Inner vibration absorbing device of high-speed electric wheel and electric wheel

A vibration damping device and electric wheel technology, applied in the direction of power devices, motion deposition, vehicle components, etc., can solve the problems of harsh working environment and poor comfort of hub motors, and achieve the effect of compact structure, small size and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

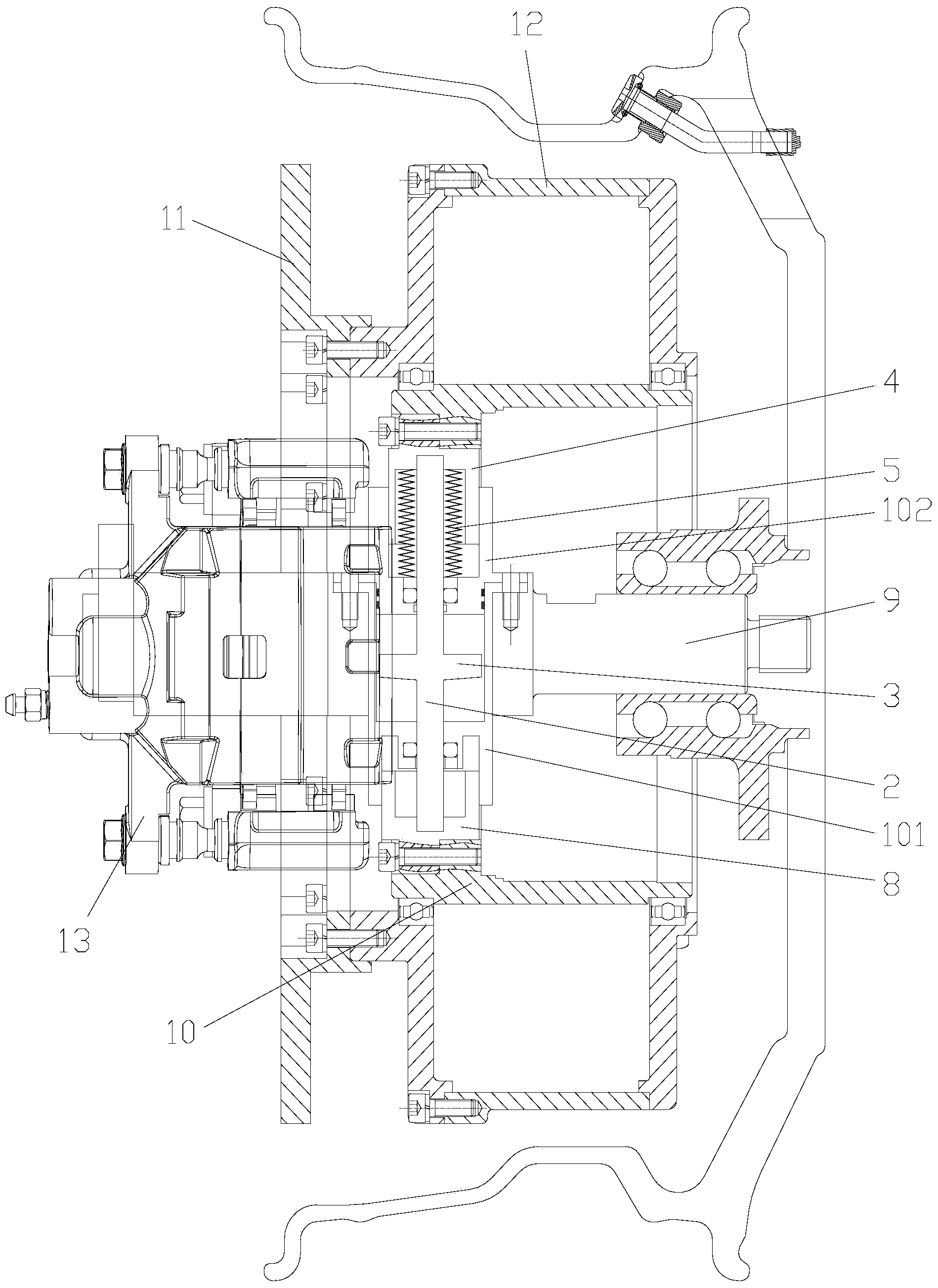

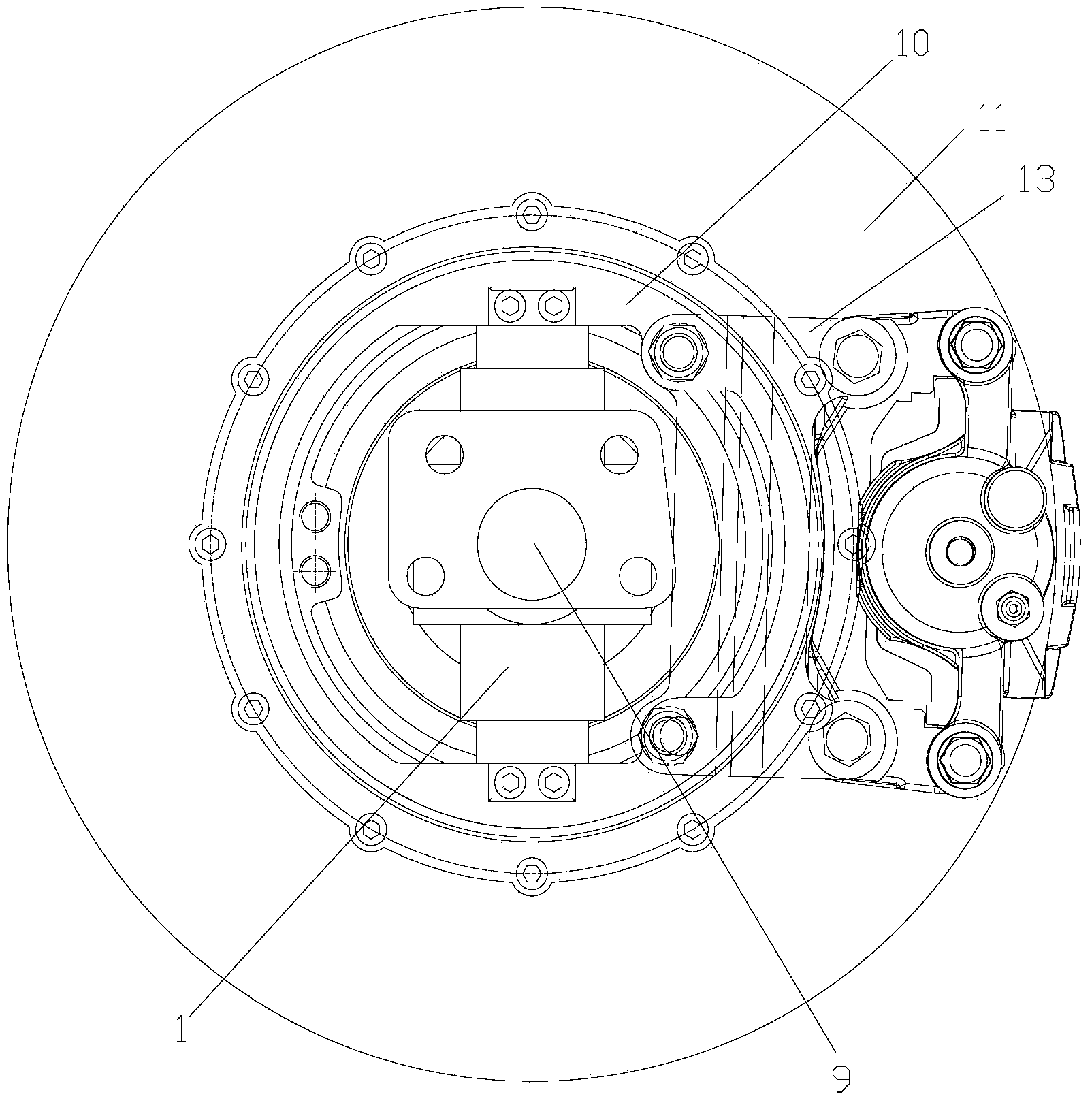

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

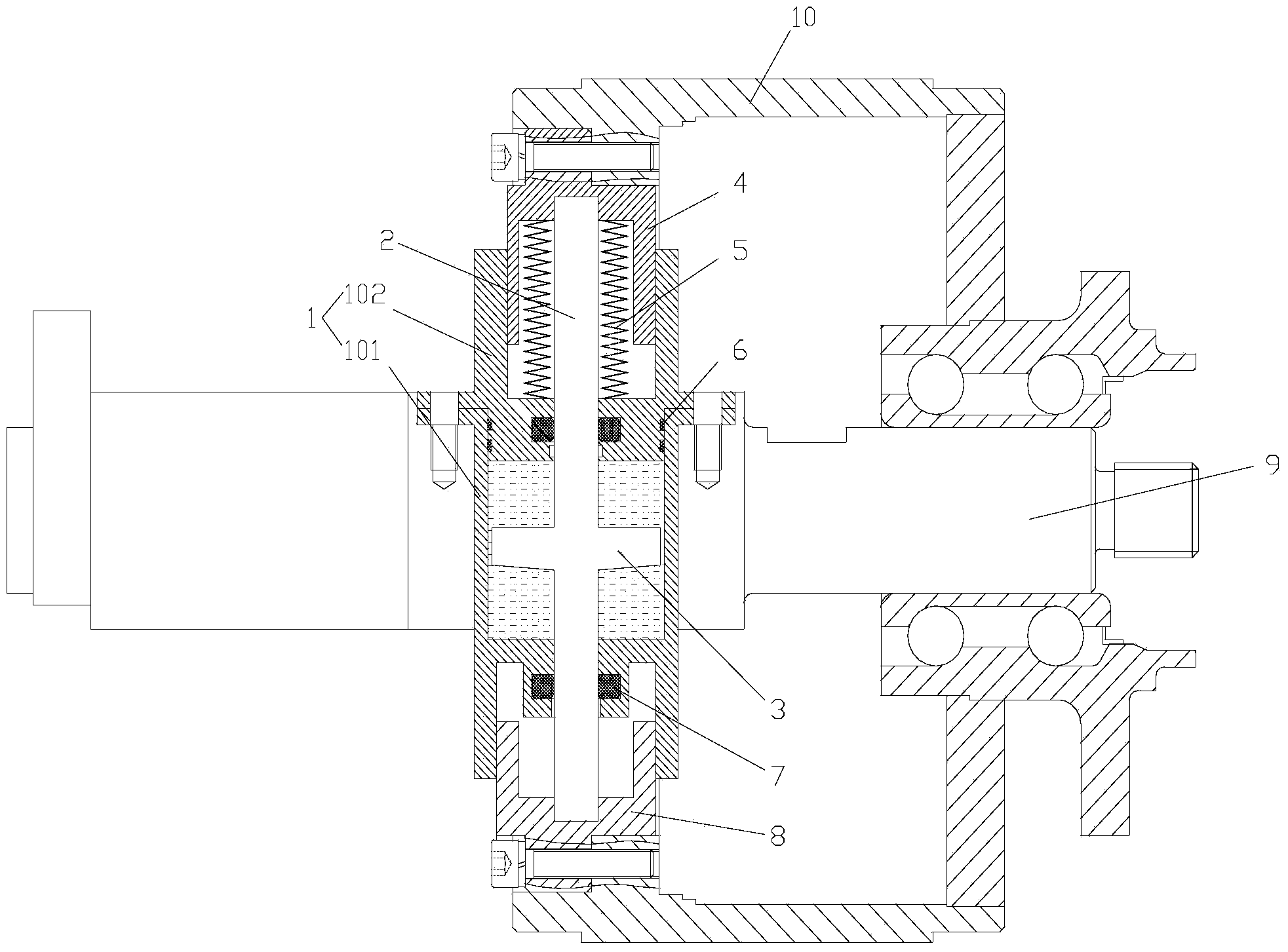

[0025] As shown in the figure, the high-speed electric wheel internal damping device of this embodiment includes a damping damper and a spring damper;

[0026] The damping shock absorber includes a damper housing 1 and a support rod 2 that is worn on the damper housing and is slidably fitted with the damper housing. Both ends of the support rod 2 protrude from the damper housing 1, so The above-mentioned support rod 2 is provided with a damping disc 3 for squeezing the damping liquid;

[0027] The spring damper includes a sleeve seat 4 and a spring 5 located in the sleeve seat, one end of the sleeve seat 4 and the support rod 2 is fixedly connected, the spring 5 is sleeved on the support rod, and the spring 5 One end bears on the damper housing 1 , and the other end of the spring 5 bears on the sleeve seat 4 .

[0028] In this embodiment, the damper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com