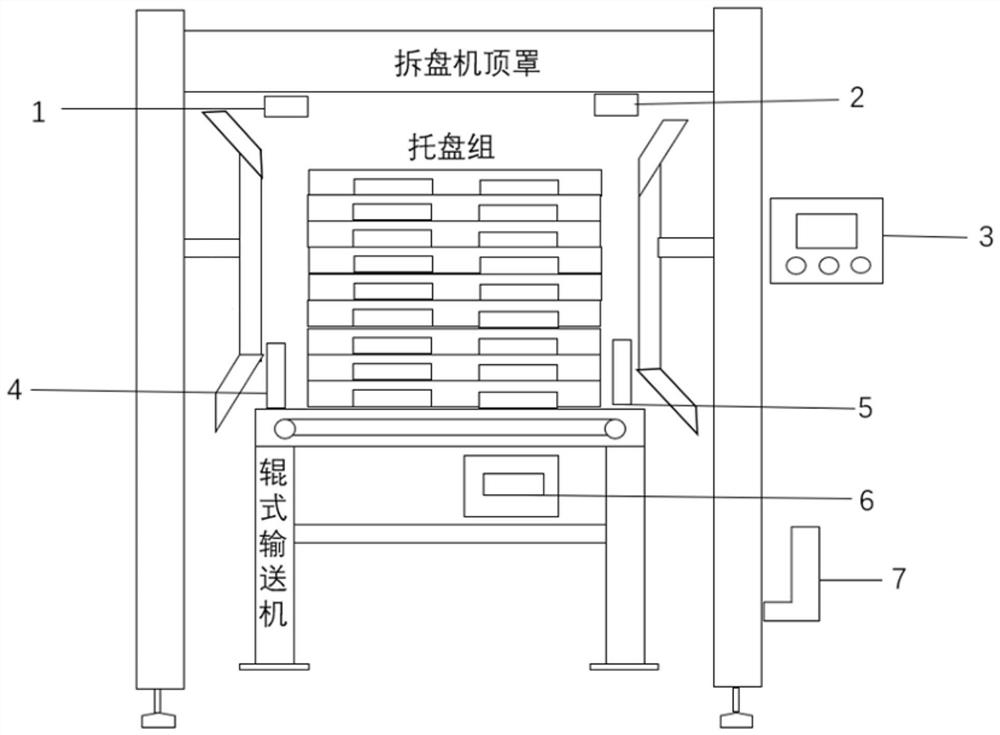

Tray group detection device of tray disassembling machine

A detection device and unpacking machine technology, which is applied to conveyor control devices, conveyors, and unstacking of objects, can solve problems such as damage, irregular stacking of pallet groups, and confusion, so as to improve work efficiency and reduce production The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

[0031] Aiming at the inaccurate detection of the appearance of the tray group currently transported to the detacher, it is easy to cause confusion and damage. The invention provides a tray group detection device for a disc unpacking machine. The diffuse reflection photoelectric switch is arranged on the left and right sides of the roller conveyor, and the reflective plate is correspondingly arranged on the disc unpacking machine cover. The signal judges whether there is a left or right inclination of the tray group, which solves the problem that the existing tray groups delivered to the detacher machine are not stacked in a standardized way, which is easy to cause confusion and damage, can improve the work effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com