An electromotive wheel hub electromotor

A technology for in-wheel motors and electric vehicles, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of inconvenient installation and maintenance, small starting current, large torque resistance, etc., to achieve convenient assembly and disassembly, easy replacement and maintenance, Guaranteed effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

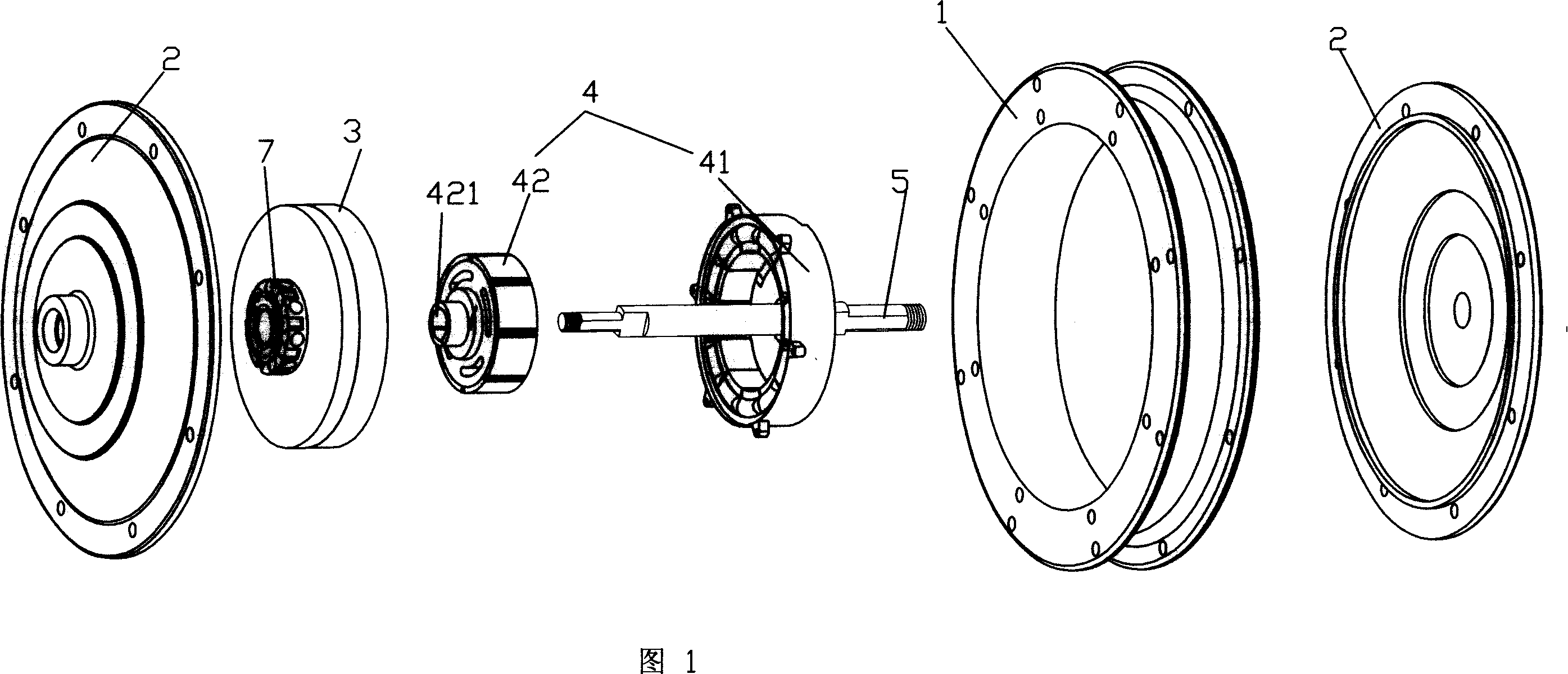

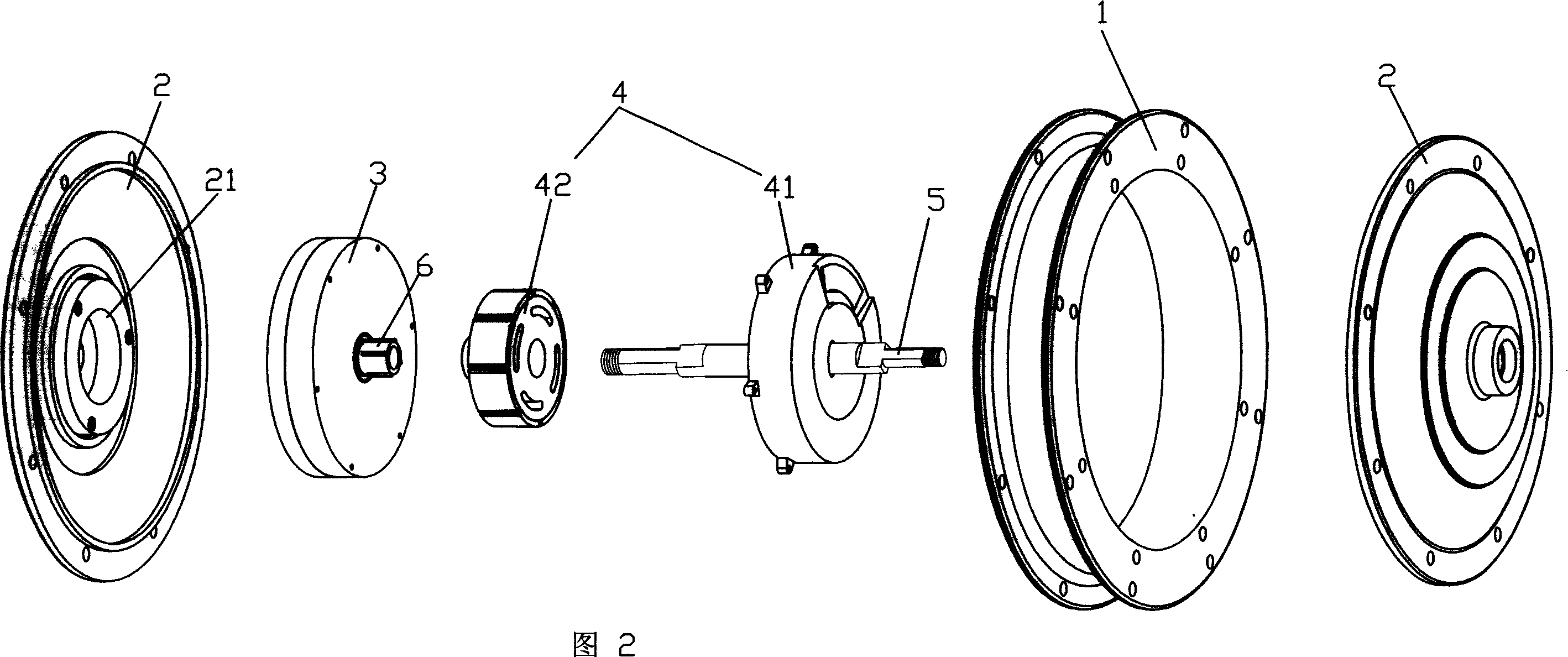

[0019] As shown in Figure 1-3, an electric wheel hub motor includes a hub shell 1, an end cover 2, a reducer 3 and a motor part 4, the reducer 3 and the motor part 4 are housed in the hub shell 1, and Both ends are closed by end caps 2 , the reducer 3 and the motor part 4 have a common main shaft 5 , and the main shaft 5 runs through the reducer 3 and the motor part 4 and passes through the end caps 2 on both sides.

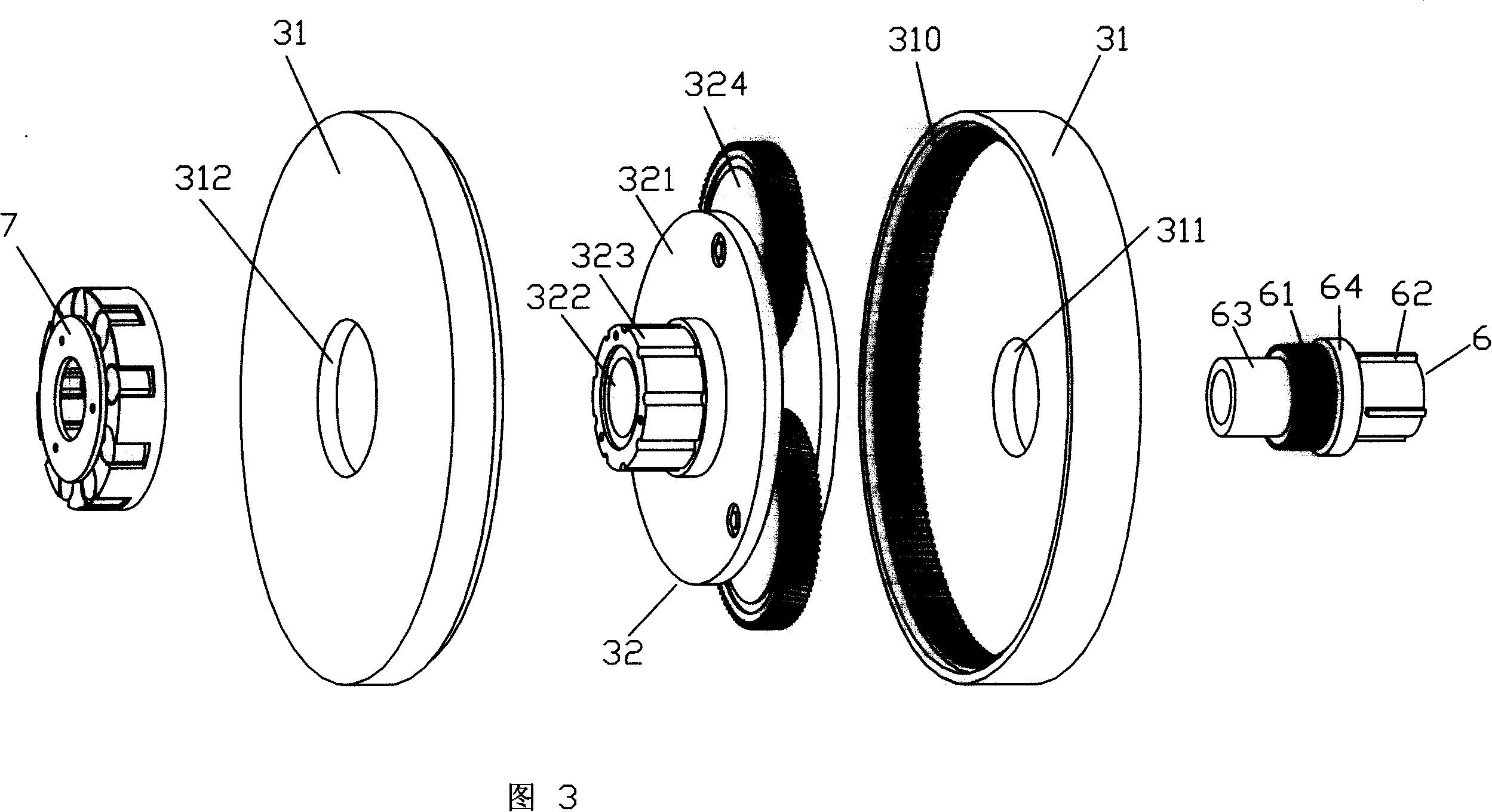

[0020] The motor part 4 includes a stator 41 and a rotor 42, the rotor 42 is accommodated in the stator 41, and the stator 41 is fixedly connected to the main shaft 5, and the reducer 3 is composed of a reducer housing 31 and a reduction gear set 32 , the reduction gear set 32 is accommodated in the reducer housing 31, and the reduction gear set 32 includes a main body 321, on which a shaft hole 322, an output end 323 and three planetary gears 324 are arranged, and the three planetary gears The teeth 324 are arranged between the two splints of the main body 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com