Patents

Literature

90 results about "Electrodynamic wheel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

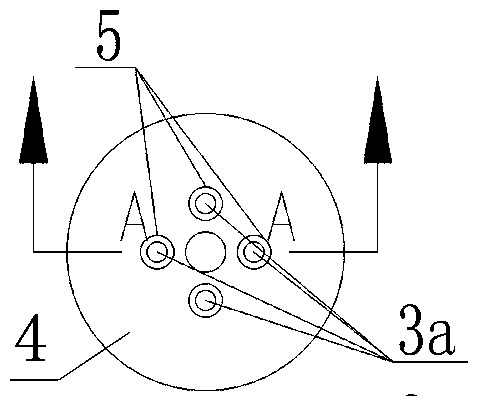

An electrodynamic wheel is a type of wheel proposed for use in electrodynamic levitation maglev. Unlike a conventional wheel, an electrodynamic wheel has a rim studded with magnets of alternating poles. As the wheel spins, which is done at a rate so that there is slip between the rim and the guideway's surface, magnetic fields are induced in the conductive guideway which repels the wheel.

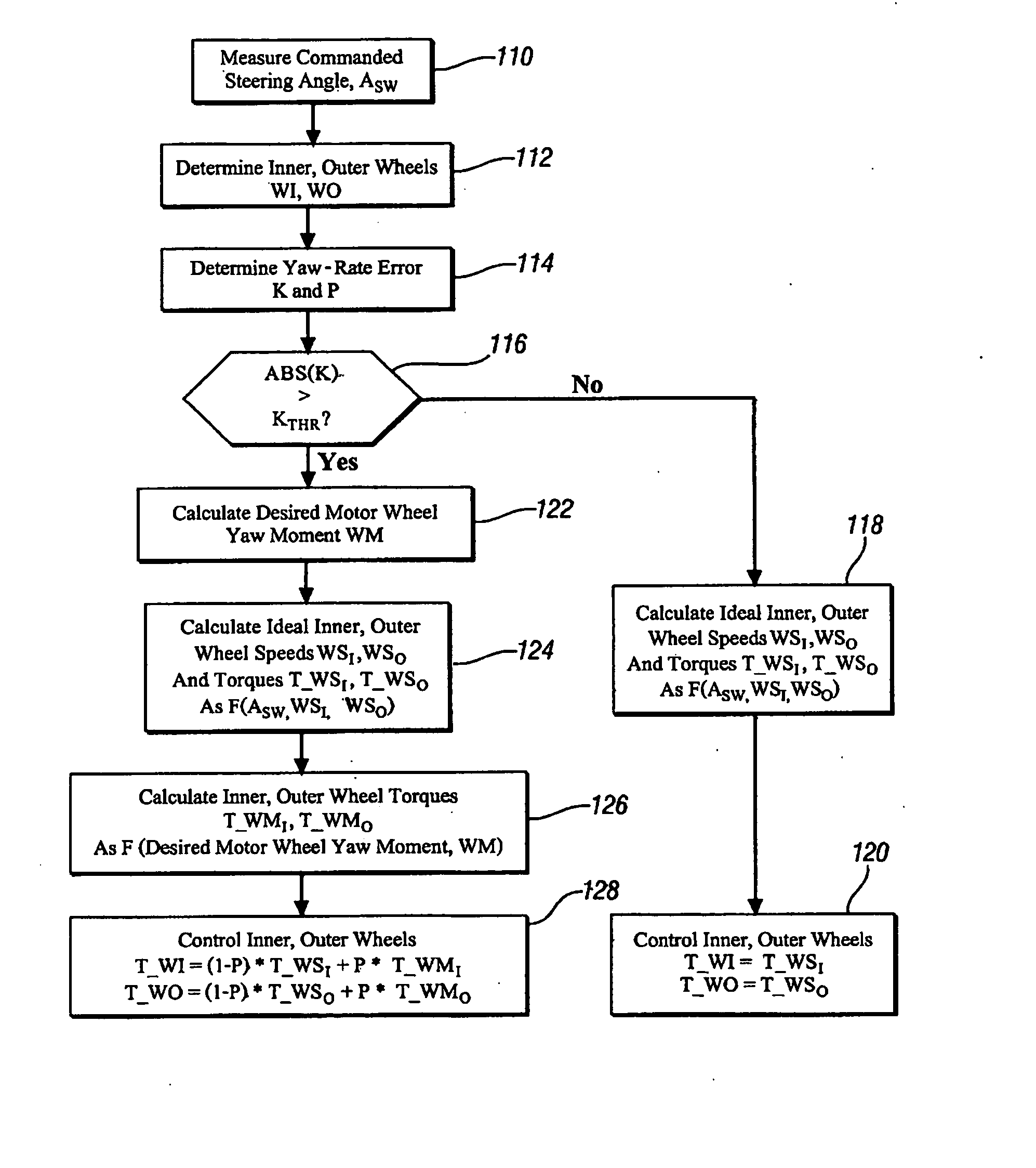

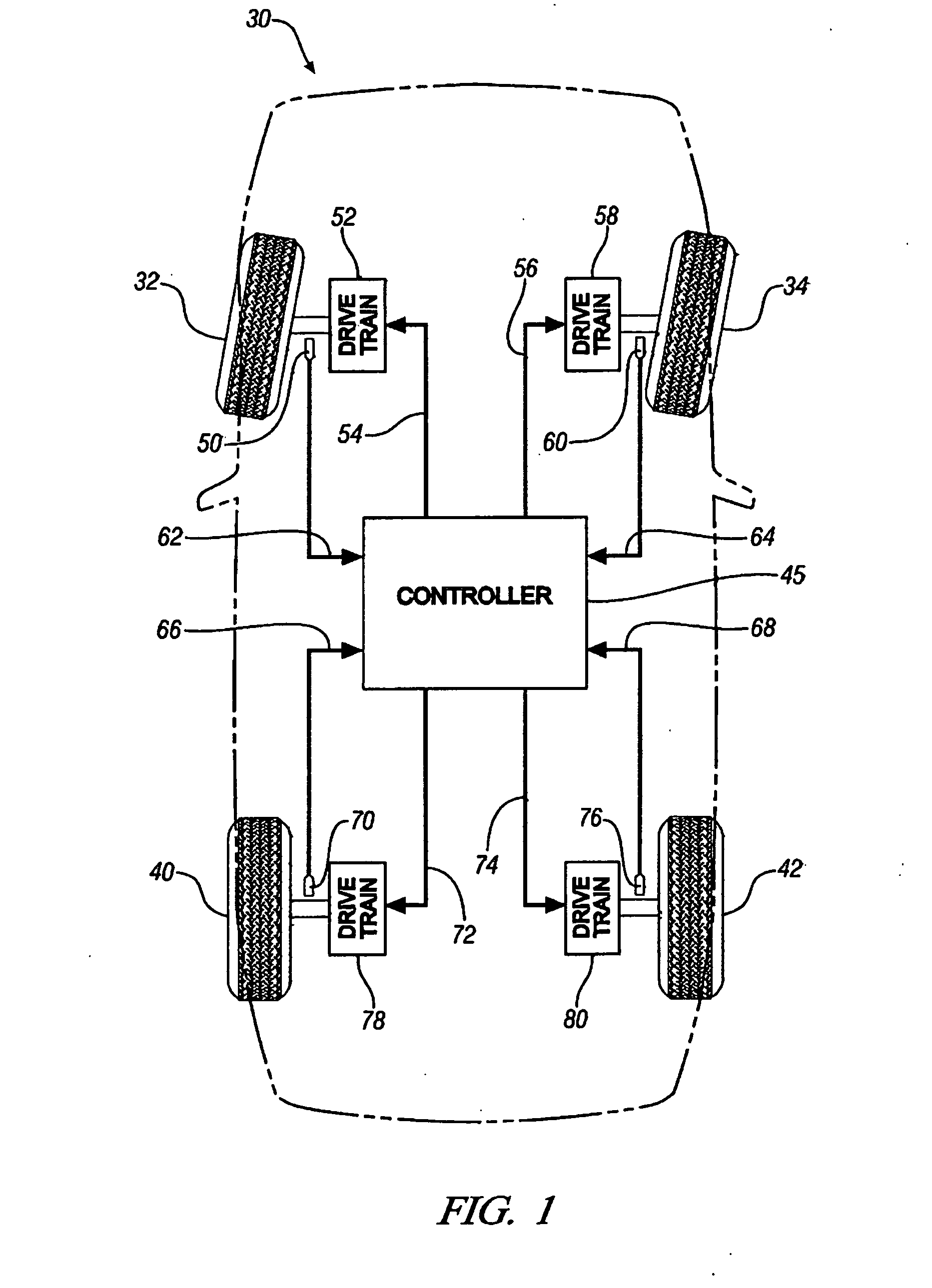

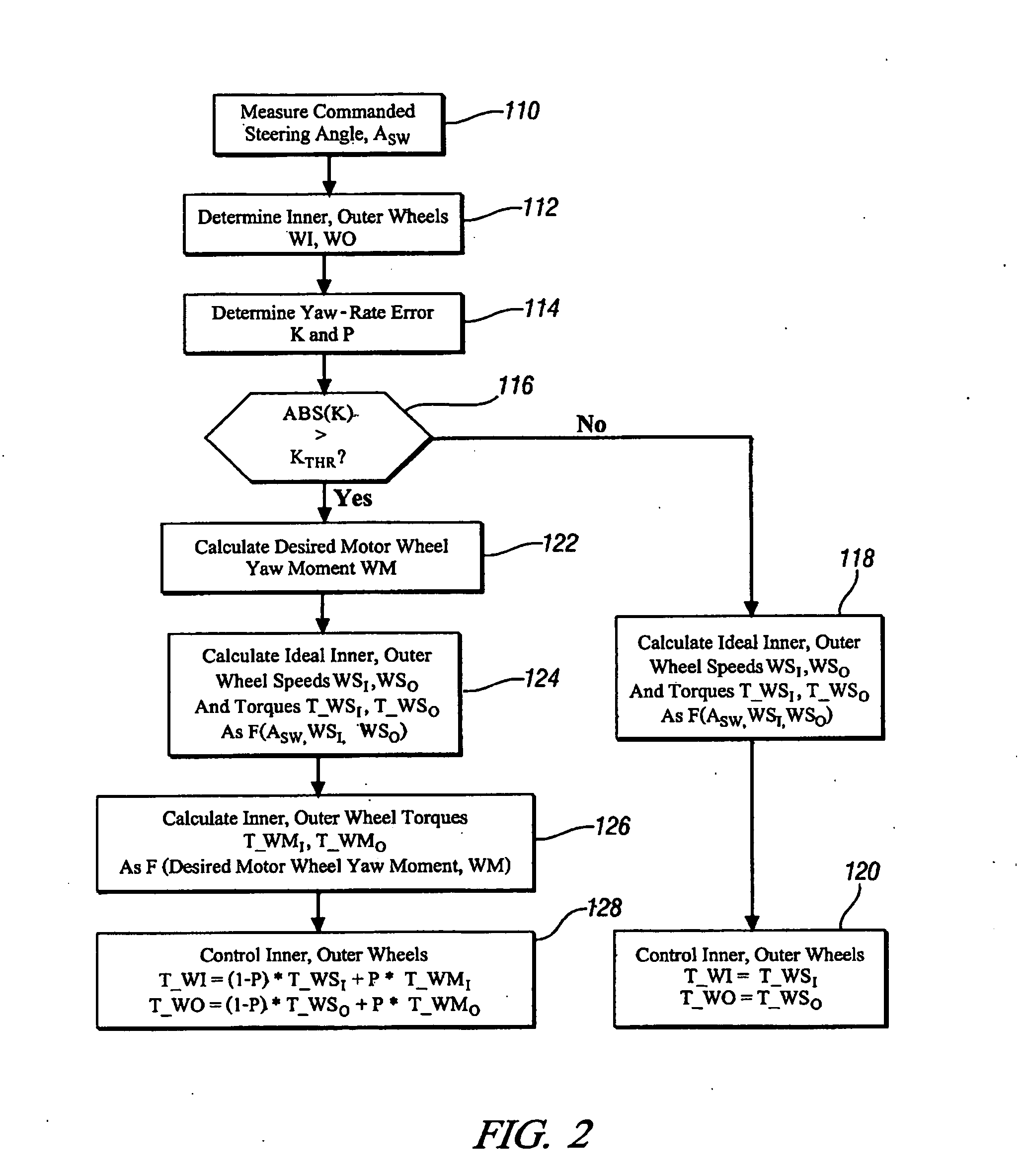

Method and apparatus to control coordinated wheel motors

ActiveUS20070021875A1Digital data processing detailsAutomatic steering controlSteering angleElectrodynamic wheel

A method and system providing coordinated torque control and speed control of a vehicle equipped with individual wheel motors, a steering system, and yaw-rate detection to achieve a desired yaw moment for the vehicle, based upon operator input and vehicle operation, is described. This includes determining a commanded steering angle, and a yaw-rate error, based upon the commanded steering angle and detected yaw-rate. A desired wheel motor yaw torque moment is calculated. First and second torque moments are calculated for inner and outer motored wheels, based upon the desired wheel motor yaw torque moment. First and second ideal wheel speeds are calculated for the inner and outer motored wheels, based upon the commanded steering angle. Torque and speed at each inner motored wheel and each outer motored wheel are calculated, based upon the yaw-rate error, the first and second torque moments, and the first and second ideal wheel speeds.

Owner:GM GLOBAL TECH OPERATIONS LLC

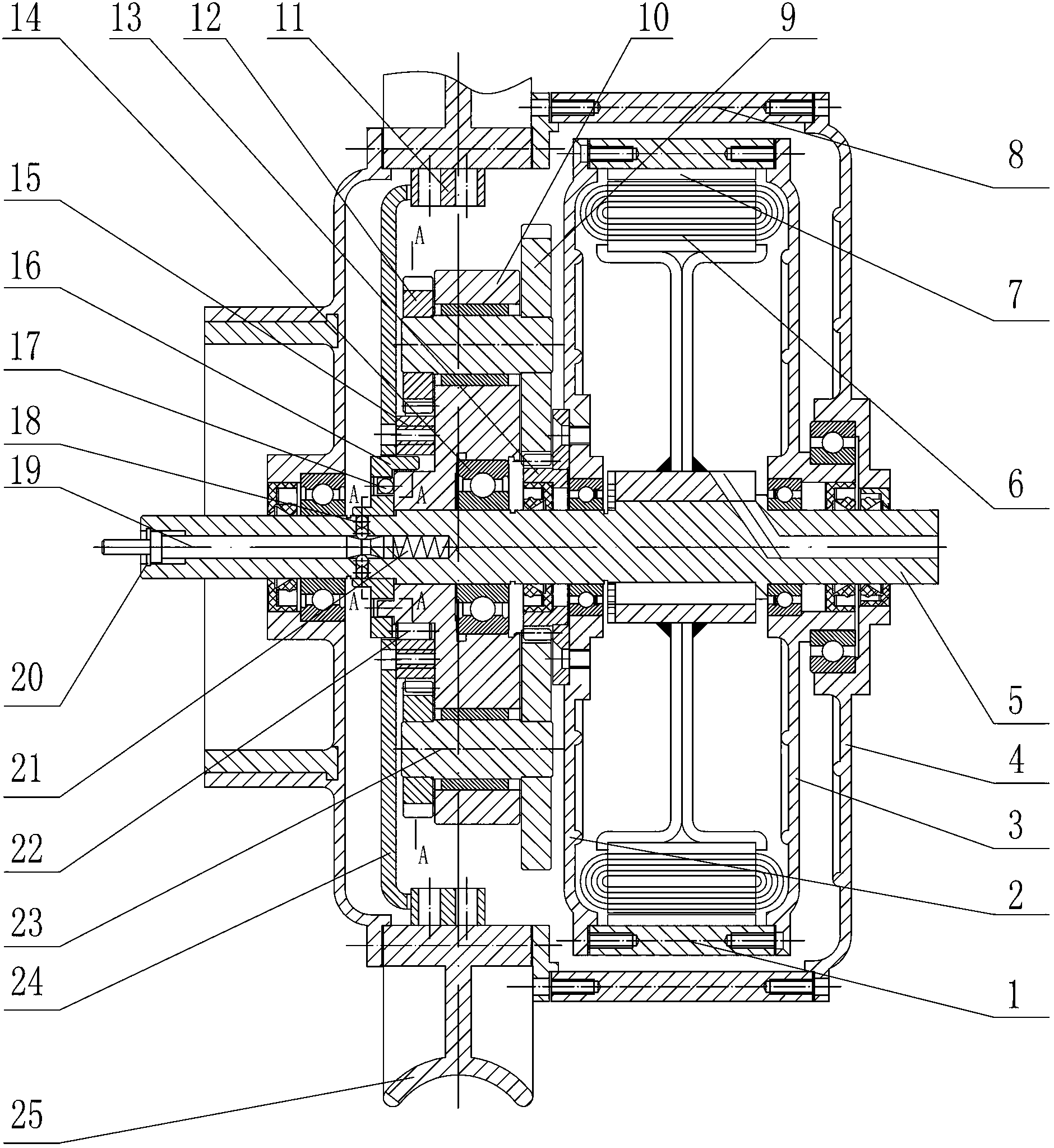

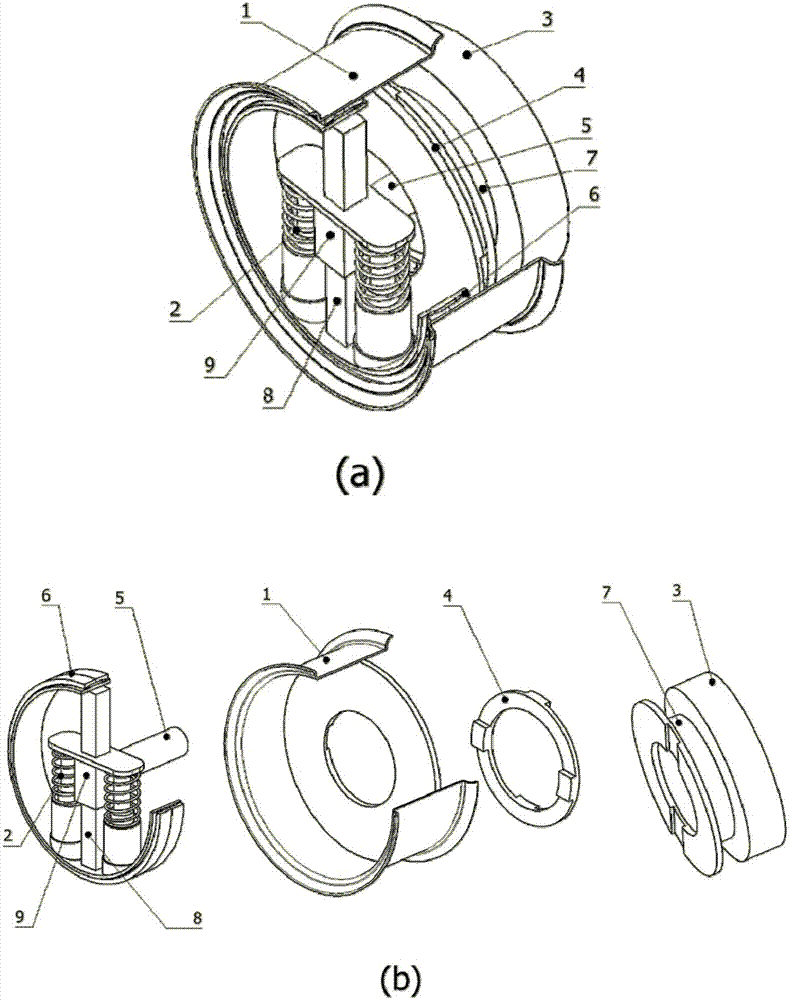

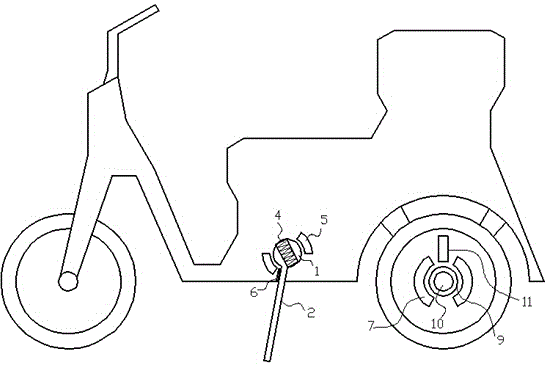

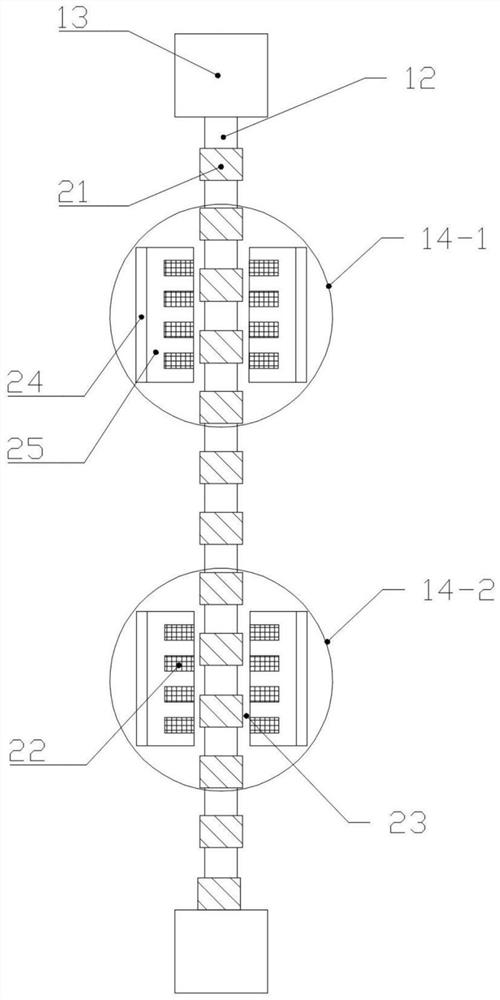

Electric vehicle hub motor double clutch planet gear-shifting mechanism

InactiveCN102801245AImprove continuation abilityImprove climbing abilityMechanical actuated clutchesToothed gearingsGear wheelEngineering

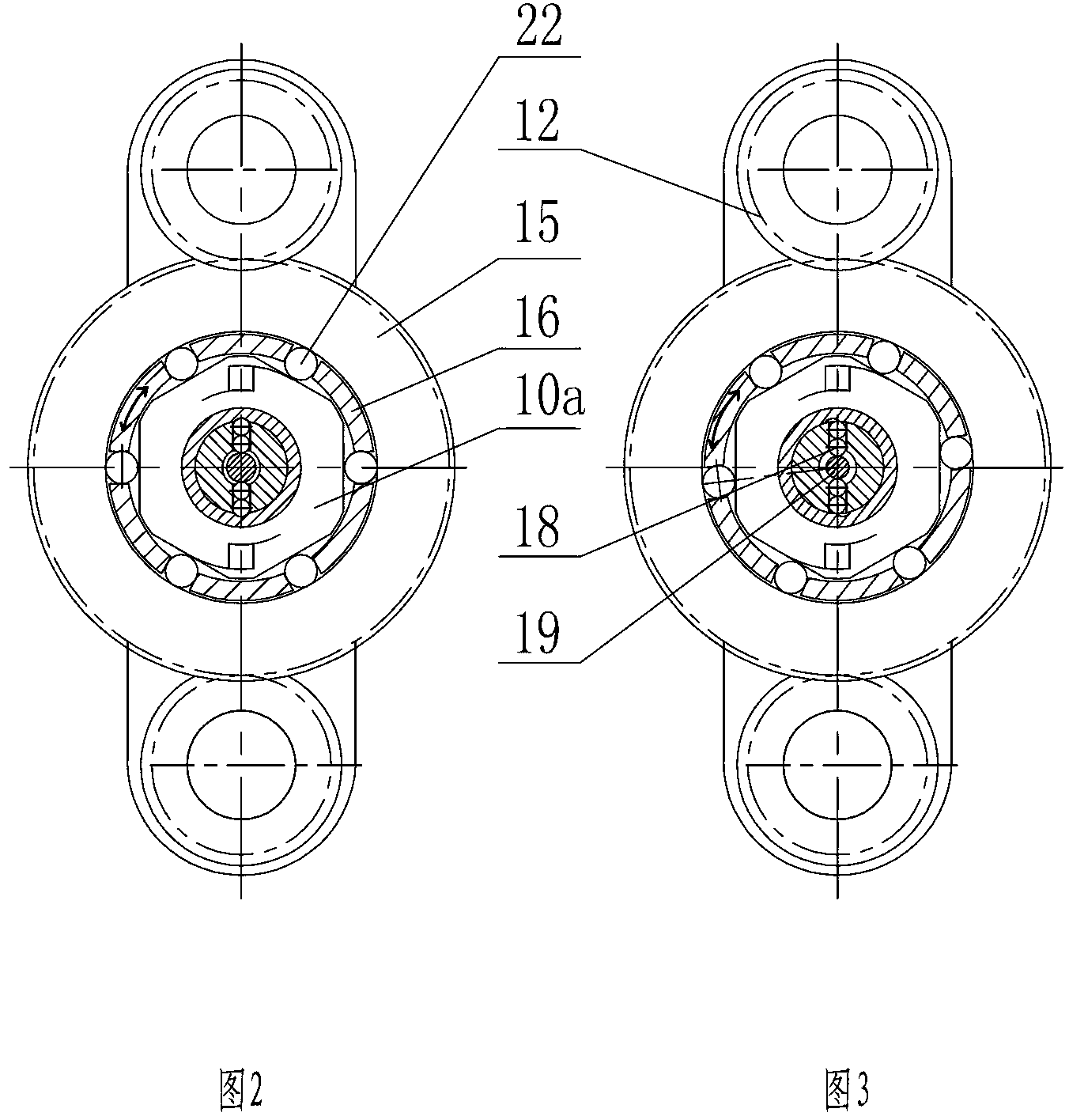

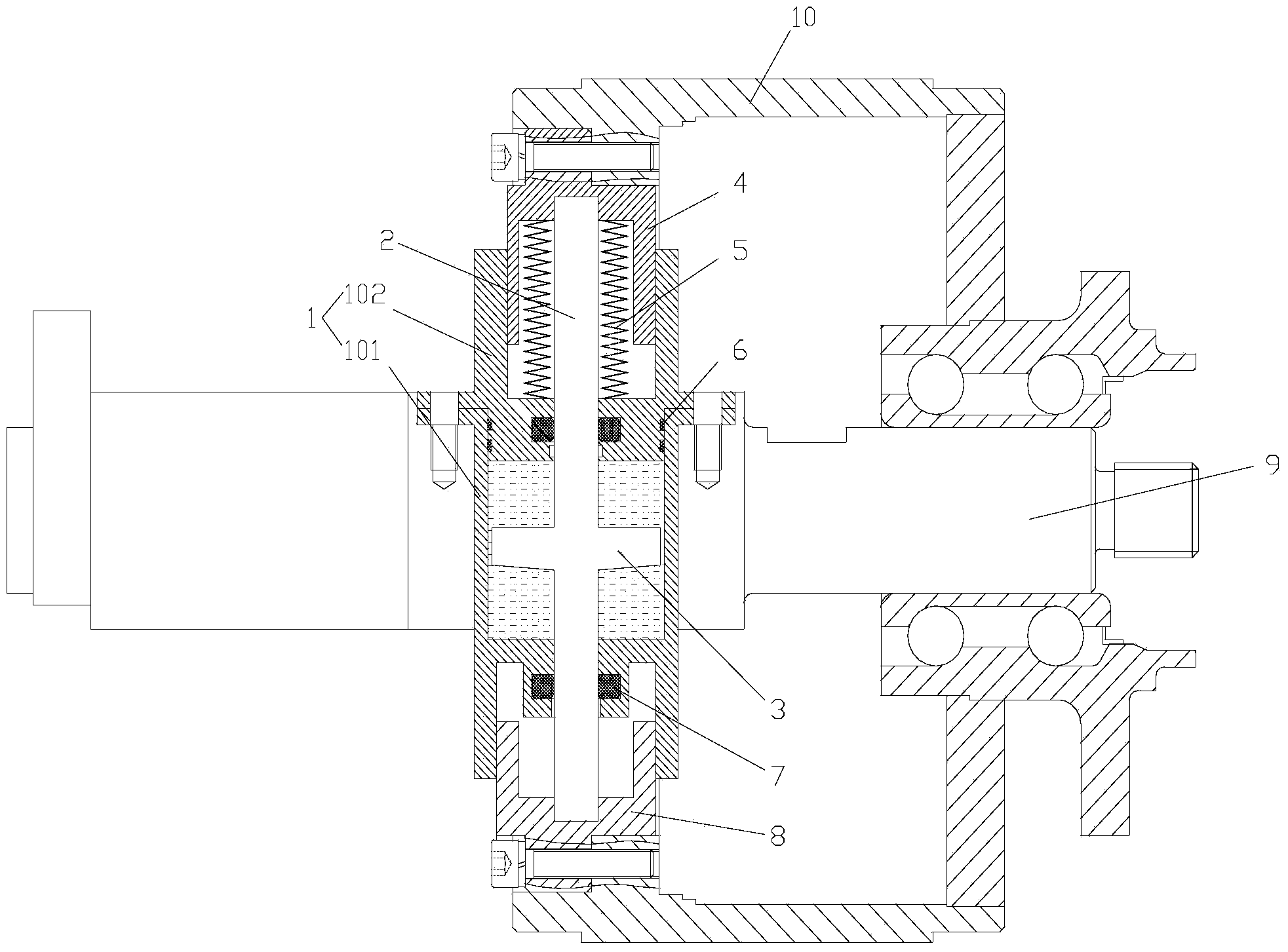

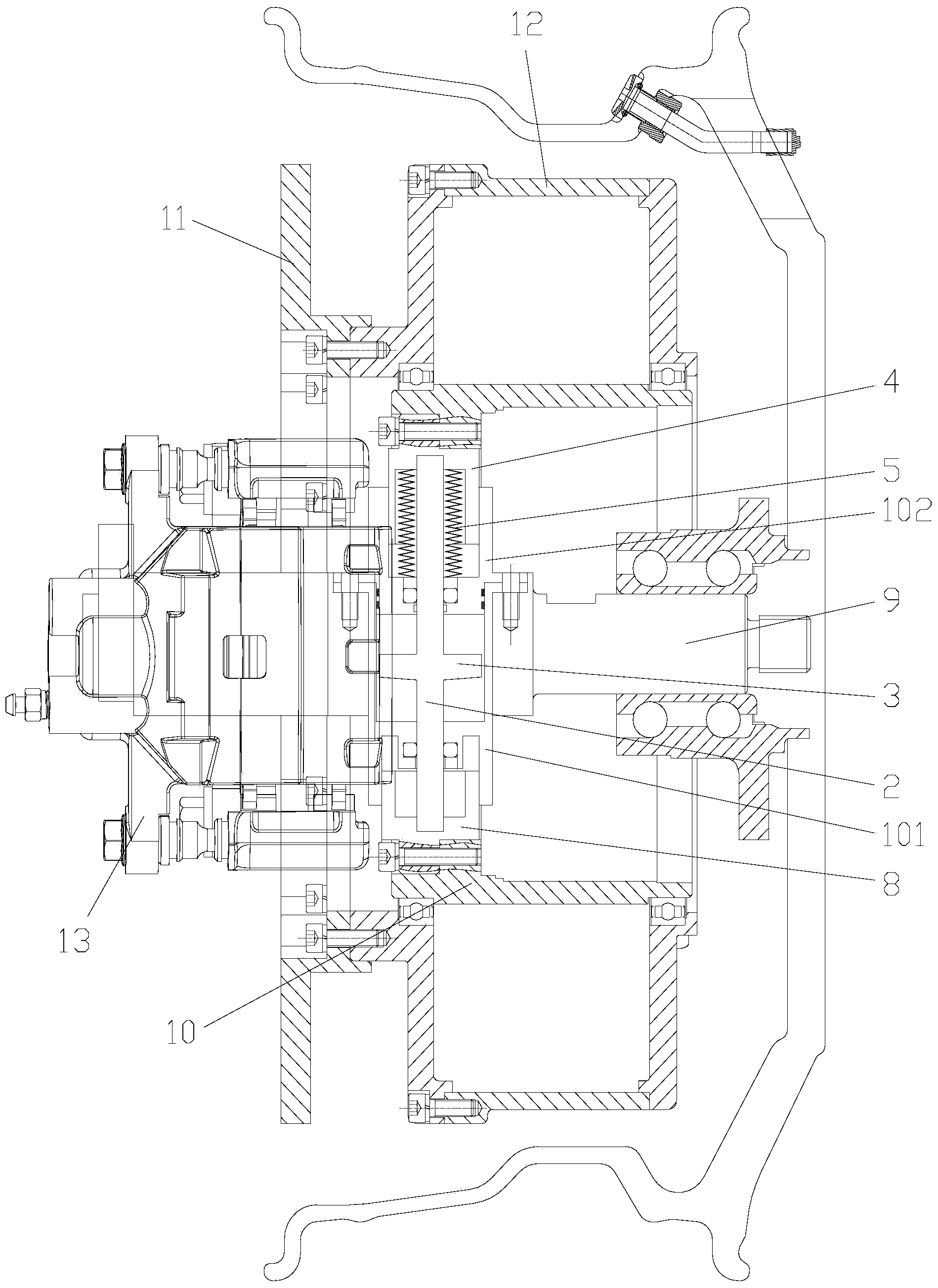

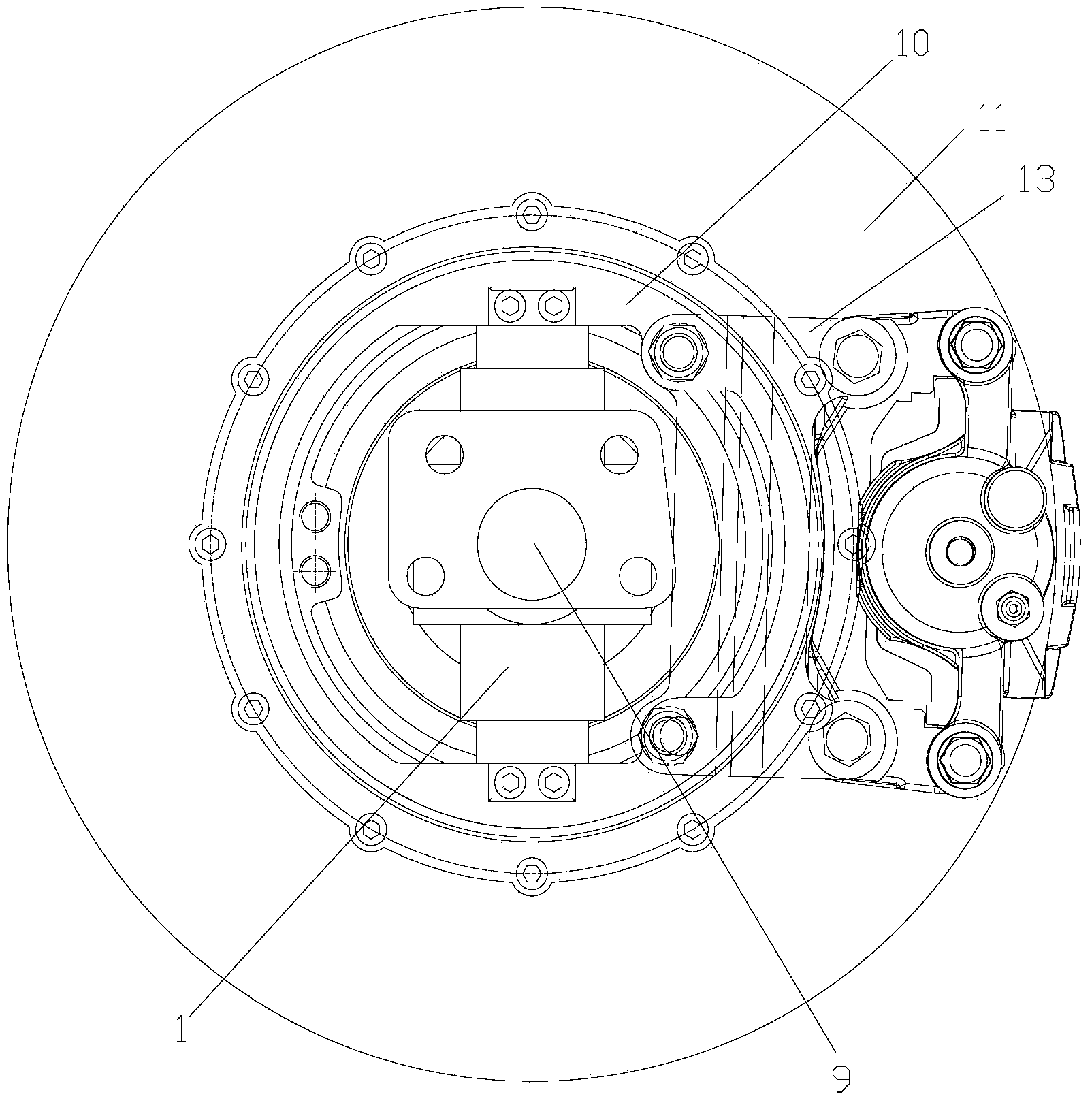

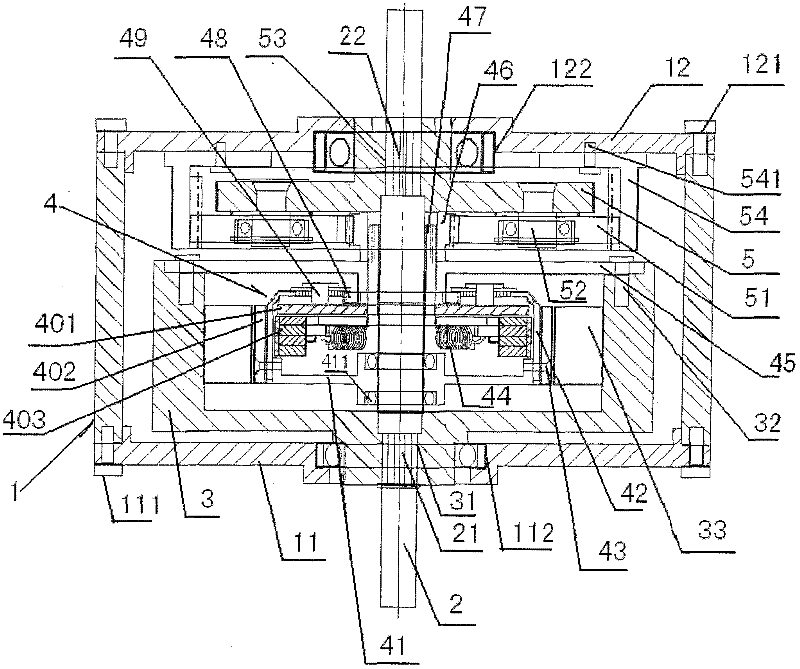

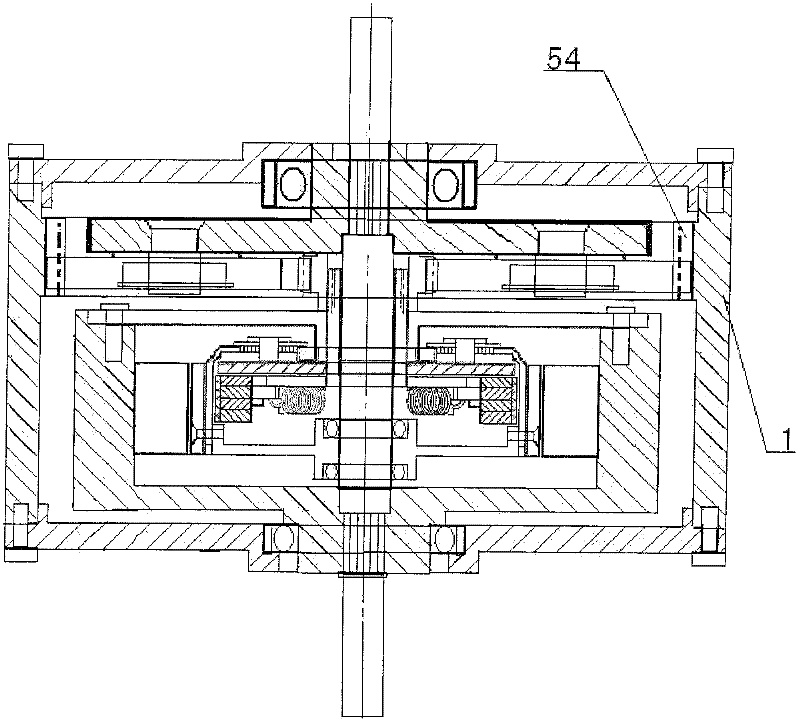

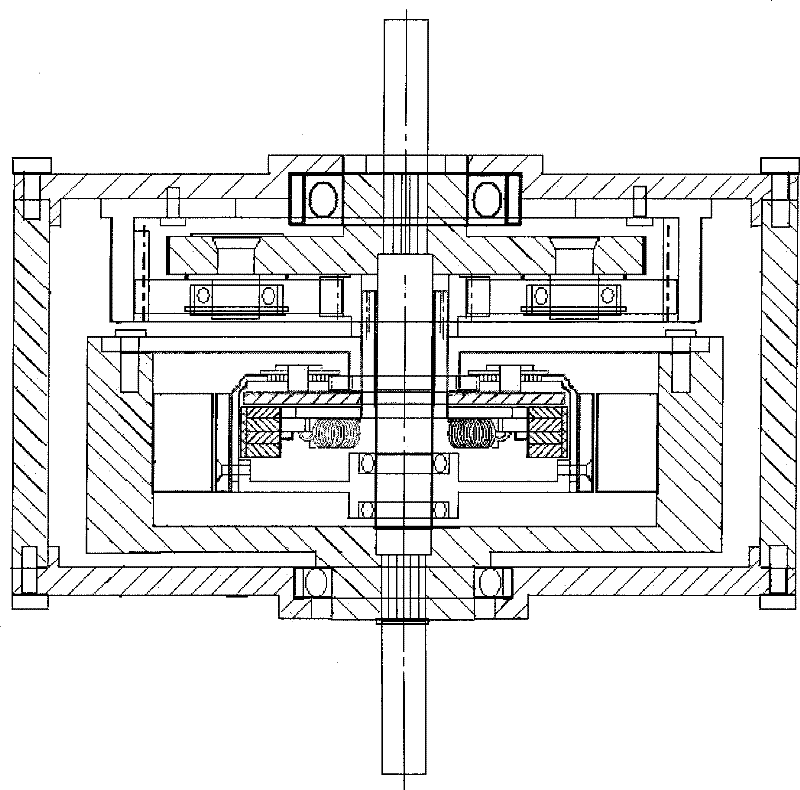

The invention discloses an electric vehicle hub motor double clutch planet gear-shifting mechanism. A motor rotor consists of a motor inner shell, a magnetic steel piece, a first inner end cover and a second inner end cover; the motor rotor, a stator and a motor shaft form a motor; a first planet speed-reducing structure consists of a first sun gear, a first planet gear, a planet carrier and a planet shaft; a second planet speed-reducing structure consists of a planet shaft, a second planet gear and a second sun gear; and a controllable bidirectional clutch consists of a retainer, a first spring, a rolling body, a push rod, a spring clamp ring, a second spring, a pin roller and a planet carrier. The hub can obtain different rotating speeds through the controllable bidirectional clutch under the condition that the input rotating speed is invariable, so that the continuation capacity and climbing capacity of the electric vehicle are effectively improved; and moreover, the gear can be prevented from being damaged, and the gear-shifting stability is ensured, so that the whole vehicle does not shake during gear shifting, and the driving comfort is greatly improved.

Owner:SICHUAN ACNASS ELECTRIC VEHICLE

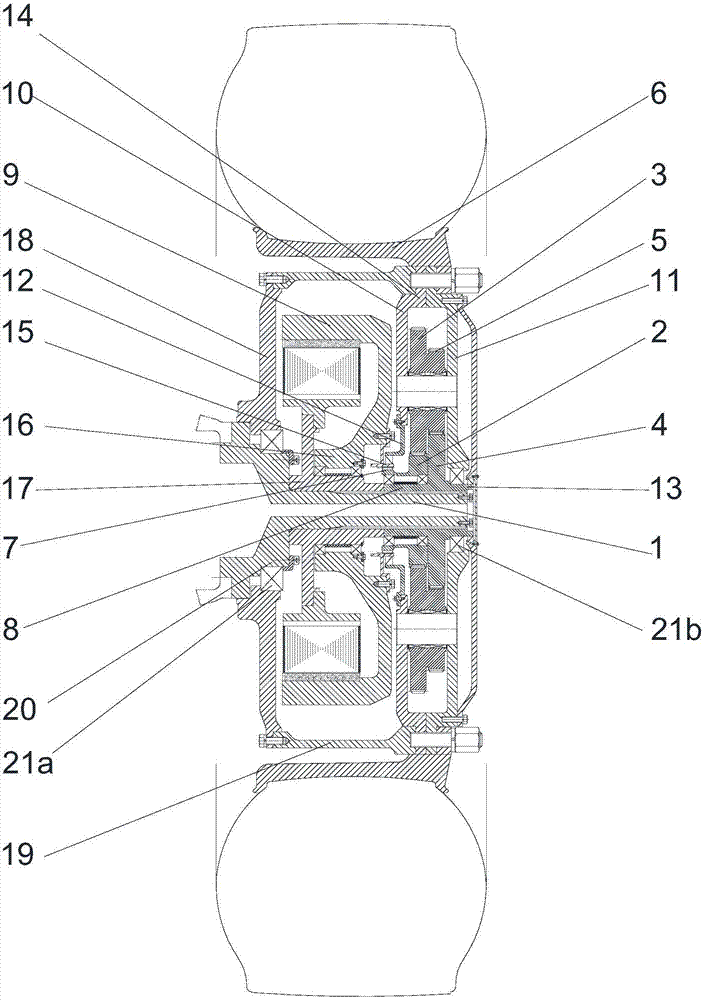

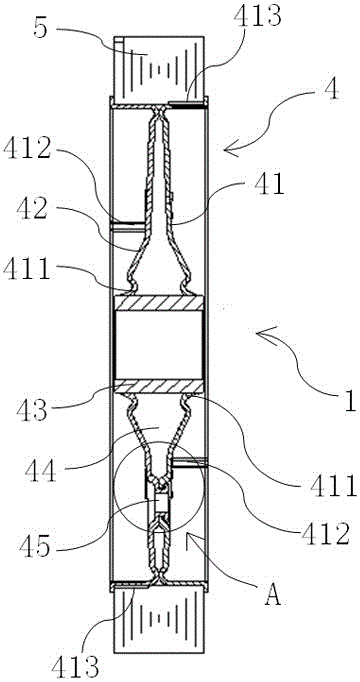

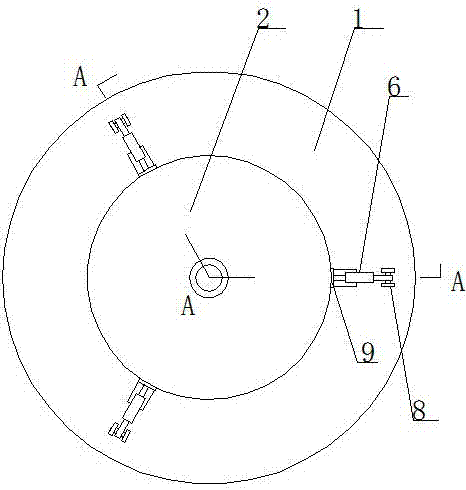

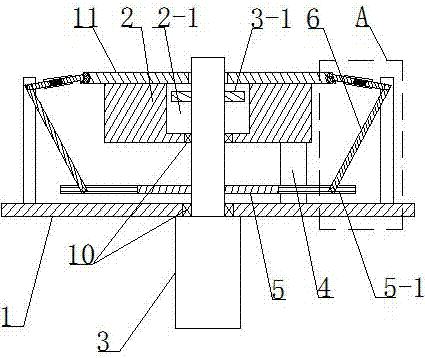

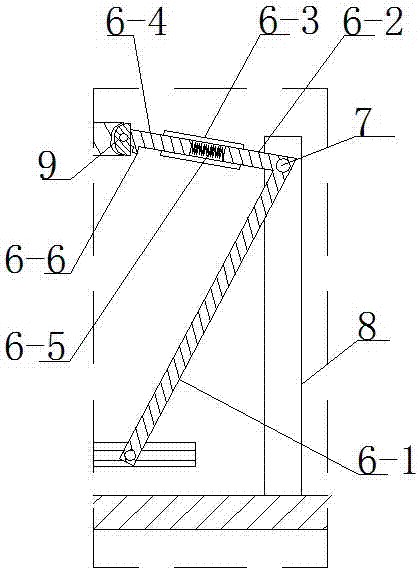

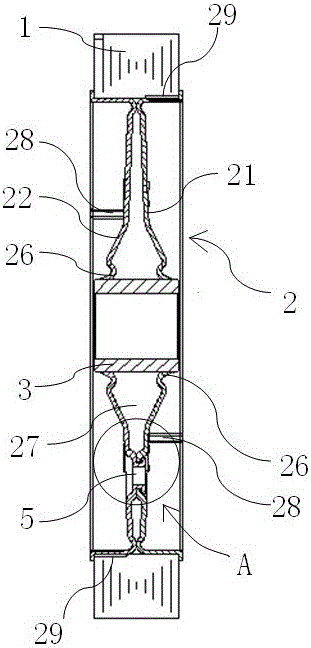

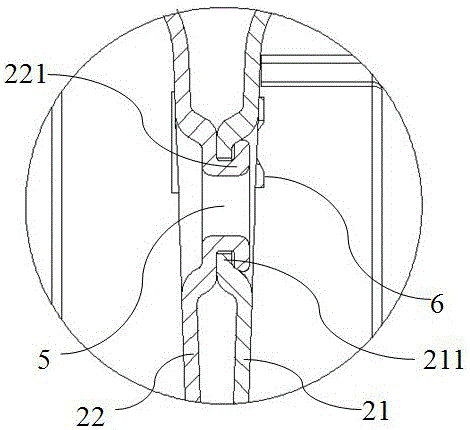

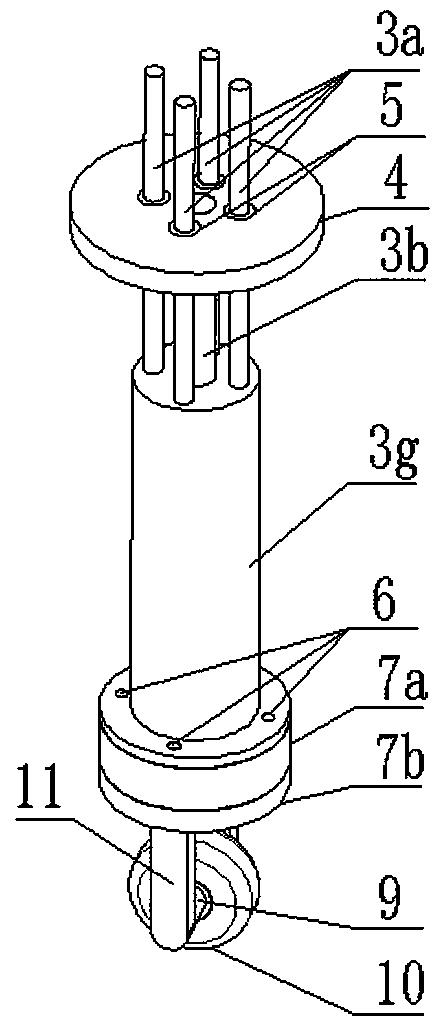

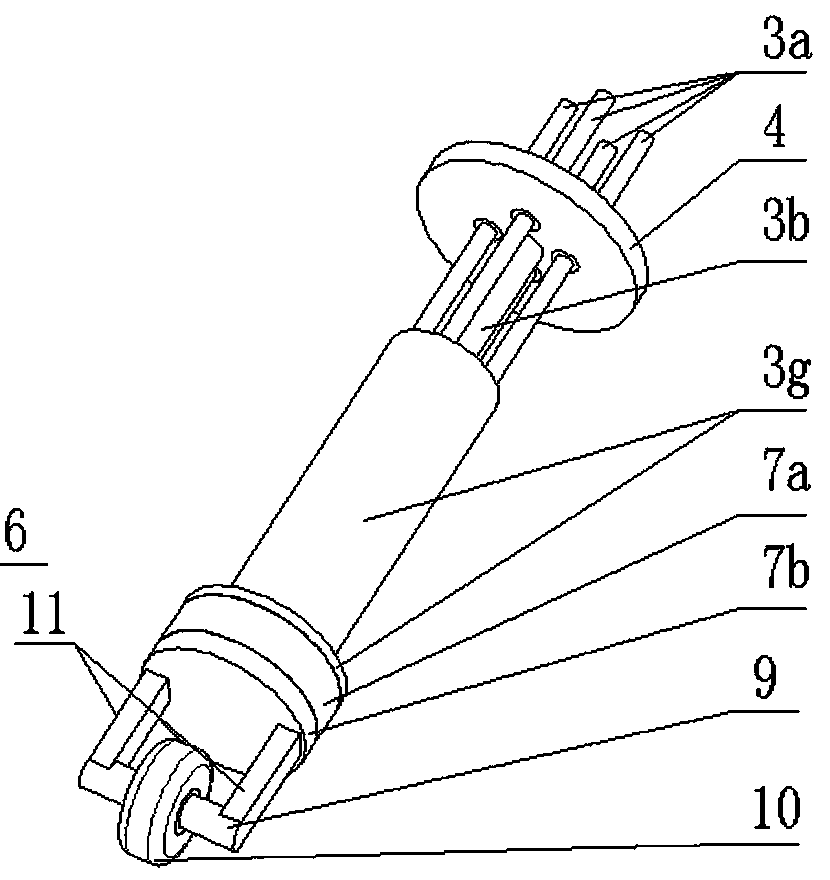

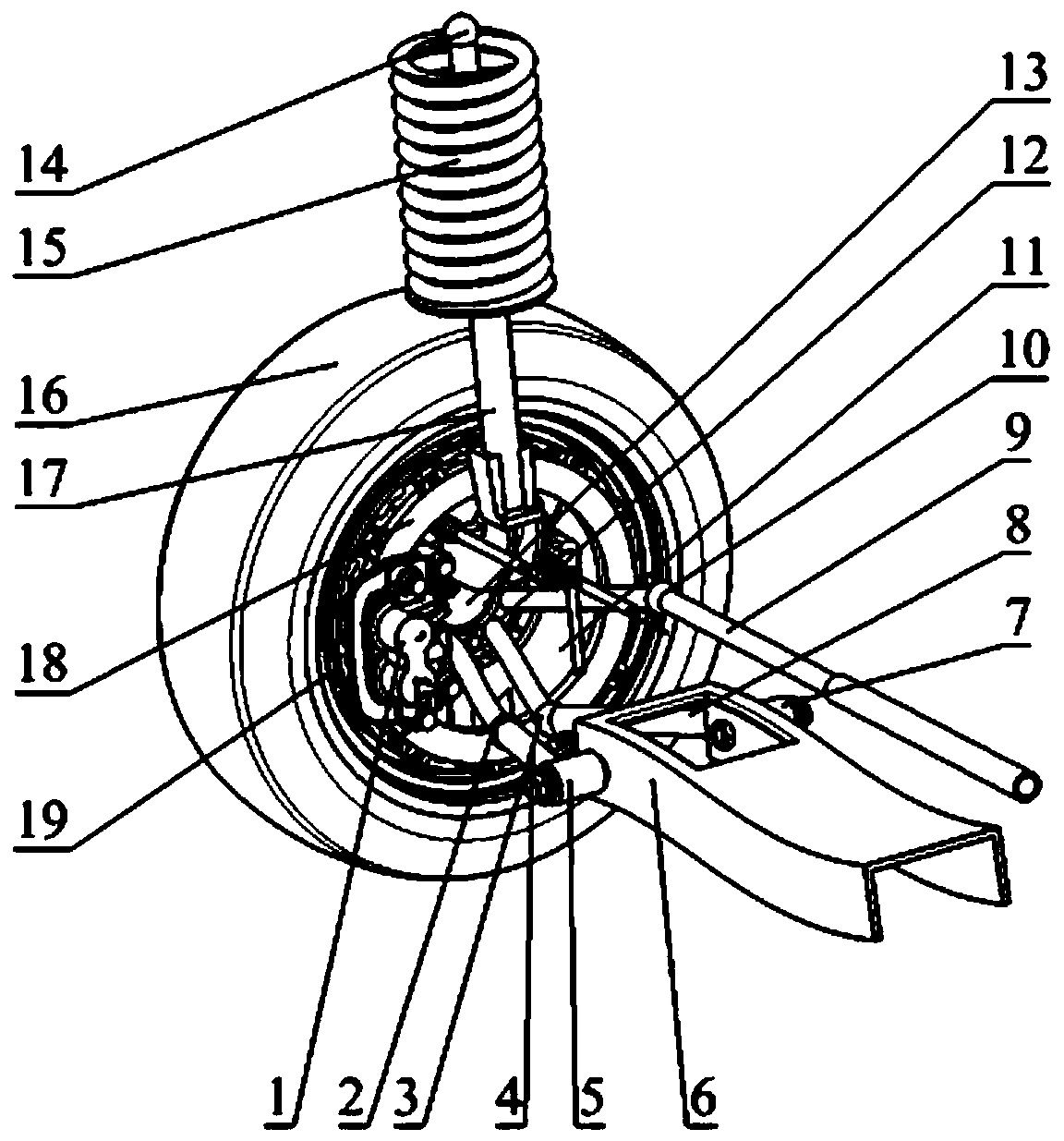

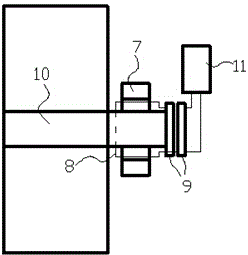

Inner vibration absorbing device of high-speed electric wheel and electric wheel

InactiveCN103921637AImprove working environmentVibration energy decays rapidlyMotor depositionResilient suspensionsMotor driveEngineering

The invention discloses an inner vibration absorbing device of a high-speed electric wheel. The inner vibration absorbing device of the high-speed electric wheel comprises a damping vibration absorber and a spring vibration absorber. The damping vibration absorber comprises a damper shell body and a supporting rod, wherein a damping disc is arranged on the supporting rod. The invention further discloses the electric wheel. The electric wheel comprises a wheel shaft and a motor stator, wherein the damper shell body is fixed to the wheel shaft, and a sleeve seat and a guide seat are respectively and fixedly connected with the motor stator. According to the inner vibration absorbing device of the high-speed electric wheel and the electric wheel, a wheel hub motor and a brake are connected to the wheel shaft through the inner vibration absorbing device, acting force and counter-acting force between the wheel shaft and the motor are transmitted through the inner vibration absorbing device, the smoothness and comfort in the process when the motor drives an electric car are largely improved, the work environment of the wheel hub motor is improved, the mass of the wheel hub motor and the brake can also play a role of the damping vibration absorber, and the adverse effect caused by increase of the mass under a spring is eliminated. In addition, the damping vibration absorber and the spring vibration absorber are integrated, so that the inner vibration absorbing device of the high-speed electric wheel and the electric wheel are compact in structure, small in size and light in weight.

Owner:CHONGQING UNIV

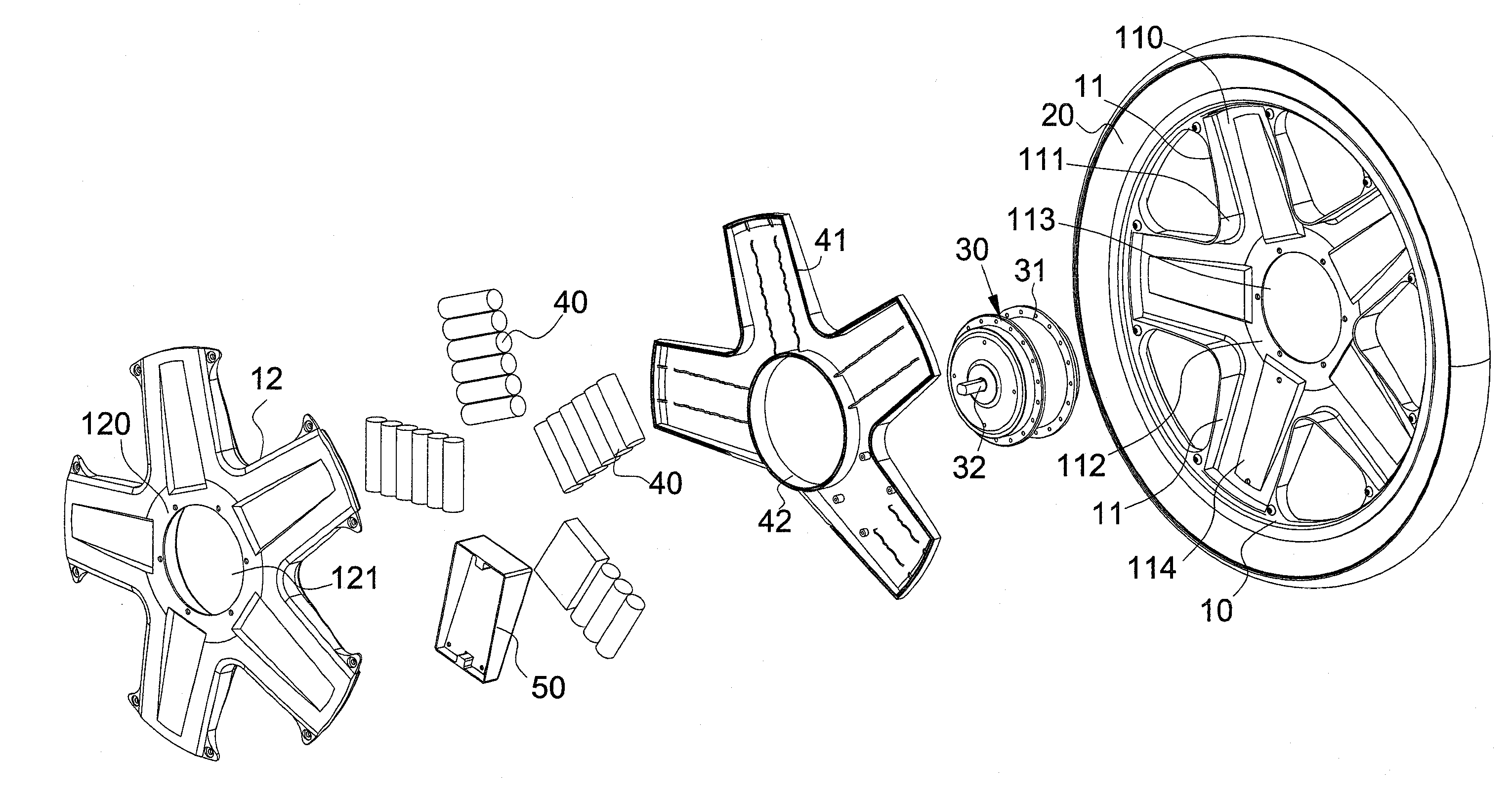

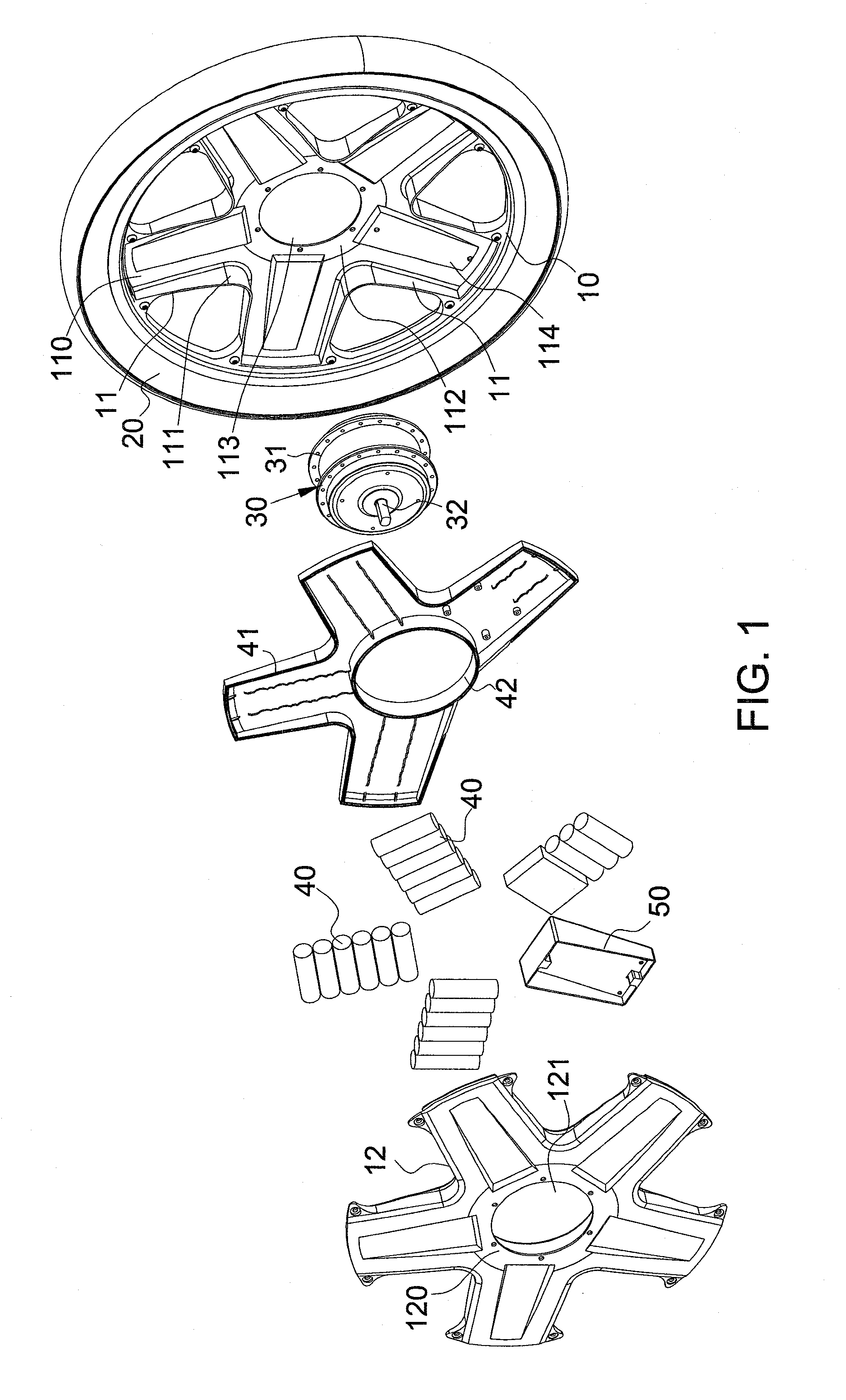

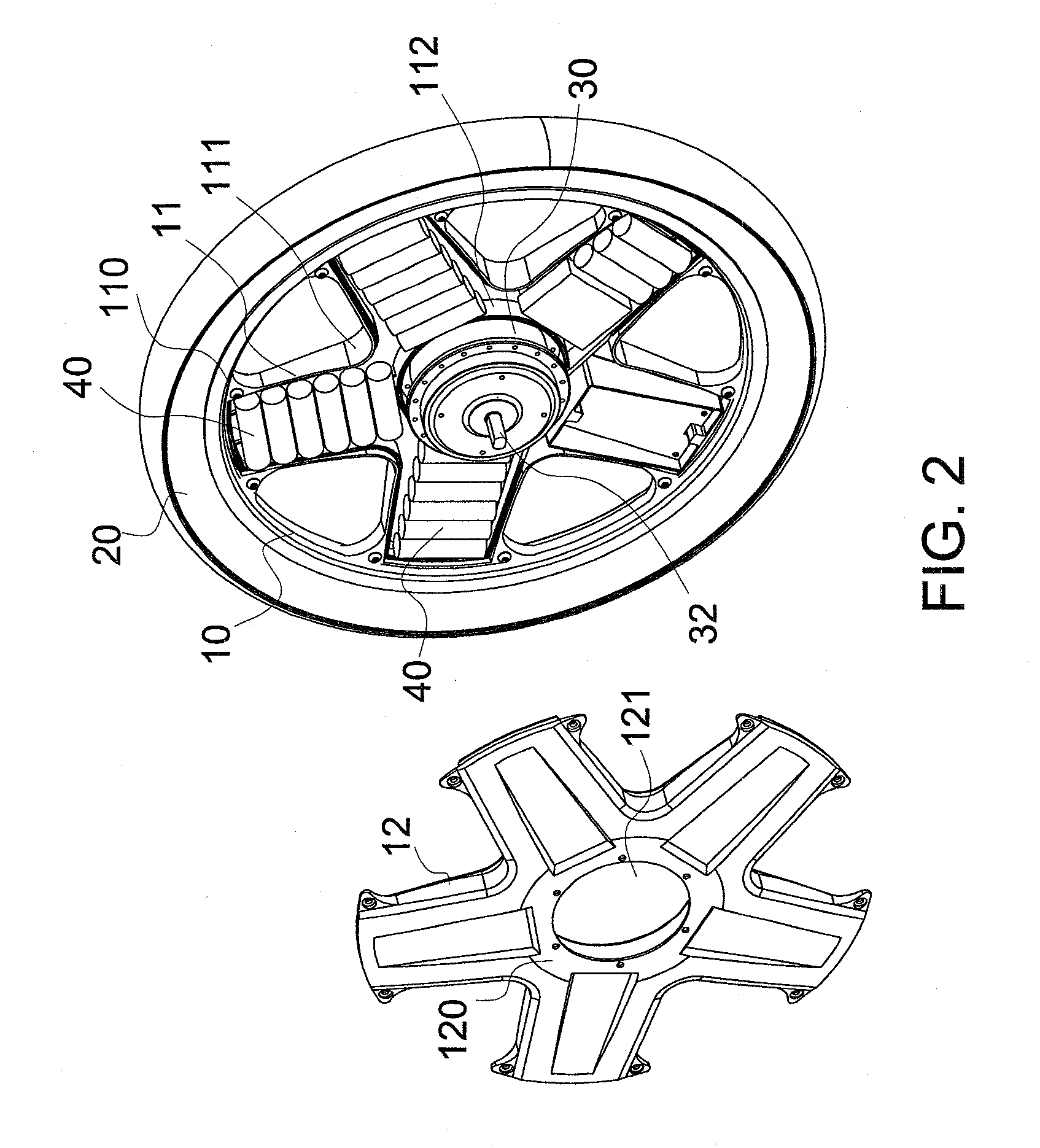

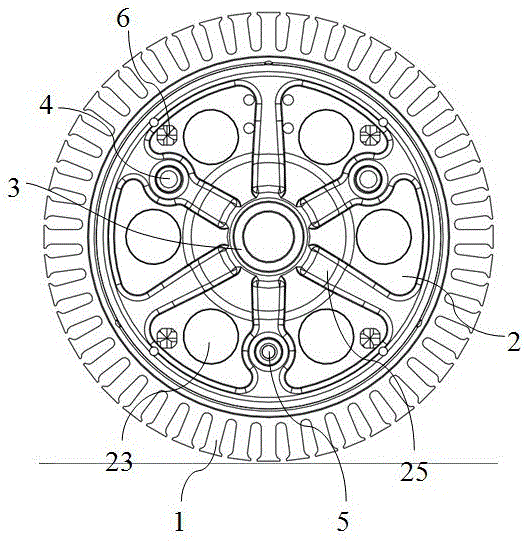

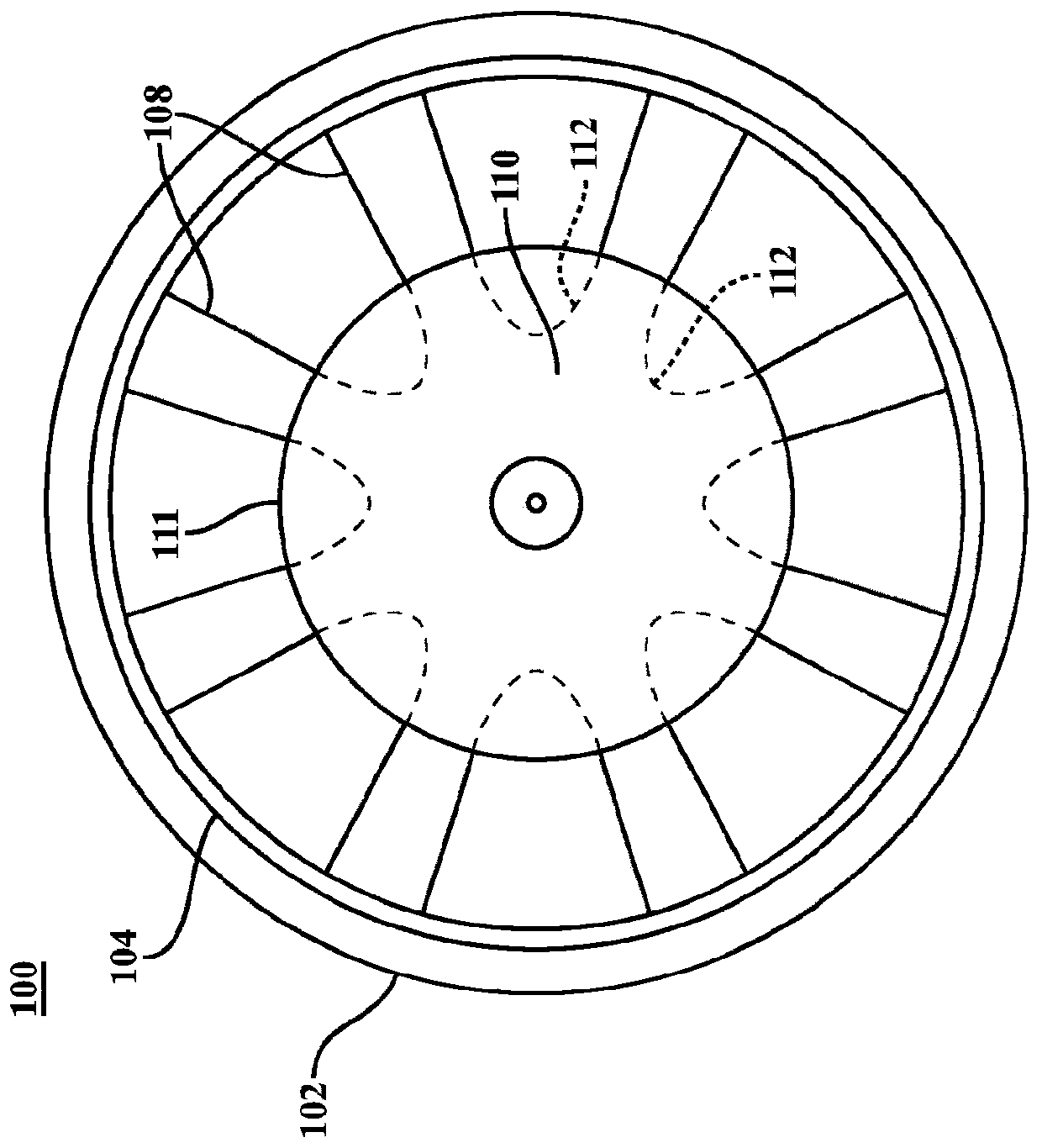

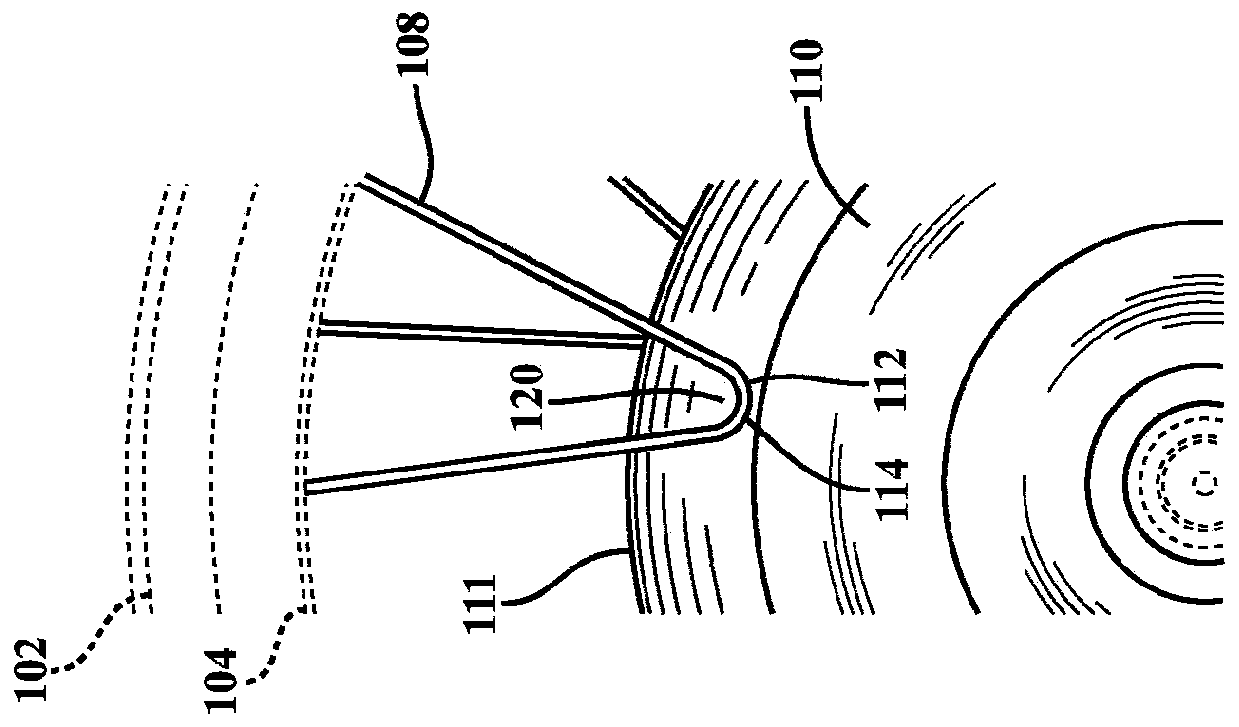

Electric wheel for electric vehicles

InactiveUS20120080934A1Improve structural strengthEasy to installDC motor speed/torque controlDigital data processing detailsVehicle frameElectrical battery

An electric wheel for electric vehicles includes a rim, connecting members, a hub motor, a battery, and a control device. The connecting members are connected to an inside of the rim and the hub motor is connected to the connecting members. The hub motor includes a shaft, a rotor and a stator. The shaft is located on a central axis of the rim and two ends of the shaft are fixed to a vehicle frame. The battery is located on the rim and the control device receives a wireless command signal and generating a control signal to control the battery to provide power to the hub motor, and to allow the hub motor to operate. The rim is equipped with the battery and the hub motor and directly connected to the vehicle frame without wires connected to the vehicle frame.

Owner:LO CHIU HSIANG

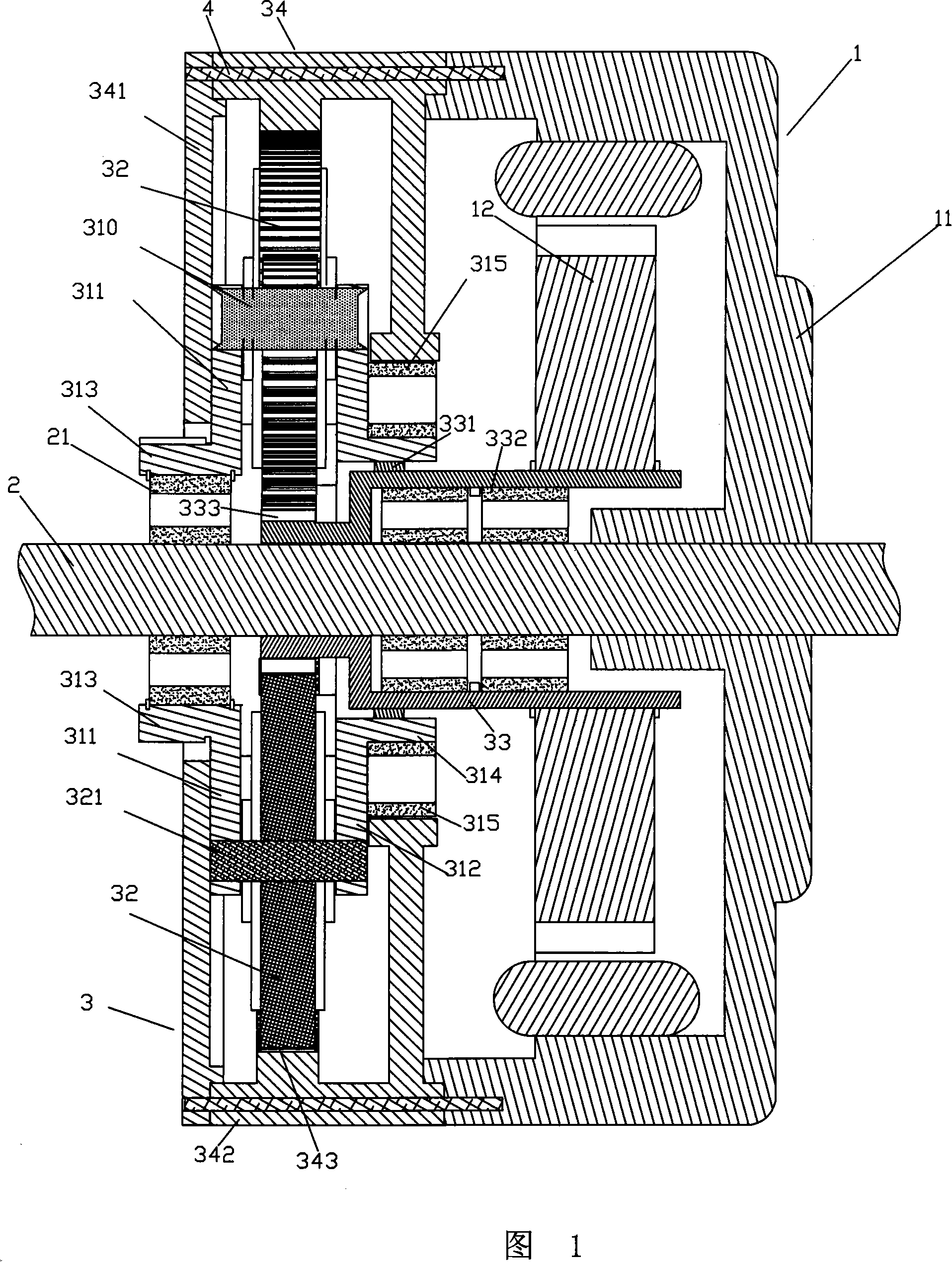

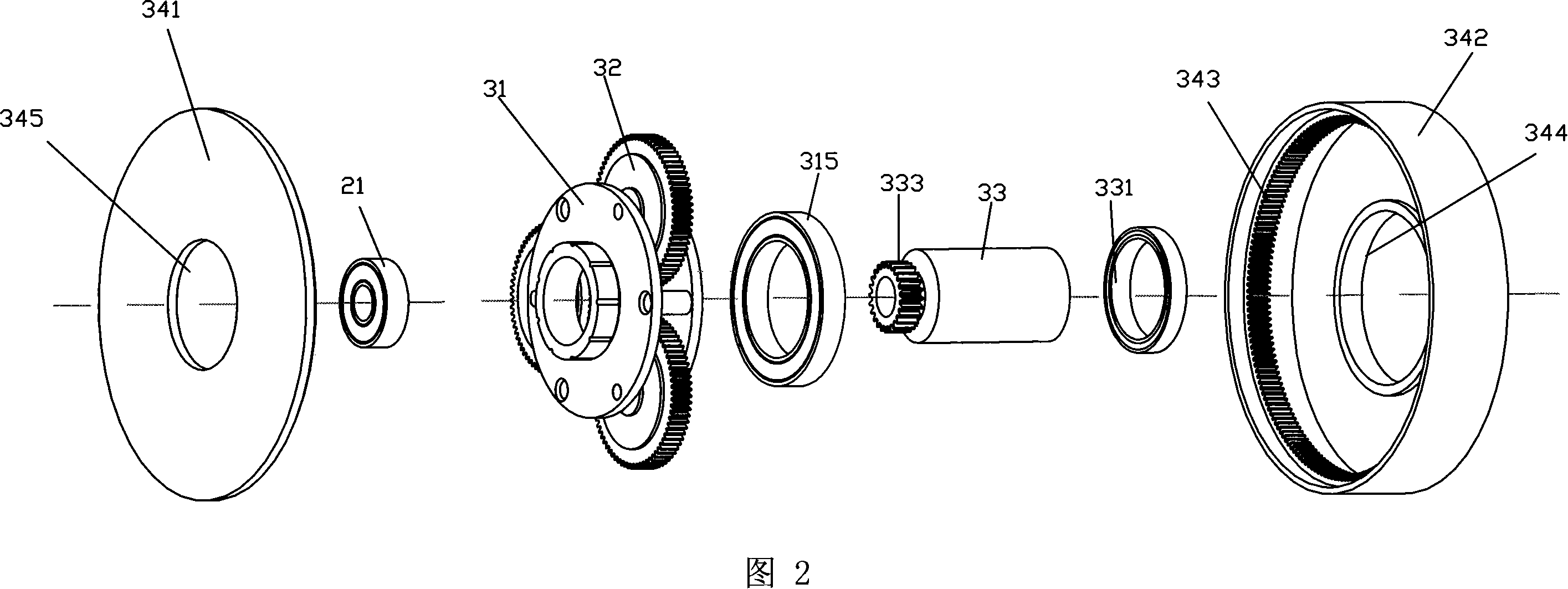

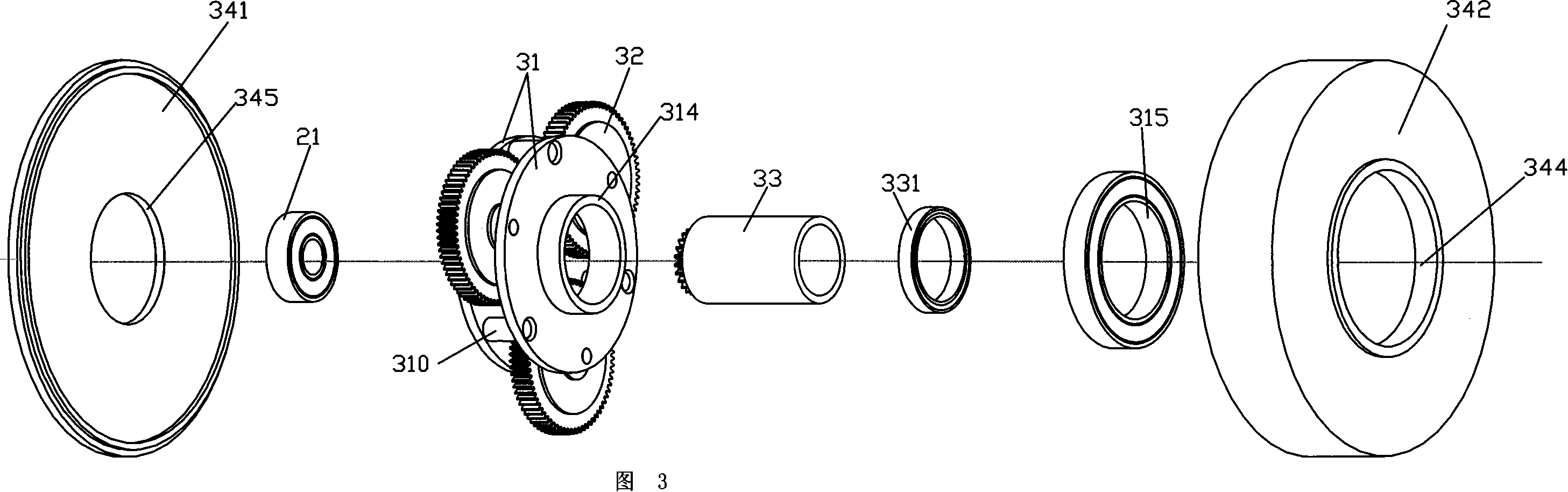

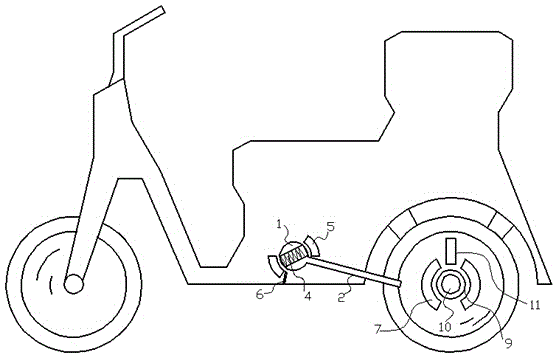

Electric vehicle hub drive device

ActiveCN106926690AApplicable to the needs of narrow installation spaceReduce weightMotor depositionControl devicesElectric machineReduction ratio

The invention provides an electric vehicle hub drive device which comprises a main supporting shaft, a motor mounted in the main supporting shaft and a planetary reducing mechanism mounted in the main supporting shaft. The planetary reducing mechanism comprises a sun wheel, a planetary wheel set, planetary carriers and a central wheel circumferentially fixed to the main supporting shaft. The transmission ratios of a first planetary wheel and a second planetary wheel are different, so that wheel shafts of the first planetary wheel and the second planetary wheel rotate around the fixed planetary carriers to drive a hub to rotate, and by arranging the central wheel and the planetary wheel set, a motor direct drive device which is small in weight and simple and compact in structure can be conveniently achieved. The electric vehicle hub drive device is large in reduction ratio and transmission ration and good in drive performance and meets the use requirement that the mounting space of the electric vehicle hub drive device is narrow, and dismounting, mounting and repair are facilitated due to modularized design. The double planetary carriers simultaneously output torque, so that output power is stable.

Owner:CHONGQING UNIV

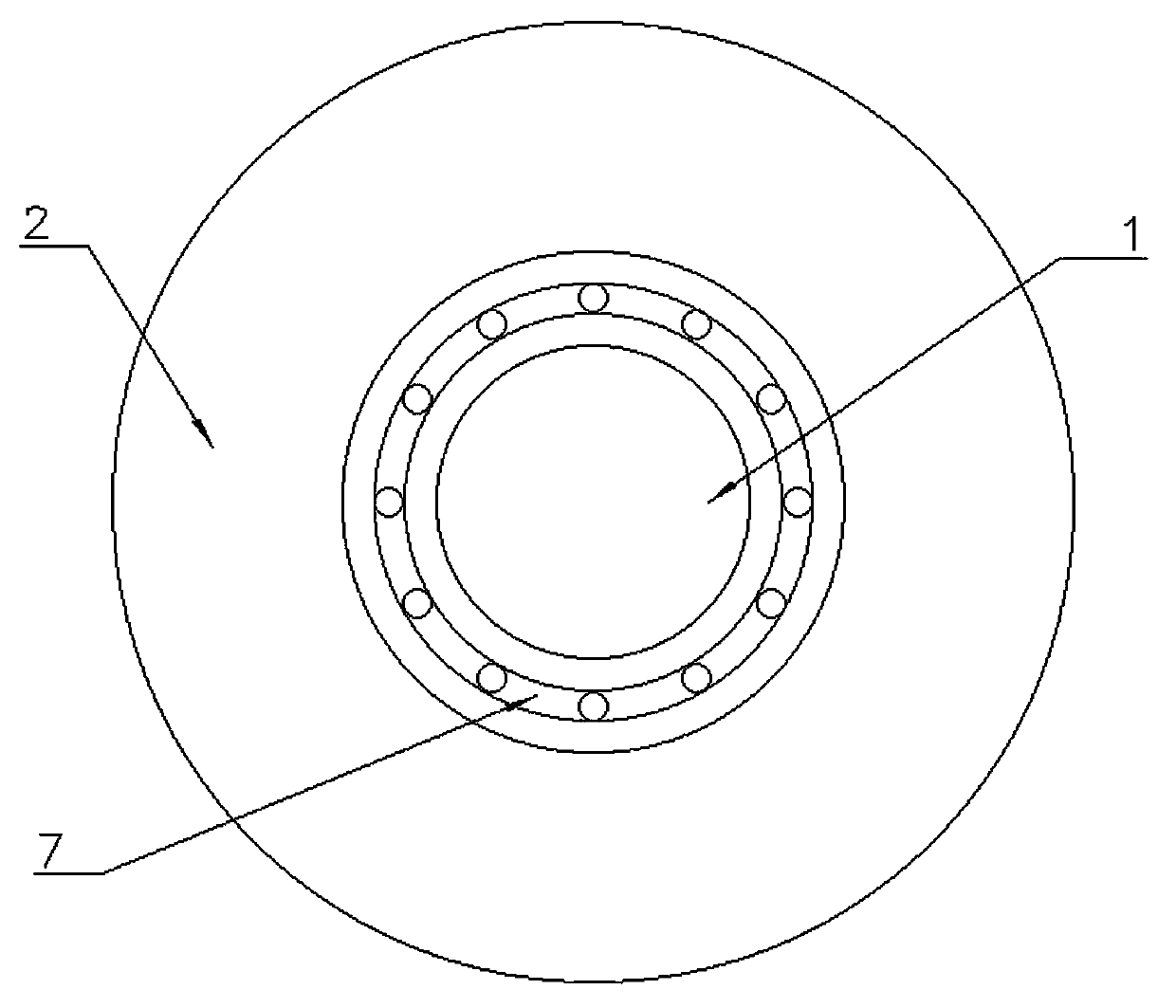

Electric wheel with built-in suspension flywheel

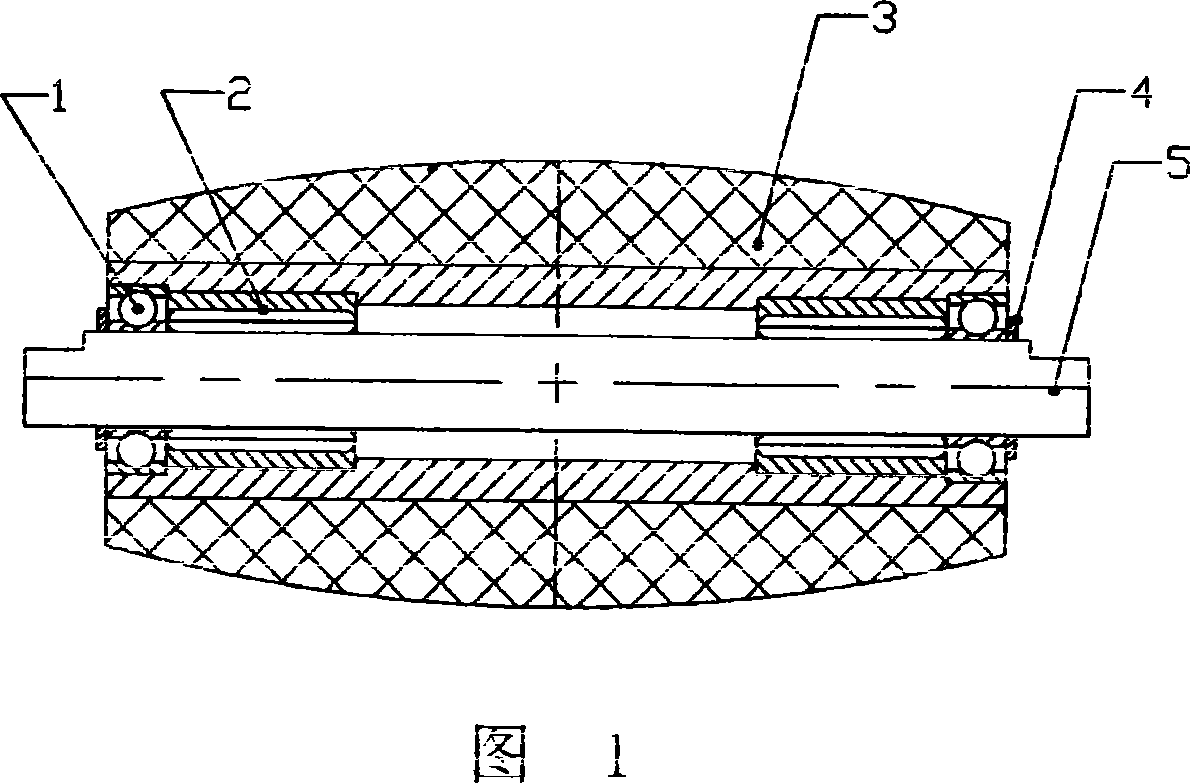

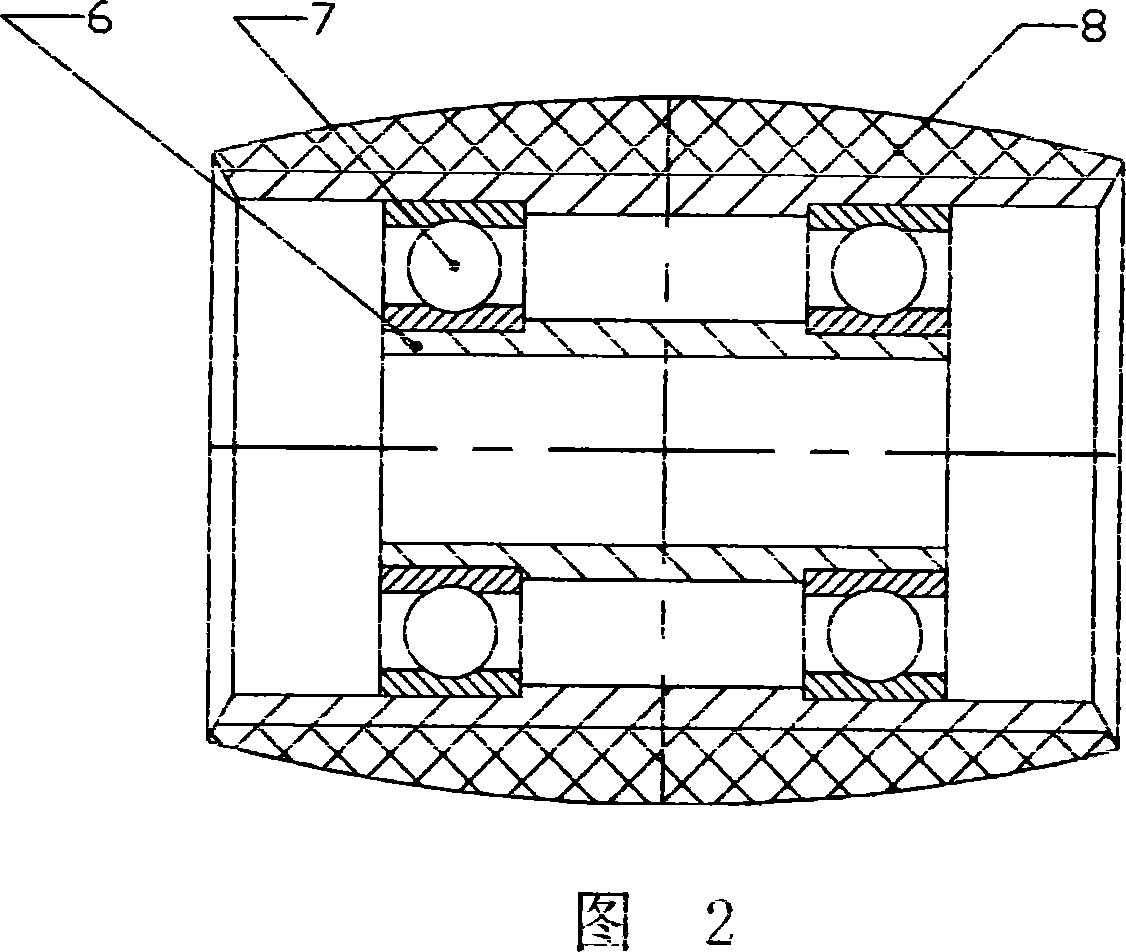

InactiveCN103950373AImprove efficiencyCompact structureBraking element arrangementsMotor depositionFreewheelElectrical conductor

The invention relates to the field of an electric wheel, in particular to an electric wheel with a built-in suspension flywheel. The electric wheel comprises a tire, a wheel axle, a wheel rim, a first bearing, a second bearing and an annular inner friction belt, wherein the wheel rim is used for installing the tire and is made of good conductor materials, the first bearing and the second bearing are annularly sheathed and fixed on the wheel axle side by side, the wheel rim is an annular casing with the U-shaped longitudinal section, the bearing outer ring outer annular surfaces of the first bearing and the second bearing are respectively and fixedly connected with two annular surfaces of a wheel rim inner circle, and a coil attachment wheel made of insulation materials is annularly sheathed and fixed on the wheel axle positioned between the first bearing and the second bearing. The electric wheel with the built-in suspension flywheel has the advantages that an integral structure is adopted, a magnet flywheel and the wheel are combined into a whole, the energy is efficiently stored, the structure is compact, the friction is small, and the efficiency is high; in addition, the magnet flywheel of the electric wheel is not in contact with the wheel rim and an iron core wound with coils under the magnetic suspension effect, and the high-speed rotation without mechanical friction is realized.

Owner:ZHONGBEI UNIV

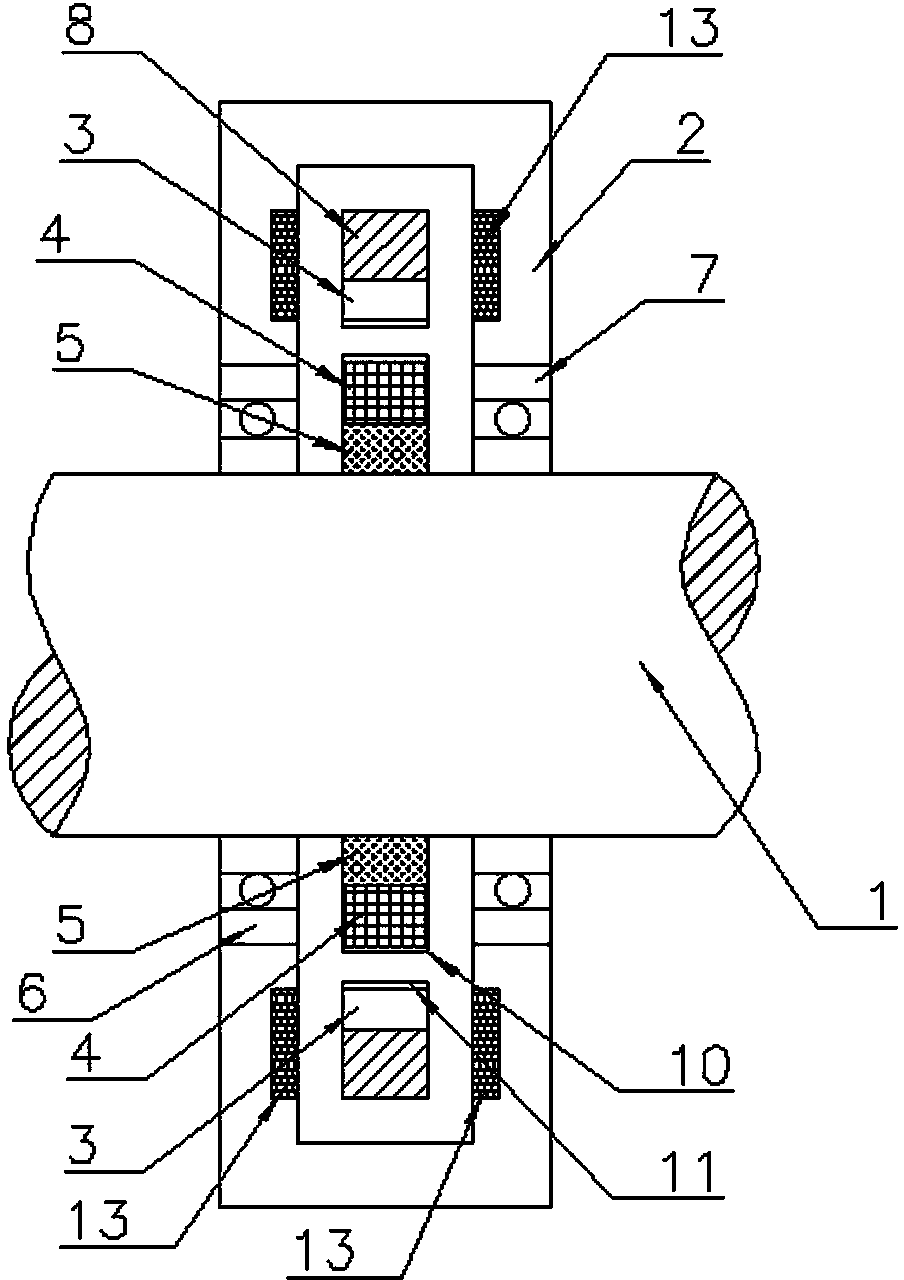

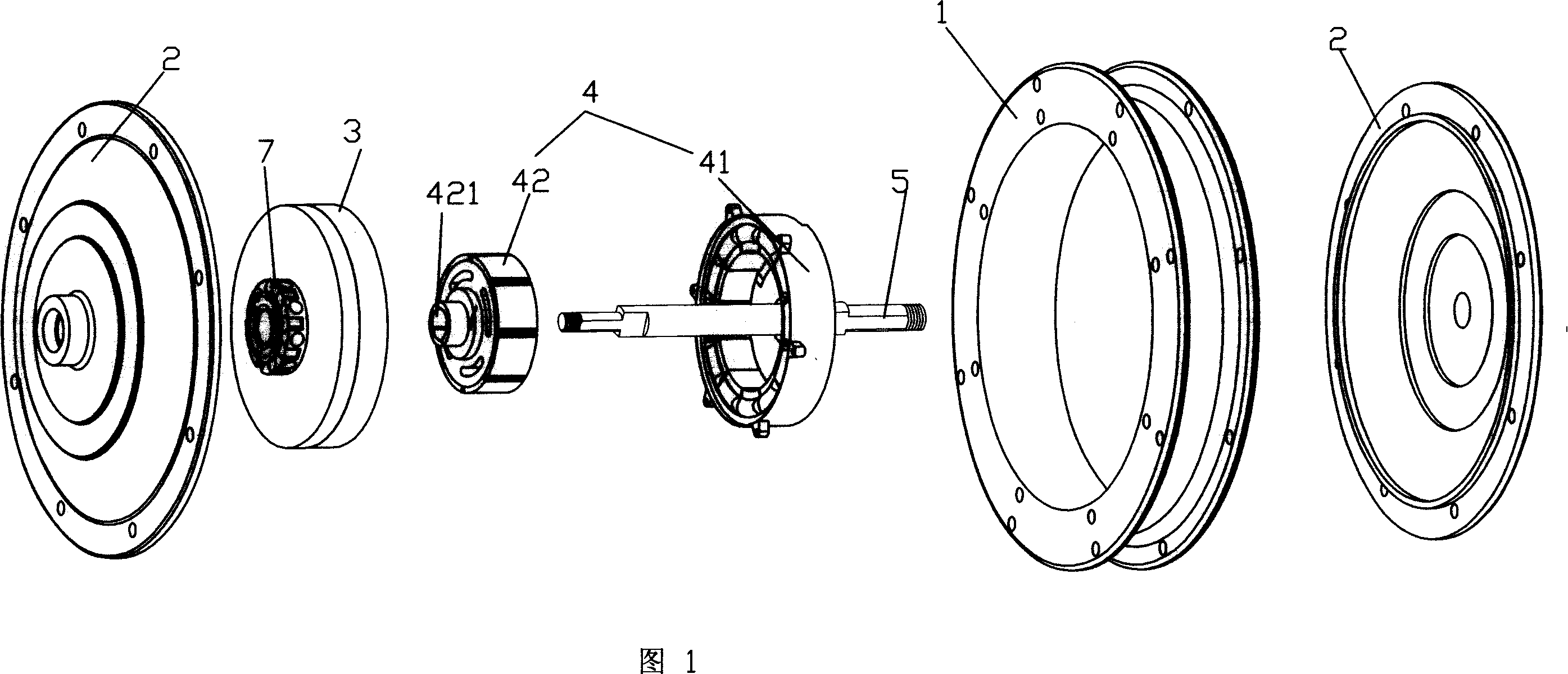

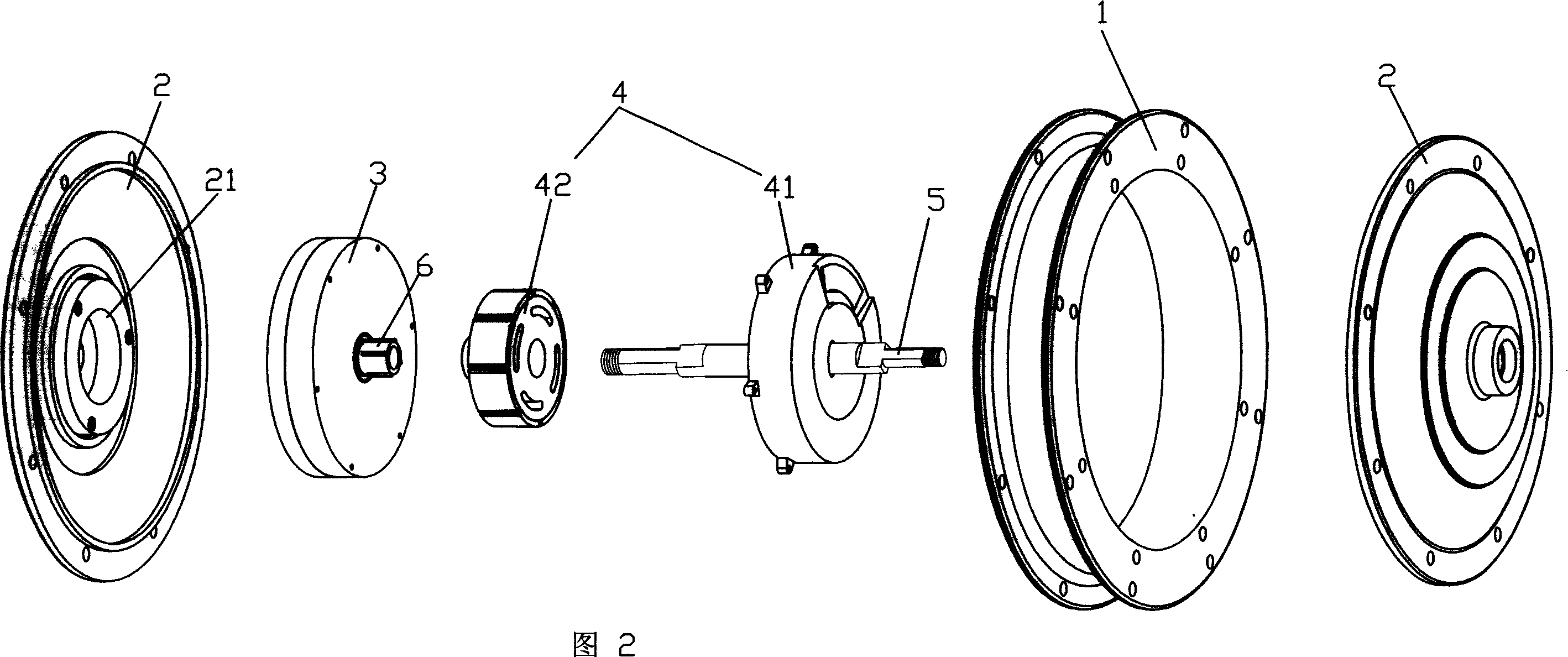

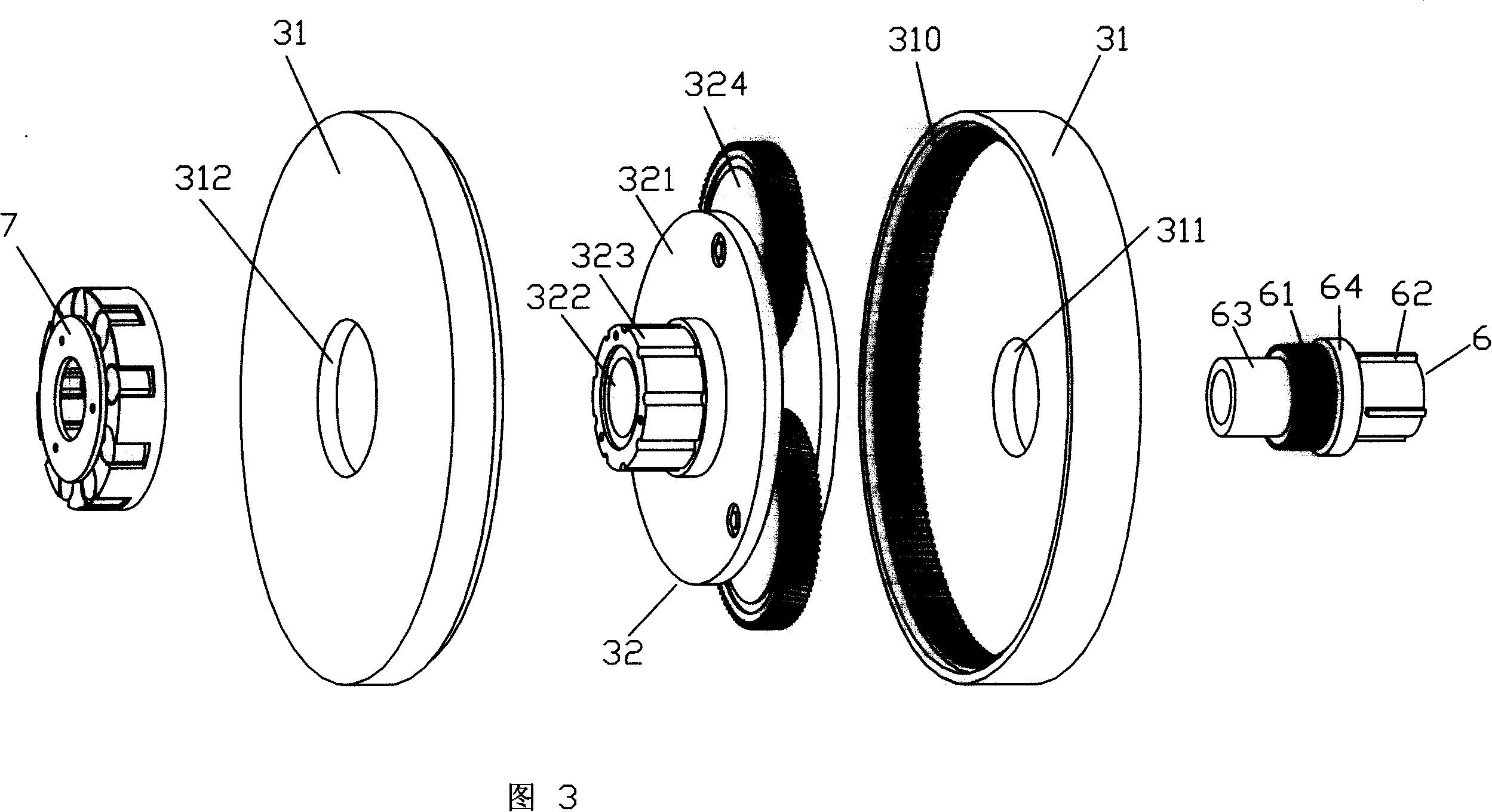

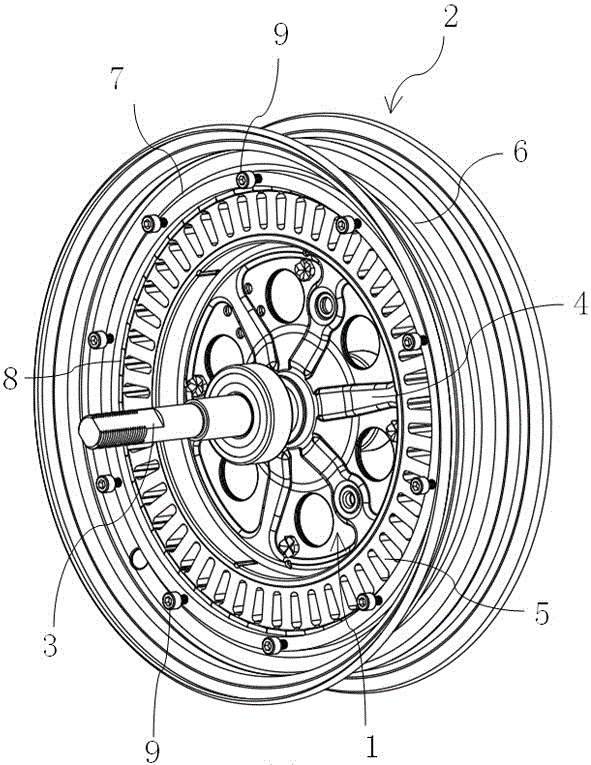

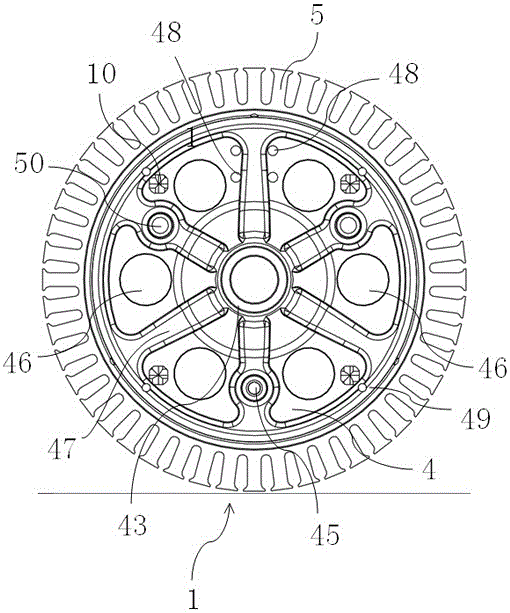

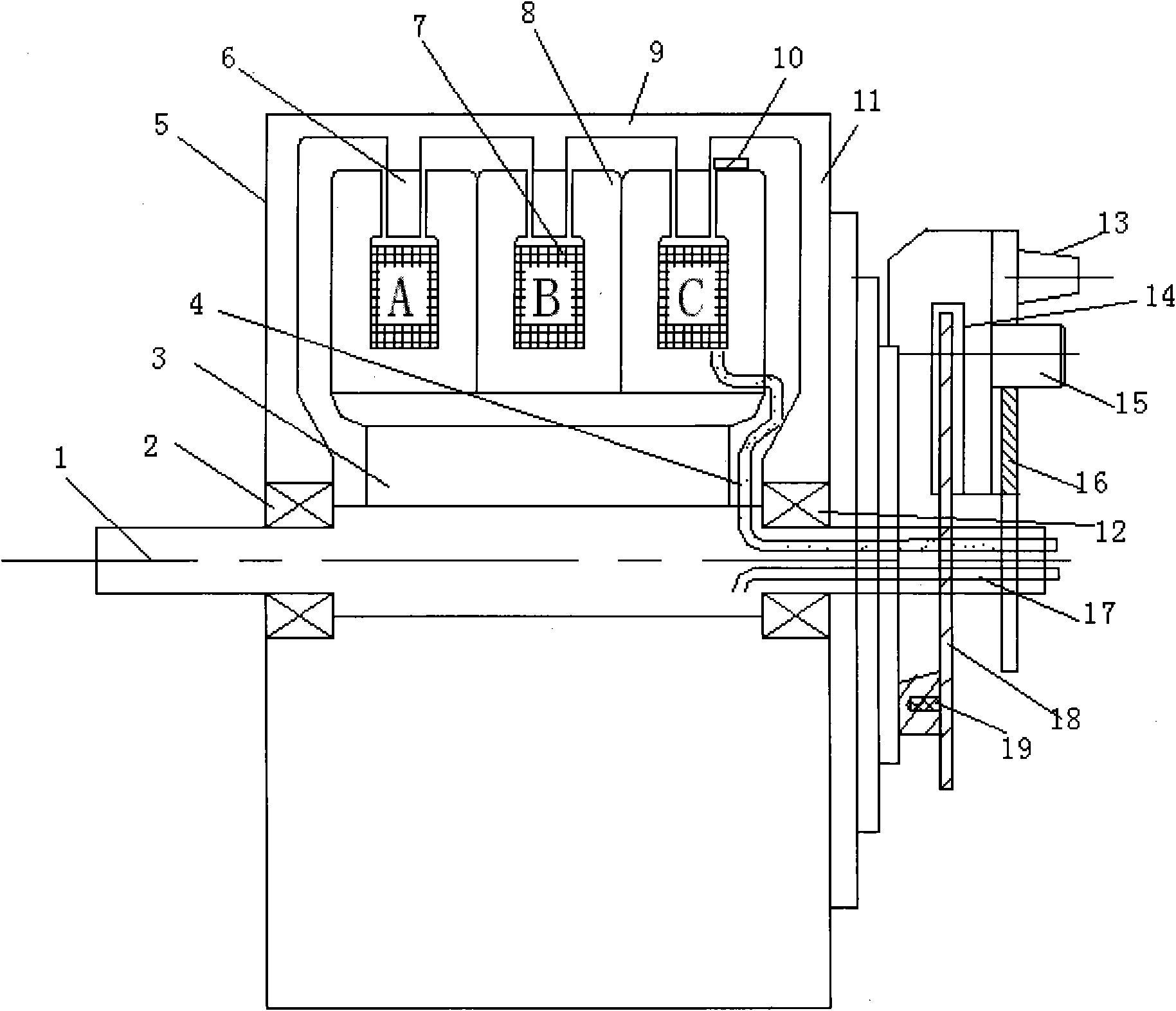

An electromotive wheel hub electromotor

InactiveCN101087088AGuaranteed stabilityReduce interactionMagnetic circuit rotating partsMechanical energy handlingReduction driveGear wheel

The invention relates to an electromobile boss motor which includes boss shell, end cap, retarder and motor parts, the motor parts include stator and rotor, the rotor is placed in stator, it characterized in that: said retarder composes retarder shell and underdriving gear set, the underdriving gear set is set in the retarder shell, input and output hole are separately set on two ends of the retarder shell, connecting axes is set on input hole, one end of connecting axes is engaged with underdriving gear set, the another end is connected with rotor, output of the underdriving gear set passes through the output axesof the retarder shell, clutch is between the output of the speed reduction gear and end cap. The structure of the product is compact, disassemble is convenient, performance is stable.

Owner:蔡国法

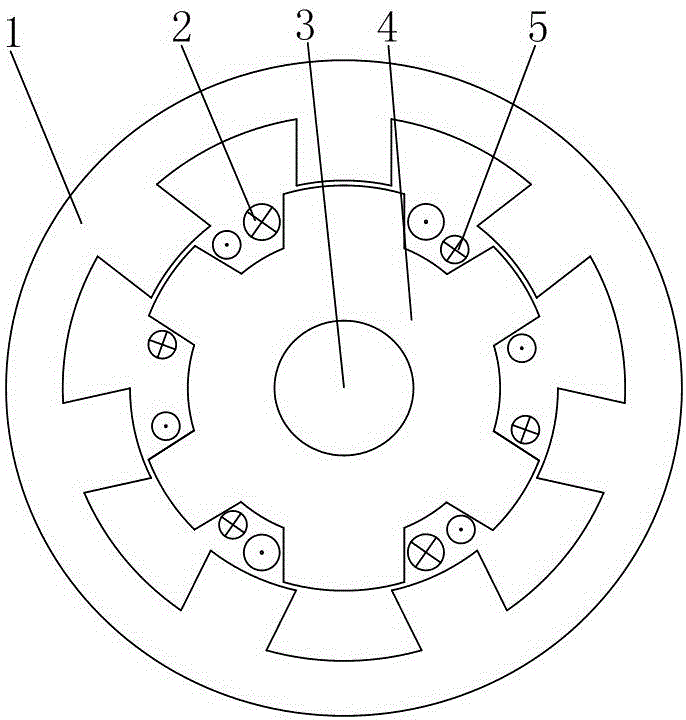

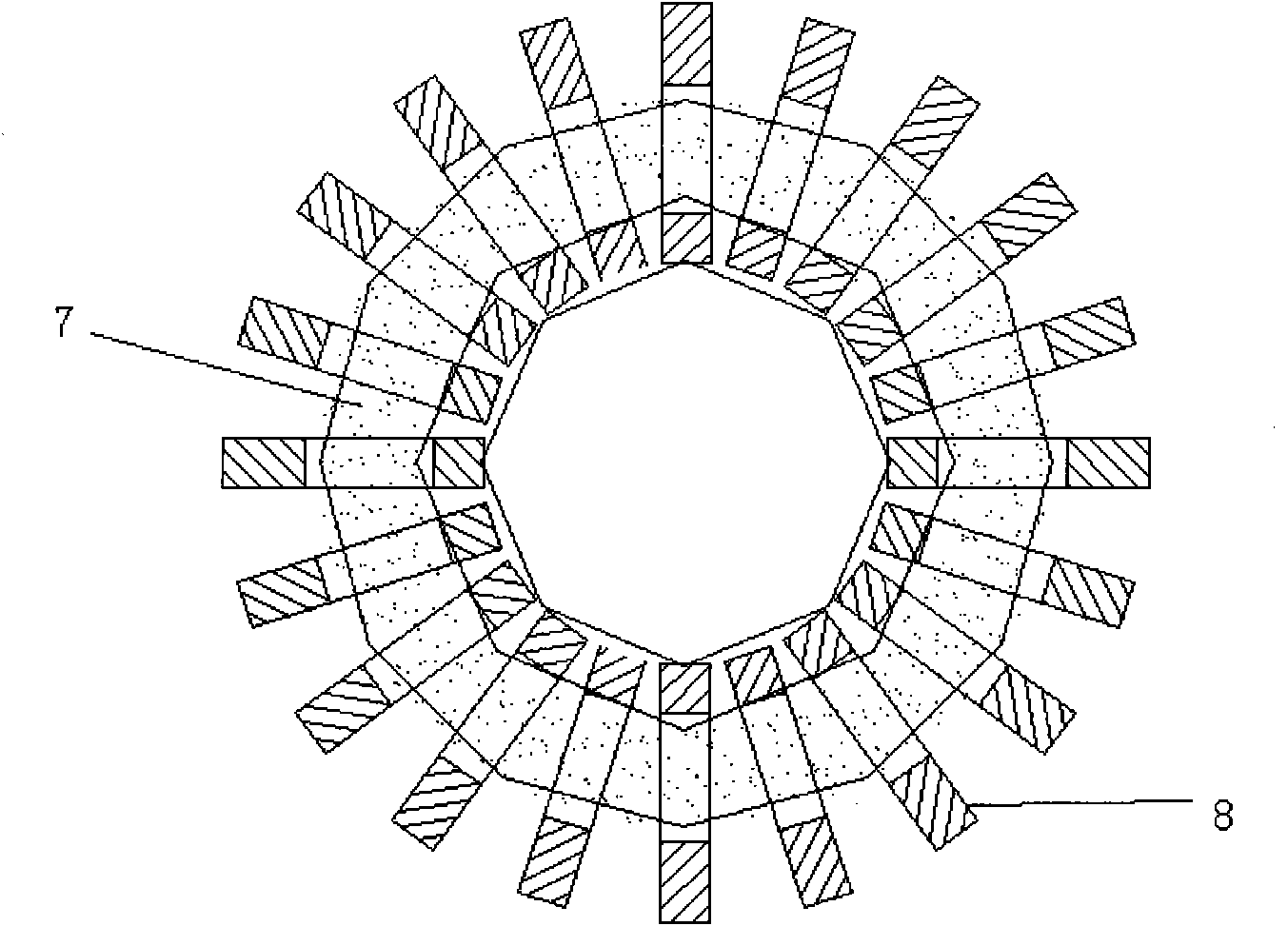

Electric car wheel hub motor

InactiveCN106100173AIncrease the cross-sectional areaIncrease current overload resistanceMagnetic circuit rotating partsMagnetic circuit stationary partsOperabilityElectric cars

The invention discloses an electric car wheel hub motor including a stator, a rotor and a connecting shaft. The stator and the connecting shaft are circumferentially positioned. The rotor sleeves the stator. The wheel hub motor is a 10-inch motor. The inner diameter of a magnetic conductive ring of the rotor is between 212.1 mm and 212.9 mm. The outer diameter of the stator is between 205.1 mm and 208 mm. While rim valve hole perforation operability is ensure and the functions of a rim are not affected, through increasing the size of a rim welding inner ring, the inner diameter of the magnetic conductive ring and the outer diameter of the stator, and optimizing the inner support structure of the stator, the moment arm and effective air gap magnetic flux of the motor are increased, and larger electromagnetic force is obtained. The output torque performance and the work efficiency of the motor are improved, and the power density and material utilization rate of the motor are increased as well. More inner space of the motor is obtained, which facilitates motor cooling, reduces motor temperature rise, and reduces the high-temperature aging speed of the motor. The motor load capacity is high, safety and reliability is high, and the motor is more environment-friendly and energy-saving.

Owner:TAIZHOU JINYU ELECTROMECHANICAL

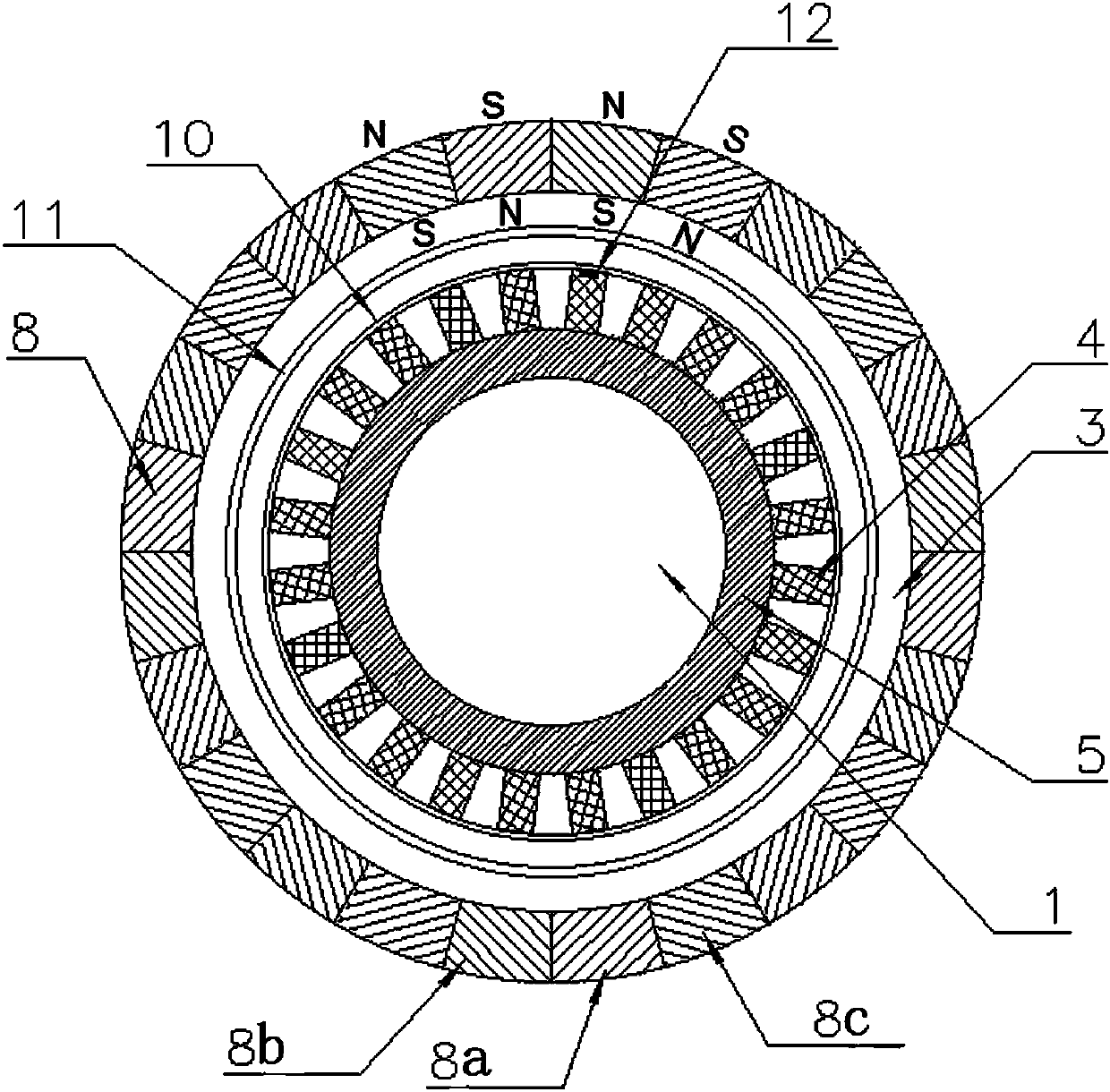

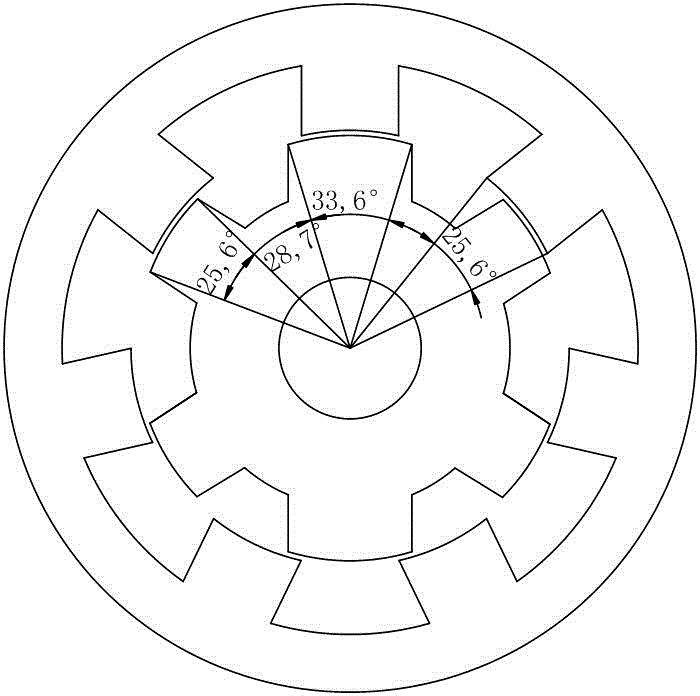

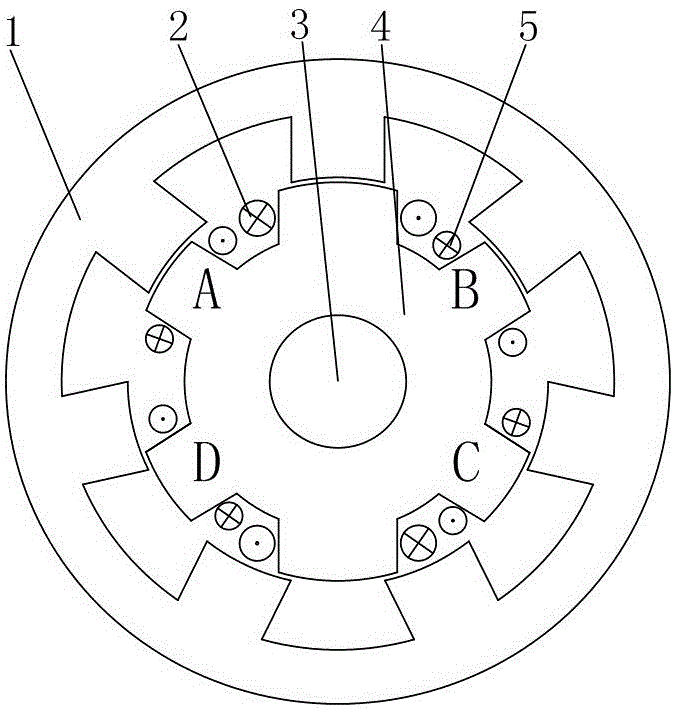

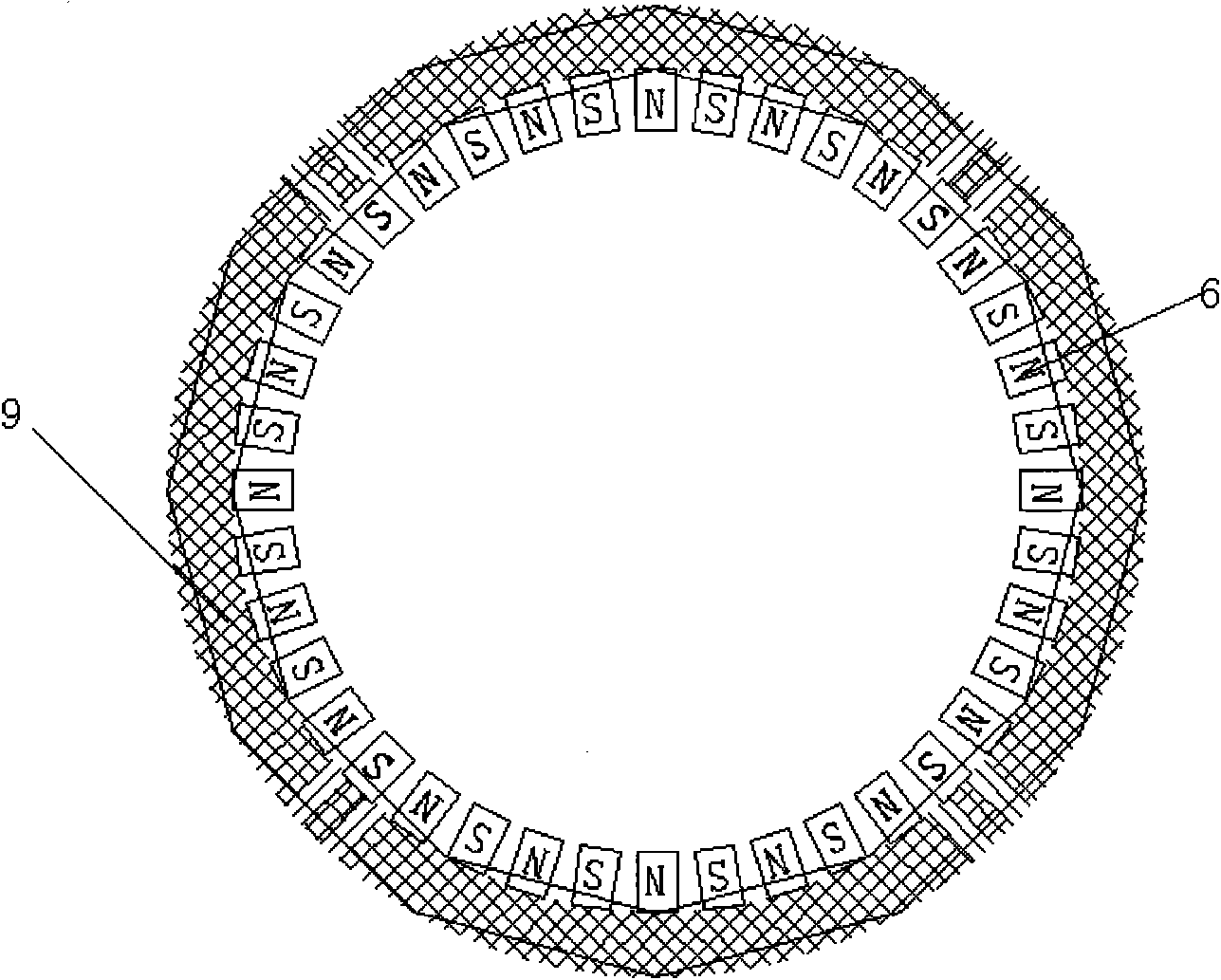

Electrombile wheel hub motor with centralized excitation function

ActiveCN106849421ASimple structureWide speed rangeBatteries circuit arrangementsMagnetic circuit rotating partsExcitation currentConductor Coil

The invention provides an electrombile wheel hub motor with a centralized excitation function. The electrombile wheel hub motor comprises a stator iron core, an outer rotor iron core, excitation windings, armature windings and a shaft, wherein seven rotor poles which are of convex pole type structures are arranged at the inner side of the outer rotor iron core, and the pole-arc coefficient of each rotor pole is 0.5; two excitation poles wound by the excitation windings and four armature poles wound by the armature windings are arranged on the stator, and the excitation poles and the armature poles respectively adopt stator poles which are of convex pole type structures; the two excitation poles are distributed at the interval of a 180-degree mechanical angle, and the pole-arc mechanical angle of the excitation poles is 33.6 degrees; two armature poles are arranged at both sides of each excitation pole, and the pole-arc mechanical angle of the armature poles is 25.6 degrees; a stator groove for placement of the armature windings and the excitation windings is arranged between each armature pole and the corresponding excitation pole, and the mechanical degree of an opening of each stator groove is 28.7 degrees. The electrombile wheel hub motor has the advantages that when the motor is used as a power generator to run, the output voltage at different rotation speeds can be controlled by adjusting the excitation current, and then the brake energy is recycled for charging a storage battery of an electrombile; when the motor is used as an electric motor to run, the output torque of the wheel hub motor can be controlled by adjusting the sizes of the excitation current and the armature current.

Owner:SHANDONG UNIV OF TECH

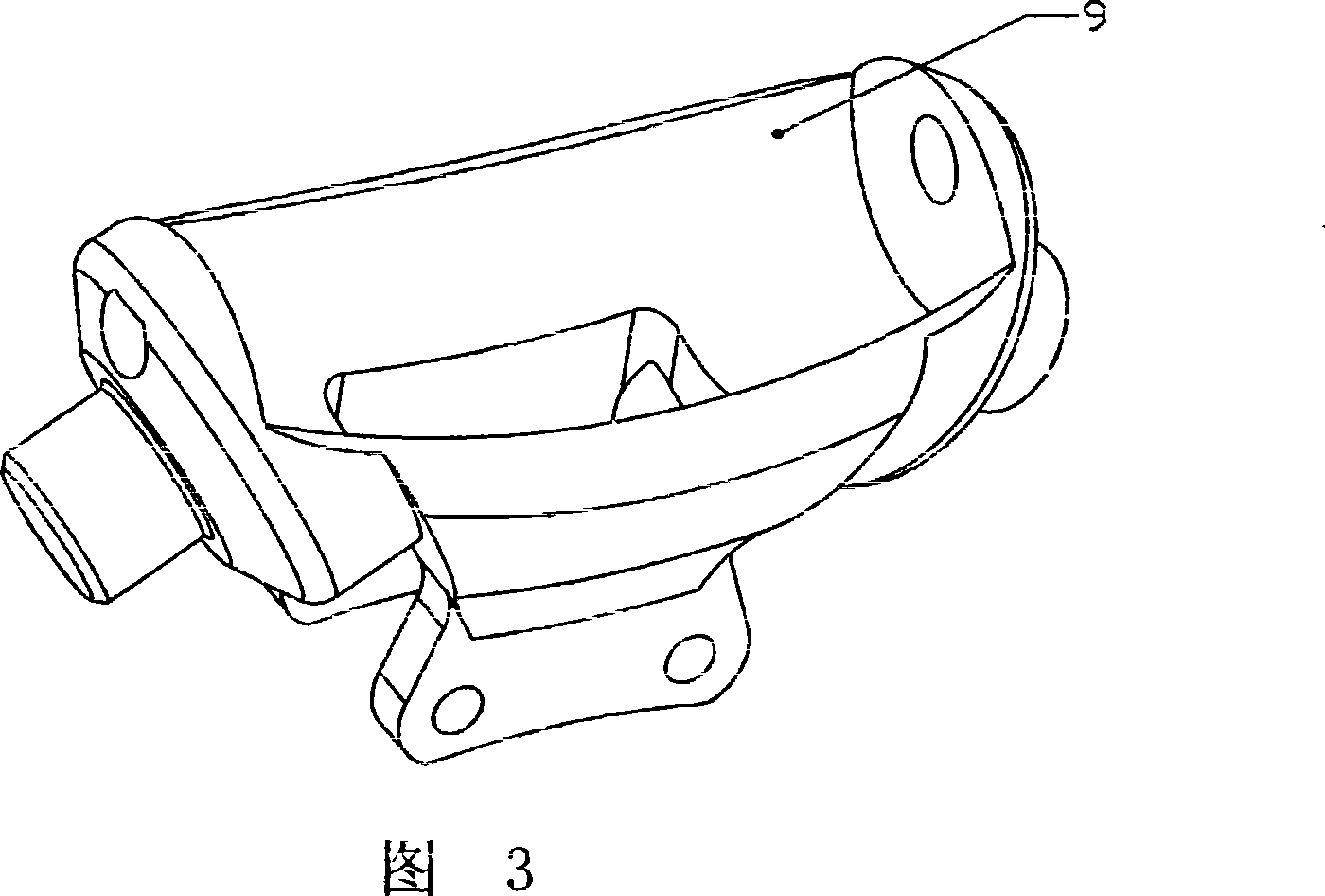

An improved drive machine for electric vehicle hub electromotor

InactiveCN101127467AImprove coaxialityMutual friction is smallMechanical energy handlingSupports/enclosures/casingsLow noiseReduction drive

The utility model relates to an improved transmission mechanism for wheel hub motors of electric vehicles, which comprises an electric motor, a wheel hub casing, a main shaft, a speed reducer and a clutch; wherein, the stator and the stator casing of the electric motor are fixedly connected on the main shaft; the rotor is arranged inside the stator and the stator casing and is connected with the speed reducer; the speed reducer is connected with the wheel hub casing through the clutch. The utility model is characterized in that: the speed reducer comprises two positioning disks, a planetary gear, a bearing, a connecting shaft and a casing. The three planetary gears are symmetrically arranged between the front and the rear positioning discs; both ends of rotating shafts of the planetary gear are fixedly connected on the front and the rear positioning discs; a circle of teeth are arranged inside the casing and meshed with the three planetary gears; the casing is mechanically fixed with the electric stator and stator casing. The utility model has the advantages of small motor output loss, low noise, and long service life.

Owner:蔡国法

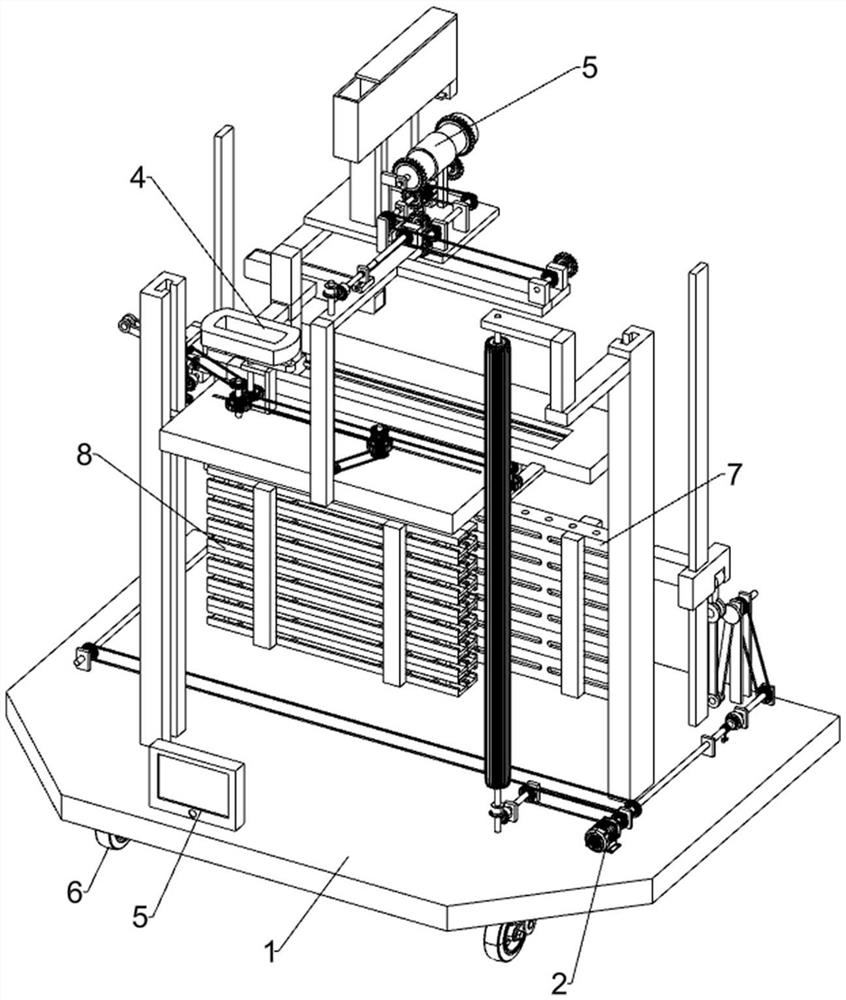

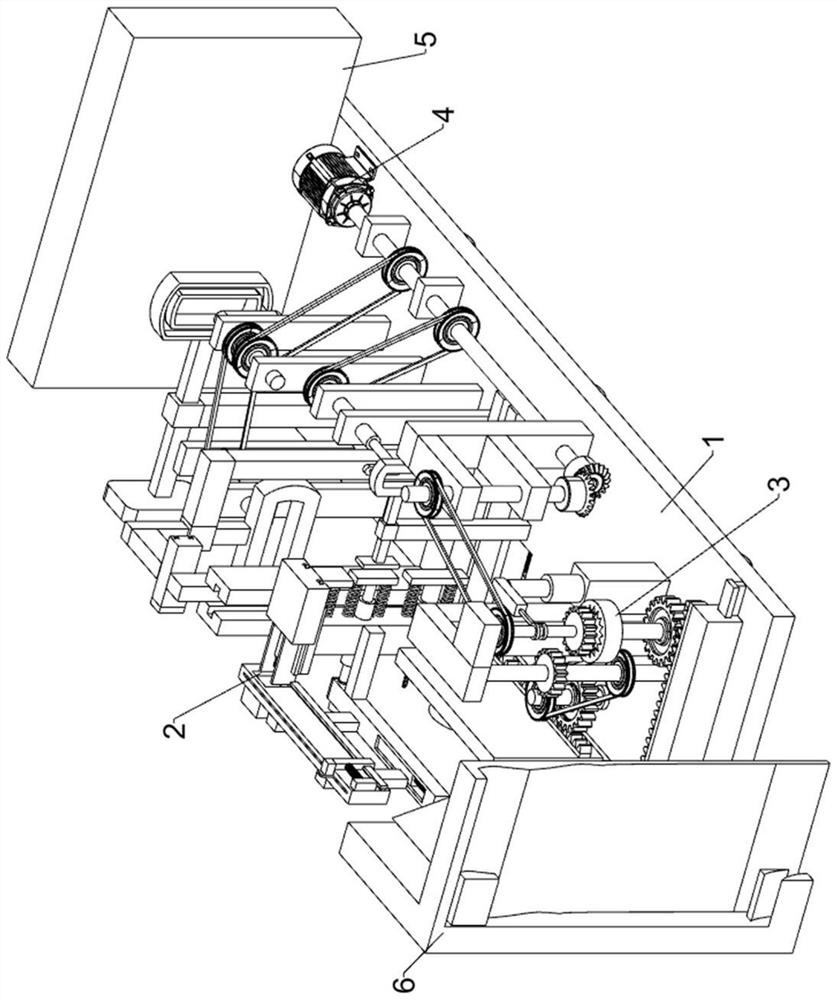

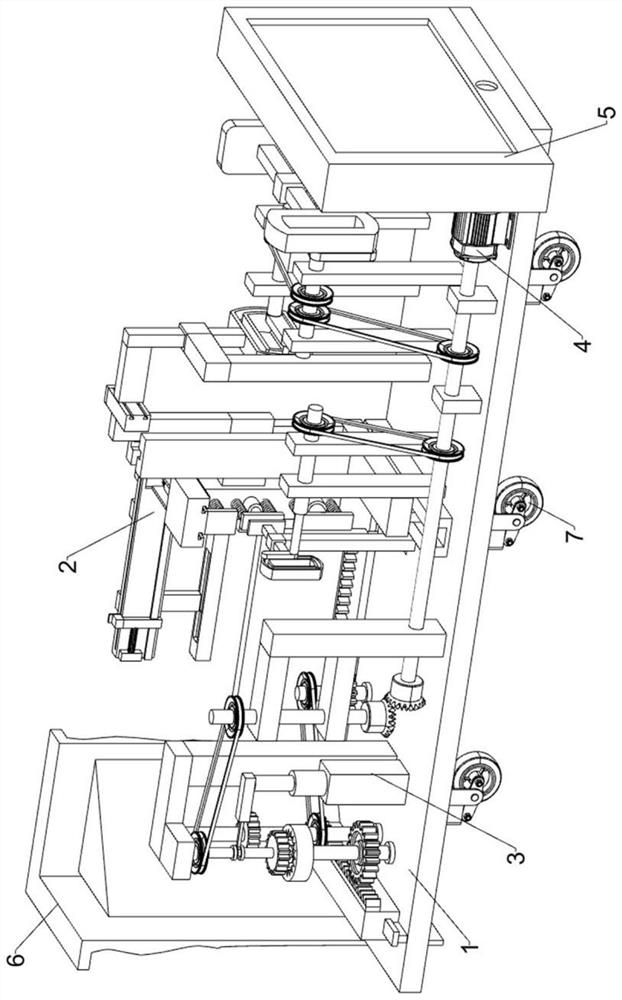

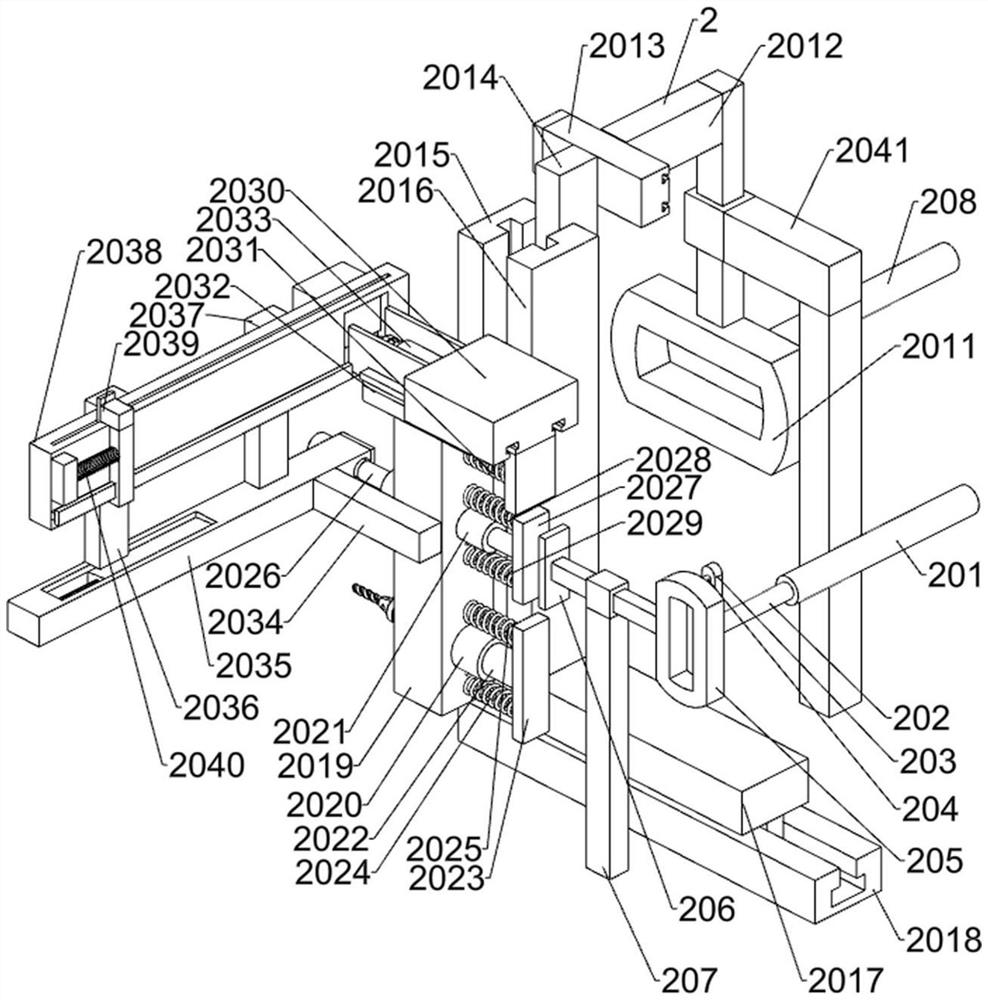

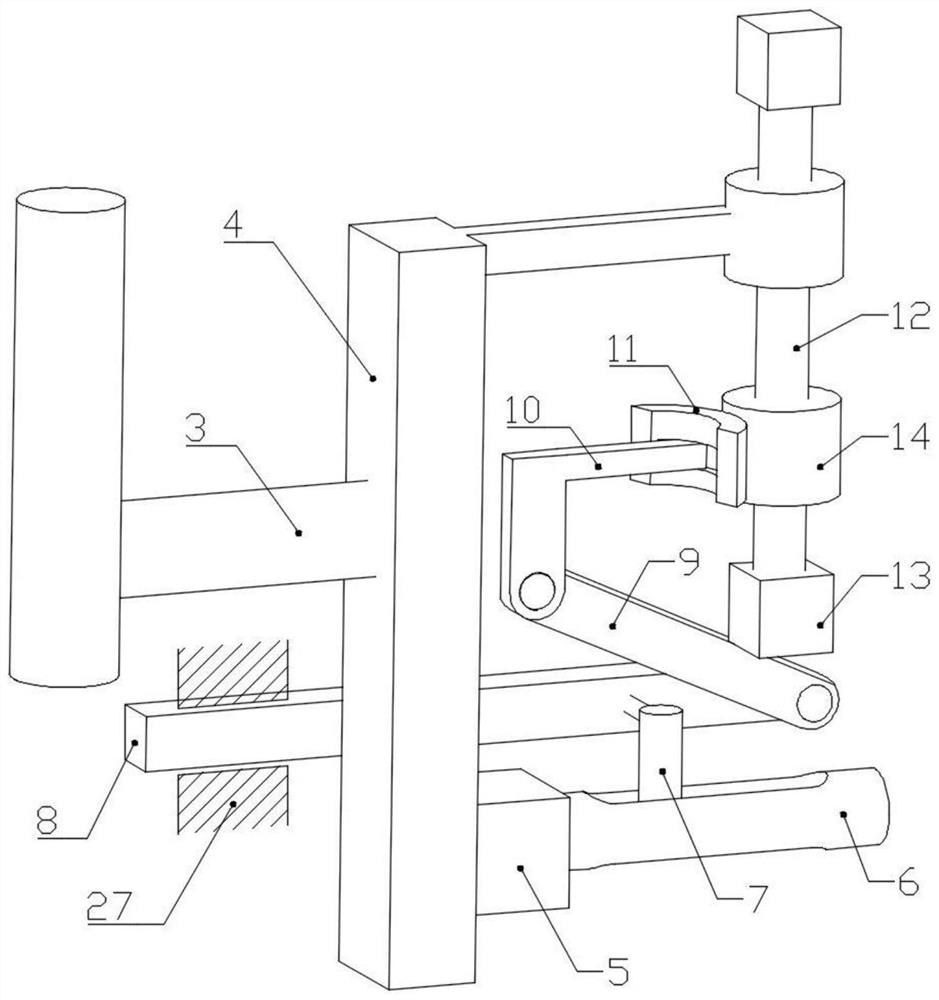

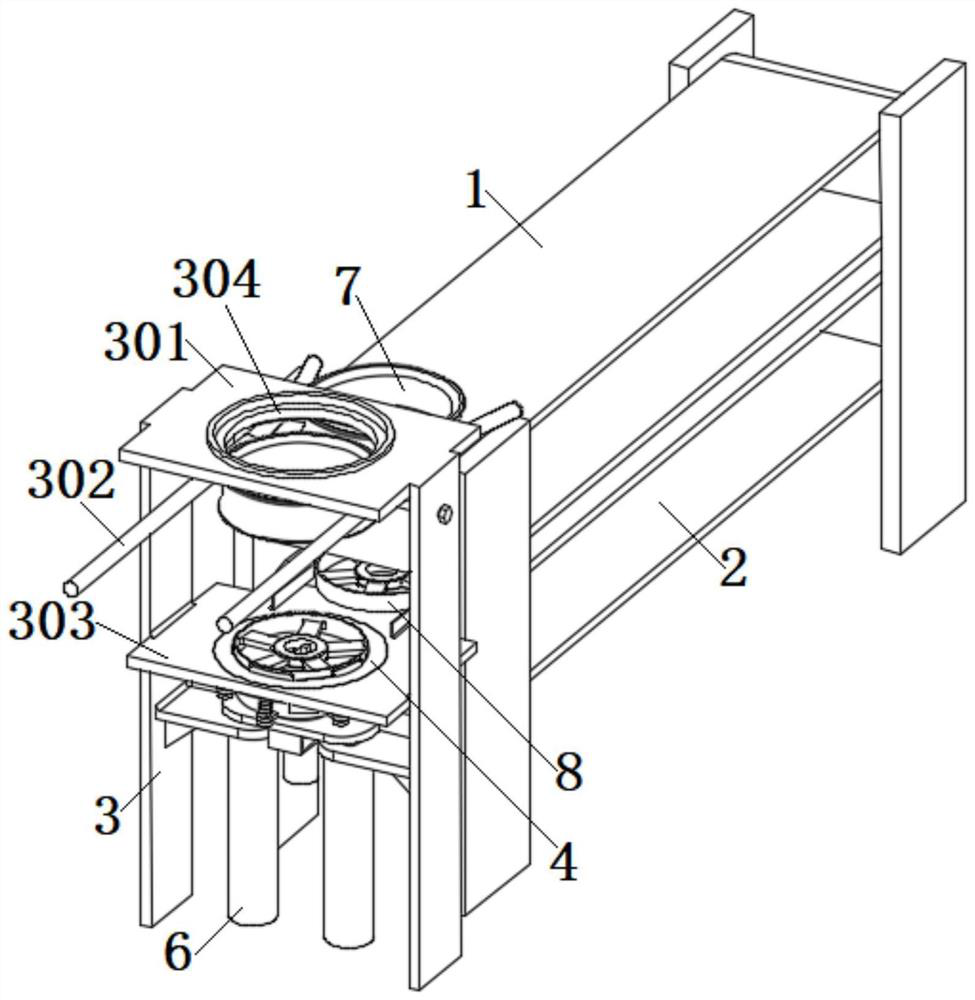

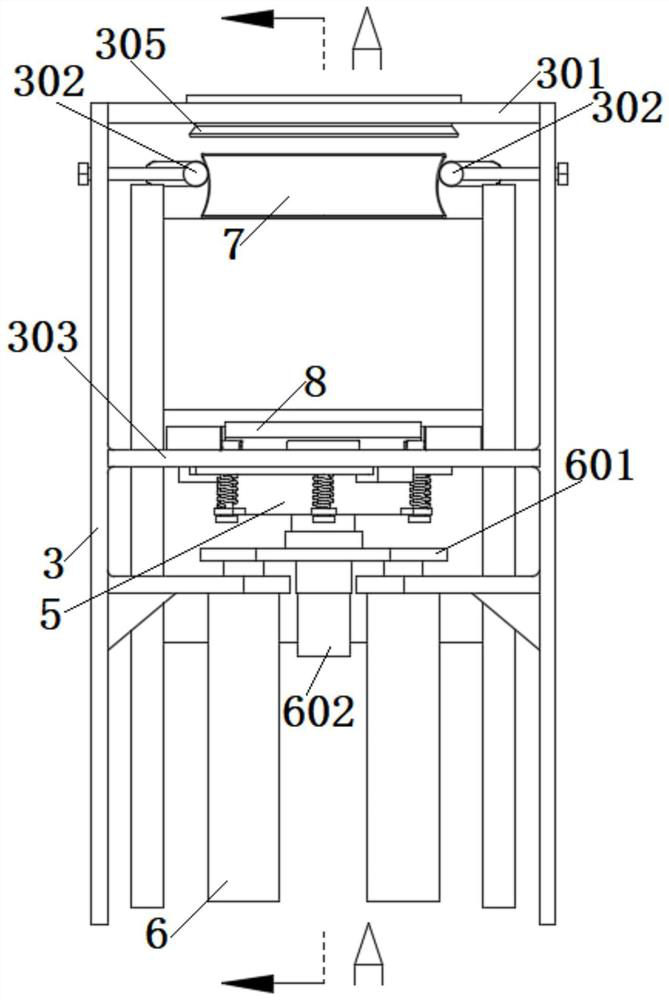

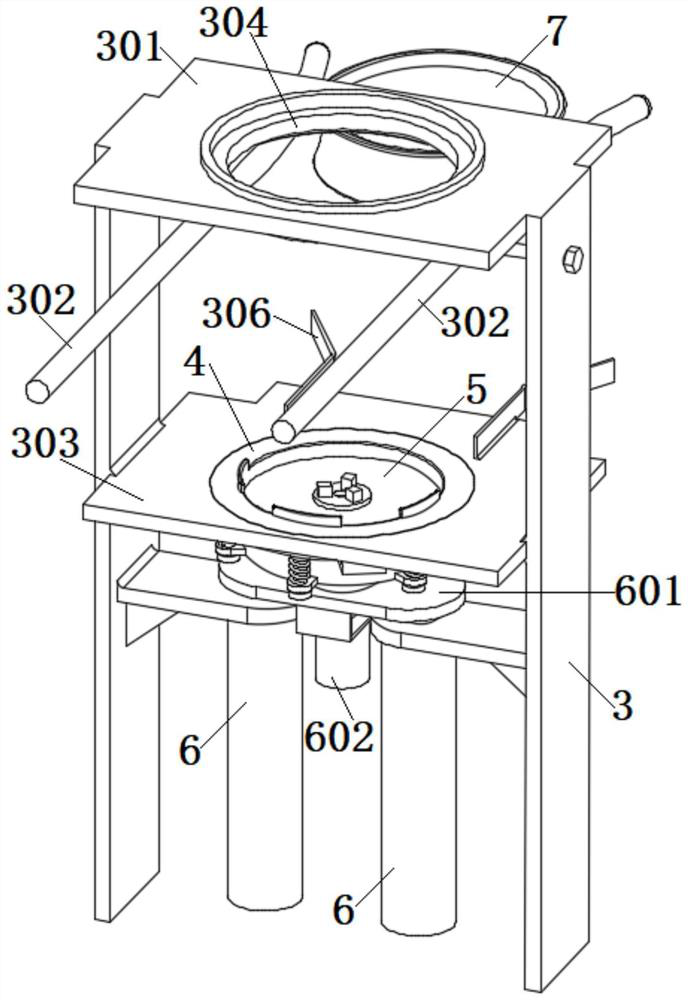

Quick clamp for electric vehicle hub

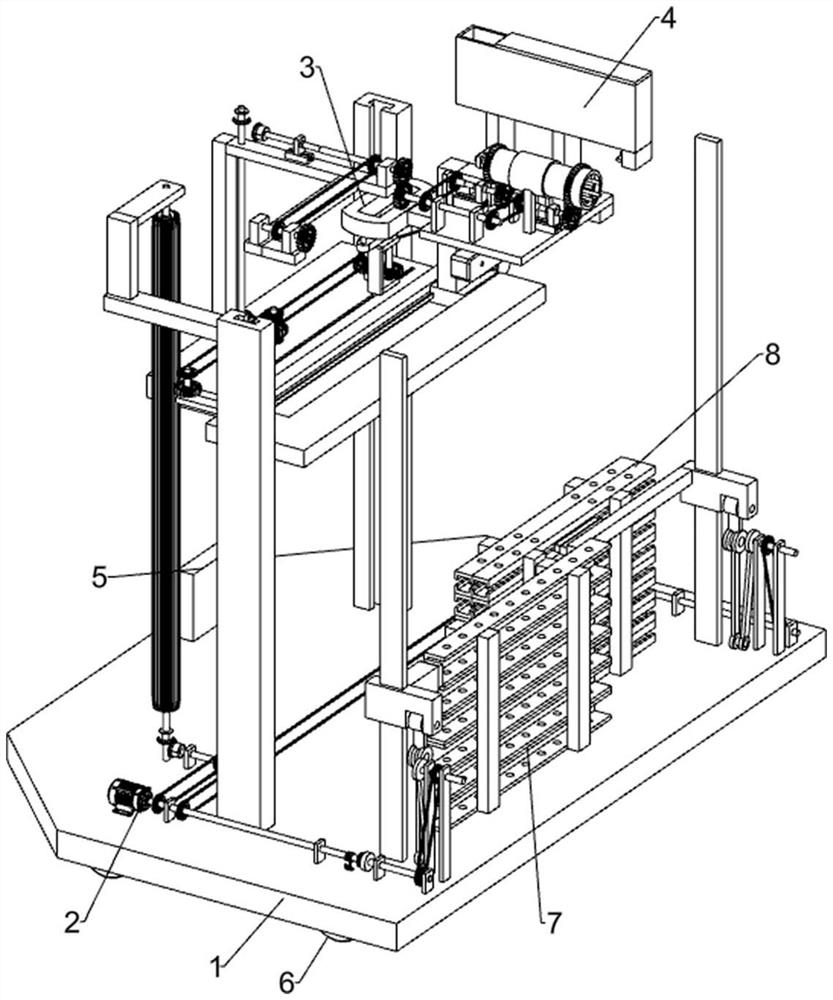

InactiveCN108000200AReduce labor intensitySimple structurePositioning apparatusMetal-working holdersEngineeringElectric vehicle

The invention discloses a quick clamp for an electric vehicle hub, and belongs to the technical field of electric vehicle manufacturing. Supporting legs connected to a workbench are fixed under a supporting table. A circular through hole is formed in the center of the supporting table. A clamping cylinder is vertically arranged and a piston rod of the clamping cylinder penetrates through the through hole of the supporting table in an upward mode. A stopping table is fixed to the upper end of the piston rod of the clamping cylinder. A plurality of evenly-distributed supporting rods are fixed tothe middle part of the piston rod of the clamping cylinder. Horizontal sliding chutes are formed in the outer ends of the supporting rods. Rolling rods are installed in the sliding chutes in a sliding mode. L-shaped pull rods are hinged to the rolling rods. Rotating shafts are installed at the corners of the pull rods in a rotating mode. The other end of each pull rod faces the center of the supporting table and is further connected with a clamping ejection block in a hinged mode. The quick clamp for the electric vehicle hub is simple in structure and convenient to clamp, machining work efficiency is improved, time is saved, and the labor intensity of workers is low. Moreover, machining cost is low, and the quick clamp can be used conveniently in mounting or dismounting and thus be quitesuitable for application and popularization.

Owner:徐州松惠机电有限公司

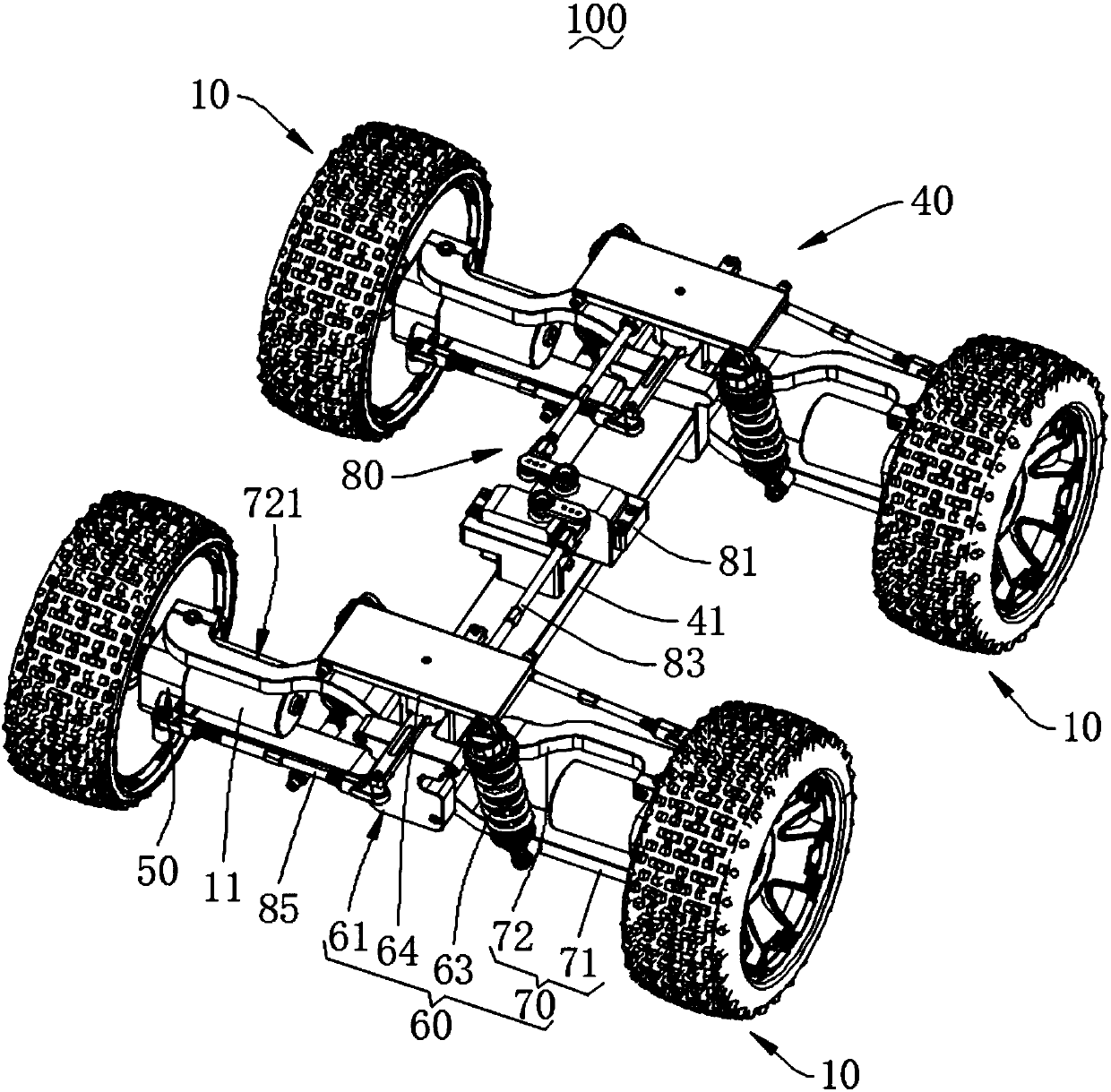

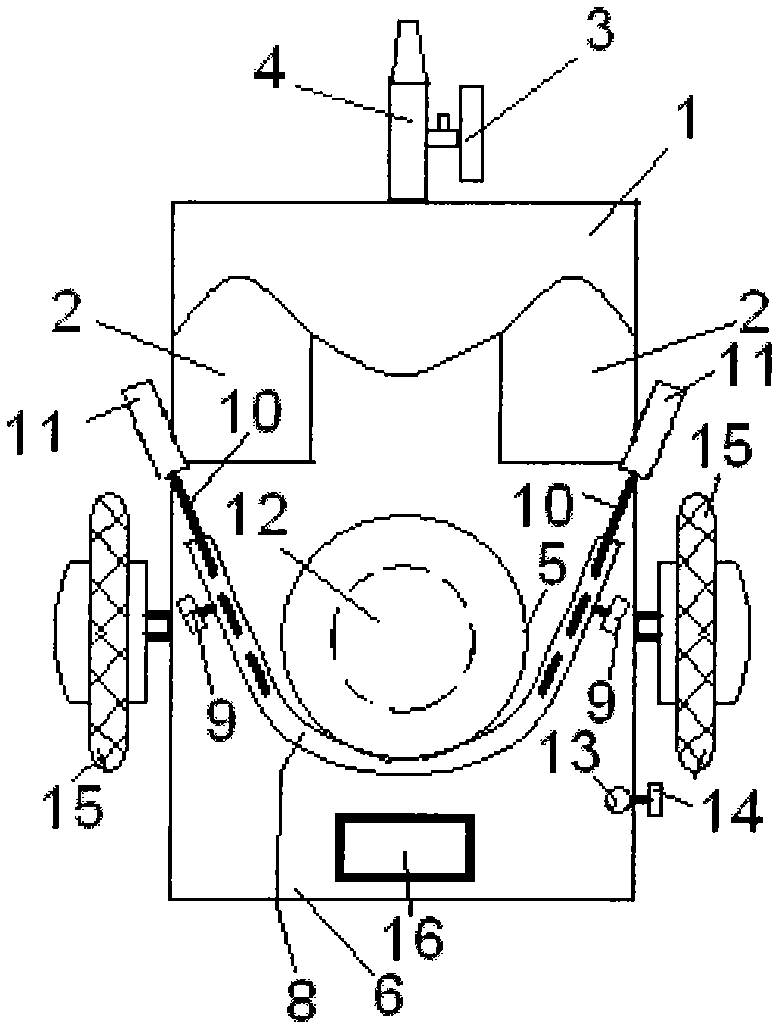

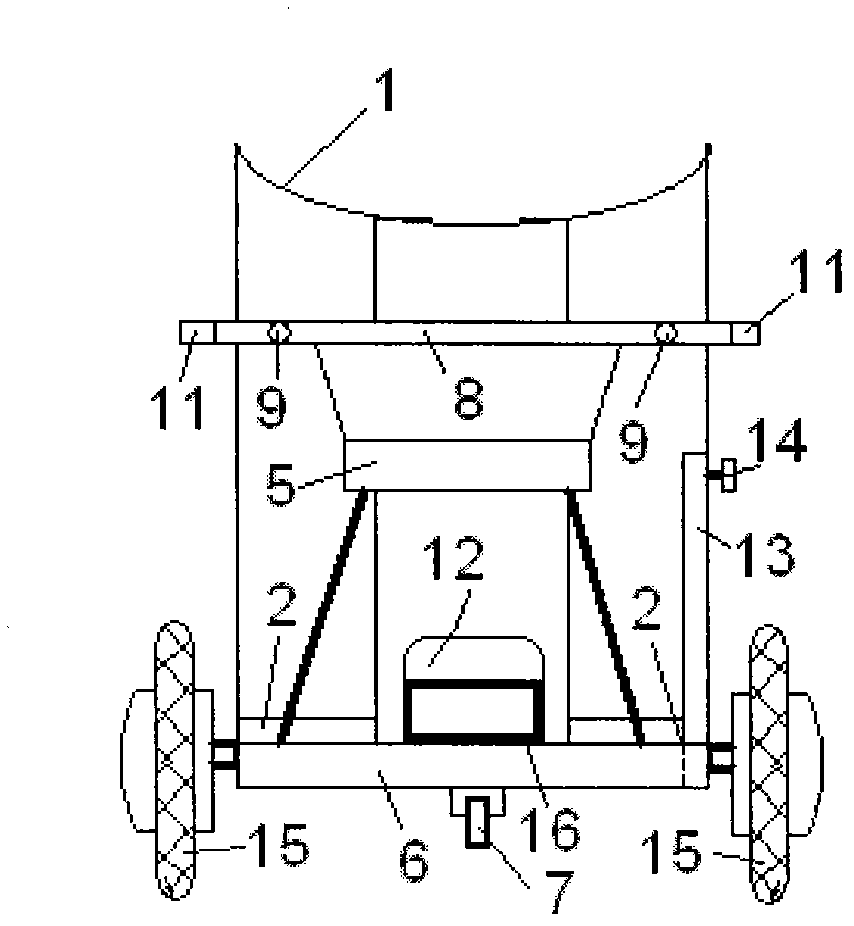

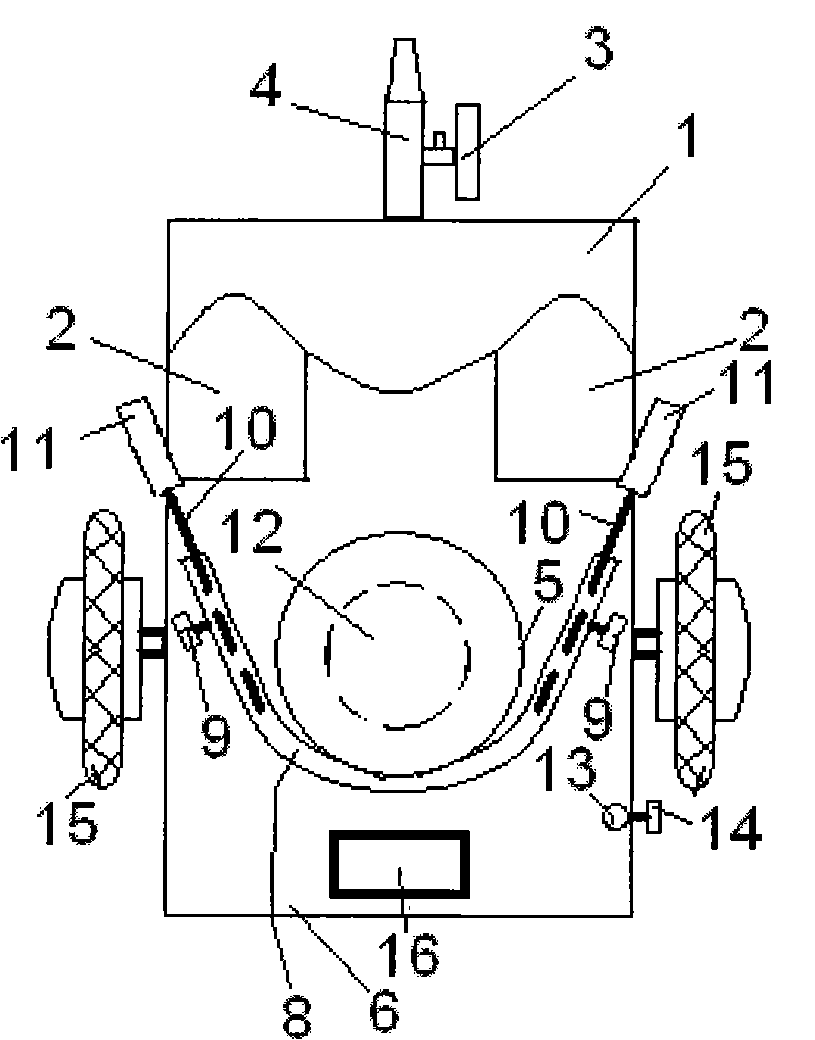

Four-wheel independently driven car

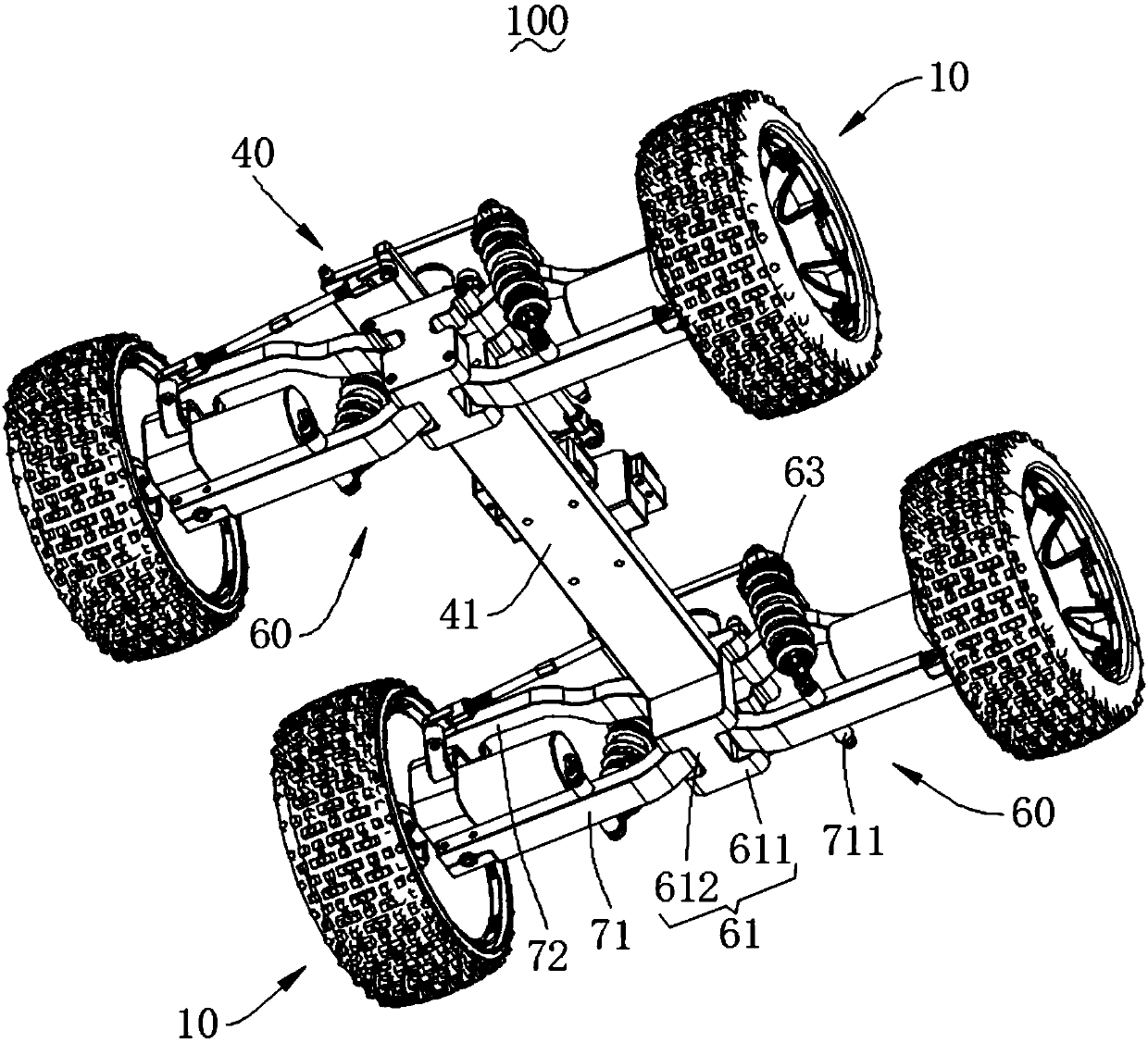

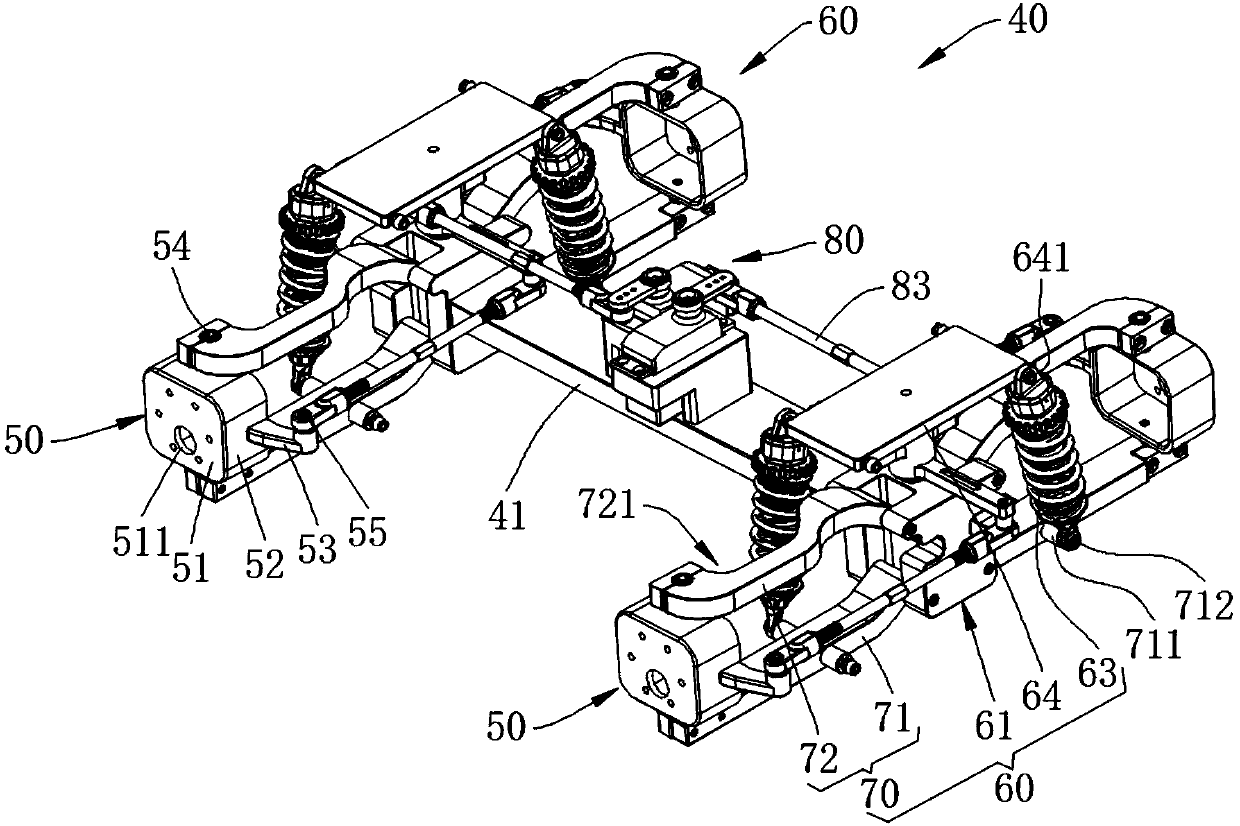

PendingCN107899252ALower center of gravitySmooth rideRemote-control toysToy vehiclesDrive wheelDrive motor

The invention provides a four-wheel independently driven car, which comprises a chassis and two pairs of electric wheels, wherein the pair of electric wheels are arranged at two sides of the front endof the chassis, and the other pair of electric wheels are arranged at two sides of the back end of the chassis; steering rudders, which are used for driving the various electric wheels to steer, arealso arranged on the chassis; the various electric wheels comprise wheel bodies and drive motors; and the drive motors are hinged on the chassis. According to the four-wheel independently driven car provided by the invention, the four electric wheels are adopted, the various electric wheels adopt the drive motors and the wheel bodies, and the wheel bodies are driven to rotate by virtue of the drive motors; and by arranging the various drive motors on the chassis, the gravity center of the four-wheel independently driven car is reduced, the four-wheel independently driven car is more stable indriving and a climbing performance is enhanced; the various wheels are directly connected to the drive motors, so that a transmission system is omitted, and subsequently, the car is simpler in structure and cost is greatly reduced; and through rotating speed control of the various drive motors, a differential speed is formed, so that a steering direction can be controlled conveniently, and meanwhile, a turning radius can be reduced.

Owner:BSD RACING TECH

Electric universal wheel

InactiveCN101073972ASave internal spaceSimple and compact single-row structureCastorsMechanical energy handlingBrushless motorsWheelchair

The invention is concerned with a versatile electric wheel belonging to wheel drove by motor. The whole wheel rim is made of drum tape of big and small roller parts and roller rack, and they connect with in-wheel DC brushless motor through bolt as a versatile electric wheel. The drum tape of big and small roller parts is the rim of electric wheel to from the versatile electric wheel, and the wheel can walk in landscape orientation, inclined direction and all direction. It has single row structure to save space of carriage interior with easy technology and low cost. It can be used for electric wheel chair, electric transport vehicle, assistant vehicle and electric sickbed, and moves in limited space in room.

Owner:黄长江

Electric vehicle in-wheel motor stator

InactiveCN106230146AImprove anti-overload performanceImprove work efficiencyElectric machinesMagnetic circuit stationary partsEngineeringElectric vehicle

The invention provides an electric vehicle in-wheel motor stator, which comprises an iron core and a support, wherein the iron core is fixed on the circumference of the support; the iron core and the support are tightly matched for circumferential positioning; a coil is wound on the iron core; two different disc-shaped supporting plates are positioned, buckled and connected via a self-riveting positioning hole structure to form the support; the supporting plates are connected via a rivet or partial butt riveting fixing is realized; the center of each supporting plate is a round hole with a turned edge; the round holes with turned edges of the two supporting plates are welded to the same sleeve; and welding between the two supporting plates and the sleeve is located at the near end of two ends of the sleeve. The stator support adopts an irregular concave and convex polygon reinforced rib structure, the surface area of the support is increased, the radial or axial irregular complex impact force applied to the support can be effectively shouldered on one hand, output torque variations of the in-wheel motor can be better borne, and on the other hand, the stator support cooling surface area is increased, cooling of the stator is facilitated, temperature rise of the motor is reduced, the bearing ability and the anti-impact ability of the motor are improved, and the electric vehicle in-wheel motor stator can be applied to all kinds of bad environments.

Owner:TAIZHOU JINYU ELECTROMECHANICAL

Electric wheel hub motor

InactiveCN102055273AEasy to brakeElectric machinesMagnetic circuit stationary partsHydraulic pumpEngineering

The invention discloses an electric wheel hub motor which comprises a shell, a motor arranged in the shell, and a disc brake which comprises a disc brake disk and a pair of brake sheets, the disc brake disk is fixed on an output shaft of the motor, and rotates synchronously with the motor; and the disc brake is fixed on an electrombile body; the pair of brake sheets are respectively and relatively arranged on two sides of one end of the disc brake disk, strong force action of a hydraulic pump is utilized in the structure, the brake sheets are driven to clamp the disc brake disk, thereby reaching a favorable braking effect.

Owner:SUZHOU EAGLE ELECTRIC VEHICLE MFG

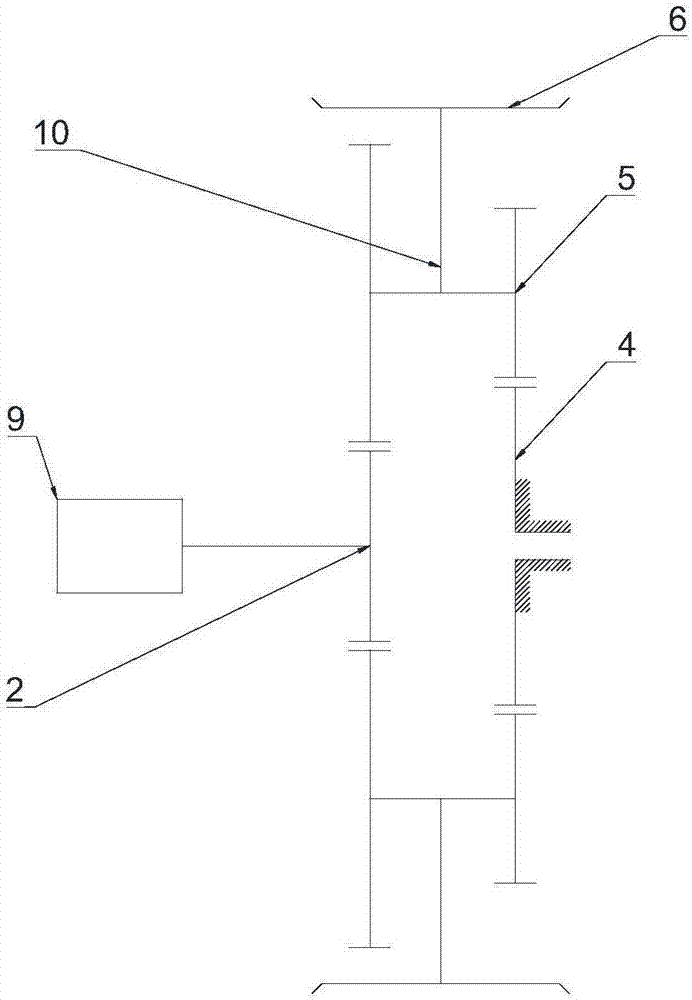

Auxiliary mounting device for building construction

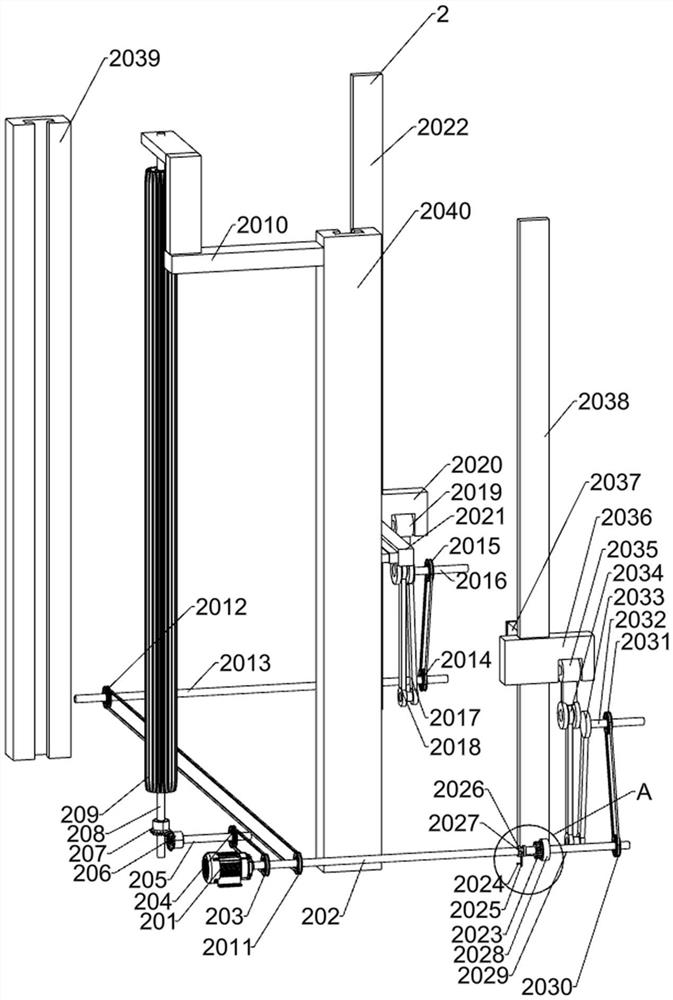

InactiveCN111910933ALow efficiencyEasy to fixVehicle to carry long loadsLoad securingArchitectural engineeringElectric cars

The invention relates to the field of building construction, in particular to an auxiliary mounting device for building construction. The technical problem is to provide the auxiliary mounting devicefor building construction. .According to the technical scheme, the auxiliary mounting device for building construction comprises a bottom frame, a transverse beam lock conveying mechanism, a transverse bar lock mounting mechanism, a transverse beam fixing mechanism and the like; and electric wheels are arranged below the bottom frame. According to the device, during use, two transverse beams are automatically transported to the positions needing to be subjected to mounting, then the two transverse beams are automatically located on the same horizontal line and are in contact with each other tobe clamped into threaded steel bars of a form, a linear lock is automatically clamped into the upper portions of the two transverse beams, and nuts are automatically screwed into threaded steel barsof the linear lock and the two transverse beams, so that the two transverse beams are fixed through the linear lock, and during use, the structure is simple, the efficiency is high, workers do not need to work high above the ground, and potential production safety hazards are greatly reduced.

Owner:陈祥德

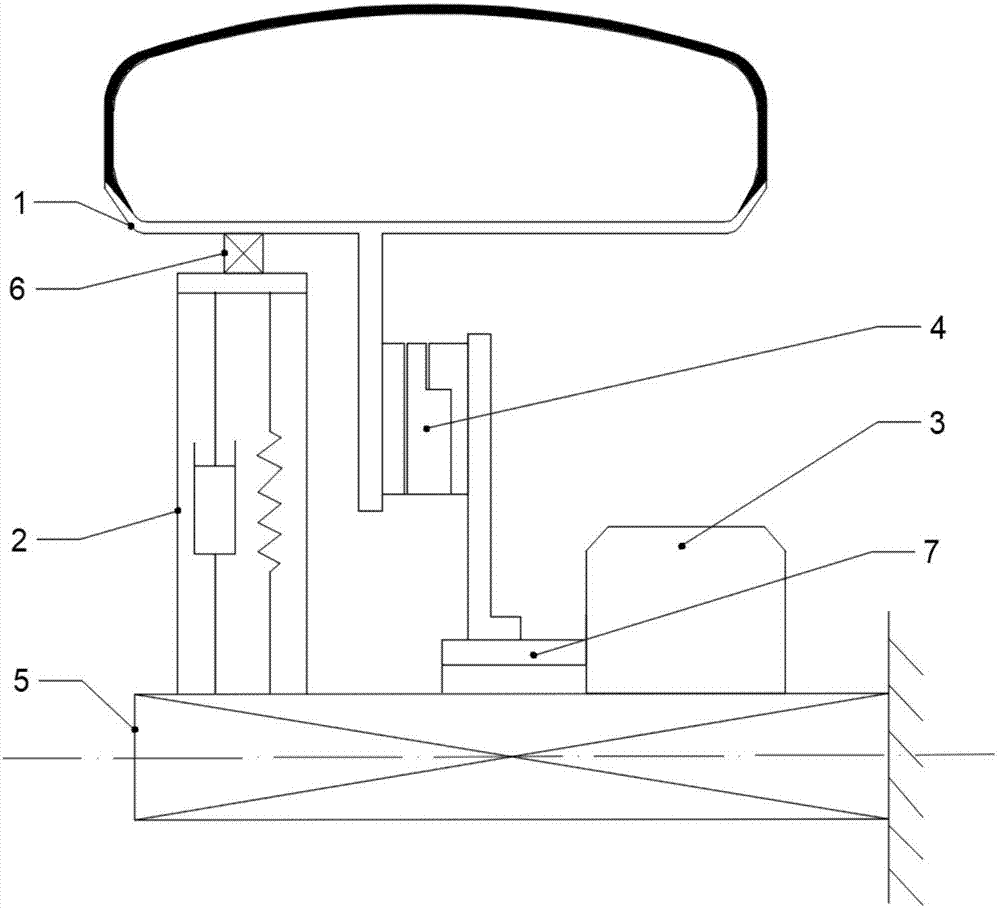

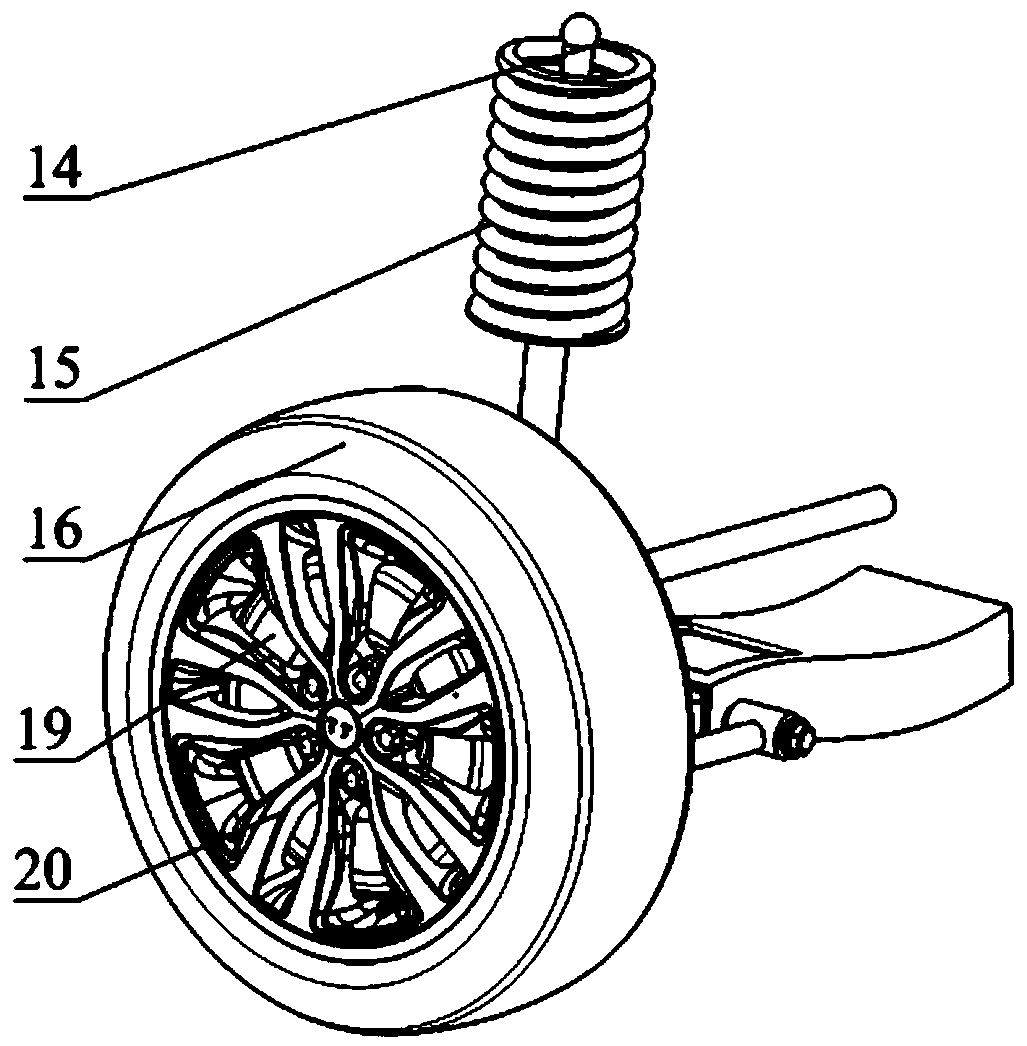

Electric wheel with built-in suspension and vehicle

ActiveCN107444007ASolve quality problemsSolve the problem of poor dynamic response of wheelsMotor depositionResilient suspensionsVehicle frameCoupling

The invention provides an electric wheel with a built-in suspension, and relates to the technical field of electric vehicles. A frame overhanging beam which is in rigid connection with a frame is adopted to replace a wheel axle of a traditional wheel, the suspension is internally arranged in the wheel, one end of the suspension is fixed to the frame overhanging beam, and the other end of the suspension is connected with a wheel rim of the wheel through a bearing; and a driving motor is installed on the frame overhanging beam, a rotor of the driving motor is connected with the wheel rim of the wheel through a flexible coupling, and torque transmission and wheel driving are achieved. According to the electric wheel with the built-in suspension, because an in-wheel suspension structure is adopted, the driving motor is installed on the frame overhanging beam, so that the mass of a wheel power device is transformed into the sprung mass portion of the suspension, and the problems that the suspension spring lower mass is increased, and the wheel dynamic response capability is poor due to the fact that a driving motor of an existing electric wheel increases the wheel mass are solved. The electric wheel with the built-in suspension can effectively improve the vehicle running stability and smoothness.

Owner:HUAZHONG UNIV OF SCI & TECH

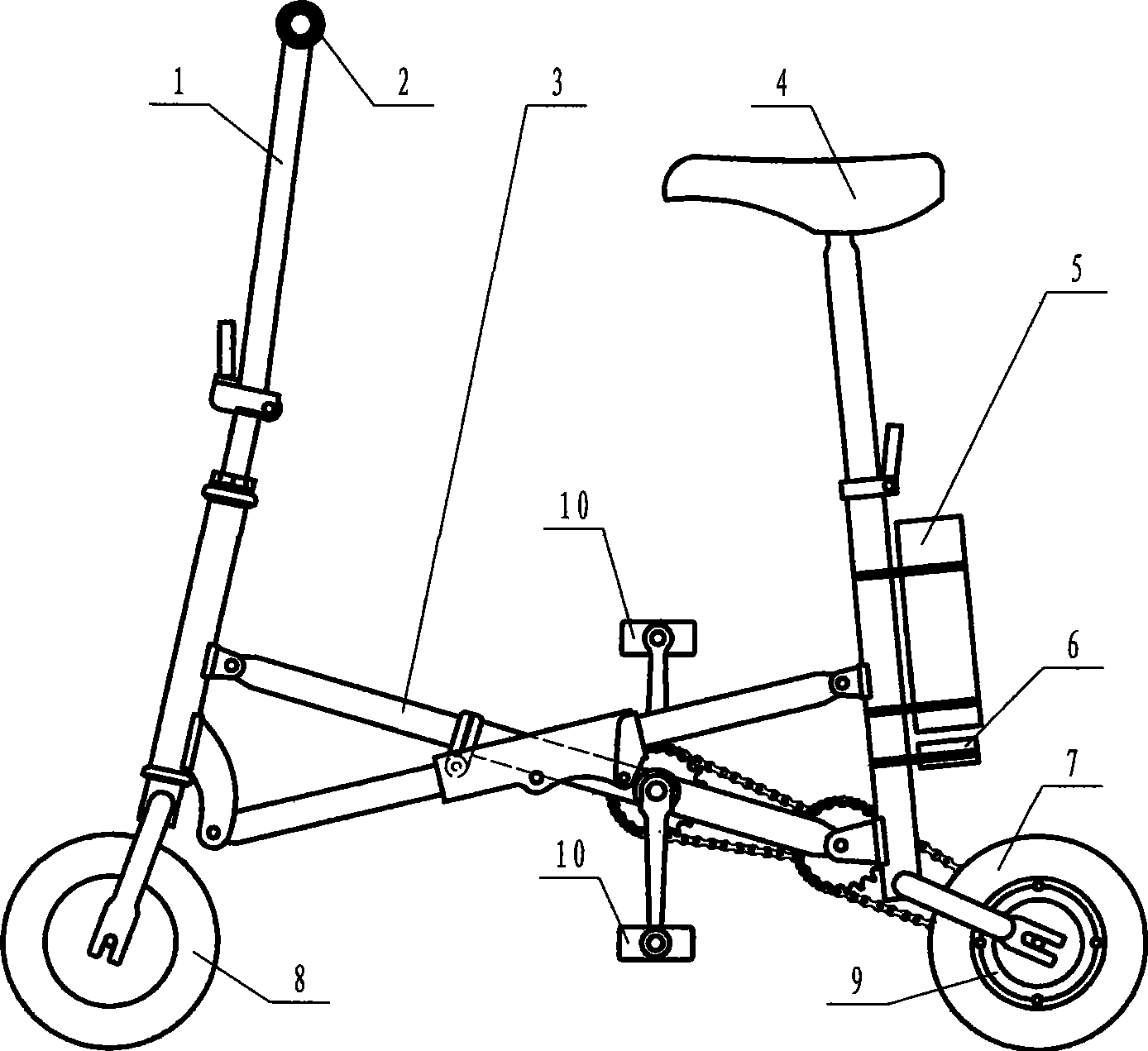

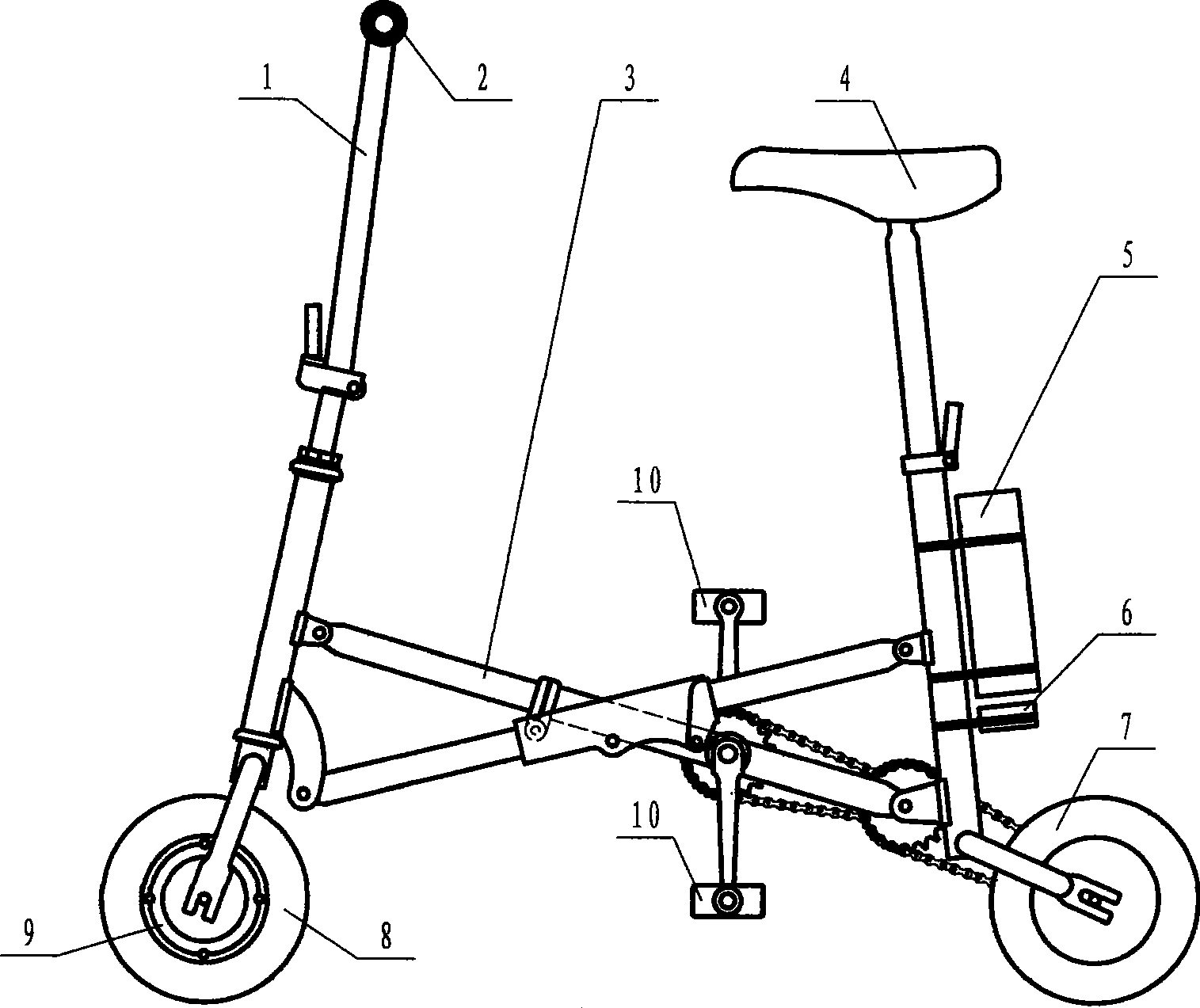

Ultra-portable folding electric bicycle

The invention provides an ultra-portable folding electric bicycle, comprising a handlebar, a bicycle frame, a saddle, a back wheel, a fore wheel and a pedal; a switch speed governor is arranged on the handlebar, and a power cell and a controller are arranged on the bicycle frame; an electric motor with the same shaft with the wheels is arranged in the back wheel of in the fore wheel, so that the back wheel or the fore wheel can become the wheels of the electric motor; the power cell, the controller, the electric motor and the switch speed governor are generally electrically connected with each other. The invention has the advantages that the bicycle of the invention can not only be driven by labour power but so be driven by electrical force; and all advantages of the ultra-portable folding electric bicycle are reserved.

Owner:詹富生

Multi-wheel type hydraulic suspension intelligent control full-electric movable platform

InactiveCN108216423AWill not affect drivingConsistent structureInterconnection systemsMotor depositionRolloverMaintainability

The invention relates to the field of new-concept electric vehicles, in particular to a multi-wheel type hydraulic suspension intelligent control full-electric movable platform. The multi-wheel type hydraulic suspension intelligent control full-electric movable platform is characterized in that a controller and speed sensors are arranged on the top of movable platform chassis, the running speeds of the movable platform chassis can be monitored by the speed sensors in real time, distance sensors and image sensors are arranged at the bottom of each tapered roller bearing inner race, angle sensors are arranged on the top of each tapered roller bearing inner race, and rotational speed sensors are arranged on each electric vehicle wheel and are used for monitoring the rotational speeds of the electric vehicle wheel. The multi-wheel type hydraulic suspension intelligent control full-electric movable platform has the advantages that the ground grip capacity can be enhanced by the multiple vehicle wheels, accordingly, the multi-wheel type hydraulic suspension intelligent control full-electric movable platform can effectively adapt to complicated road surfaces, rollover risks can be prevented even if a few wheels are damaged, and a vehicle can run to maintenance places without being affected; the multiple hydraulic suspension electric vehicle wheels are structurally and functionally consistent with one another, and the maintainability and the interchangeability of the multi-wheel type hydraulic suspension intelligent control full-electric movable platform with a multi-wheel structure can be improved as compared with the traditional four-wheel structure.

Owner:ZHONGBEI UNIV

Transmission mechanism of hub drive automatic transmission motor of electric vehicle

InactiveCN102678845AReduce volumeMeet hill climbToothed gearingsGearing detailsVehicle frameGear drive

A transmission mechanism of a hub drive automatic transmission motor of an electric vehicle is composed of a hub, an upper end cover, a lower end cover, the motor, an automatic transmission, a planetary gear speed reducing mechanism, a spindle and the like. The transmission mechanism is characterized in that the automatic transmission is provided with a sun gear fixing plate, a driving disc, a cover casing, a location plate and a planetary gear reducer. Magnetic steel is arranged outside the cover casing, a stator is arranged outside the magnetic steel, the stator is fixed on a motor casing, the cover casing is connected with the location plate along an opening, and the spindle is fixedly connected with the motor casing and a planetary carrier of the planetary gear speed reducing mechanism through the center of the automatic transmission and extends to the outside of the upper cover and the lower cover to be fixedly connected with a vehicle frame. The motor casing and the planetary carrier of the planetary gear speed reducing mechanism are matched with an upper end cover bearing inner hole and a lower end cover bearing inner hole, a sun gear is matched with the sun gear fixing plate, a shoe block is connected with a pull spring, a diving disc is connected with a driving gear through a driving disc spline, the driving gear drives a planetary gear which drives a gear ring, the gear ring is fixedly connected with the upper end cover or the hub, and the upper end cover and the lower end cover are connected with the hub to form the transmission mechanism of the hub drive automatic transmission motor of the electric vehicle.

Owner:金碧波

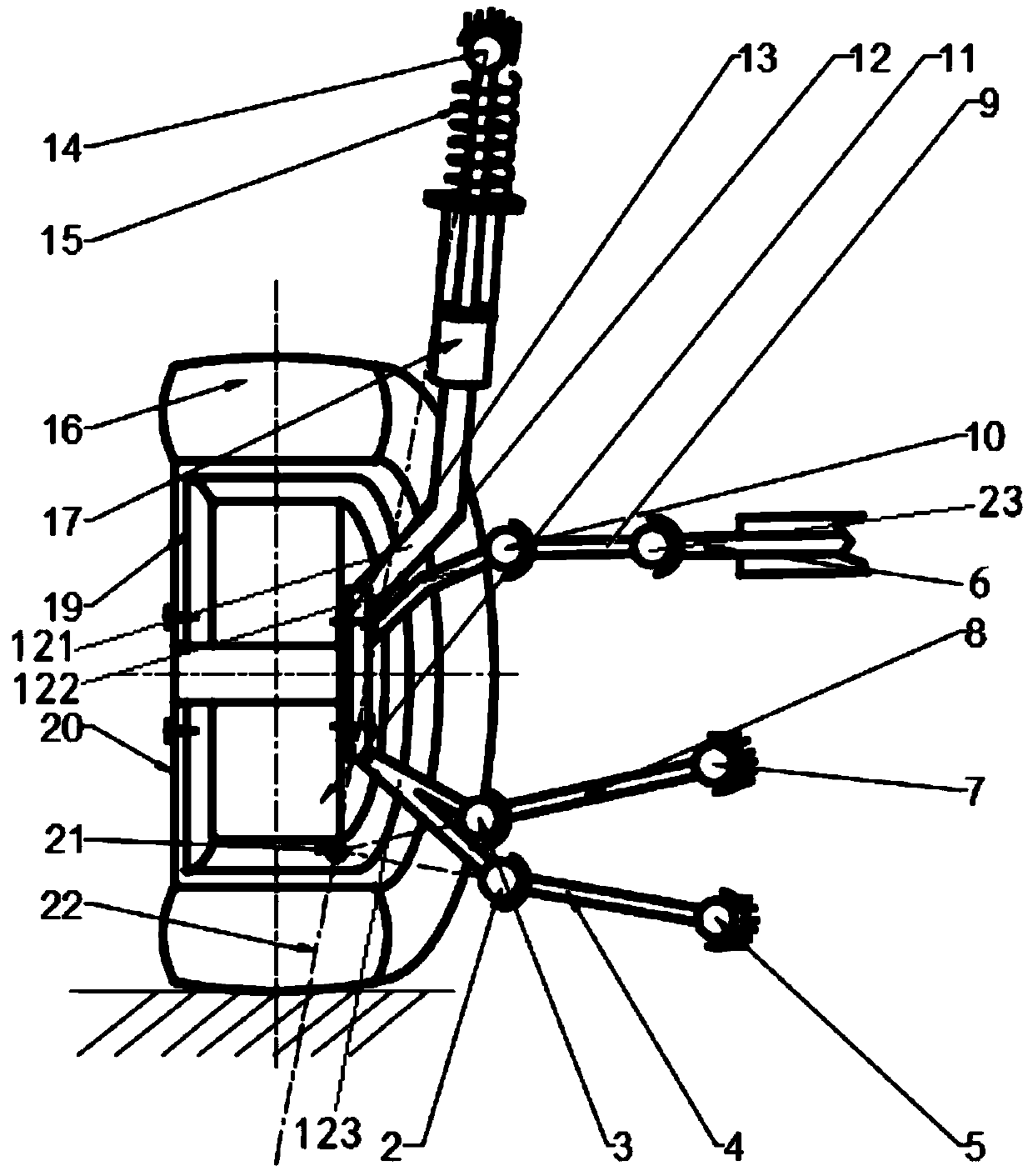

Electric wheel Macpherson suspension structure capable of adjusting position of main pin axis

PendingCN111186274AFlexible adjustmentImprove stabilitySteering linkagesResilient suspensionsVehicle frameControl arm

The invention relates to an electric wheel Macpherson suspension structure capable of adjusting the position of a main pin axis. The Macpherson suspension structure comprises a wheel, a hub motor, a Macpherson suspension and an auxiliary frame. The hub motor is mounted on the wheel. The Macpherson suspension comprises a steering knuckle, a shock absorber and control arms. The steering knuckle is mounted on the hub motor. One end of the shock absorber is connected with a vehicle body through a spherical hinge, and the other end is fixed on the steering knuckle. The control arms comprise a firstcontrol arm and a second control arm. The first control arm and the second control arm are respectively connected with the steering knuckle and the auxiliary frame through spherical hinges, the extension lines of the connecting lines of the centers of the spherical hinges at the two ends of the first control arm and the second control arm are intersected to form a virtual spherical hinge point, and the virtual spherical hinge point is connected with the center of the spherical hinge at one end of the shock absorber to form a virtual main pin axis. Compared with the prior art, the Macpherson suspension structure has the advantages of simple structure, high flexibility, space saving and the like.

Owner:TONGJI UNIV

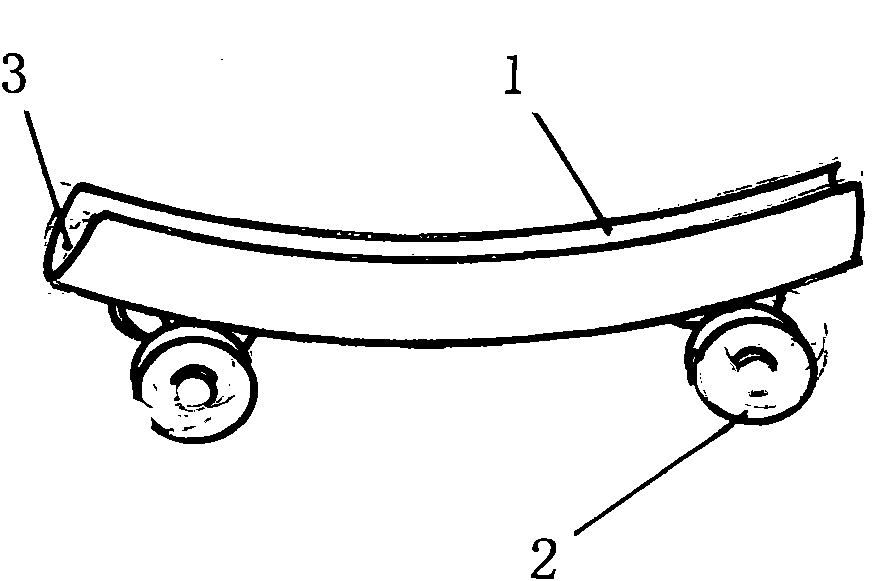

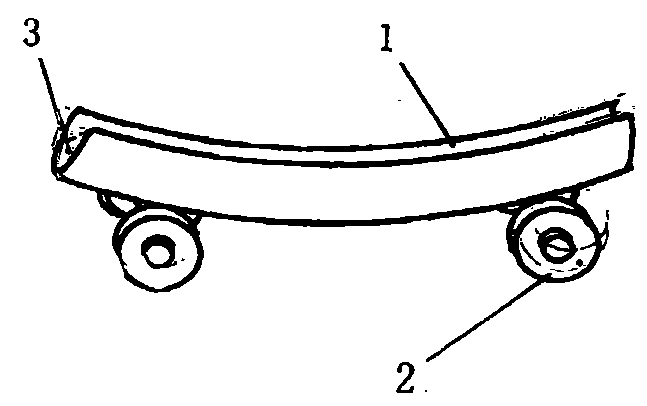

Spare wheel for electric vehicle

The invention provides a spare wheel for an electric vehicle. A plurality of casters are arranged below a frame which can be placed under an electric vehicle wheel for use; the frame has a circular arc structure which is matched with the electric vehicle wheel; and a longitudinal wheel trough is formed above the frame. The spare wheel is mainly configured for the electric vehicle for use; after the wheel is burst in a running process of the electric vehicle, the device can be placed below the wheel to support the wheel to push, and the burst tire is prevented from being damaged through rolling due to direct pushing; and when leaved unused, the spare wheel can be directly received in an electric vehicle trunk for later use.

Owner:李文睿

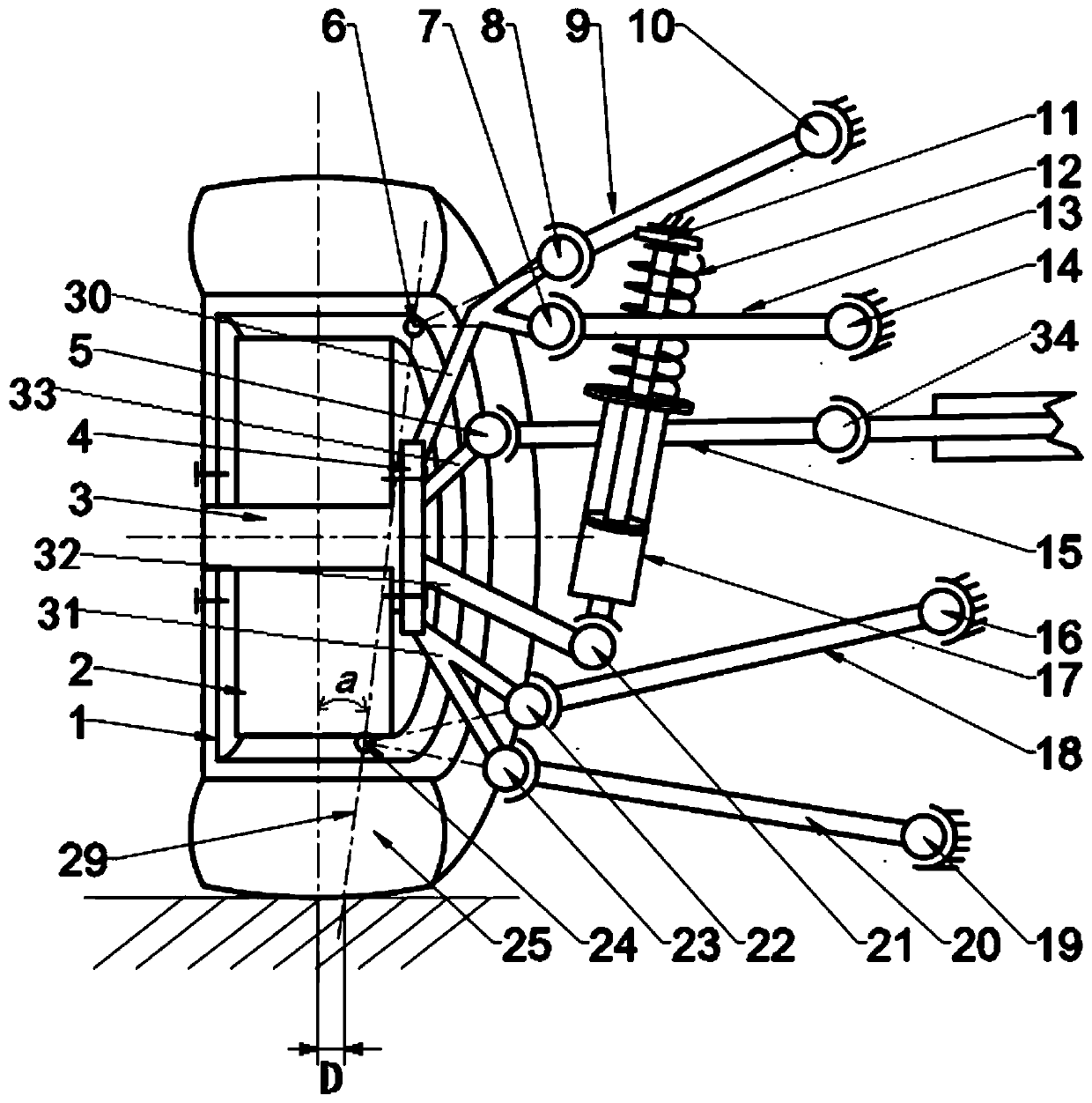

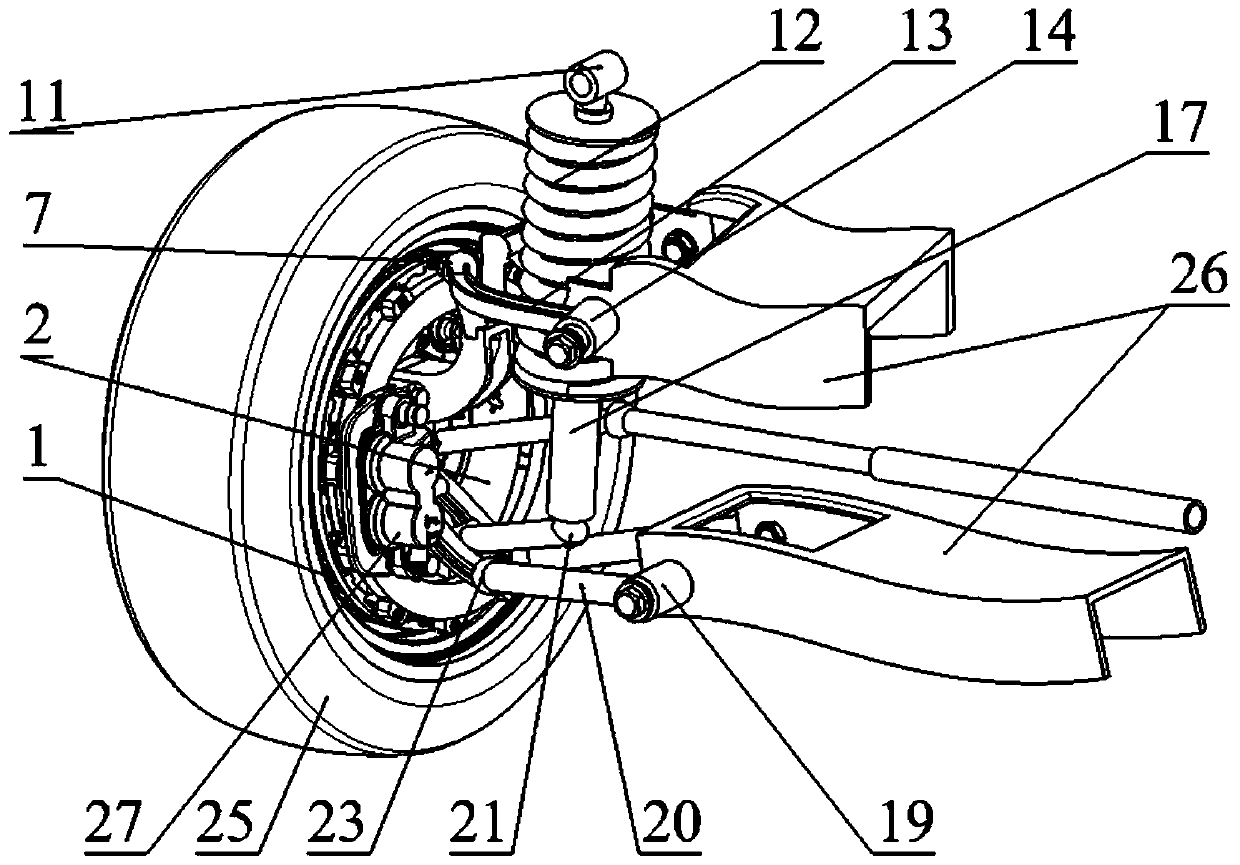

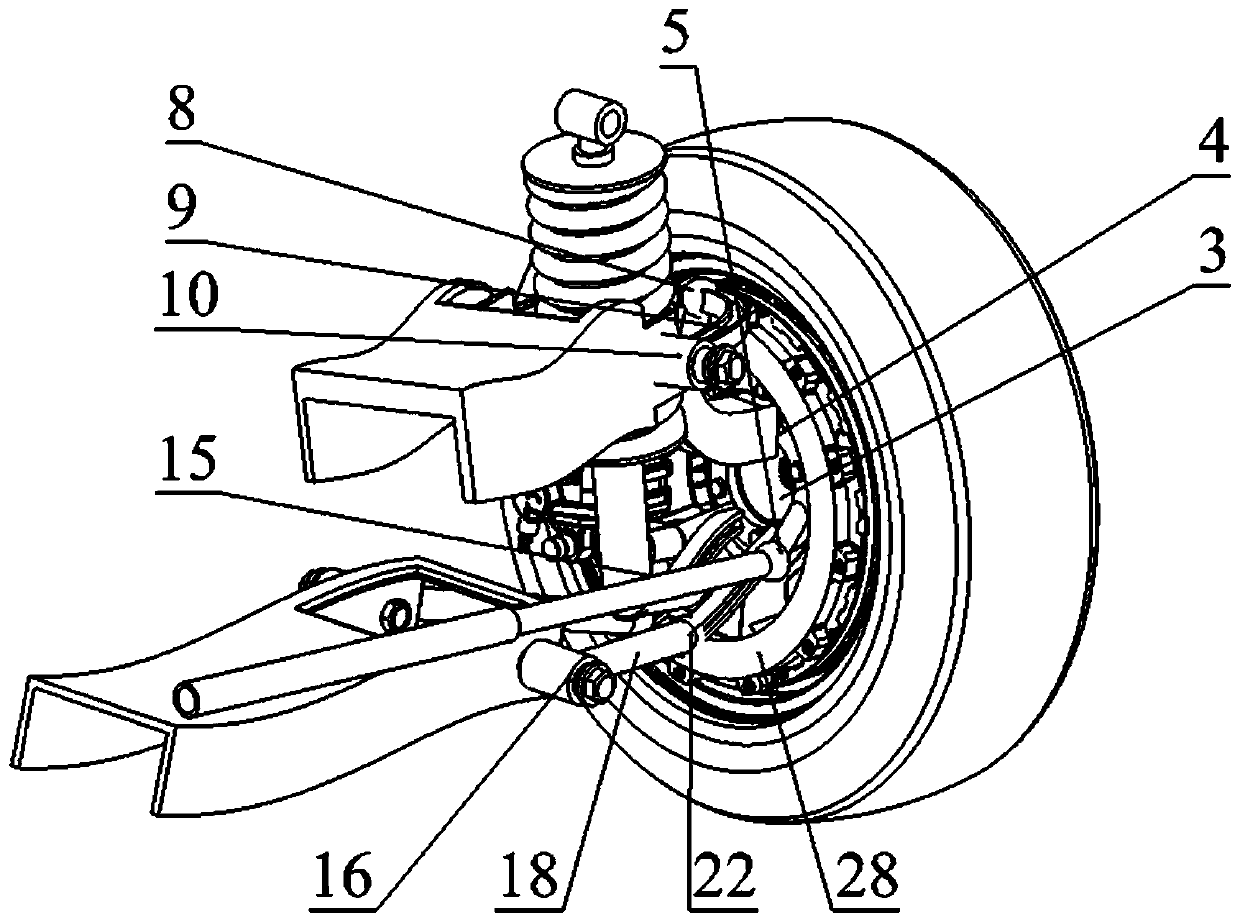

Electric wheel independent suspension structure with four control arms

ActiveCN111186270AImprove steering easeImprove handling stabilityBraking element arrangementsResilient suspensionsVehicle frameClassical mechanics

The invention relates to an electric wheel independent suspension structure with four control arms. The independent suspension structure comprises a wheel (25), a hub motor, a steering knuckle (4), aframe (26) and an independent suspension. The steering knuckle (4) is fixedly connected with the hub motor. The independent suspension comprises a vibration reduction assembly and a control arm assembly. The control arm assembly comprises a first upper control arm (9), a second upper control arm (13), a first lower control arm (18) and a second lower control arm (20) of which the two ends are connected with the steering knuckle (4) and the frame (26) through spherical hinges respectively, wherein the extension lines of the connecting lines of the centers of spherical hinges at the two ends ofthe first upper control arm (9) and the second upper control arm (13) intersect at an upper virtual spherical hinge point (6), and the extension lines of the connecting lines of the centers of spherical hinges at the two ends of the first lower control arm (18) and the second lower control arm (20) intersect at a lower virtual spherical hinge point (24). Compared with the prior art, the structurehas the advantages of space saving, strong flexibility and the like.

Owner:TONGJI UNIV

Stand of electric vehicle

ActiveCN104527844AExtended service lifeReduce wearCycle standsMechanical energy handlingEngineeringElectric vehicle

The invention relates to a stand of an electric vehicle. The stand of the electric vehicle comprises a rotating plate, and a supporting rod which is fixed on the rotating plate; the rotating plate is shafted to a rotating shaft; a cylindrical electromagnet is fixed on the rotating plate; a pair of tile-shaped positioning permanent magnets is symmetrically distributed in the periphery of the rotating plate; a power supply mechanism is arranged on a wheel shaft of the electric vehicle, comprising a generating permanent magnet, a generating coil and an electric brush; a pair of tile-shaped generating permanent magnets is symmetrically fixedly assembled in the periphery of the wheel shaft; the generating coil which synchronously rotates with the wheel shaft is assembled between each generating permanent magnet and the wheel shaft; two pins of the generating coil are coupled with the electric brush which sleeves the wheel shaft; the power supply mechanism is sequentially connected with a rectifier and the electromagnet. The stand can be automatically raised and lowered down; meanwhile, parts are worn a little; therefore, the service life is prolonged.

Owner:铜陵易难信息科技有限公司

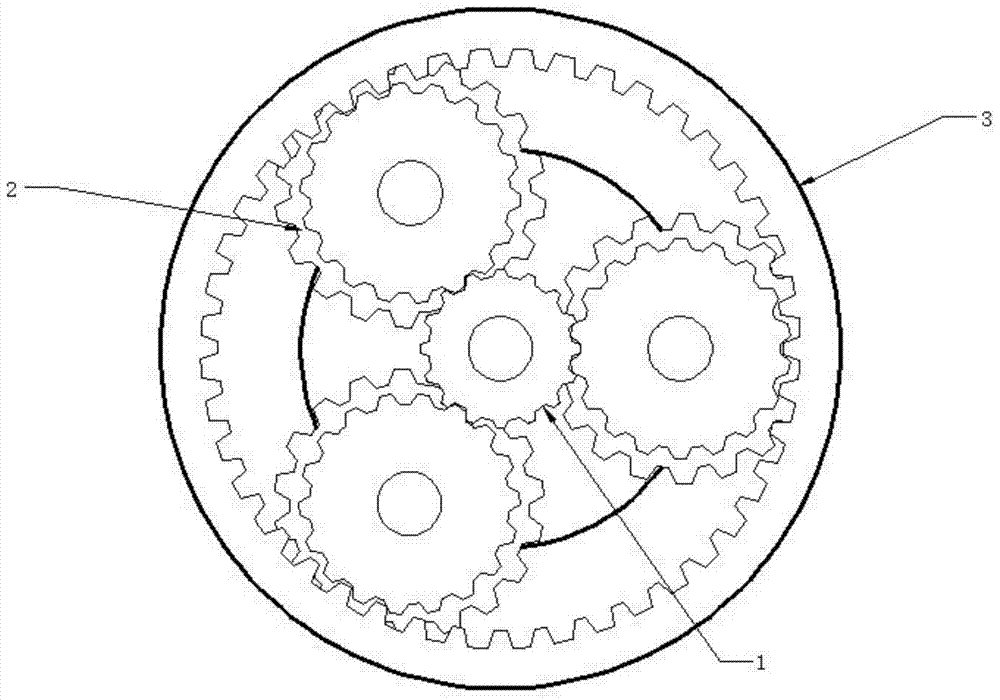

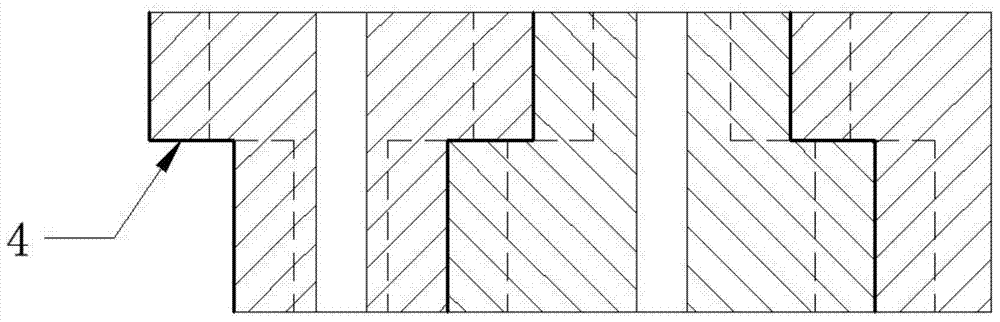

Firm and durable gear for hub motor of electric vehicle

InactiveCN104728348AReduce wearIncrease tightnessToothed gearingsPortable liftingGear wheelElectric vehicle

The invention provides a firm and durable gear for a hub motor of an electric vehicle. The firm and durable gear comprises a sun gear, three large planetary gears and an outer gear ring. The three large planetary gears are meshed with the sun gear which is positioned in the center, and the outer annular gear ring is positioned outside the three large planetary gears and meshed with the same. The sun gear is provided with a sun gear boss, each large planetary gear is provided with a planetary boss, teeth of each planetary boss are meshed with teeth of the sun gear, and the outer gear ring is provided with an outer gear ring boss meshed with the planetary boss. Teeth of the sun gear, the large planetary gears and the outer gear ring are coated with abrasion-resistant layers with abrasion-resistant compositions. Therefore, abrasion resistance of the gears can be improved, and service lives of the gears can be prolonged. The firm and durable gear for the hub motor of the electric vehicle has the advantages that closeness of the gears is improved, abrasion of the gears is alleviated, and durability of the gears is improved.

Owner:TIANJIN CHANGJUN ELECTRICAL TECH

Power-driven cart device convenient for conveying patients during oxygen inhalation, transfusion and abdomen supporting

The invention provides a power-driven cart device convenient for conveying patients during oxygen inhalation, transfusion and abdomen supporting, belonging to the technical field of medical equipment. Patients who are suffered from digestive system diseases and particularly abdominal hydrops are very inconvenient to take examinations in various departments in a hospital. In the technical scheme provided by the invention, the lower end of a hanging-bottle-rack insertion pipe (13) screwed with a fastening screw (14) is fixed in a base plate (6) on which the bottom end of a small-size oxygen-cylinder insertion drum (12) below a seat (5) is fixed, a pedal plate (2) is fixed on the base plate (6) provided with two power-driven cart wheels (15) and a universal wheel (7), the supporting legs of the seat (5) are fixed on the base plate (6), two ends of a backrest pipe (8) on the seat (5) are respectively provided with two telescopic rods (10) in an insertion way, and two gripping handles (11)are respectively and fixedly connected with the two telescopic rods (10). The power-driven cart device provided by the invention has the advantage that a patient can stand or move on the cart so thatmedical examination can be carried out conveniently and smoothly.

Owner:孔军

Auxiliary mounting device for indoor decoration

The invention relates to the field of indoor decoration, in particular to an auxiliary mounting device for indoor decoration. The technical problem to be solved by the invention is to provide the auxiliary mounting device for indoor decoration. The auxiliary mounting device for indoor decoration comprises a bottom frame, a buckle pre-installation mechanism, a corner buckle plate installation mechanism, a skirting line pressing buckle mechanism, a control screen, a right-angle pressing buckle and electric wheels, and the electric wheels are arranged above and below the bottom frame. When the auxiliary mounting device is used, automatic drilling on a wall surface is achieved, a wooden plug is automatically embedded into a drilled hole, then a buckle is automatically fixed to the wooden plug,then a PVC skirting line is automatically clamped into the right-angle pressing buckle of a wall corner, and then the PVC skirting line is automatically clamped into an installed pressing buckle; andduring use, a worker only needs to place the PVC skirting line at a wall corner without operating a steel nail gun, so that the production efficiency is improved, and the potential safety hazard is greatly reduced.

Owner:山东智汇新谷科技企业孵化器有限公司

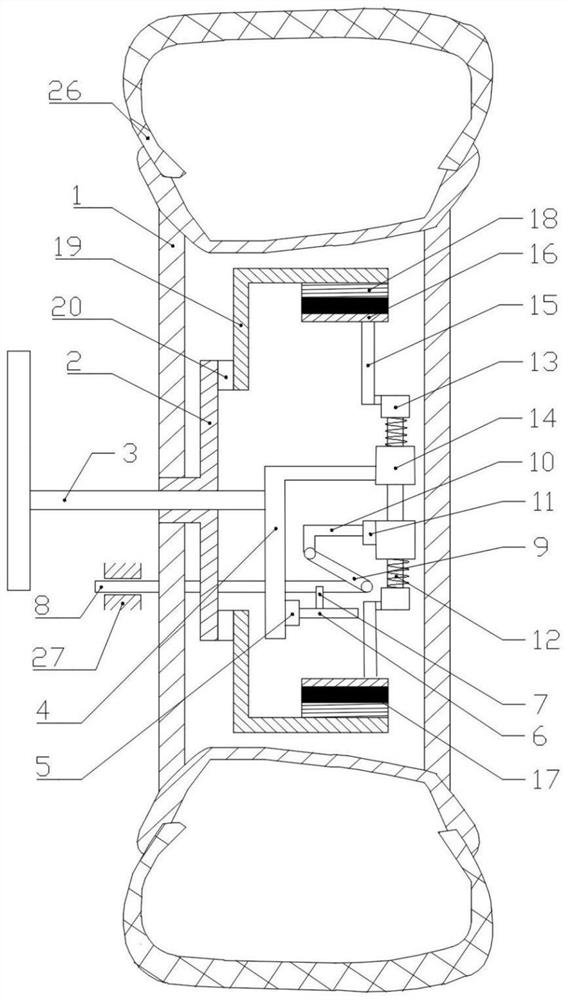

Electric wheel with energy recovery and multi-direction vibration reduction functions

ActiveCN113531033AReduce vibrationShock suppressionBatteries circuit arrangementsNon-rotating vibration suppressionVertical vibrationElectric machine

The invention discloses an electric wheel with energy recovery and multi-directional vibration reduction functions. The electric wheel comprises a vertical vibration transfer module, a shimmy transmission assembly, a vibration and shimmy synchronous suppression module, a hub motor module and a wheel module. The vertical vibration transfer module is installed on a vehicle body and comprises an axle and a first connecting block. The first connecting block is fixed on the axle. The axle is rotationally connected with a rotating disc. The wheel module is installed on the rotating disc. The hub motor module comprises a stator, a rotor and a middle transfer disc. The rotor is connected with the rotating disc through the middle transfer disc. The middle transfer disc can transfer a torque of the rotor to the rotating disc and allows the rotor to jump in the radial direction of the rotating disc. The stator is installed on the inner side of the rotor. For the electric wheel disclosed by the invention, through mechanical design in the wheel directly, vibration reduction (vertical vibration and shimmy vibration of the wheel) of the wheel in multiple directions can be realized only by using one vibration reducer.

Owner:HANGZHOU DIANZI UNIV

Apparatus and method for motorized wheels

ActiveCN107206907BRegistering/indicating working of vehiclesAnti-collision systemsHeat managementElectrical battery

The invention relates to a user interface, a torque arm assembly, a method of assembling a spoked wheel, a method of battery maintenance and a method for thermal management, respectively, for an electric wheel.

Owner:SUPERPEDESTRIAN INC

Welding device for electric vehicle hub

PendingCN114161057AEasy to weldRealize the effect of automatic clampingWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryElectric cars

The invention discloses a welding device for an electric vehicle hub, which belongs to the technical field of hub production equipment and comprises a rim conveying mechanism, a spoke conveying mechanism, a clamping mechanism, an upper top ring and a telescopic mechanism. The clamping mechanism is sequentially connected with a top plate, a pair of guide rods and a bottom plate from top to bottom through the rack; the top plate is rotationally connected with a positioning ring; the upper top ring and the positioning ring are concentrically arranged; a chuck is connected in the upper top ring; the chuck is connected with an output shaft of the motor through a connecting shaft; and the telescopic mechanism clamps and fixes the rim through the jacking base by utilizing the upper jacking ring and the positioning ring, and drives the spoke to enter the rim through the chuck. According to the wheel rim and spoke welding device, the wheel rim conveying mechanism and the spoke conveying mechanism are used for conveying a wheel rim and a spoke correspondingly, an upper jacking ring and a positioning ring are used for clamping and fixing the wheel rim, and the chuck drives the spoke to enter the wheel rim, so that the wheel rim and the spoke are welded conveniently, and the problems that existing manual clamping is high in labor intensity and low in production efficiency are solved.

Owner:JIANGSU JUN SUPER ELECTRIC CAR ACCESSORIES MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com