Auxiliary mounting device for building construction

An installation device and building construction technology, which can be used in construction, building structure, and building material processing, etc., and can solve problems such as worker fatigue, hidden safety hazards, and dangers of high-altitude operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

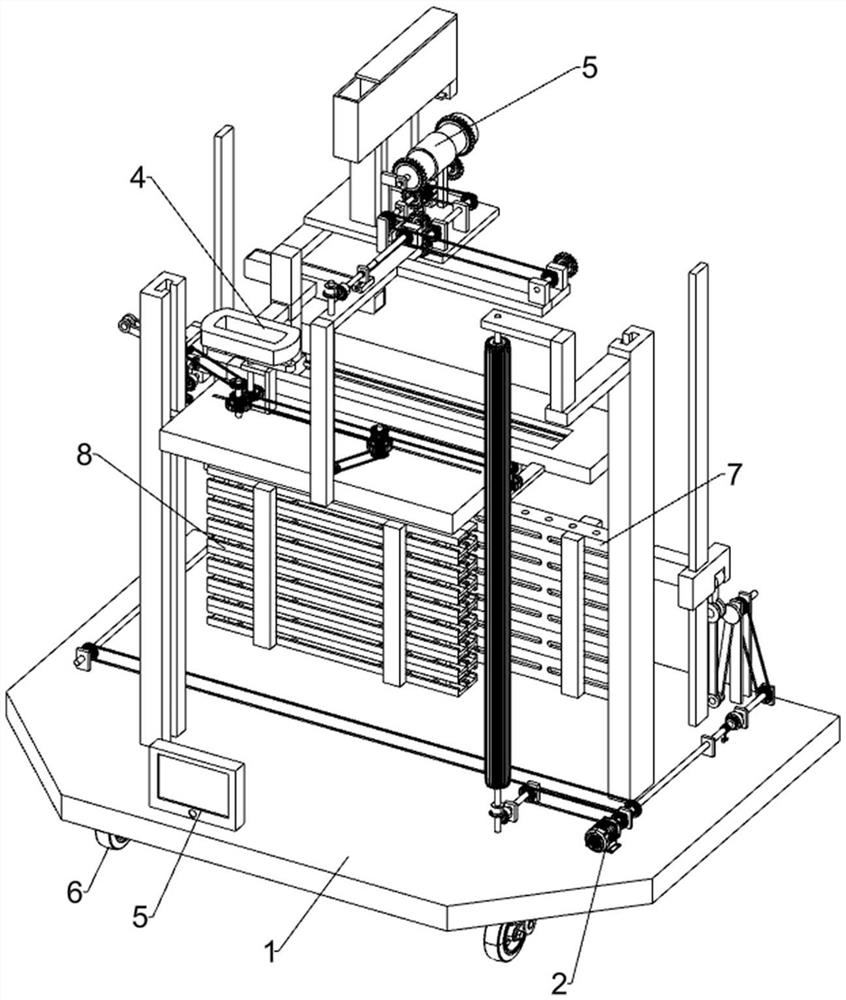

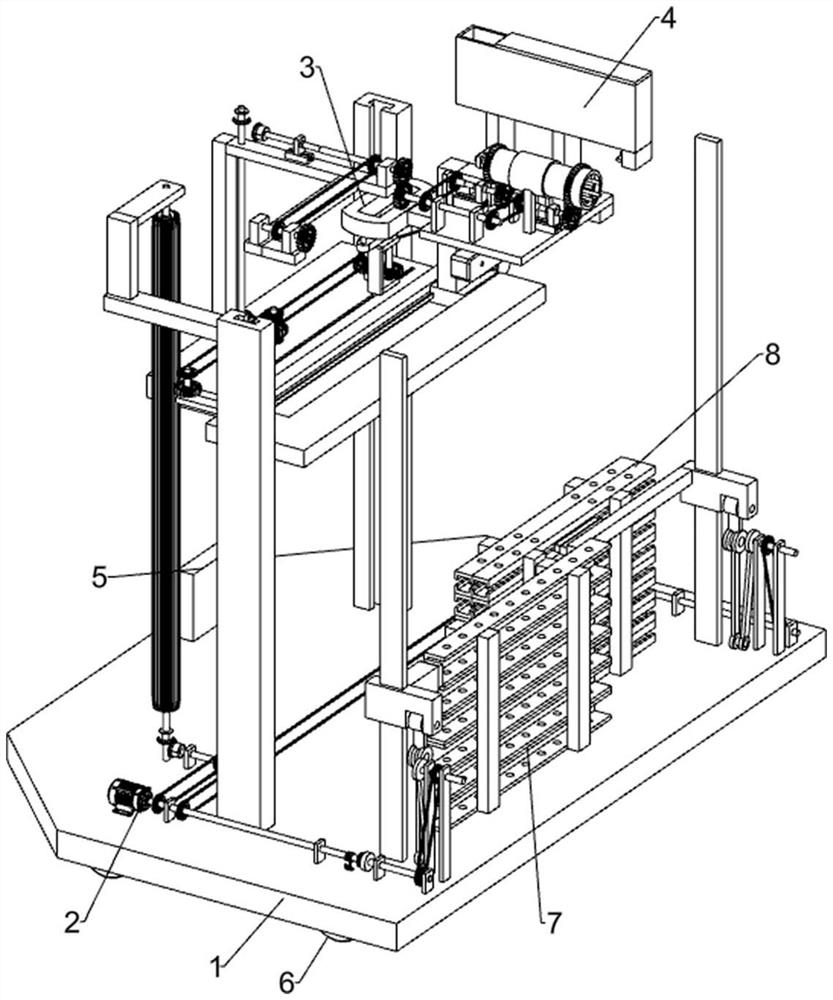

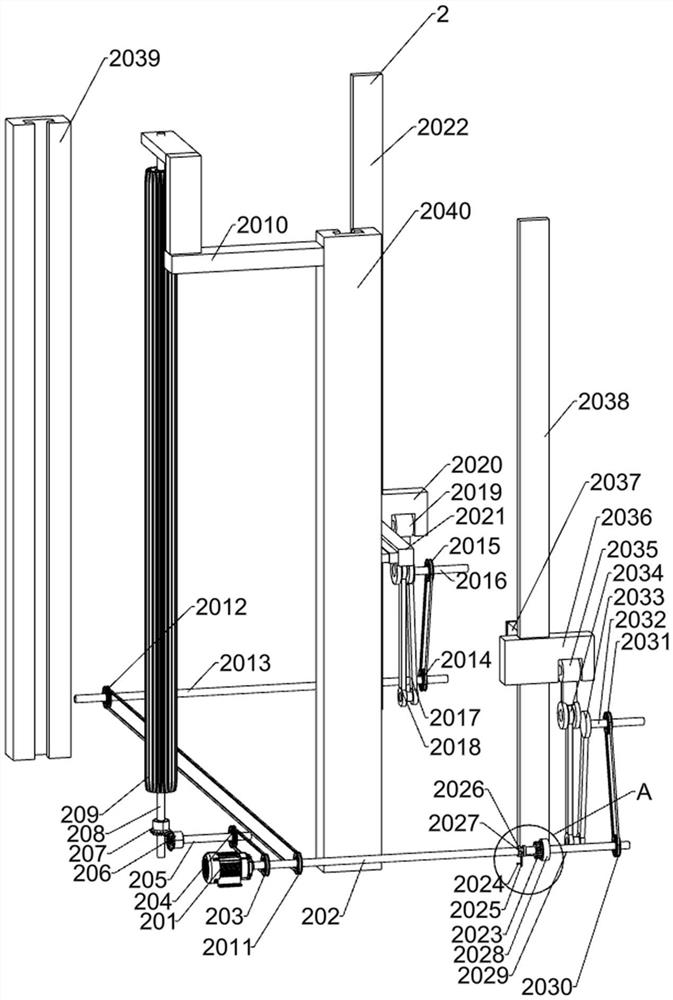

[0030] An auxiliary installation device for building construction, such as Figure 1-9 As shown, it includes an underframe 1, a transom lock transport mechanism 2, a transom lock installation mechanism 3, a transom fixing mechanism 4, a control panel 5, an electric wheel 6, a linear lock 7 and a transom 8; Control panel 5, linear lock 7 and transverse beam 8; a beam lock transportation mechanism 2 is arranged above the bottom frame 1; an electric wheel 6 is arranged under the bottom frame 1; the cross beam lock transportation mechanism 2 is connected with the horizontal bar lock installation mechanism 3; The bar lock installation mechanism 3 is connected with the beam fixing mechanism 4 .

[0031]When preparing for work, first place the linear lock 7 and the transverse beam 8 on the top of the chassis 1, then manipulate the control panel 5 to control the electric wheel 6 to drive the device to move to the front of the template that needs to be installed and fixed. The beam 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com