Component-deficient type plant long fiber, and preparation method and application thereof

A missing-type, long-fiber technology, which is applied in the field of component-deficient plant long fibers and its preparation, can solve problems such as high cost, low production efficiency, and environmental hazards, improve weather resistance, reduce production safety hazards, and reduce environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

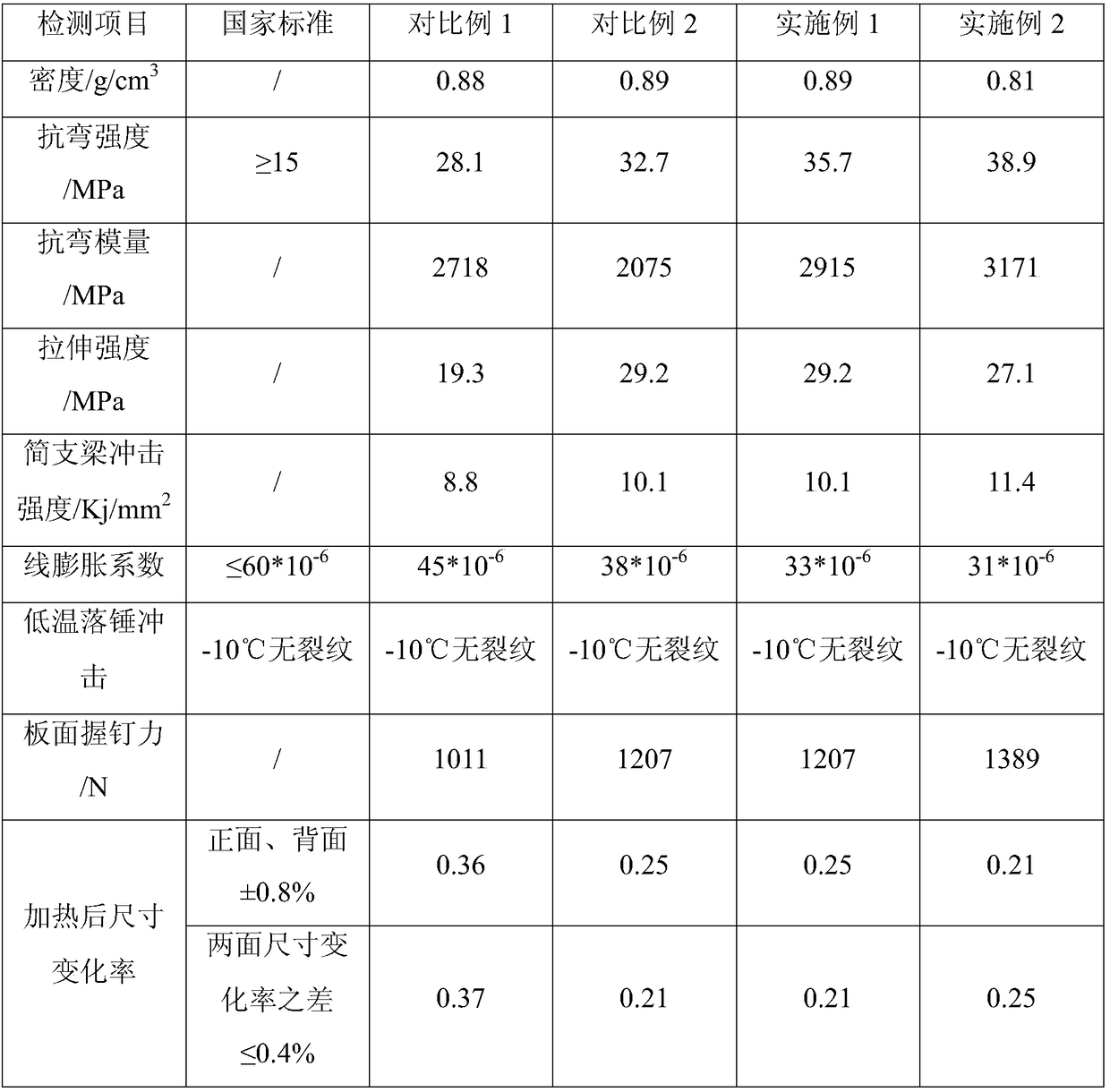

Examples

Embodiment 2

[0051] The preparation process is as follows:

[0052] (1) Pulverization: pulverize the wheat straw to obtain a length of 5-10 cm;

[0053] (2) Washing: the wheat straw obtained in step (1) is washed with hot water to remove dust and remove wax;

[0054] (3) Twin-screw dynamic extrusion to prepare long fibers: transport the wheat straw cleaned in step (2) to a twin-screw extrusion kneader, and simultaneously feed steam into the extruder to collect materials for heat preservation and reaction.

[0055] (4) Secondary water washing: washing the material obtained in step (3) to elute components such as hemicellulose and polysaccharide dissociated in step (3).

[0056] (5) Dehydration: Extrude and dehydrate the material after the secondary washing to reduce the moisture to 30%;

[0057] (6) Drying: dry the dehydrated material to make the plant fiber homogeneous and fluffy, and the water content is reduced to 3%wt, wherein the proportion of cellulose is 47%, the proportion of hemi...

Embodiment 1

[0062] The preparation process is as follows:

[0063] (1) Pulverization: pulverize the wheat straw to obtain a length of 5-10 cm;

[0064] (2) Washing: the wheat straw obtained in step (1) is washed with hot water to remove dust and remove wax;

[0065] (3) Twin-screw dynamic extrusion to prepare long fibers: transport the wheat straw cleaned in step (2) to a twin-screw extrusion kneader, and simultaneously feed steam into the extruder to collect materials for heat preservation and reaction.

[0066] (4) Secondary water washing: washing the material obtained in step (3) to elute components such as hemicellulose and polysaccharide dissociated in step (3).

[0067] (5) Dehydration: Extrude and dehydrate the material after the secondary washing to reduce the moisture to 30%;

[0068] (6) Drying: dry the dehydrated material to make the plant fiber homogeneous and fluffy, and the water content is reduced to 3%wt, wherein the proportion of cellulose is 47%, the proportion of hemi...

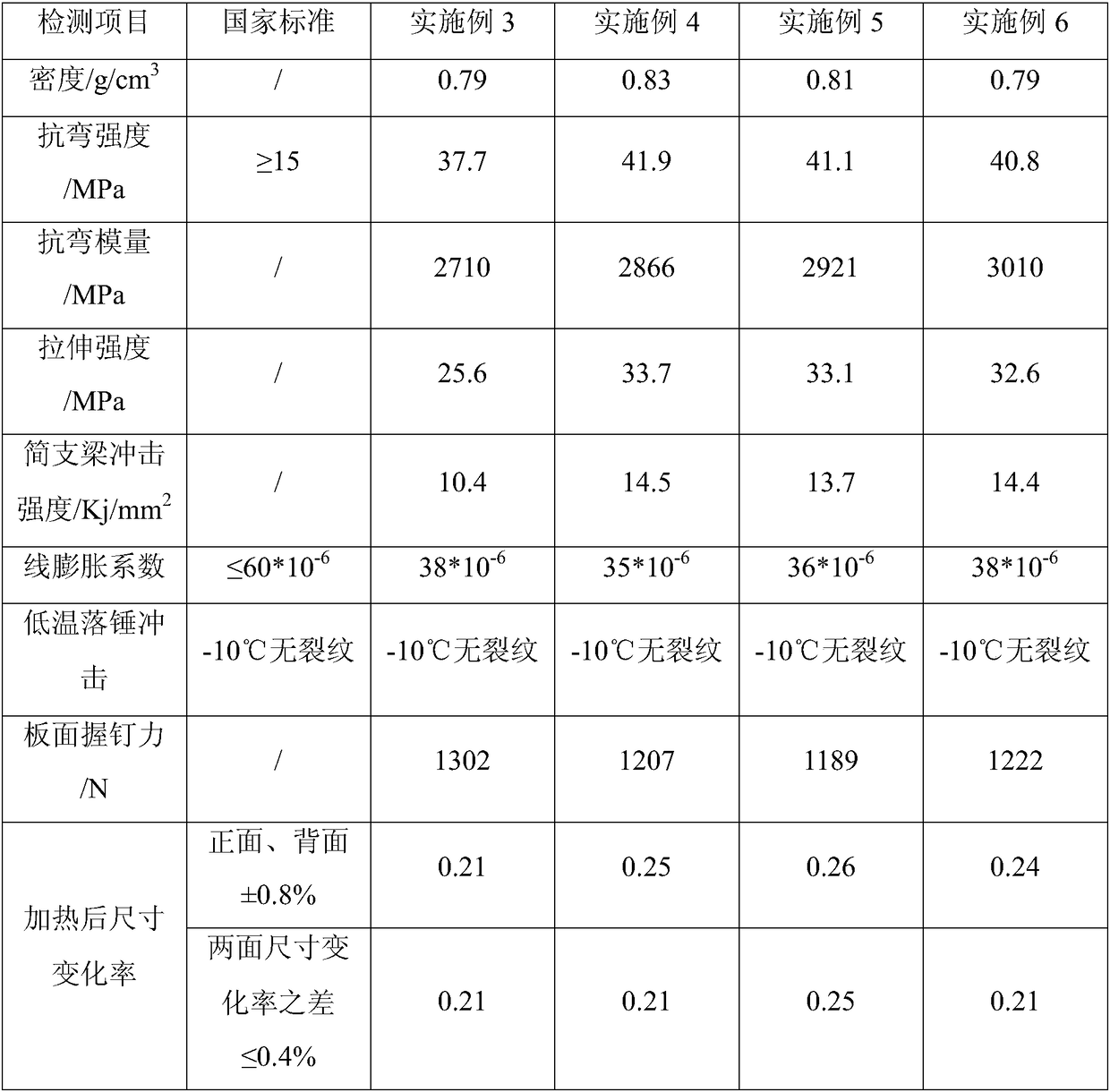

Embodiment 3

[0082] The preparation process is as follows:

[0083] (1) Pulverization: pulverize the wheat straw to obtain a length of 5-10 cm;

[0084] (2) Washing: the wheat straw obtained in step (1) is washed with hot water to remove dust and remove wax;

[0085] (3) twin-screw dynamic extrusion to prepare long fibers: the wheat straw after step (2) cleaning is transported in the twin-screw extrusion kneading machine, and sodium hydroxide solution (2% w / w) is passed into the extruder at the same time ), collect materials and keep warm for reaction.

[0086] (4) Secondary water washing: washing the material obtained in step (3) to elute components such as lignin and a small amount of hemicellulose dissociated in step (3).

[0087] (5) Dehydration: Extrude and dehydrate the material after the secondary washing to reduce the moisture to 30%;

[0088] (6) Drying: dry the dehydrated material to make the plant fiber homogeneous and fluffy, and the water content is reduced to 3%wt, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com