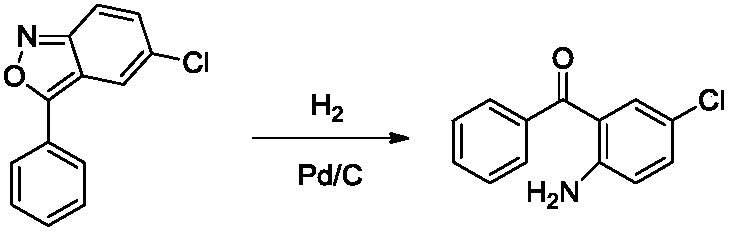

Method for synthesizing 2-amino-5-chlorobenzophenone by microchannel reactor

A technology of microchannel reactor and chlorobenzophenone, which is applied in chemical instruments and methods, chemical/physical/physical chemical reactors, preparation of organic compounds, etc., can solve the problems of long reaction time, low times of catalyst recovery and mechanical application, etc. Violent explosion and other problems, to achieve the effect of improving recycling efficiency, increasing intrinsic reaction speed, and reducing degradation impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The method that embodiment 1. microchannel reactor synthesizes 2-amino-5 chlorobenzophenones.

[0035] 1) Weigh 150 g of the raw material 5-chloro-3-phenyl-2,1-benzisoxazole, add 1.2 L of anhydrous methanol and 1.2 L of tetrahydrofuran, stir and dissolve, then add 5 g of Pt / Pt with a Pt content of 5%. C catalyst, fully stirred and mixed to form material I, adjust the flow rate of the slurry pump so that the flow rate of material I is 45.0g / min, and enter the preheating module of the microreactor.

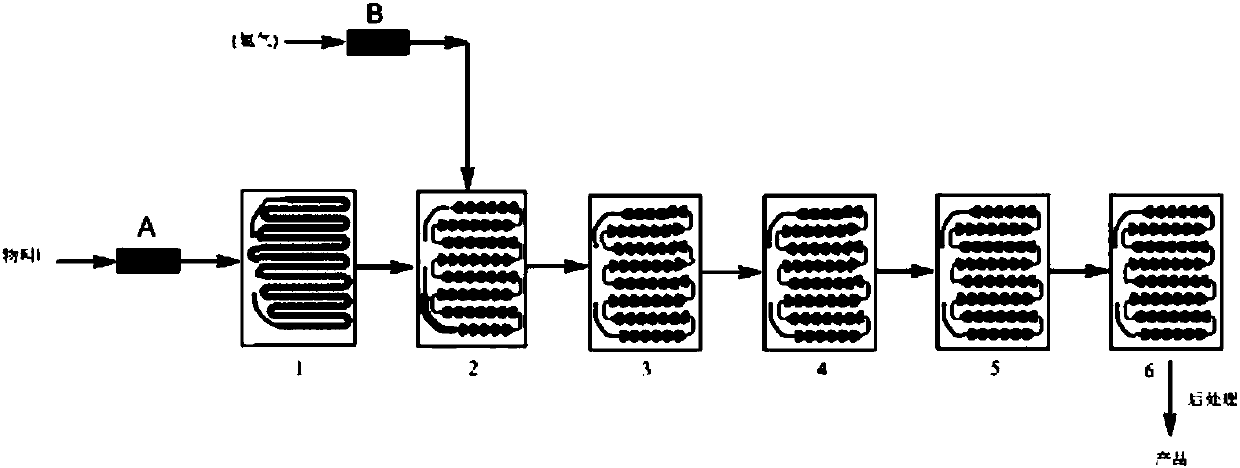

[0036] 2) Regulating H 2 The flow rate of the gas flow meter is 400ml / min, and directly enters the reaction module group without preheating to generate catalytic hydrogenation reaction with material I, such as figure 2 As shown, the molar ratio of 5-chloro-3-phenyl-2,1-benzisoxazole to hydrogen is 1:1.2, the reaction temperature is 50°C, the residence time of the reaction is 30s, and the reaction pressure is 1.5Mpa; Then enter the cooling module, the temperature of the cooli...

Embodiment 2

[0037] The method of embodiment 2. microchannel reactor synthesis 2-amino-5 chlorobenzophenones.

[0038] 1) Weigh 180 g of raw material 5-chloro-3-phenyl-2,1-benzisoxazole, add 1.5 L of absolute ethanol and 1.5 L of ethyl acetate, stir and dissolve, add 9 g of Pd content of 10% Pd / C catalyst, fully stirred and mixed to form material I, adjust the flow rate of the slurry pump so that the flow rate of material I is 42.0g / min, and enter the preheating module of the microreactor.

[0039] 2) Regulating H 2 The flow rate of the gas flow meter is 350ml / min, directly enters the reaction module group without preheating and the catalytic hydrogenation reaction occurs with the material I, such as figure 2 As shown, the molar ratio of 5-chloro-3-phenyl-2,1-benzisoxazole to hydrogen is 1:1.1, the reaction temperature is 80°C, the residence time of the reaction is 32s, and the reaction pressure is 1.2Mpa; Then enter the cooling module, the temperature of the cooling module is 20°C, col...

Embodiment 3

[0040] The method of embodiment 3. microchannel reactor synthesis 2-amino-5 chlorobenzophenones.

[0041] 1) Weigh 200 g of raw material 5-chloro-3-phenyl-2,1-benzisoxazole, add 1.5 L of anhydrous methanol and 1.5 L of tetrahydrofuran, stir and dissolve, add 20 g of Pd / Pd with a Pd content of 3%. C catalyst, fully stirred and mixed to form material I, adjust the flow rate of the slurry pump so that the flow rate of material I is 40.0g / min, and enter the preheating module of the microreactor.

[0042] 2) Regulating H 2 The flow rate of the gas flow meter is 500ml / min, and directly enters the reaction module group without preheating to generate catalytic hydrogenation reaction with material I, such as figure 2 As shown, the molar ratio of 5-chloro-3-phenyl-2,1-benzisoxazole to hydrogen is 1:1.5, the reaction temperature is 90°C, the residence time of the reaction is 40s, and the reaction pressure is 0.6Mpa; Then enter the cooling module, the temperature of the cooling module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com