Multi-station automatic feeding device for sheet forming

An automatic feeding and multi-station technology, applied in the direction of positioning device, feeding device, storage device, etc., can solve the problems of low production efficiency and high labor intensity, so as to improve production efficiency, reduce labor intensity, and reduce hidden dangers of production safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

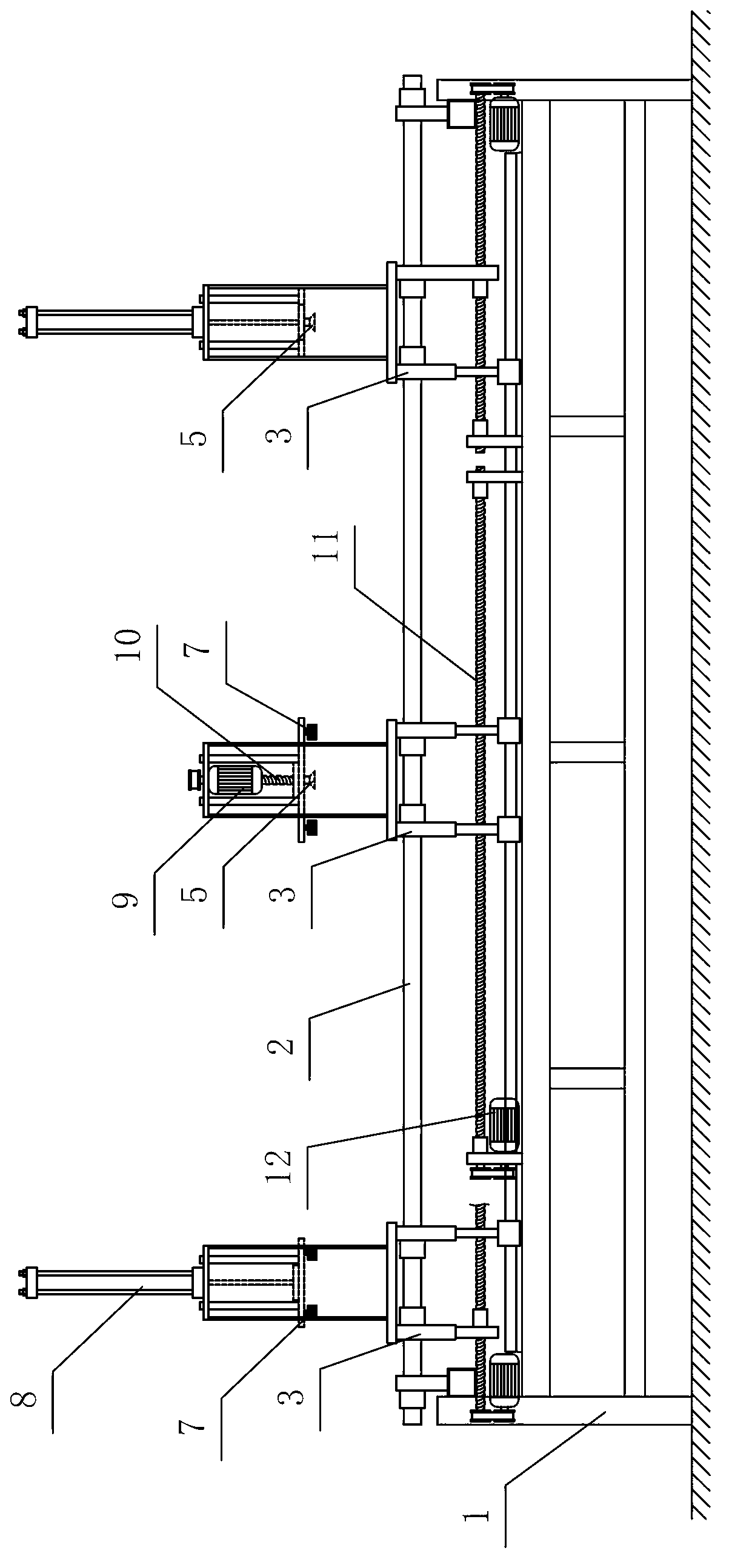

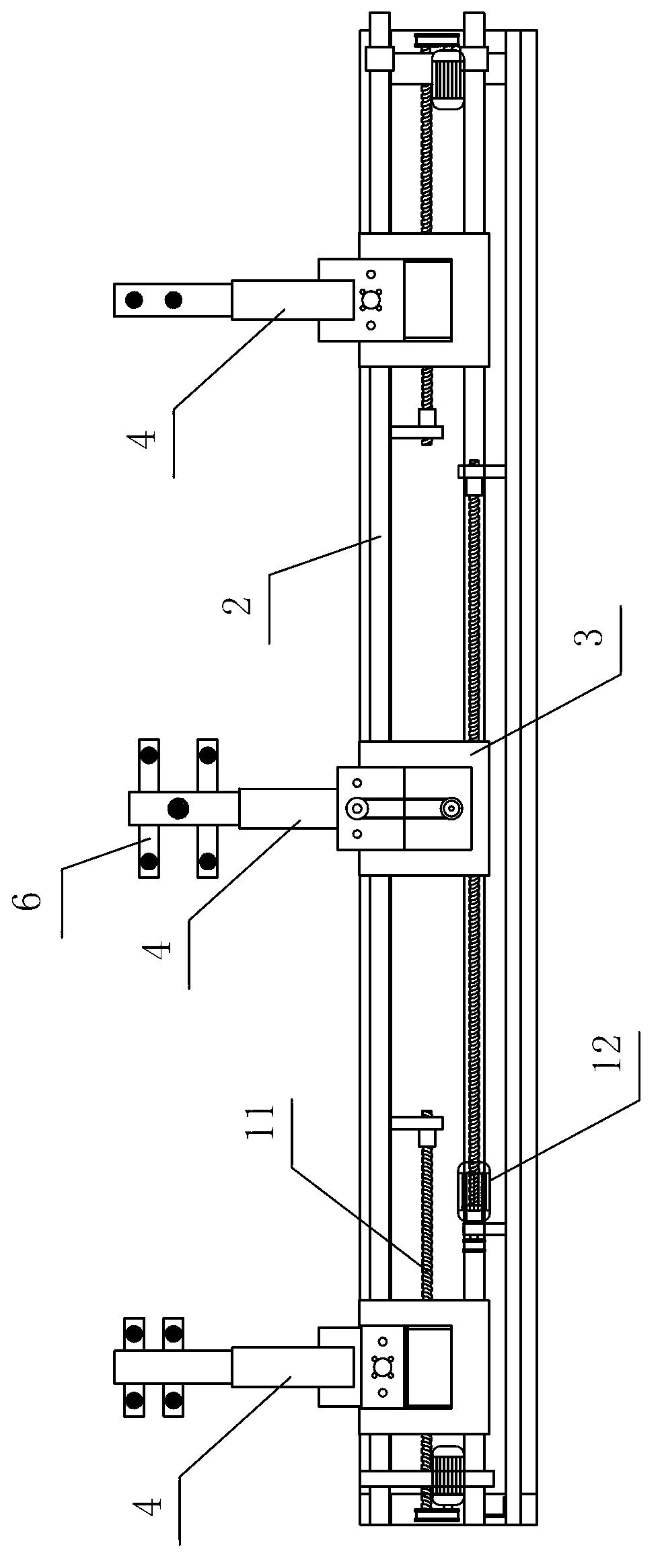

[0010] Such as figure 1 , 2 As shown, a multi-station automatic feeding device for sheet metal forming includes a frame 1 on which a guide rail 2 is fixed, and a reciprocating suction cup manipulator is installed on the guide rail 2 corresponding to each forming station. The suction cup manipulator includes a slide seat 3 which is slidably fitted on the guide rail, a cross arm 4 extending laterally to the forming station, a suction plate fixed on the lower side of the extension end of the cross arm 4, and a drive fixed on the slide seat 3. The driving device for cross arm 4 lifting up and down. Specifically, a frame body 6 can be fixed at the bottom of the extension end of the cross arm 4 as required, and the suction tray can be fixed at the bottom of the frame body 6 . Suction pan can adopt pneumatic suction pan 5 or electromagnet suction pan 7. The driving device for cross arm 4 lifting can be driven by cylinder 8 or servo motor 9 screw rod 10. The cylinder 8 and servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com