Method for manufacturing environmentally-friendly polyurethane elastomer conveying belt and aqueous adhesive therein

A technology of polyurethane elastomer and production method, which is applied in polyurea/polyurethane adhesives, adhesives, conveyors, etc., can solve the problems of human injury, volatile, strong odor, etc., and reduce production safety hazards and flex fatigue Less damage and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

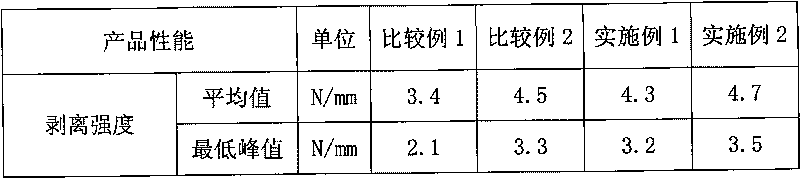

Embodiment 1

[0034] First, mix 100g of water-based polyurethane, 2g of thickener and 0.5g of defoamer in the water-based adhesive component, and then add 1g of cross-linking agent and stir well within 2 hours before going on the coating machine to make the water-based adhesive component.

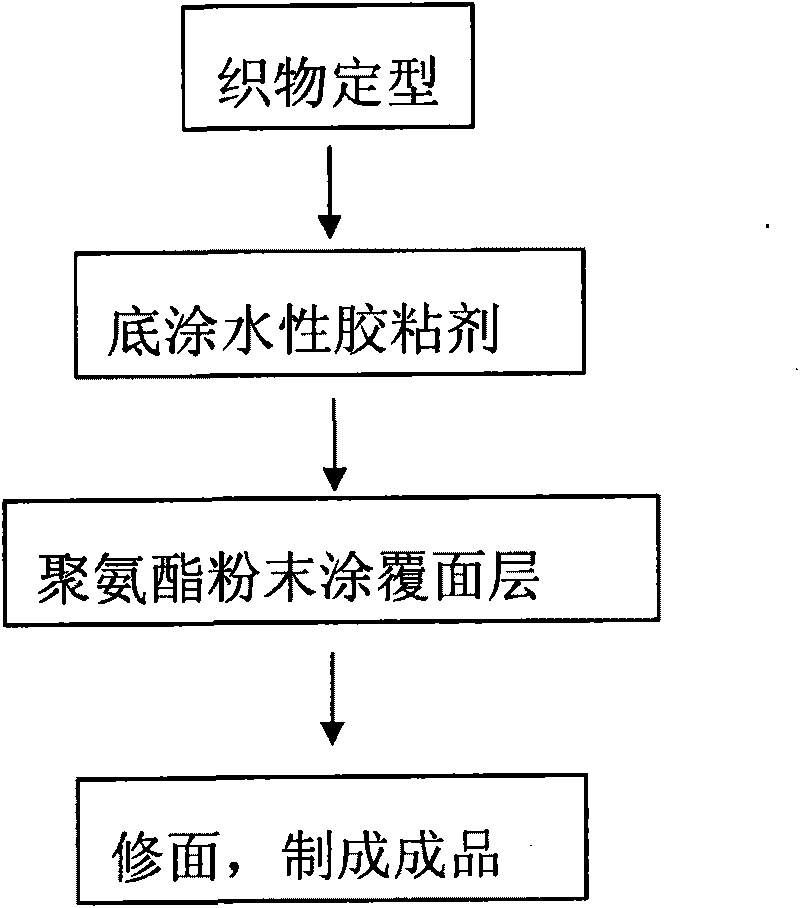

[0035] see figure 1 As shown, the production method of the environment-friendly polyurethane elastomer conveyor belt of the present invention adopts a coating process, and utilizes an oven heating method to produce, and the production process includes the following steps in sequence:

[0036] The first step: the polyester fabric core is heated and dried in the oven of the production line, and the fabric is stentered;

[0037] The second step: the shaped fabric is coated with a water-based adhesive by a coating machine, and then dried in an oven;

[0038] Step 3: Coat the surface layer (polyurethane powder) with a coating machine knife, and then enter the oven for heating and melting;

[0039] Step 4: P...

Embodiment 2

[0041] Other formulations and production processes are the same as in Example 1, except that the amount of cross-linking agent is different, and the cross-linking agent is 2 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com