Side push plate device of cold rolling copper belt recoiling machine

A side push plate and copper strip roll technology, applied in the field of side push plate devices, can solve the problems of the guide plate being easily damaged by impact, high accident rate, and reduced service life, so as to reduce production safety hazards, shorten maintenance time, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

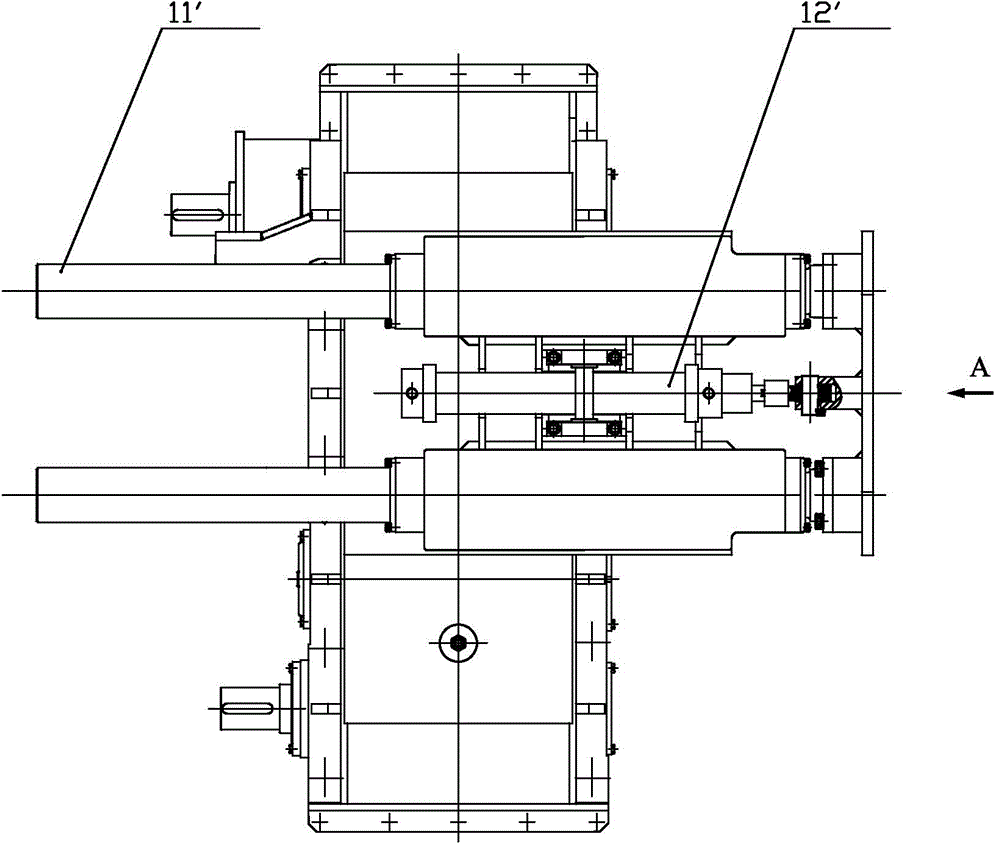

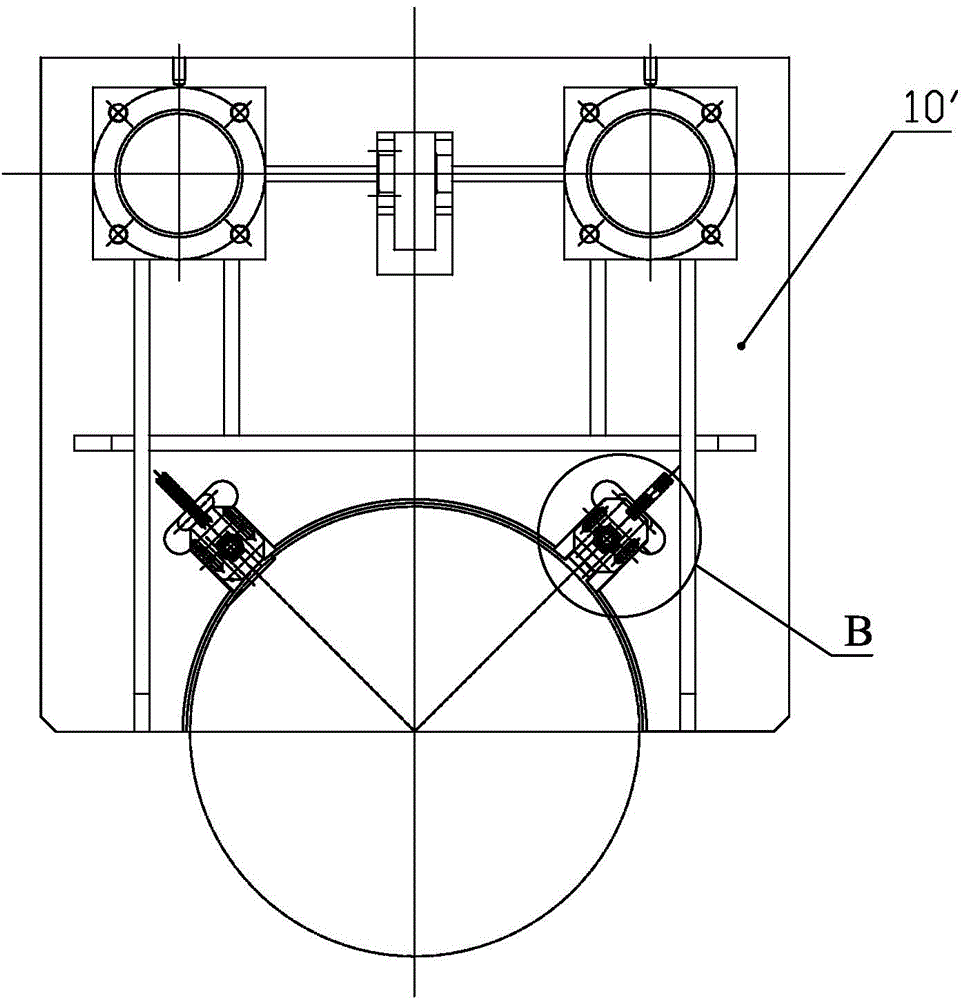

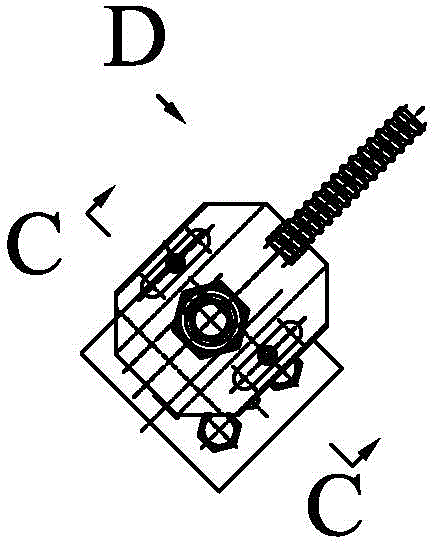

[0038] Such as Figure 6-Figure 12As shown, a side push plate device of a cold-rolled copper strip coiler includes a side push plate frame body 1, a guide rod 2, a hydraulic cylinder 3 and a reel 4, and the side push plate frame body 1 is provided with a pneumatic valve 5. The pneumatic valve 5 includes a cylindrical valve cavity 501 vertically fixed on the rear end of the side push plate frame body 1, a cylindrical valve core 502 located in the valve cavity 501 and fixed on the The control panel 503 at the front end of the spool 502; a sealing ring group 508 is provided between the spool 502 and the valve cavity 501, and the sealing ring group is composed of six sealing rings, and a sealing ring can also be added appropriately according to specific conditions. The number of groups of rings, the side push plate frame body 1 is provided with a through hole 512 for the valve core 502 to pass through, and an elastic support part is also provided between the control board 503 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com