Electrombile wheel hub motor with centralized excitation function

A hub motor and electric vehicle technology, applied in electric vehicles, motors, collectors, etc., can solve the problems of high fault tolerance and high efficiency of electric hub motors, and achieve simple structure, less iron consumption, and short flux linkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention provides a centralized excitation electric wheel hub motor. In order to make the technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail with reference to the accompanying drawings and examples. It should be understood that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

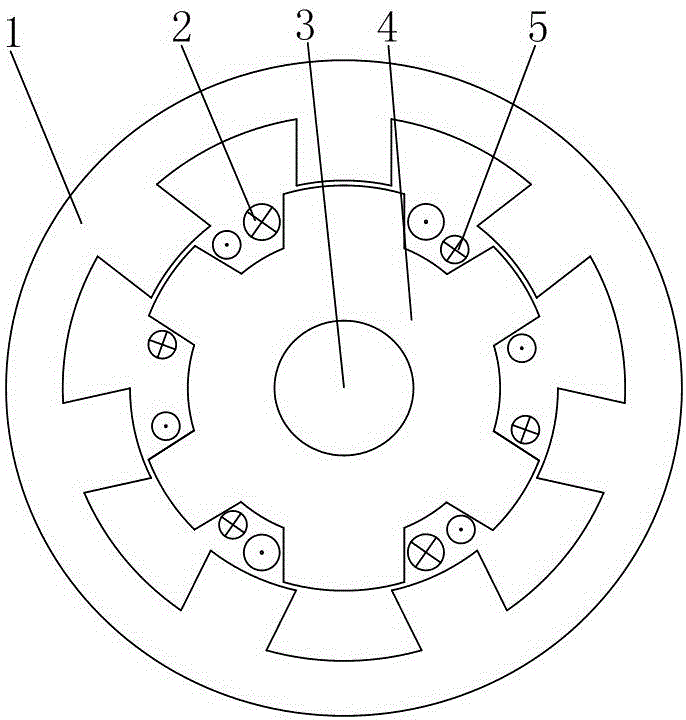

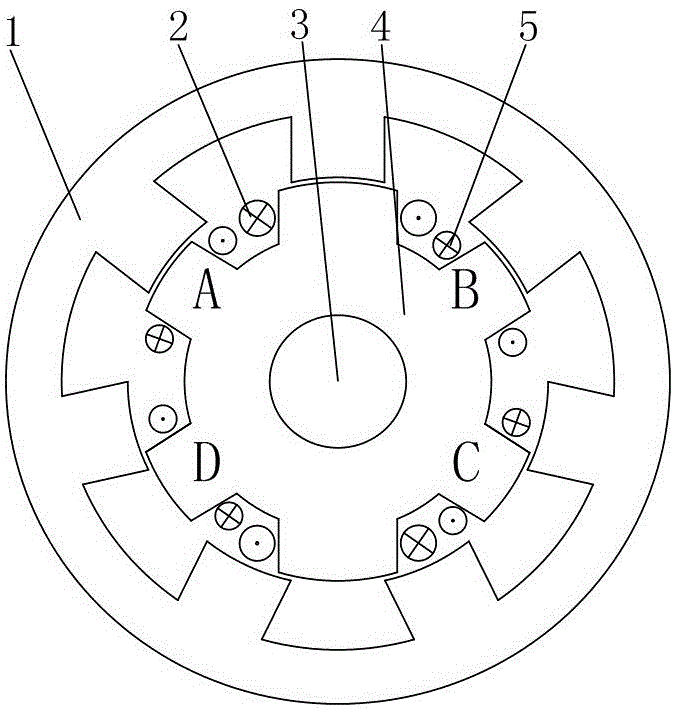

[0036] figure 1 The centrally excited electric wheel hub motor of the present invention is provided in longitudinal section, which is composed of stator core (4), outer rotor core (1), field winding (2), armature winding (5) and shaft (3). The rotor core (1) is fixed on the electric wheel hub, and the electric vehicle is directly driven when the rotor rotates.

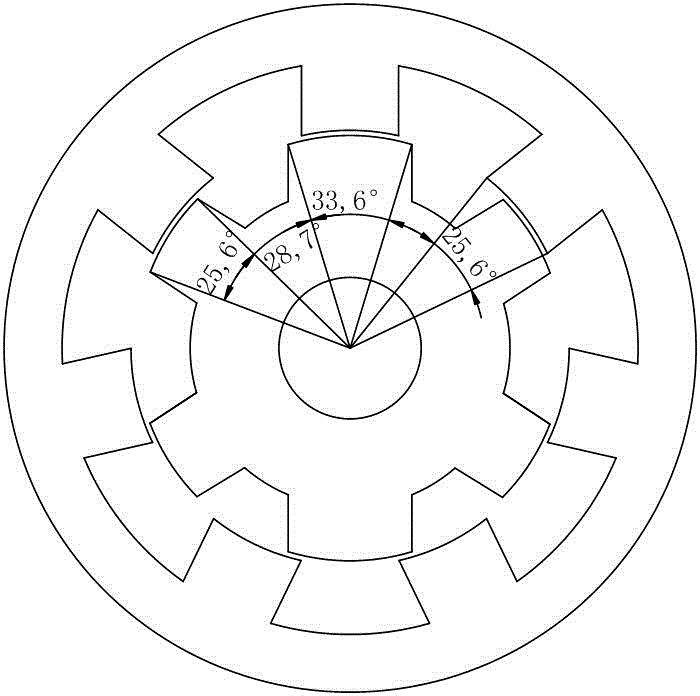

[0037] There are 7 rotor poles with a salient pole structure on the inside of the outer rotor core, and the pole arc coefficient of the rotor poles is equal to 0.5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com