Non-standard door assembly packaging system

A packaging system and assembly device technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of high labor intensity of operators, large production site occupation, and low production efficiency, so as to reduce production safety hazards and realize The effect of streamlining and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

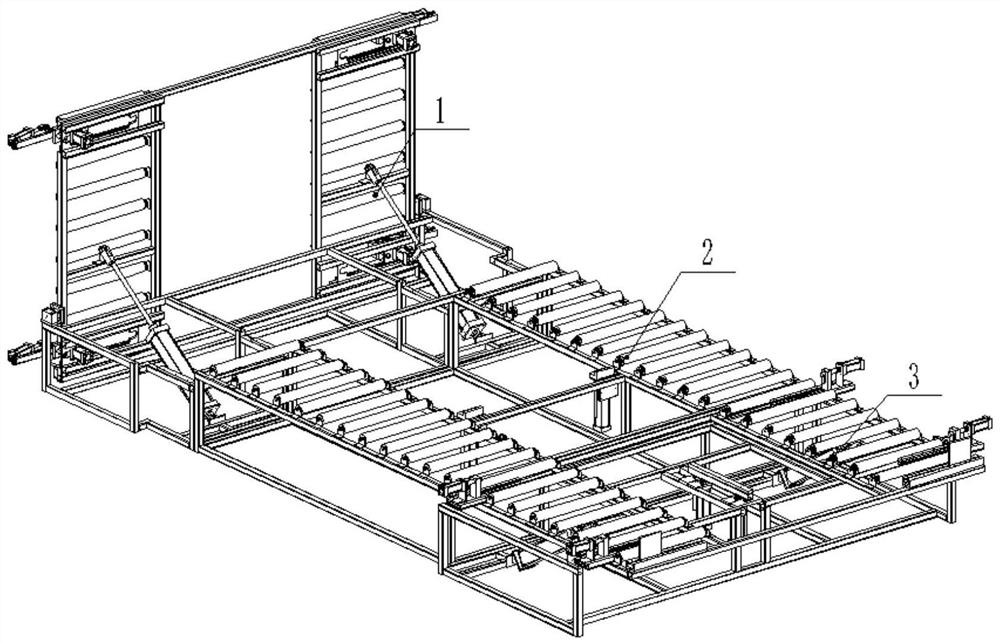

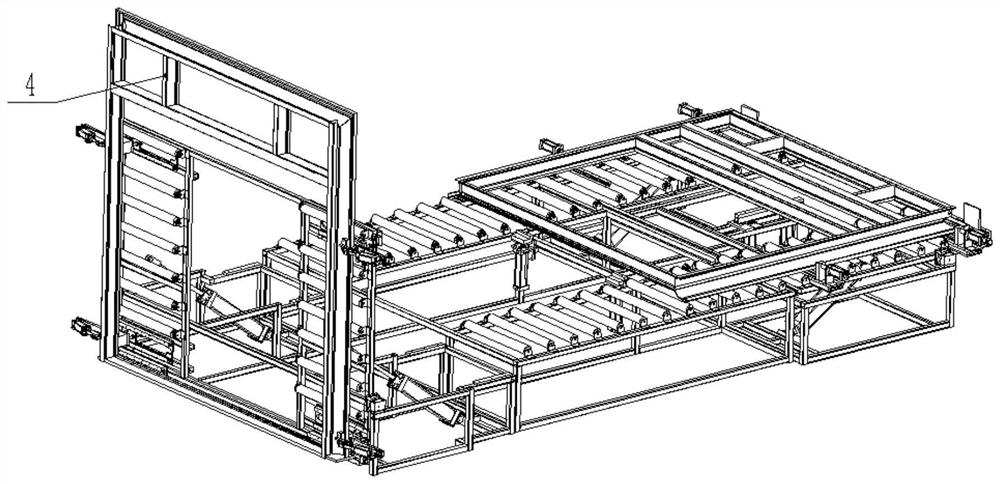

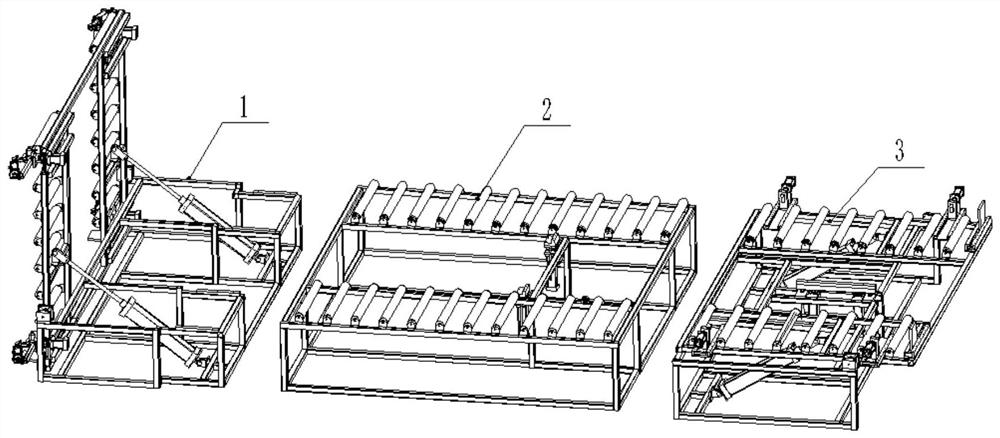

[0035] Such as Figure 1-3 As shown, a non-standard door assembly packaging system includes: a rotary assembly device 1, a transitional packing frame 2 and a rotary transport device 3 arranged in sequence; the rotary assembly device 1 includes an assembly chassis 5, and an assembly chassis 5 The assembly side frame 6 connected by rotation and the first driving part 8 for driving the assembly side frame 6 to rotate on the assembly bottom frame 5, the bottom of the assembly side frame 6 is provided with a first door fan support mechanism 11, and the assembly side frame 6 The first assembly clamping mechanism 10 is provided on both sides; the transition packing frame 2 is used to transfer the door leaves on the rotating assembly device 1 to the rotating transport device 3, and the rotating transport device 3 is used to transfer the The door leaf is limited and turned over.

[0036] The non-standard door 4 assembly and packaging system provided by the present invention uses a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com