Water-based double-component light-cured polyurethane resin and preparation method thereof

A polyurethane resin, water-based two-component technology, applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesive types, etc., can solve hidden safety hazards in the production process, cumbersome preparation process, increase production costs, etc. problems, to achieve the effects of reducing production safety hazards, simple preparation process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

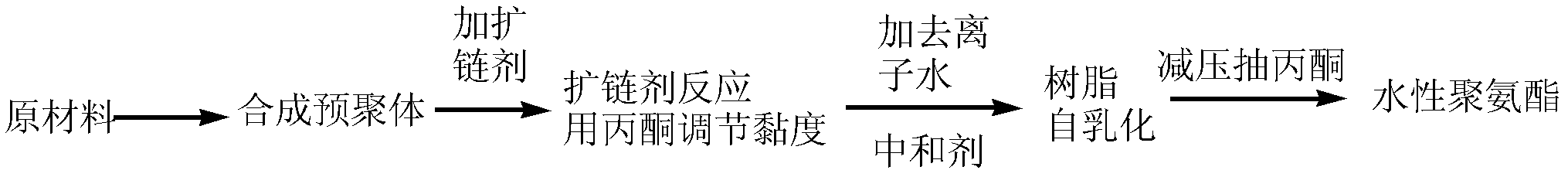

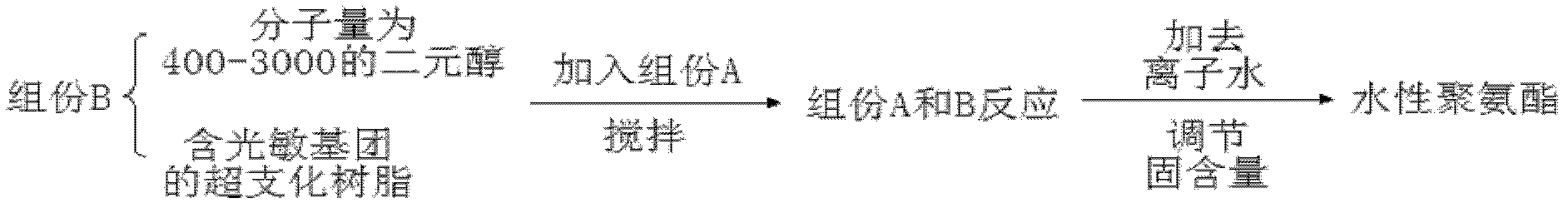

Method used

Image

Examples

Embodiment 1

[0038] 1) Add 6g of trimethylolpropane into a 250ml three-neck flask with stirring, nitrogen inlet and outlet, then add 0.3g of p-toluenesulfonic acid catalyst, under the protection of nitrogen, heat to 140°C and slowly add 54g of dihydroxy Methyl propionic acid, and stirred for 1 hour, stop nitrogen flow, vacuumize (vacuum degree is 400 Pa), and continue to react for 2 hours to obtain a hydroxyl-terminated hyperbranched polymer.

[0039] 2) After cooling the hydroxyl-terminated hyperbranched polymer obtained in step 1 to 90°C, add 42g of maleic anhydride and 30g of acetone as a solvent. The reaction process was tracked by the acid value titration method. When the acid value of the solution became about half of the initial value and did not decrease with time, the reaction was stopped to obtain a carboxyl-terminated hyperbranched polymer.

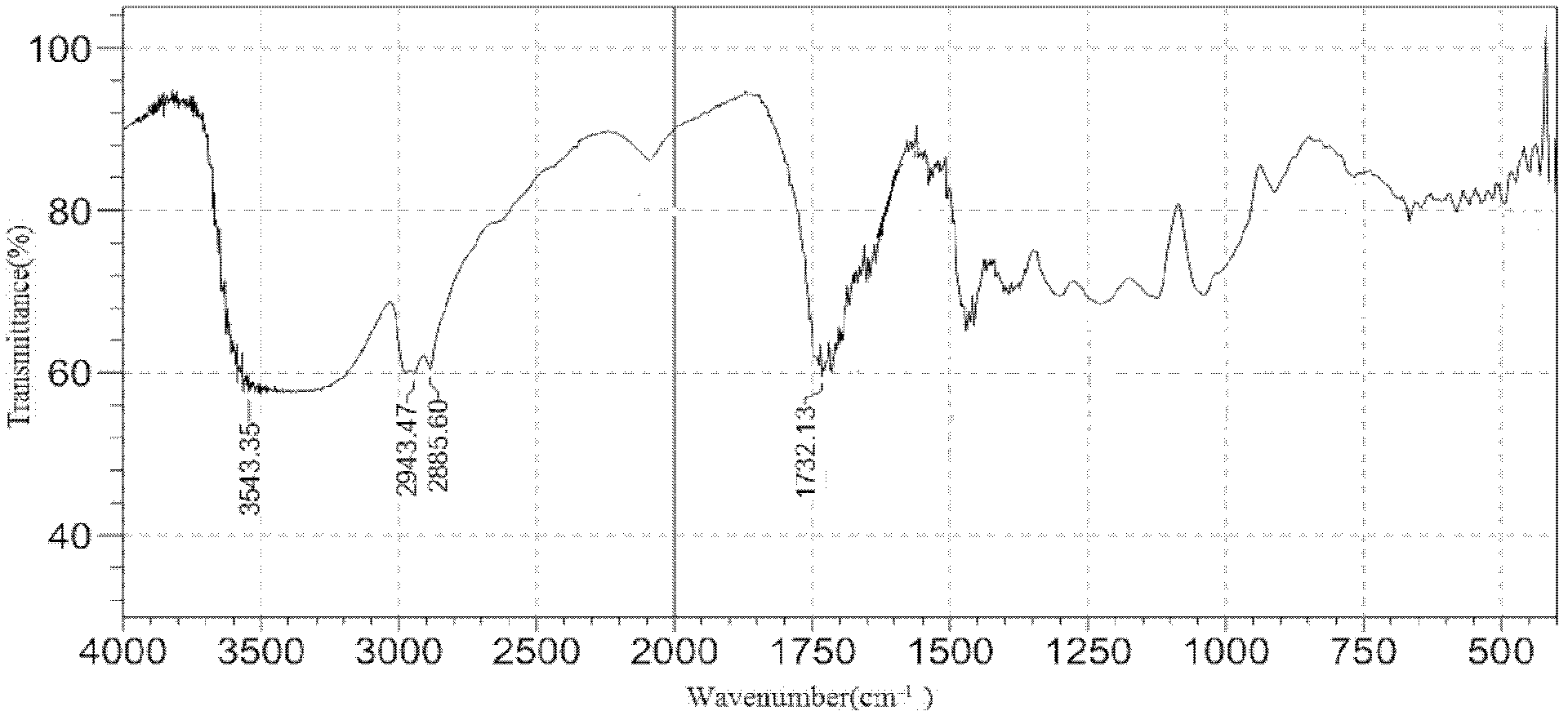

[0040] 3) Raise the temperature of the carboxyl-terminated hyperbranched polymer obtained in step 2) to 105°C, then add 8g of glycidyl met...

Embodiment 2

[0046] Do not change other conditions in example 1, only change 8g glycidyl methacrylate to 16g glycidyl methacrylate, can obtain solid content and be the aqueous photocurable polyurethane resin of 40 Wt.%, wherein photosensitive group content increases to 0.34 mmol / g.

Embodiment 3

[0048] Without changing the other conditions in Example 1, only 10 g of polyethylene glycol (molecular weight 1000) is replaced by 20 g of polyethylene glycol (molecular weight 2000), and a water-based photocurable polyurethane resin with a solid content of 42Wt.% can be obtained, in which the soft chain The segment content increases, and the flexibility of the film-forming material increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com