Low viscosity poly-alpha-olefin lubricant base oil, preparation method and system thereof

An olefin lubricating oil and low-viscosity technology, applied in the field of preparation of lubricating base oil, can solve the problems such as the inability to recover the catalyst, the consumption and the increase of labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

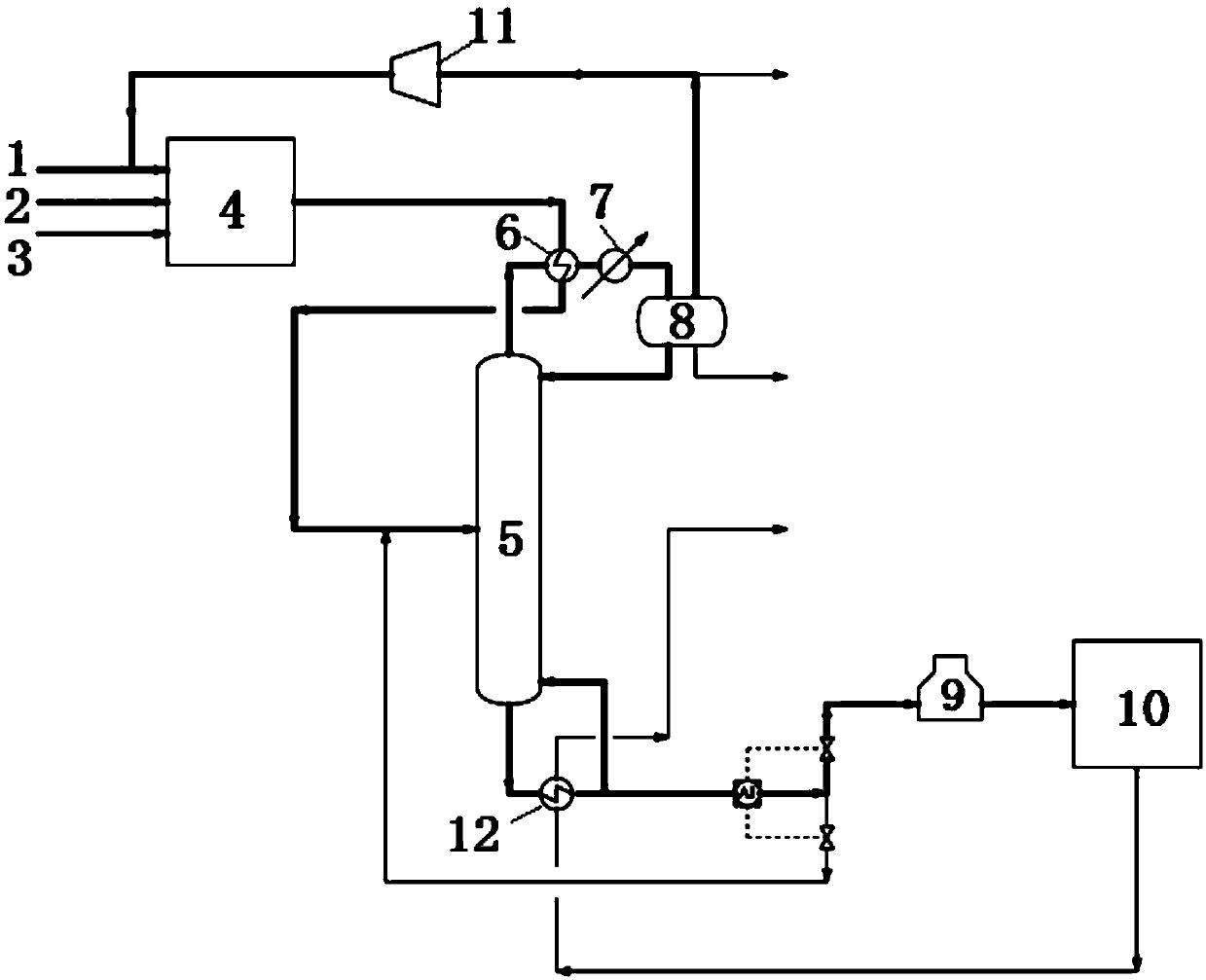

[0043] The method for preparing low-viscosity poly-alpha-olefin lubricating oil base oil of the present disclosure makes the reaction aid and BF by heating in the gas-liquid separation device 3 Depolymerization of the formed complex can prepare polyalphaolefins with qualified F content and can continuously separate BF in polyalphaolefin products 3 Catalyst, without manual intermittent pouring, greatly reducing production safety hazards; this method can make poly-alpha-olefin products and BF 3 The catalyst is completely separated, and no F-containing wastewater is produced during the production process, and BF can be recycled 3 Catalyst, reducing catalyst waste.

[0044] According to the present disclosure, the gas-liquid separation device may include at least one of a gas-liquid separation tower, a gas-liquid separation tank, and a heat exchanger, preferably a gas-liquid separation tower, so as to control separation operating conditions and improve separation efficiency.

[...

Embodiment 1

[0067] Such as figure 1 As shown, in this embodiment, the gas-liquid separation tower 1 is used as the gas-liquid separation device, and the raw material containing α-olefin is 1-decene, which contains BF 3 BF in the catalyst 3 The content is 90%, the reaction auxiliary agent is 1-octanol, and the F content of the liquid phase product at the bottom of the tower is measured online by combustion ion chromatography (refer to ASTM D7359 for the specific method).

[0068] Make α-olefin raw material 1-decene, containing BF 3 The catalyst, circulating catalyst and reaction aid 1-octanol enter the polymerization reaction device 4 for polymerization reaction, the reaction temperature is 25°C; the reaction pressure is 0.15MPa; the raw material containing α-olefin, BF 3 The molar ratio of catalyst and 1-octanol is 1:0.01:0.01, resulting in BF-containing 3 The mixed product of catalyst, 1-octanol and poly-1-decene, the mixed product enters the gas-liquid separation tower 5 (the number ...

Embodiment 2

[0073] The process is carried out according to the method of Example 1, the difference is that the gas phase product at the top of the gas-liquid separation tower 5 is directly returned to the polymerization reaction device without passing through the first heat exchanger 6 and cooler 7 .

[0074] According to the method of this embodiment, after stable operation, the processing capacity of the mixed product entering the gas-liquid separation tower is 1kg / h, and the BF in the mixed product 3 The separation rate of the catalyst was 99.99%, and the F content in the hydrogenation product was 2 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com