Full-automatic assembly line for rotating disc type button switch conductive system

A turntable, fully automatic technology, applied in the direction of electric switches, circuits, assembly machines, etc., can solve the problems of low automation, low production efficiency, low product quality, etc., and achieve high automation, high efficiency, and low equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The assembly body of the device of the present invention is the b cover and the c cover which have basically the same structure, and the assembly objects of the device of the present invention are the upper contact piece 224 and the lower contact piece 225 .

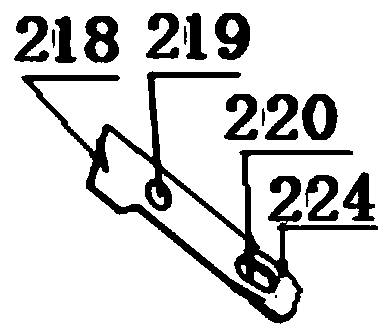

[0030] Such as Figure 1a , One side of the upper contact piece 224 is provided with a bottom plate surface one 218, and a mounting hole one 219 (for installing a self-tapping screw 235) is provided near the bottom plate surface one 218, and the other side of the upper contact piece 224 is called a bent edge one 220.

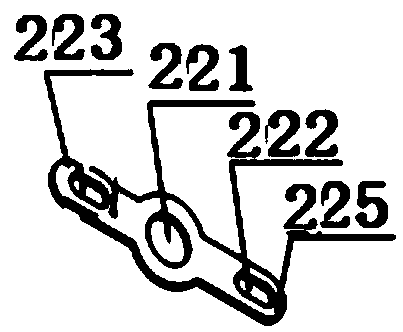

[0031] Such as Figure 1b , the second mounting hole 221 (for installing another self-tapping screw 235) is provided at the middle position of the lower contact piece 225, and the two sides of the second mounting hole 221 of the lower contact piece 225 are respectively called the second floor surface 222 and the second bending edge 223.

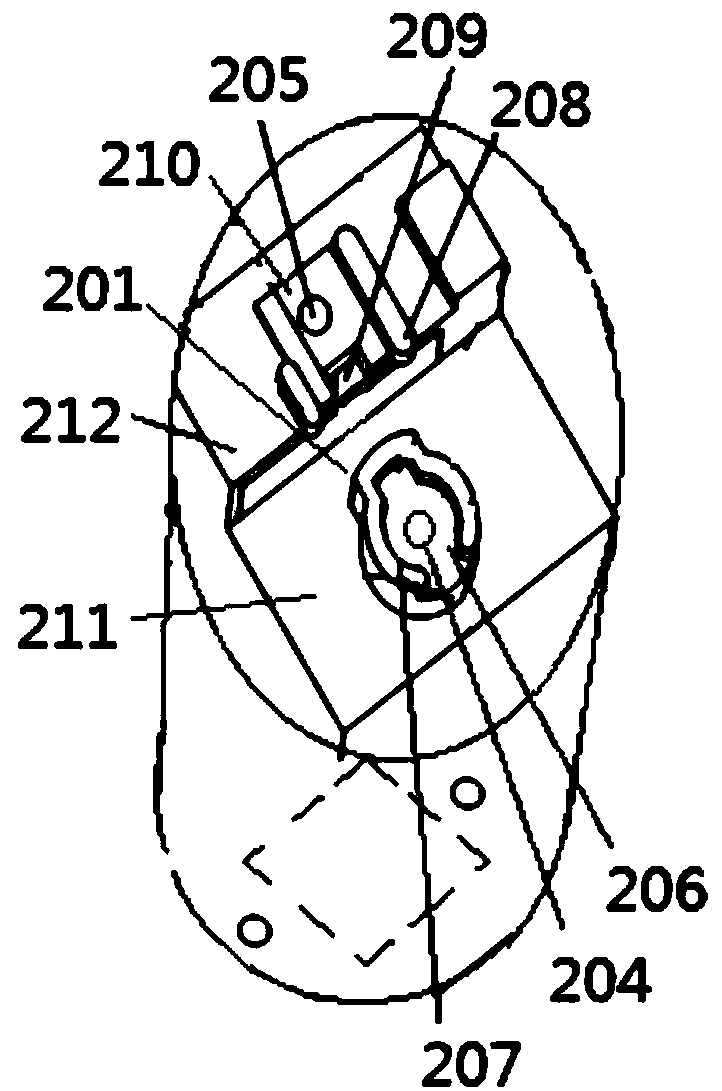

[0032] Such as Figure 1c, the main body of the b cover is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com