Stamping control system and stamping method

A control system and punching technology, applied in the field of punching, to achieve the effect of reducing the probability of hidden dangers in production, improving safety and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to explain the stamping control system and the stamping method provided by the present invention more clearly, the specific description will be given below in conjunction with the embodiments.

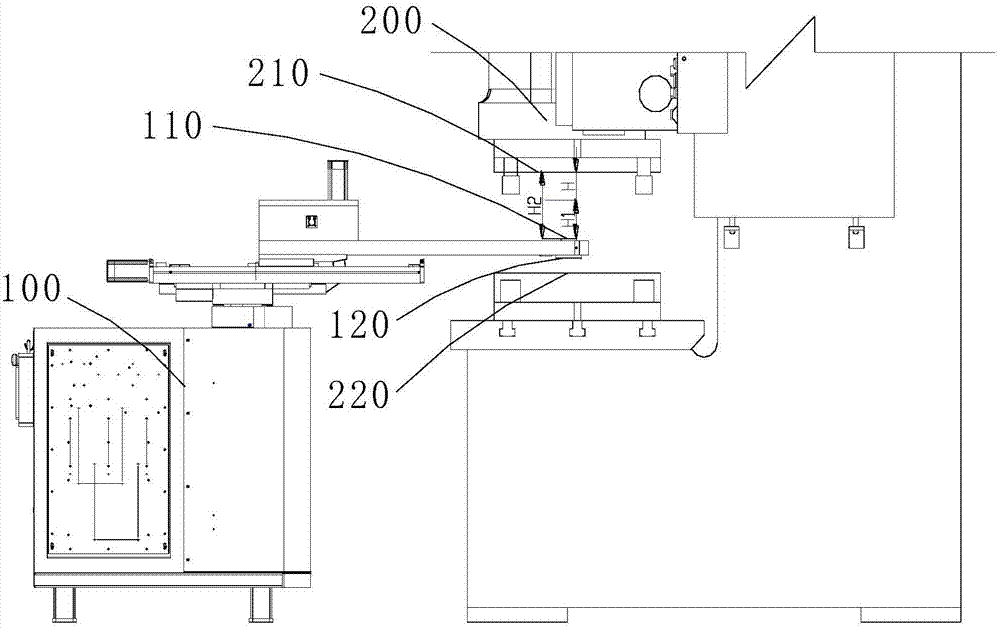

[0028] In one embodiment, as figure 1 As shown, the stamping control system includes a manipulator 100, a punch press 200 and a control system. The end of the manipulator is used to grip the material, and when the material is gripped, the material is kept on the lower surface 120 of the end of the manipulator. The punch press 200 has an upper die face 210 and a lower die face 220 .

[0029] Wherein, the control system is used to control the operation of the manipulator 100 and the punch press 200 , that is to say, this embodiment uses one system to control the manipulator 100 and the punch press 200 . Specifically, the control system is set in the manipulator 100 , that is, the manipulator 100 and the punch press 200 are controlled through a motion control card inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com