Elastic expansion module and lifting device using the same

A technology of elastic telescopic and lifting devices, which is applied in the direction of machines/supports, supporting machines, mechanical equipment, etc., and can solve the problems of bulky overall, shortened service life, and inability to make thinner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

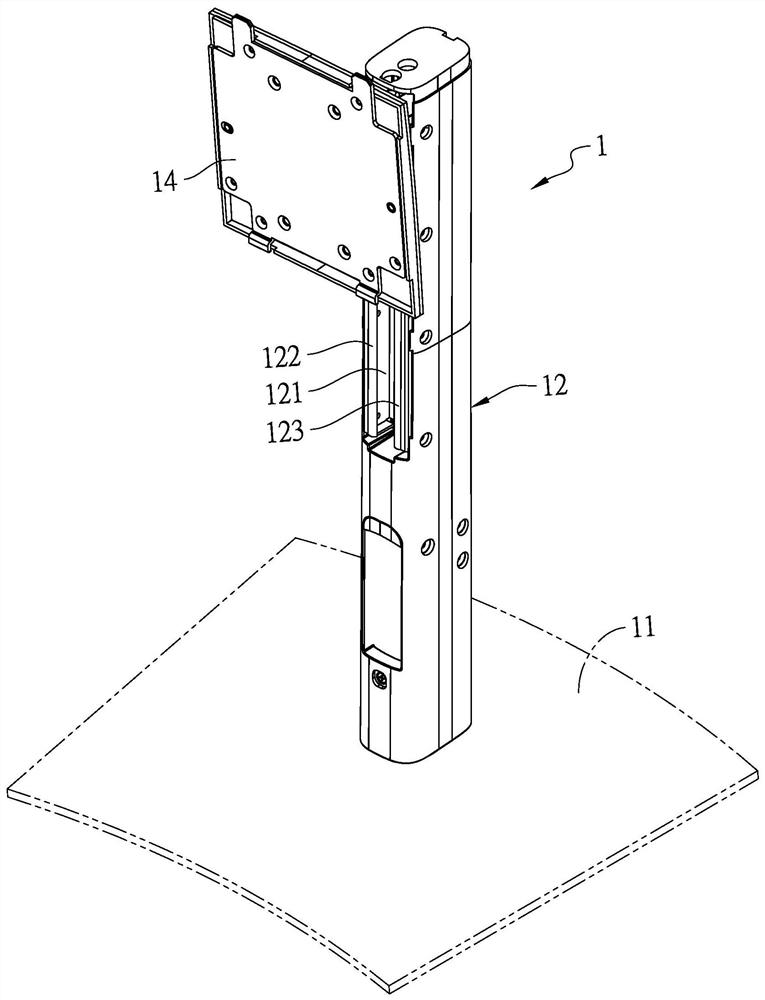

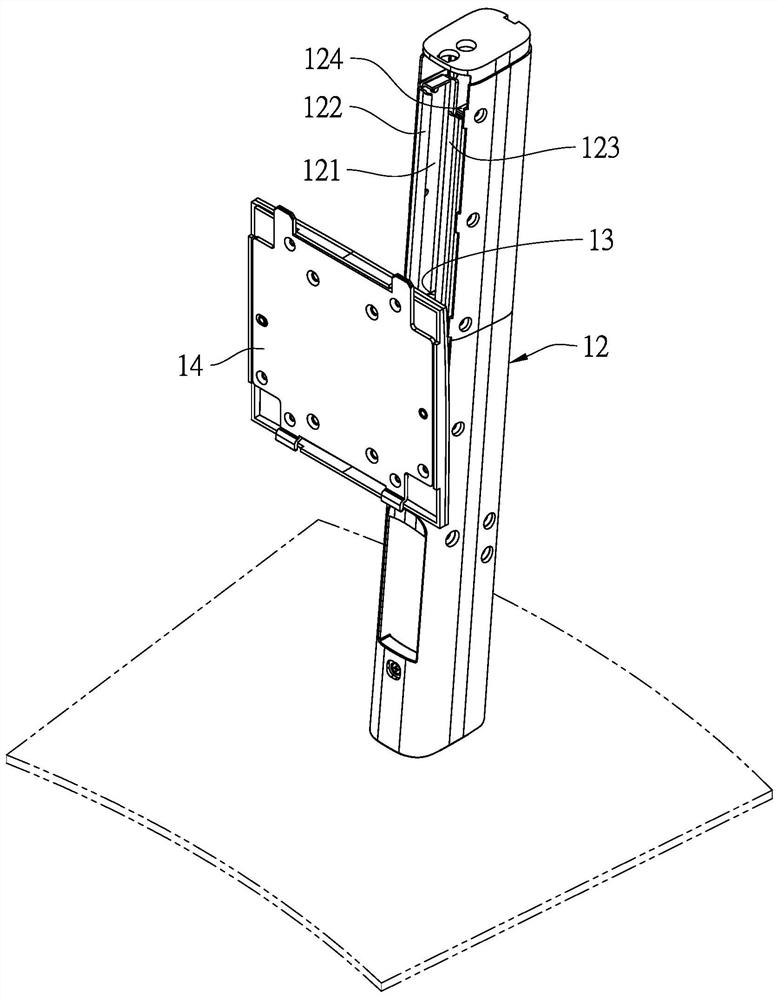

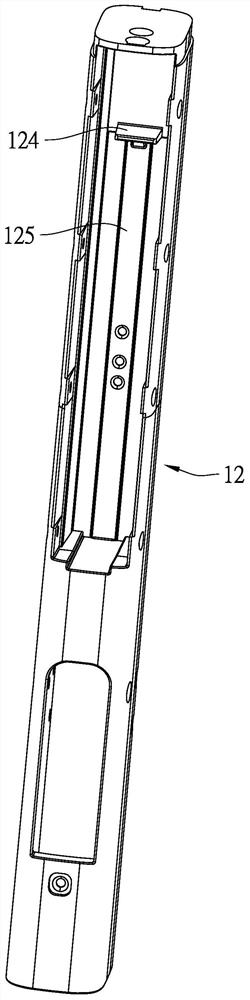

[0063] see Figure 1 to Figure 8 As shown, it is a preferred embodiment of the lifting device 1 of the present invention, including a base 11 , a bracket 12 , an adapter 13 and an elastic expansion module 2 . Among them, the base 11 is for placing on the desktop; the bottom surface of the bracket 12 is connected with the top surface of the base 11, so that the long and straight support 12 is erected to form a standing posture on the base 11, and one side of the support 12 is concave to form a The elongated limiting slot 121 is used to connect one end of the elastic expansion and contraction module 2 (the other end of the second frame body 4 and the other end of the coil spring of the second constant force spring 6 ) and its opposite end (the first frame body 3 and the first The other end of the constant force spring 5 (coil spring portion) can be mutually clutched with each other, and the opposite end of the elastic expansion and contraction module 2 is positioned on the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com