Mechanical arm driven in compound manner

A robotic arm and composite technology, applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of potential safety hazards, large space occupation, and production space occupation, so as to increase the stroke range, improve production efficiency, and improve operation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

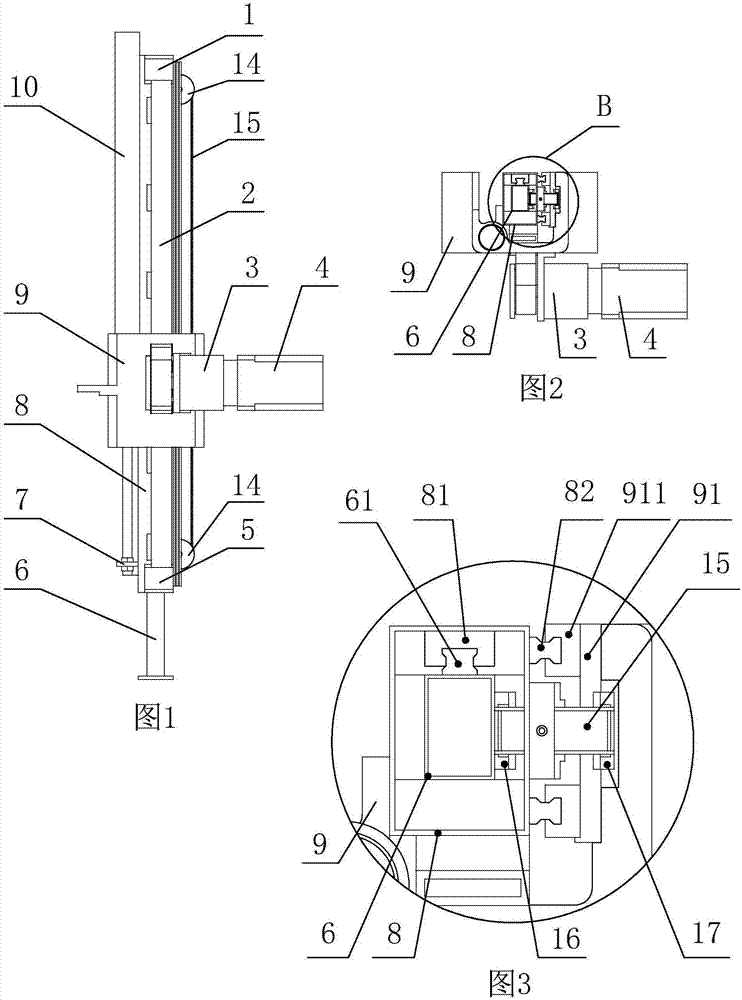

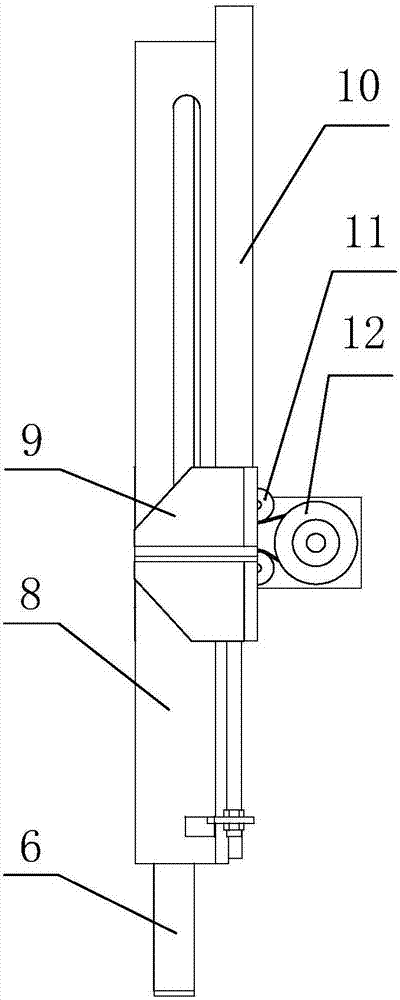

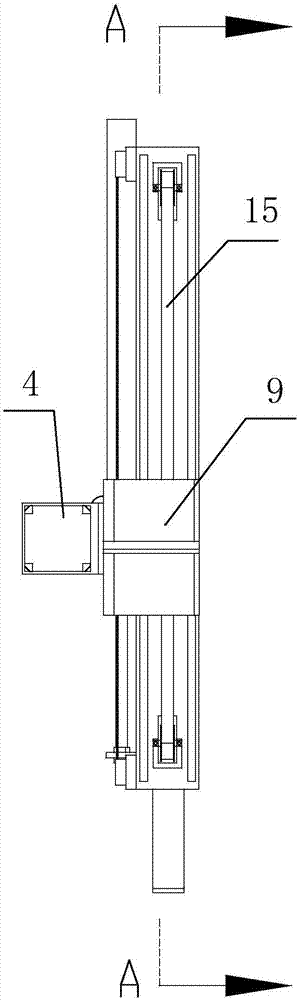

[0028] A mechanical arm with compound transmission, including a double sliding arm and a driving device, the double sliding arm includes an outer sliding arm and an inner sliding arm nested in the outer sliding arm and slidingly connected with the outer sliding arm, the outer sliding arm includes Outer profile 8, the outer profile is a rectangular long frame tube, the inner side of the outer profile is provided with a slide block 81, the outer side of the outer profile is provided with a slide rail 82, and the outer profile is fixed on the machine base through the slide rail 82 on the outer side The slide rail seat 9 on the body is slidably connected, the inner slide arm includes the inner profile 6, and the outer surface of the inner profile is provided with a slide rail 61, and the inner profile slides and cooperates with the outer profile through the slide rail on the outer surface and the slider on the inner surface of the outer profile ;

[0029] The driving device is a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com