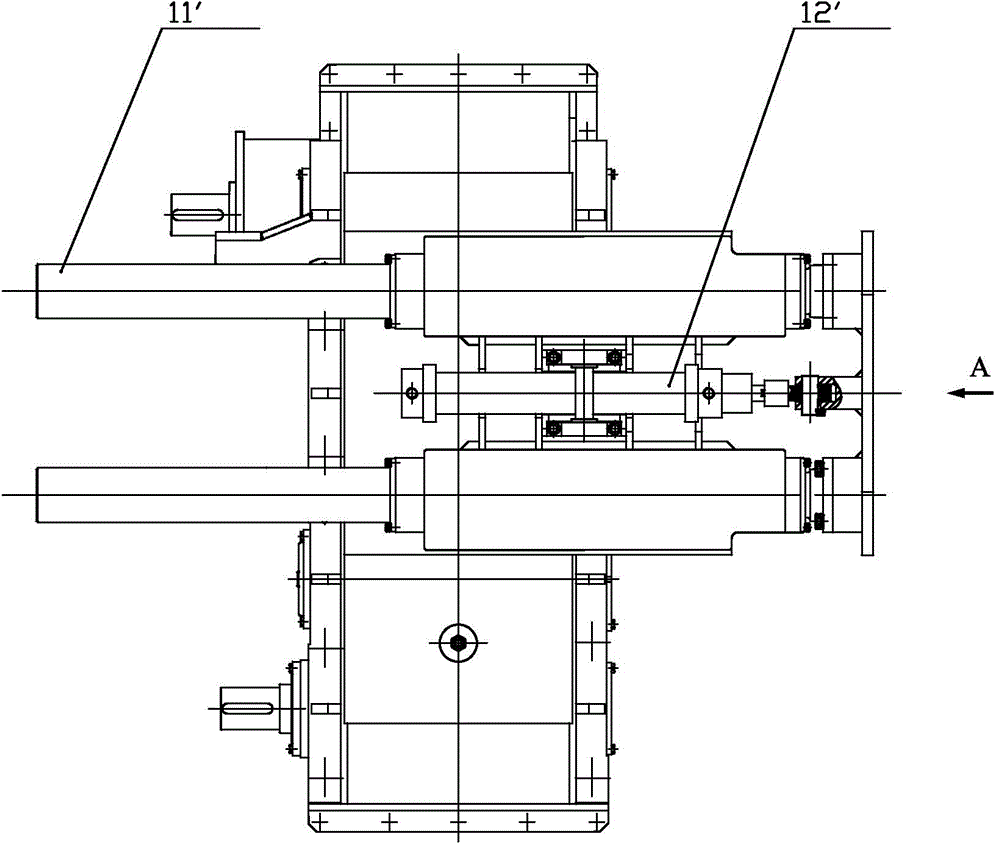

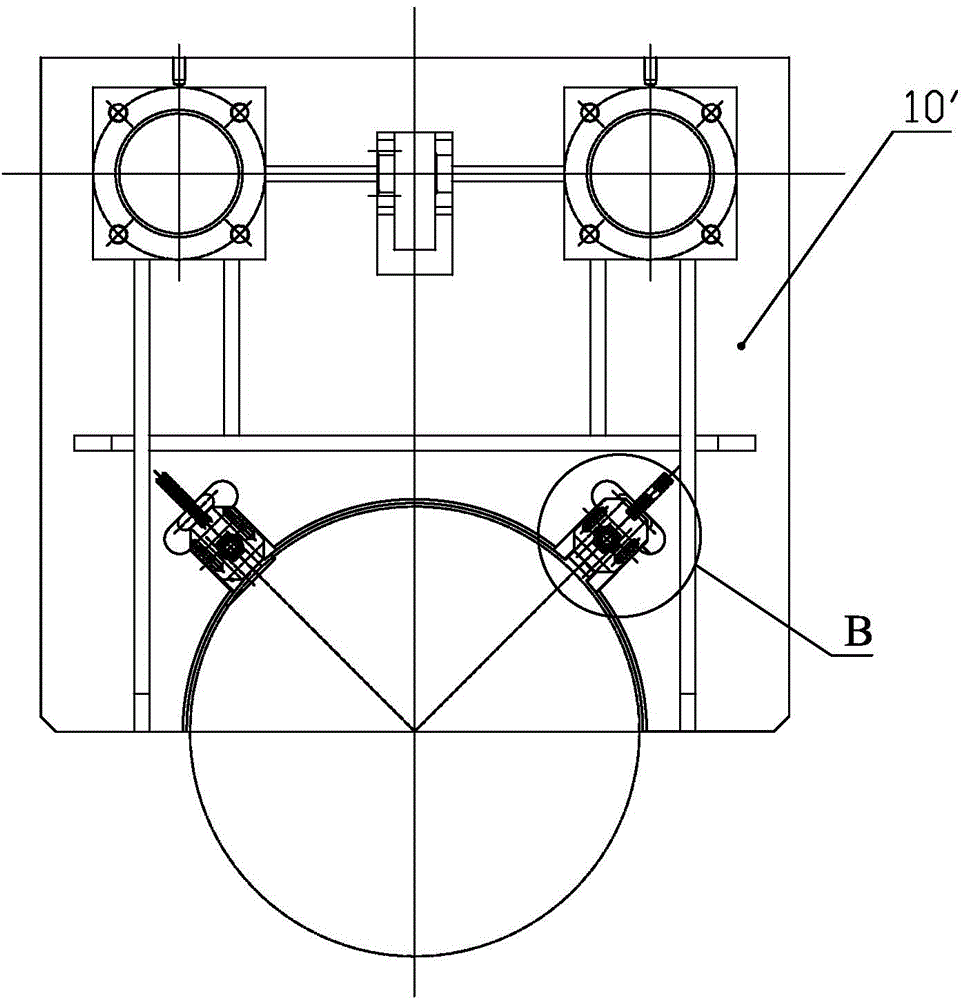

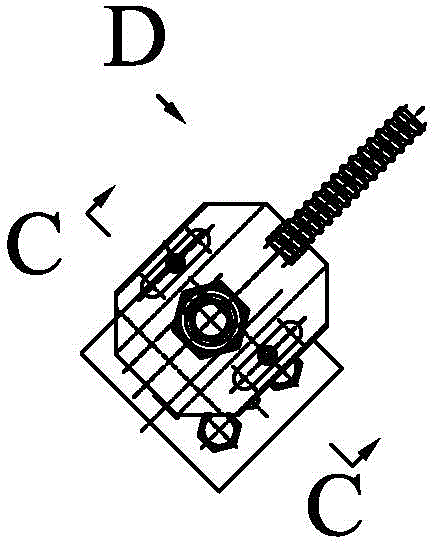

Parallel slot milling machine

ActiveCN104439455AIncrease productivityImprove machining accuracyAutomatic workpiece supply/removalMilling equipment detailsEngineeringAlternating current

The invention discloses a parallel slot milling machine which is special equipment for processing a notch in an alternating-current electromagnet armature. The parallel slot milling machine comprises a workbench, wherein a feeding mechanism, an electrical equipment control tank, a charging mechanism, a clamping mechanism, a milling mechanism, a material returning mechanism and a hydraulic valve bank are arranged on the workbench, a milling head driving unit is arranged under the workbench, the milling mechanism comprises a milling oil cylinder arranged vertically and a milling platform arranged under the milling oil cylinder, a through hole is formed in the milling platform, two milling heads are also arranged on the milling platform and are arranged symmetrically relative to the axis of the through hole, an armature clamp can move up and down in the through hole after clamping an armature to be processed, the feeding mechanism, the charging mechanism, the clamping mechanism, the milling mechanism and the material returning mechanism are cooperated under the control of the electrical equipment control tank, the notch of the armature can be processed automatically, the production efficiency and the processing precision of the armature are remarkably improved, and the production potential safety hazard can be reduced.

Owner:无锡新力电器有限公司

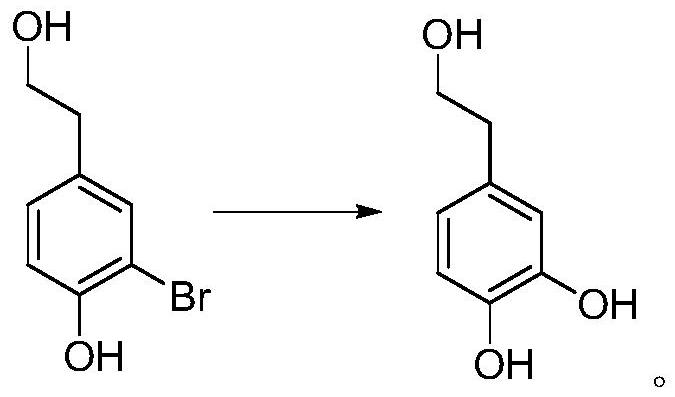

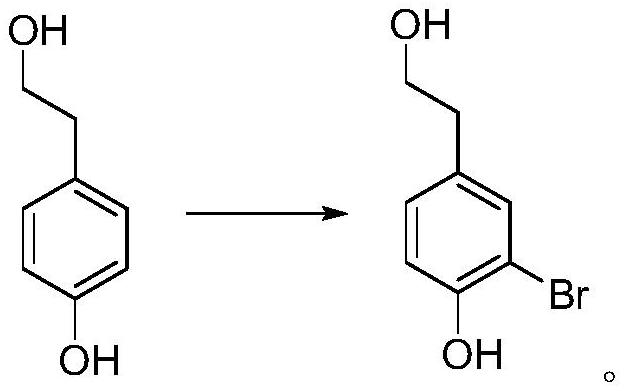

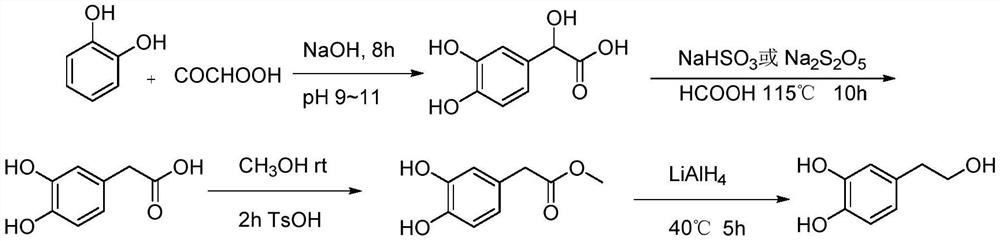

Synthesis method for hydroxytyrosol

ActiveCN112457171ASolve the problem of being too longGood choiceOrganic chemistryOrganic compound preparationHydroxytyrosolPtru catalyst

The invention belongs to the field of organic synthesis, and discloses a synthesis method for hydroxytyrosol. The method comprises a step b that: a reaction is carried out on 3-bromine-4-hydroxy phenylethanol, an alkali metal hydroxide and a copper catalyst, wherein the copper catalyst is at least one selected from 8-hydroxyquinoline copper, copper acetylacetonate and BFMO-cuprous iodide. According to the process route, hydroxyl protection and deprotection steps are omitted, bromine does not need to be replaced with methoxyl, hydroxyl substitution is achieved in a sodium hydroxide aqueous solution under catalysis of the copper catalyst, and therefore, selectivity is good, the reaction route is short, the product can be obtained only through two steps, and the problem that an existing process route is too long is solved.

Owner:SHENZHEN DIECKMANN TECH CO LTD

Rocker-type transverse shearer

Owner:HUNAN UNIV OF SCI & TECH

Micro-emulsified mint essence for cigarette paper as well as preparation method and application of micro-emulsified mint essence

InactiveCN111100756APlay a protective effectPlay a sustained release roleNon-fibrous pulp additionPaper coatingMentholMentha spicata

The invention provides a micro-emulsified peppermint essence for cigarette paper, which comprises the following components in parts by weight: 4-15 parts of zanthoxylum-like peppermint oil, 2-10 partsof Asian peppermint oil, 1-5 parts of menthol, 5-15 parts of cyclodextrin, 10-30 parts of an emulsifier and 25-50 parts of distilled water, and is prepared by a micro-emulsification method. The micro-emulsified mint essence for cigarette paper can be well applied to cigarette paper perfuming production, can significantly endow cigarettes with mint natural characteristic aroma and cool feeling with better consistency before and after the cigarettes are smoked, and improves the smoking quality of the cigarettes.

Owner:广州华芳烟用香精有限公司 +1

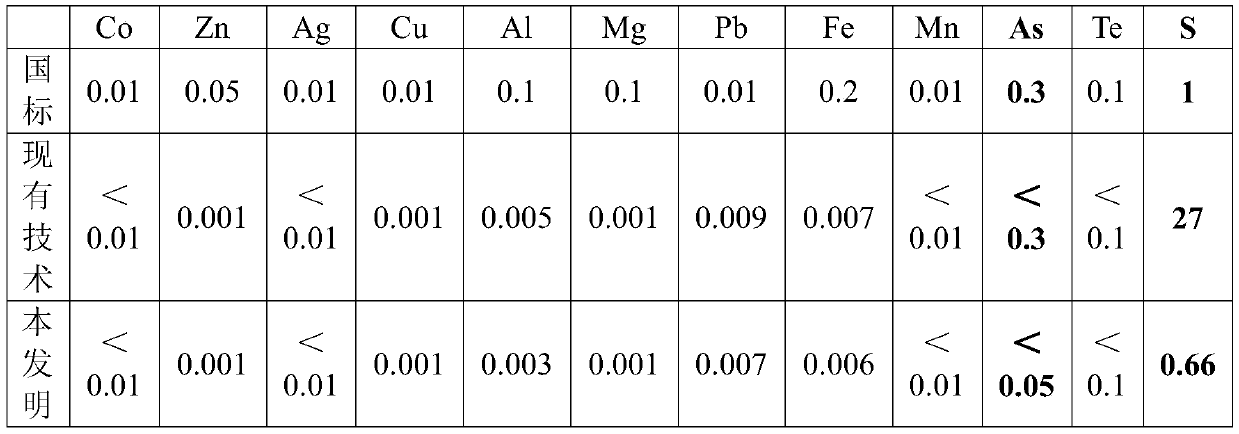

Production process for converting deep pickling yellow phosphorus into electronic grade red phosphorus

The invention discloses a production process for converting a deep pickling yellow phosphorus into an electronic grade red phosphorus. The industrial yellow phosphorus is successively subjected to thesteps containing deep pickling, chlorination, rectification, hydrogen reduction and atmospheric pressure high temperature conversion to obtain the electronic grade red phosphorus with the purity of 99.9999%. According to the above process, the traditional industrial yellow phosphorus pickling process is improved, on the one hand, a traditional relatively mild gas-introduction stirring is replacedby a mechanical deep stirring, and an interlayer outside the kettle is circulated with hot water to keep warm, so that the yellow phosphorus and nitric acid are fully contacted, impurities that cannot be removed by subsequent processes such as S, C, As and the like are removed, additives are not needed in the reaction process, the product purity is improved, the yellow phosphorus recovery rate isgreatly improved, and the yield of the electronic grade red phosphorus is increased; and on the other hand, a traditional quartz reaction kettle is replaced by an inner glass-lined cast iron kettle with an outer interlayer, so that production safety hidden dangers are reduced.

Owner:贵州金鼎电子信息新材料有限公司

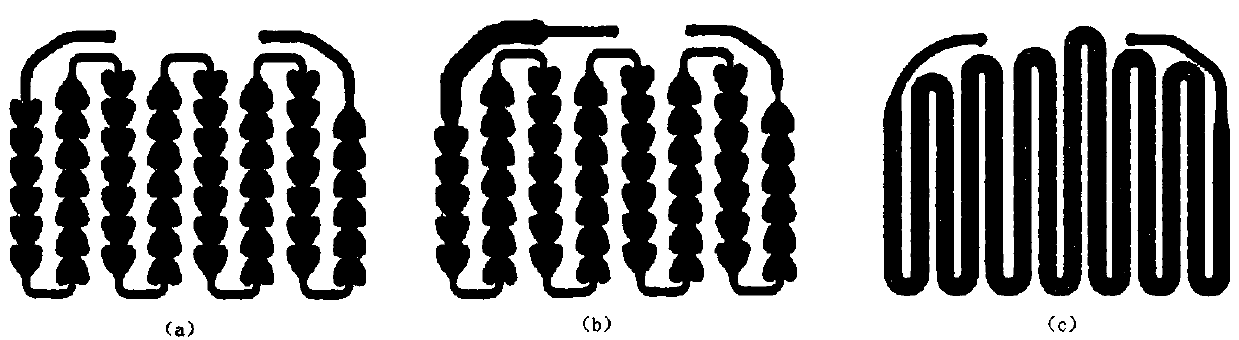

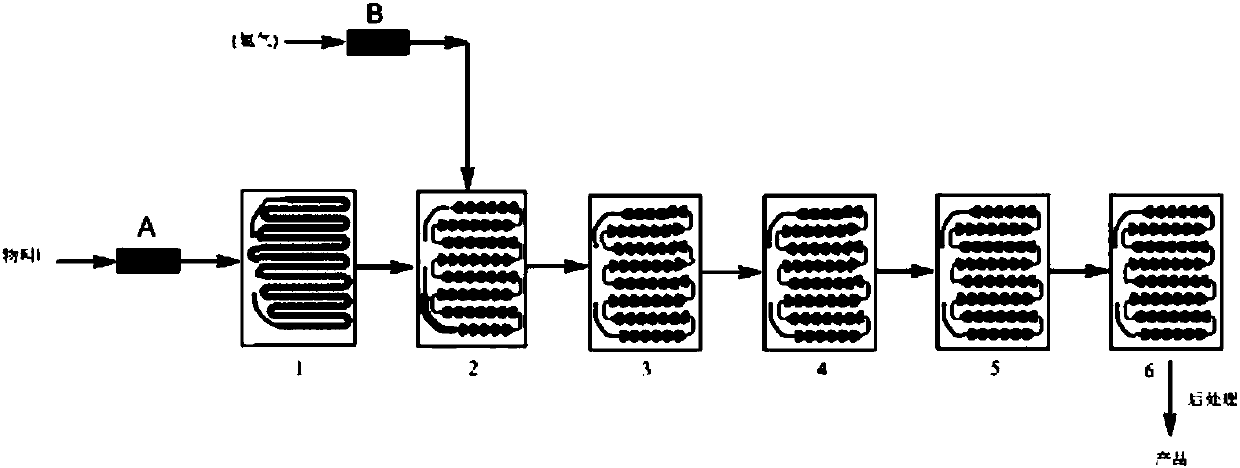

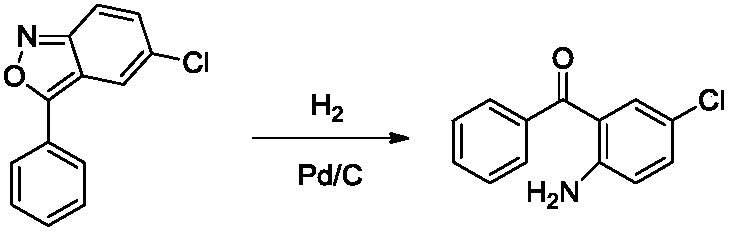

Method for synthesizing 2-amino-5-chlorobenzophenone by microchannel reactor

ActiveCN107935872AIncrease the speed of the intrinsic responseDegraded impurities are reducedOrganic chemistryOrganic compound preparationPsychoactive drugActivated carbon

The invention discloses a method for synthesizing 2-amino-5-chlorobenzophenone by a microchannel reactor, belongs to the field of synthesis of psychoactive drugs in organic synthesis, and solves the problems of low yield, poor purity, high risk of violent explosion, degradation caused by high reaction time under high temperature and high pressure conditions, low frequency of catalyst recycling andreuse and the like during the synthesis of a traditional catalytic hydrogenation reactor. The method for synthesizing the 2-amino-5-chlorobenzophenone in the microchannel reactor specifically includes the following steps: 1). adding hydrogenation reaction precursor 5-chloro-3-phenyl-2,1-benzisoxazole into an organic solvent, and then adding an activated-carbon-loaded noble metal catalyst to obtain a mixture as a material I to enter a preheating module of the microreactor; and 2). after preheating of the material I, injecting the material I and material II hydrogen into a reaction module groupof the microreactor for reaction, collecting a reaction solution flowing out from a cooling module, and treating to obtain the 2-amino-5-chlorobenzophenone. The method is suitable for the large-scaleproduction of the 2-amino-5-chlorobenzophenone.

Owner:HEILONGJIANG XINCHUANG BIOLOGICAL TECH DEV CO LTD

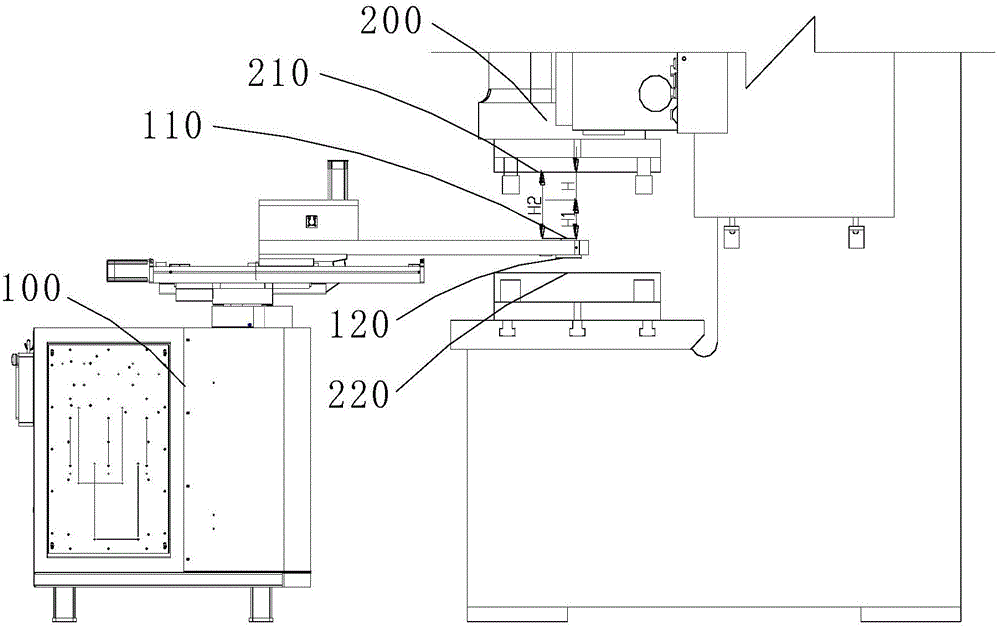

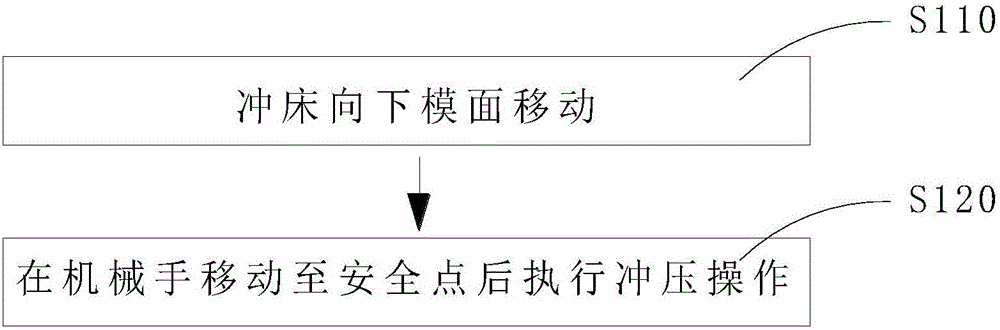

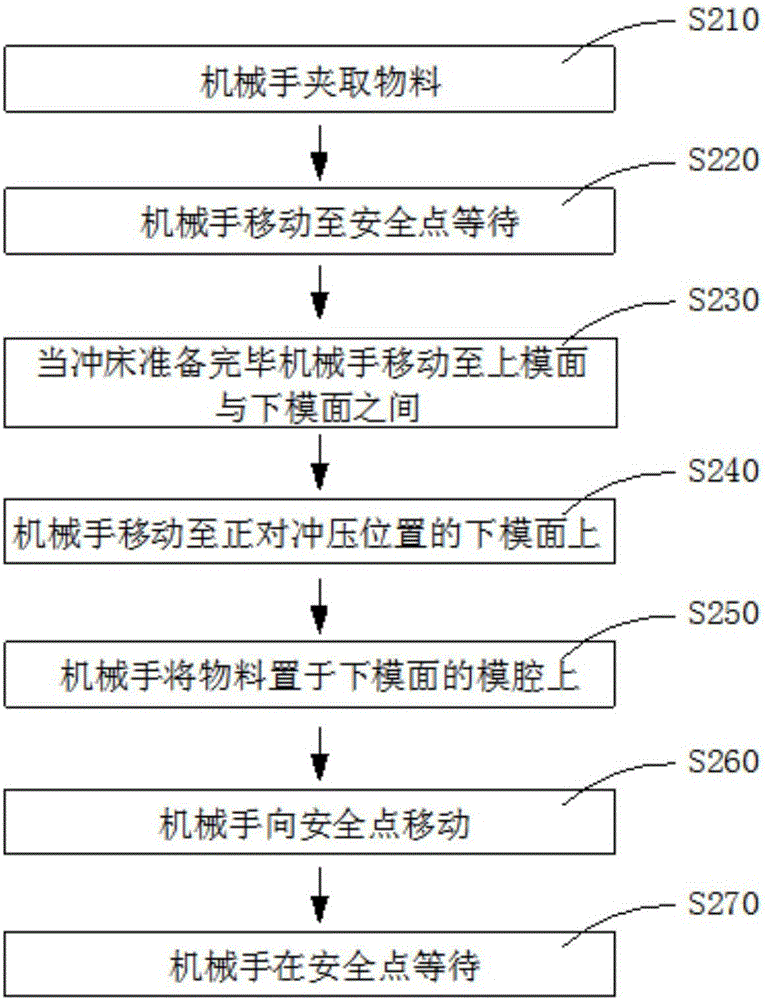

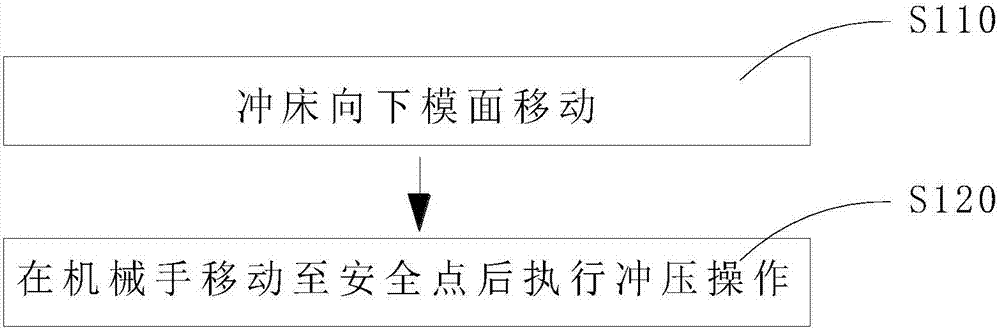

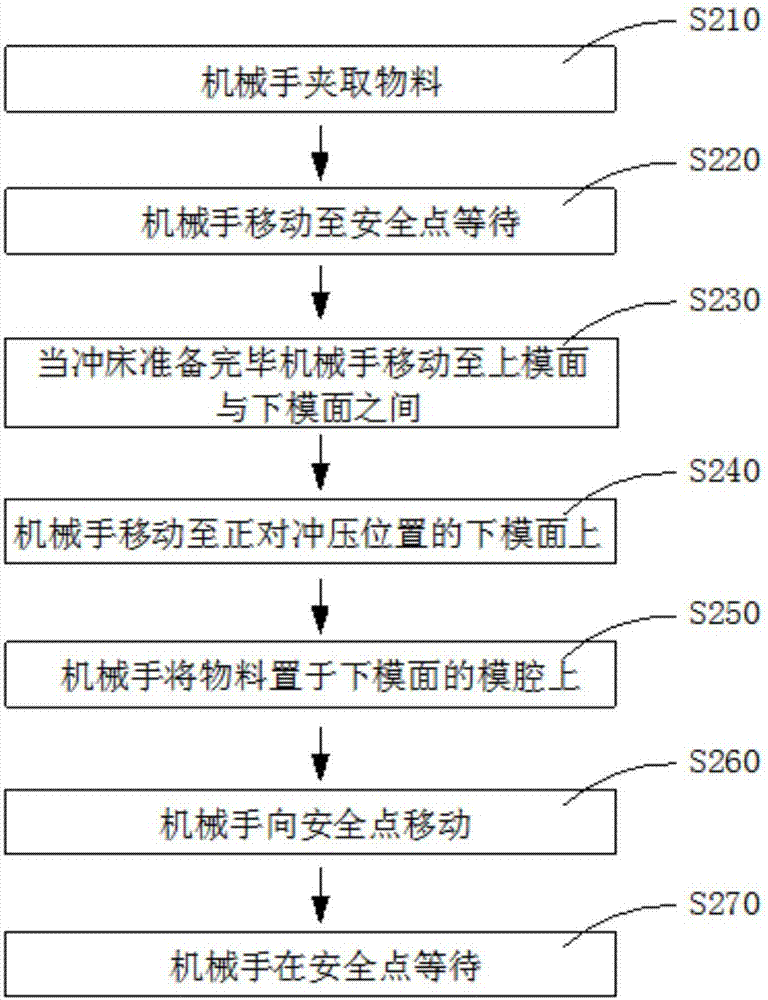

Stamping control system and stamping method

The invention relates to a stamping control system and a stamping method. A manipulator and a stamping machine are controlled by virtue of one control system, and according to the control system, when the manipulator is located between an upper die surface and a lower die surface, an actual distance between the upper end surface of the tail end of the manipulator and the upper die surface is controlled to be greater than or equal to a safe distance, and the safe distance is 1 / 3 to 1 / 5 of a distance between the upper die surface and the lower die surface. The manipulator and the stamping machine stop running simultaneously as long as any of the manipulator and the stamping machine is failed, thus a risk in the traditional stamping control system is avoided that when any of the manipulator and the stamping machine is failed, the other one still runs, and at least the safe distance between the manipulator and the stamping machine can be ensured when the tail end of the manipulator is located between the upper die surface and the lower die surface; therefore, the safety of the manipulator and the stamping machine is further improved, and the occurrence probability of potential safety hazards of stamping control system production is reduced.

Owner:SHENZHEN TONGCHUAN TECH

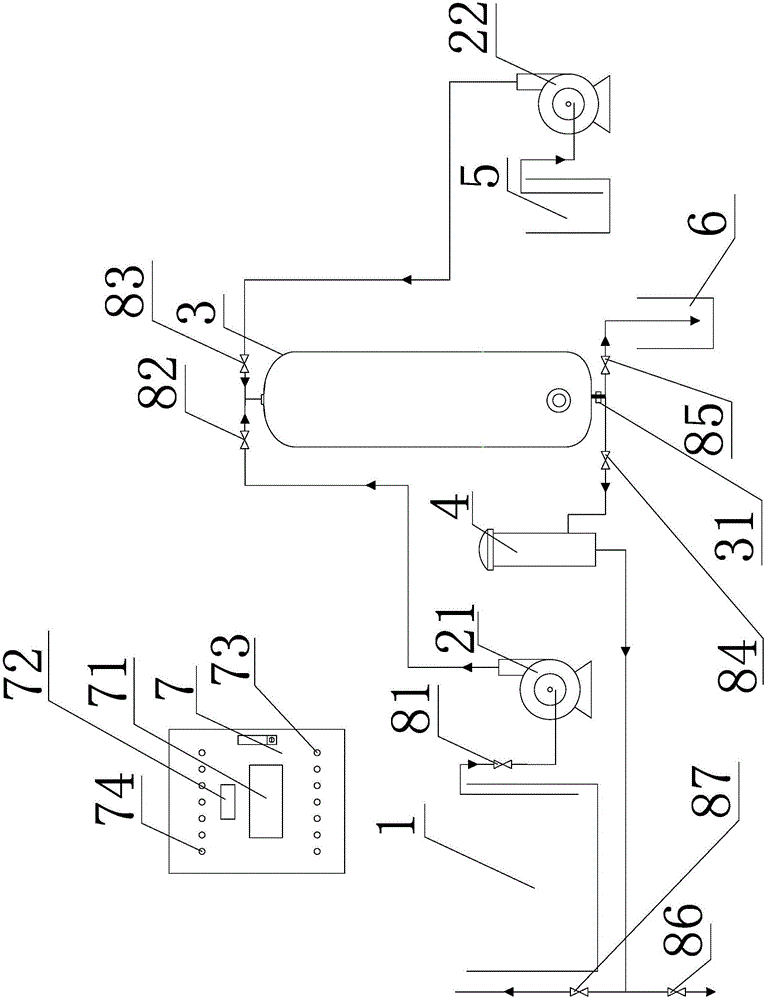

Filtering device allowing activated carbon to be replaced through automatic program

ActiveCN105753199AAvoid cumulative elevationReduce production safety hazardsWater treatment parameter controlSpecific water treatment objectivesActivated carbonSolenoid valve

The invention provides a filtering device allowing activated carbon to be replaced through an automatic program.The filtering device comprises an electroplating liquid tank feed pump connected with an electroplating liquid tank, an activated carbon treatment device, a secondary filter, an activated carbon discharge tank, an activated carbon replacing tank, an activated carbon conveying pump, an intelligent control system, a solenoid valve assembly and a pipeline assembly connected with the solenoid valve assembly, wherein the electroplating liquid tank feed pump, the activated carbon conveying pump and the solenoid valve assembly are connected with a control module in the intelligent control system, an activated carbon separator is arranged at the outlet end of the activated carbon treatment device, and the activated carbon treatment device is connected with a pressure display meter.A traditional activated carbon electroplating liquid filtering system is improved, the effect of automatically replacing the activated carbon is achieved, all equipment operation is automatically controlled basically, the filtering device is easy and convenient to use and high in treatment efficiency, the efficiency is remarkably improved compared with an existing scheme of cleaning a filter, and a great deal of pure water for cleaning the filter is saved.

Owner:江门市瑞期精细化学工程有限公司

Environmental-friendly method for preparing bromine-based alkyl

InactiveCN102766013AGuarantee Occupational Safety and HealthReduce production safety hazardsHalogenated hydrocarbon preparationAlcoholBromine

The invention discloses an environmental-friendly method for preparing bromine-based alkyl. The method comprises the steps as follows: adding a hydrobromic acid solution in a reaction vessel in advance, and then preheating until steam is generated; and slowly adding the mixture of the hydrobromic acid solution and an ethanol solution into the reaction vessel or slowly adding both in a separated way at the same time, as for the former way, during the adding process, heating the reaction vessel to 100-140 DEG C to cause reaction so as to prepare bromine-based alkyl, wherein the ethanol solution is the normal butanol solution or the methanol solution; and bromine-based alkyl is bromobutane or bromomethane. According to the invention, poisonous and harmful raw materials are reduced from the source, which reduces potential safety hazards during production and ensures the occupational safety and health of staff. During the process, no waste gas is generated, no solid waste is discharged, and waste water can be recycled after being subjected to neutralization and desalting processing, as a result, zero discharge of 'the three wastes' is realized, and the purpose of environment protection is achieved. Therefore, the method has the advantages of low cost, simplicity in operation, and easiness in industrialization application.

Owner:连云港海水化工有限公司

Side push plate device of cold rolling copper belt recoiling machine

ActiveCN104084450AEliminate misalignmentReduce production safety hazardsHydraulic cylinderPneumatic valve

The invention discloses a side push plate device of a cold rolling copper belt recoiling machine, and relates to the field of cold rolling copper belt recoiling machines. The side push plate device comprises a side push plate frame body, guiding rods, a hydraulic cylinder and a winding drum, wherein a pneumatic valve is arranged on the side push plate frame body; the pneumatic valve comprises a valve cavity fixed on the side push plate frame body, a valve core positioned in the valve cavity and a control plate fixed on the front end of the valve core, and an elastic supporting part is also arranged between the control plate and the cavity wall of the valve cavity; the side push plate frame body is provided with at least two guiding parts, the at least two guiding parts are distributed along the excircle of the winding drum, the guiding rods are arranged on the guiding parts, and the guiding plates are driven by a double-acting air cylinder to radially move along the winding drum. The side push plate device provided by the invention has the advantages that a pneumatic principle is adopted, the lifting movement of the guiding plates is realized through a manner that the pneumatic valve drives an air cylinder piston rod to stretch, and thus a potential safety hazard is eliminated.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Graphene hygienic disinfection wet tissue

PendingCN112336635AEasy to disinfectReduce concentrationCosmetic preparationsToilet preparationsBiotechnologyDisinfectant

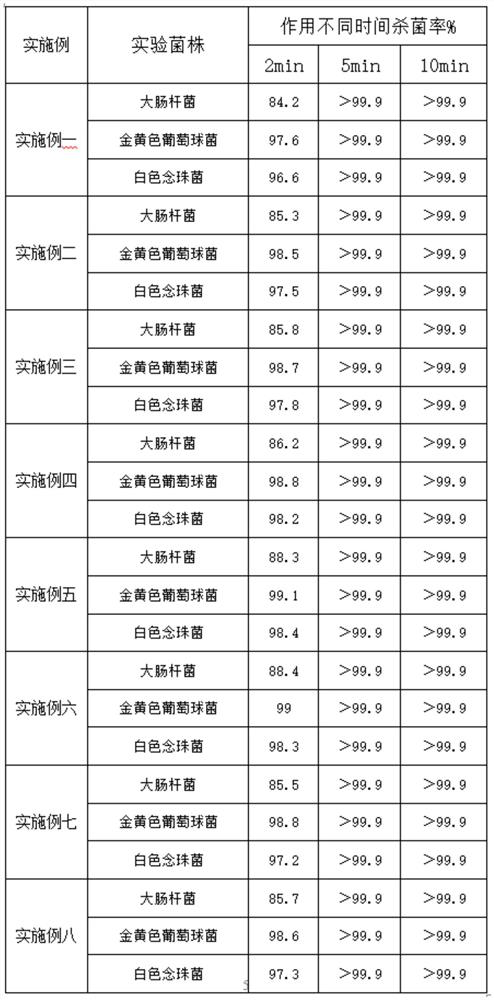

The invention discloses a graphene hygienic disinfection wet tissue, which comprises a graphene spunlace non-woven fabric and a wet tissue liquid, and the wet tissue liquid comprises ultrapure water and isopropanol, wherein the ultrapure water accounts for 25%-60% of the weight of the wet tissue liquid, the isopropanol accounts for 40%-75% of the weight of the wet tissue liquid, and the viscose content of the graphene spunlace non-woven fabric is 10%-50%. According to the invention, because of strong permeability and sterilization and disinfection effects of isopropanol, the concentration of disinfection liquid can be reduced, a disinfectant does not need to be added, and the harm of chemical substances is avoided. The graphene has a sterilization effect, and three sterilization mechanismsof the graphene perform sterilization in a physical mode, so that the graphene has a very good sterilization effect on bacteria. The hygienic disinfection wet tissue does not contain irritant substances such as essence, does not have side effects on skin surface disinfection, has diverse uses, is convenient to carry and use, is rapid to volatilize without residues. The hygienic disinfection wet tissue of the invention has the advantages of simple production process, convenient operation and 99.9% of killing effect on Escherichia coli, Staphylococcus aureus, Candida albicans and the like.

Owner:QINGDAO DT NANO TECH CO LTD

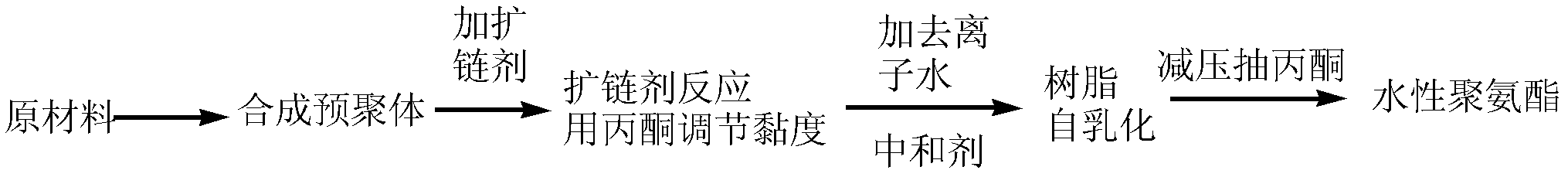

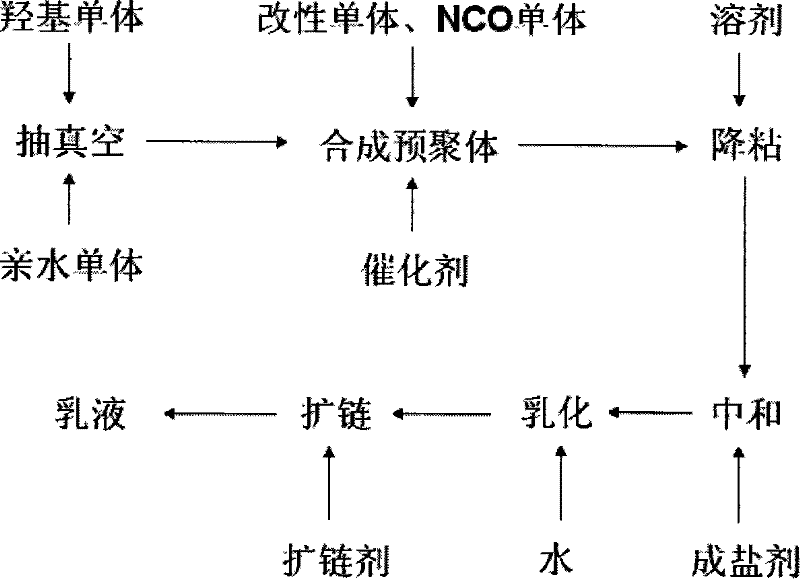

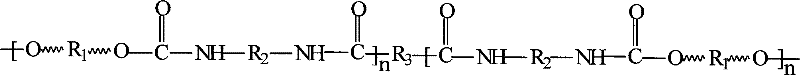

Preparation method of waterborne polyurethane adhesive and application in roads reflecting material

ActiveCN101284980BImprove performanceAdaptablePolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentHydrophilic monomerEpoxy

The invention relates to the nano-powder preparation field, in particular to a method for preparing nearly spherical nanometer oxide powder having good monodispersity and uniform particle size distribution with ultrasonic atomization. The method is characterized in that: the synthesis of water polyurethane is divided into three stages; a first stage is stepwise polymerization, i.e. polyurethane prepolymer is formed from oligomer polylol, hydrophilic monomers, modified monomers and isocyanate through stepwise polymerization; a second stage is the dispersion of the prepolymer in water after neutralization and salt formation; a third stage is the formation of water polyurethane emulsion after hydrophilic chain extender is added. The invention adopts a route of polymerizing modified monomers and polyurethane monomers jointly with different reaction mechanisms to ensure that modified monomers and polyurethane monomers are interpenetrated or grafted, thus obtained products have multiple material characteristics, i.e. the characteristics of acrylic acid, epoxy, hydroxyl silane and other materials are led into the products at the same time when the advantages of polyurethane material are maintained, so as to ensure that target products have stronger adaptability and better performance.

Owner:溧阳常大技术转移中心有限公司

Full-automatic cleaning machine transferring system for glass cover plate

PendingCN110193495AReduce distortionReduce the possibility of deformationFlexible article cleaningCleaning using liquidsTransport systemGlass cover

The invention discloses a full-automatic cleaning machine transferring system for a glass cover plate. The full-automatic cleaning machine transferring system for the glass cover plate comprises a mechanical arm and a carrying mechanism; the mechanical arm comprises a first cross beam, a second cross beam, a pickup assembly and a fixed connection piece connected between the first cross beam and the second cross beam; the carrying mechanism comprises a first carrying assembly and a second carrying assembly; the first carrying assembly comprises a first carrying guide rail and a first carrying part arranged on the first carrying guide rail; the first carrying part is used for moving in the direction of a horizontal axis along the first carrying guide rail; the second carrying assembly comprises a second carrying guide rail and a second carrying part arranged on the second carrying guide rail; the second carrying part is used for moving in the direction of a vertical axis along the secondcarrying guide rail; the second carrying guide rail is arranged on the first carrying part; the second cross beam is arranged on the second carrying part; and a first limiting switch is powered off after inducting that a movable segment rotates relative to a fixed segment. By utilizing the full-automatic cleaning machine transferring system for the glass cover plate, the operating stability of afull-automatic cleaning machine can be improved.

Owner:深圳市信濠光电科技股份有限公司

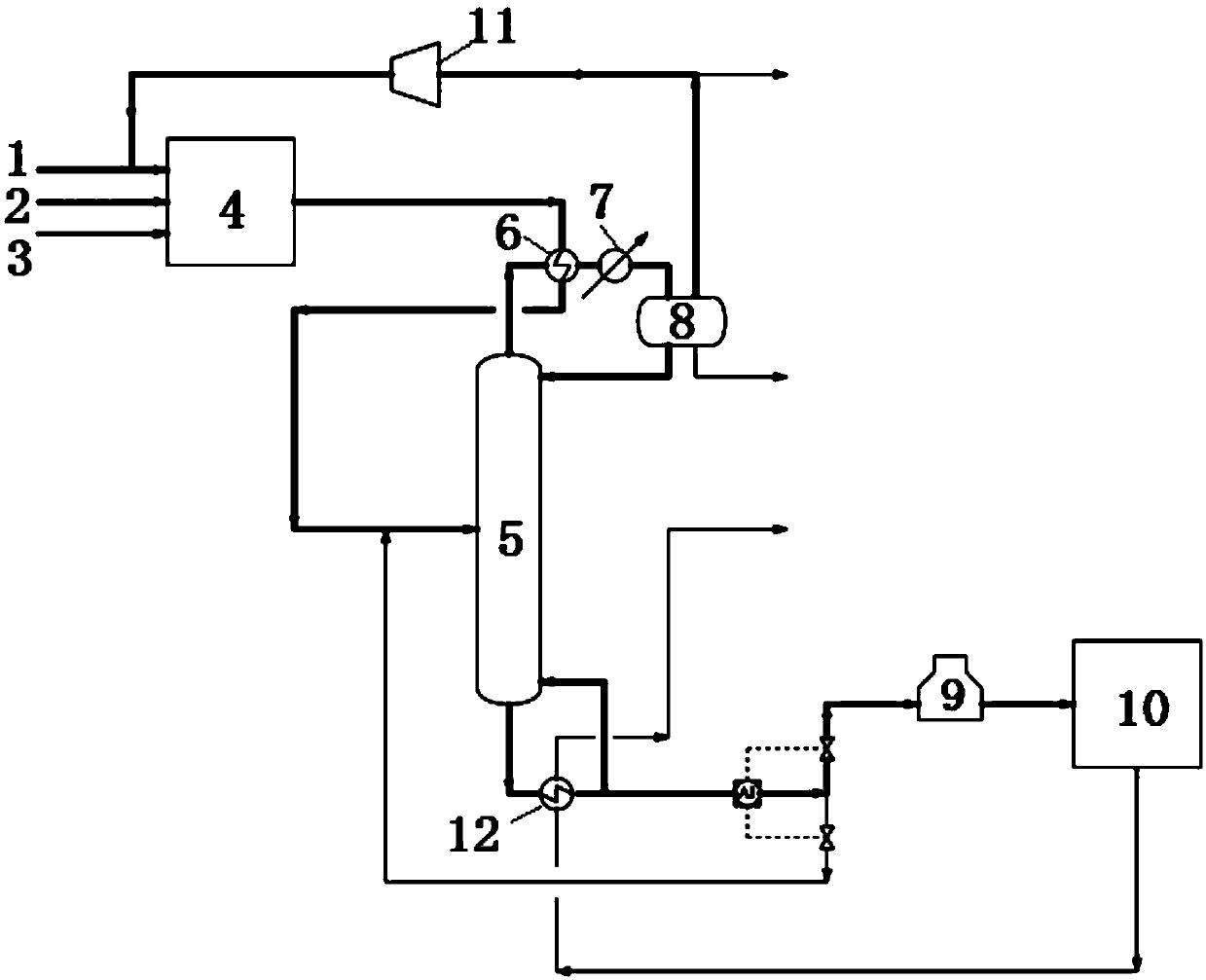

Low viscosity poly-alpha-olefin lubricant base oil, preparation method and system thereof

The invention relates to low viscosity poly alpha lubricant base oil, a preparation method and system thereof. The method comprises the following steps: (1) polymerizing a raw material containing alpha-olefin, a catalyst containing BF3 and reaction auxiliaries in a polymerization device to obtain a mixed product containing the BF3 catalyst, reaction auxiliaries and poly alpha-olefin; (2) feeding the mixed product in a gas-liquid separation device, heating to separate liquid and gas to obtain a gaseous product mainly comprising the BF3 catalyst and a liquid mainly comprising the poly alpha-olefin; and (3) returning at least part of the gaseous product to the polymerization device. The poly alpha-olefin with qualified content of F, prepared by the method can be used for continuously separating the BF3 catalyst in the poly alpha-olefin product, does not need manual intermittent discharging, no F-containing wastewater in the producing process, the BF3 catalyst can be recycled, and catalystwaste can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stamping control system and stamping method

The invention relates to a stamping control system and a stamping method. A manipulator and a stamping machine are controlled by virtue of one control system, and according to the control system, when the manipulator is located between an upper die surface and a lower die surface, an actual distance between the upper end surface of the tail end of the manipulator and the upper die surface is controlled to be greater than or equal to a safe distance, and the safe distance is 1 / 3 to 1 / 5 of a distance between the upper die surface and the lower die surface. The manipulator and the stamping machine stop running simultaneously as long as any of the manipulator and the stamping machine is failed, thus a risk in the traditional stamping control system is avoided that when any of the manipulator and the stamping machine is failed, the other one still runs, and at least the safe distance between the manipulator and the stamping machine can be ensured when the tail end of the manipulator is located between the upper die surface and the lower die surface; therefore, the safety of the manipulator and the stamping machine is further improved, and the occurrence probability of potential safety hazards of stamping control system production is reduced.

Owner:SHENZHEN TONGCHUAN TECH

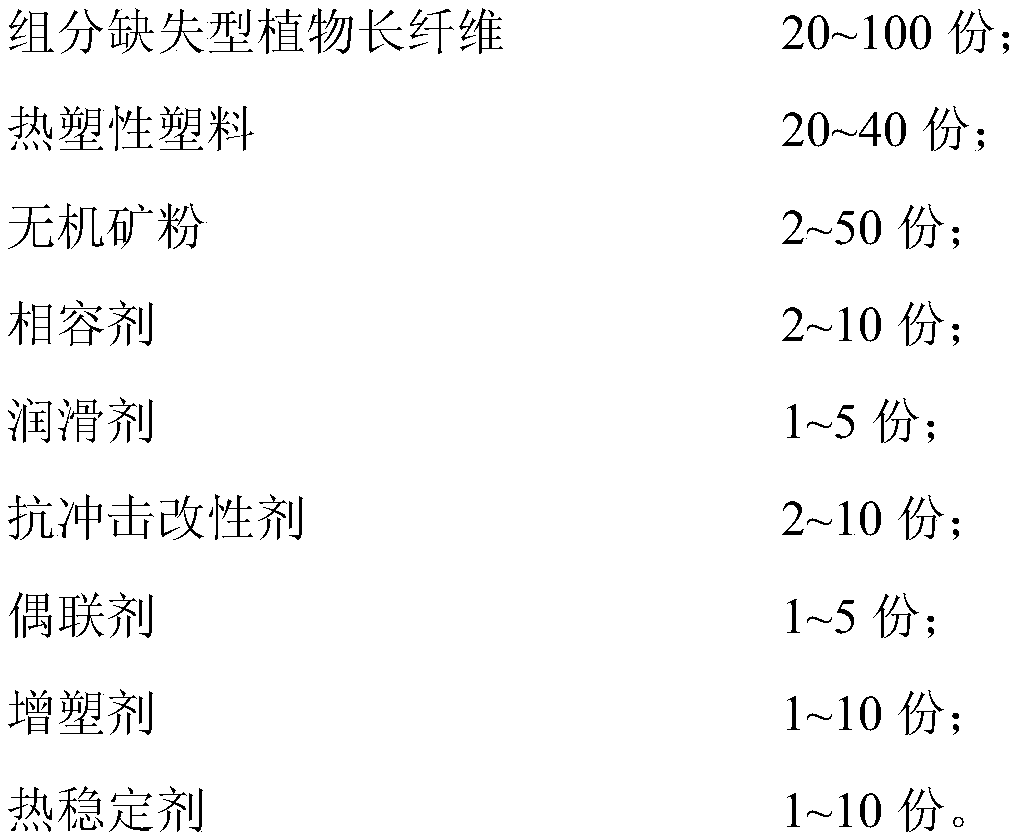

Component-deficient type plant long fiber, and preparation method and application thereof

ActiveCN108999007AImprove mechanical propertiesGood weather resistanceFilament/thread formingRaw material divisionFiberPlastics industry

The invention discloses a component-deficient type plant long fiber and a preparation method thereof. The preparation method comprises the following steps: crushing a wood fiber raw material, washingcrushed wood fiber with water, conveying washed crushed wood fiber, together with steam, into a double-screw extrusion thread-rolling machine, collecting a material, and carrying out a heat-preservingreaction; and after completion of the heat-preserving reaction, subjecting an obtained product to secondary washing with water so as to obtain the component-deficient type plant long fiber. Accordingto the invention, the component-deficient type plant long fiber can be effectively produced by mass; meanwhile, the plant long fiber is used to prepare a reinforced wood-plastic composite material, so environmental pollution in the production process is reduced; production safety hazards are reduced; and mechanical properties and weather resistance of the wood-plastic composite material are significantly improved; thus, the component-deficient type plant long fiber provided by the invention has positive significance on the whole wood-plastic industry.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD

Casting aluminum bar smelting device for aluminum profile production

PendingCN112361808AImprove heating efficiencyShorten melting timeStirring devicesCharge composition/stateEngineeringElectric drive

The invention provides a casting aluminum bar smelting device for aluminum profile production, and relates to the technical field of aluminum material smelting. The casting aluminum bar smelting device comprises a hot melt barrel; a supporting frame is of a frame structure, and a heat insulation outer barrel is connected into the top of the supporting frame; an external connecting opening is arranged at the rear side of the heat insulation outer barrel, and the right end of the heat insulation outer barrel is connected with a hand wheel; the hot melt barrel is connected to the interior of theheat insulation outer barrel, and a top connecting plate is arranged at the top of the hot melt barrel; a pneumatic motor is connected with the top end of a stirring shaft, the stirring shaft is located in the hot melt barrel, and the hot melt barrel is fixedly connected with the heat insulation outer barrel through bolts; and a handle is arranged at the top of a heat insulation sealing cover. According to the casting aluminum bar smelting device for the aluminum profile production provided by the invention, the pneumatic motor drives the stirring shaft to rotate and stirring blades at the bottom of the stirring shaft to fully stir molten aluminum in the hot melt barrel, so that a medicament added into the molten aluminum is fully mixed with the molten aluminum, the added medicament is uniformly mixed with the molten aluminum, the original electric drive is converted into pneumatic drive, and the device is simpler and more reliable.

Owner:徐思佳

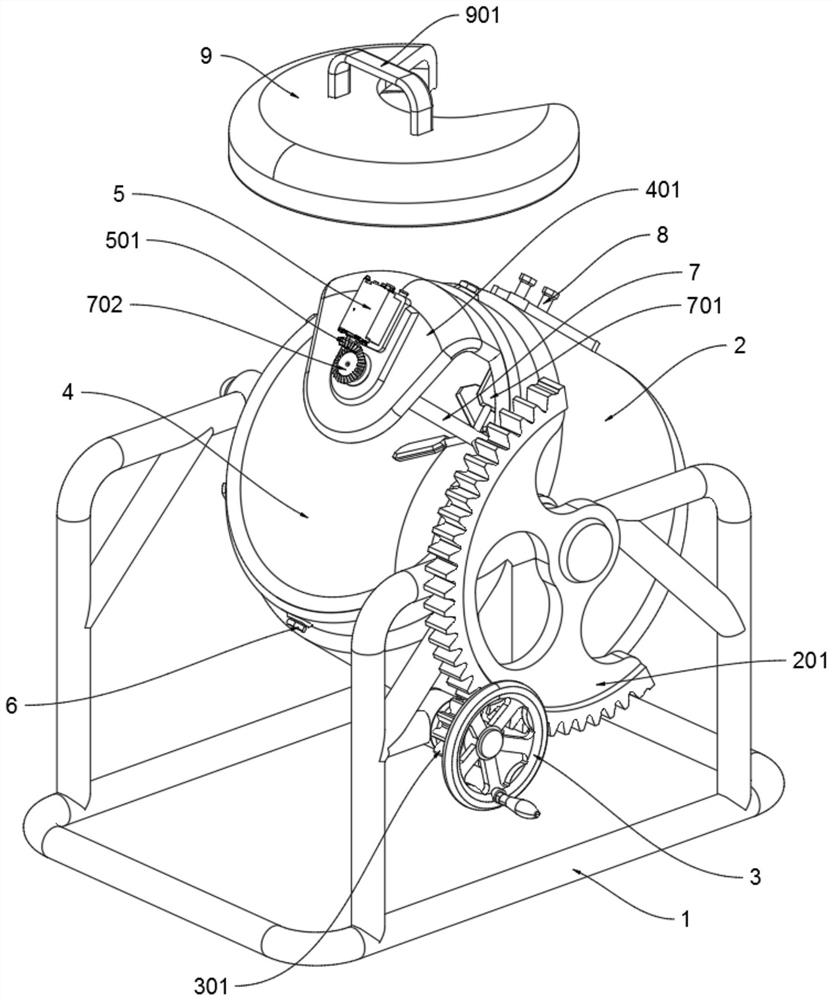

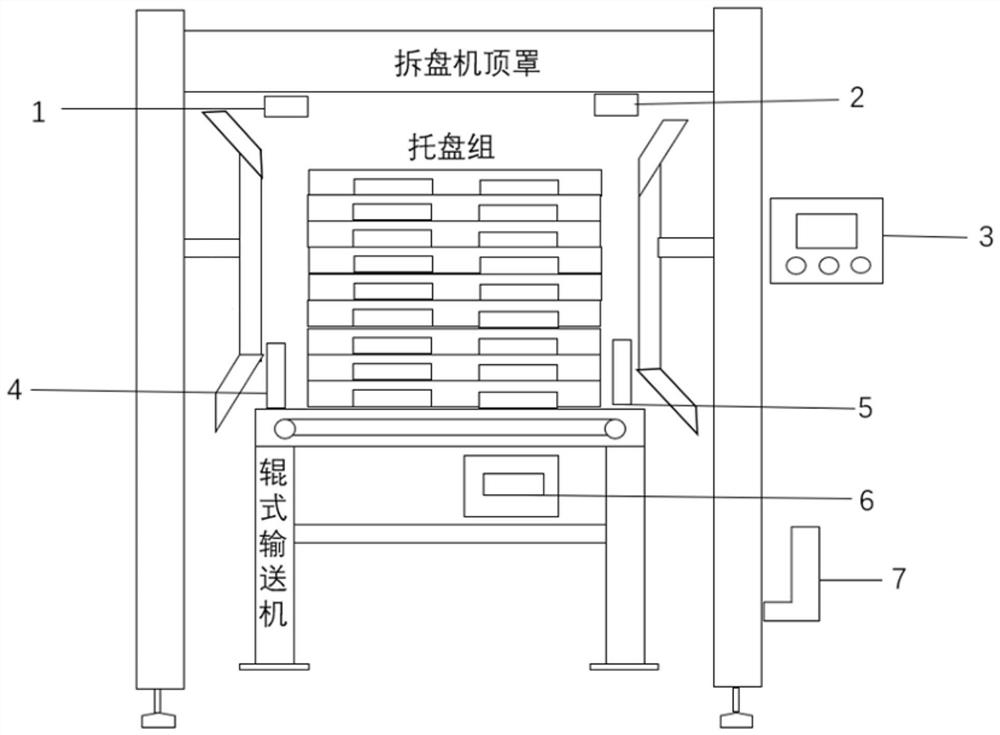

Tray group detection device of tray disassembling machine

PendingCN113998474AImprove work efficiencyReduce production safety hazardsConveyorsControl devices for conveyorsPhotoswitchEngineering

The invention provides a tray group detection device of a tray disassembling machine. The tray group detection device comprises a first reflecting plate, a second reflecting plate, a first diffuse reflection photoelectric switch, a second diffuse reflection photoelectric switch and a controller. The first reflecting plate is arranged on the left side of the tray disassembling machine top cover, and the second reflecting plate is arranged on the right side of the tray disassembling machine top cover. The first diffuse reflection optoelectronic switch is arranged on the left side of a roller type conveyor, corresponds to the first reflecting plate and is used for detecting the left side edge of a tray set on the roller type conveyor. The second diffuse reflection optoelectronic switch is arranged on the right side of the roller type conveyor and corresponds to the second reflecting plate, and the first diffuse reflection optoelectronic switch is used for detecting the right side edge of a tray set on the roller type conveyor. The controller judges whether the tray group on the roller conveyor is inclined leftwards or rightwards according to a photoelectric signal of the first diffuse reflection photoelectric switch or the second diffuse reflection photoelectric switch, and reports the appearance condition of the tray group. The working efficiency of the tray disassembling machine can be improved, and potential safety hazards of production are reduced.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com