Production process for converting deep pickling yellow phosphorus into electronic grade red phosphorus

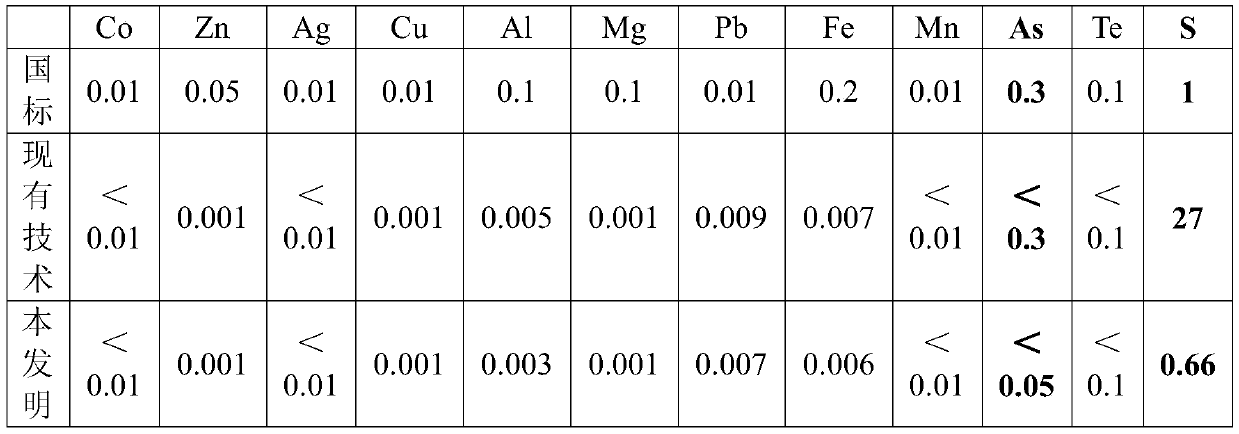

A production process and electronic-grade technology, applied in the field of elemental phosphorus preparation, can solve the problems of low recovery rate of yellow phosphorus, insufficient stirring, hidden safety hazards, etc., and achieve the effects of improving product purity, increasing yield, and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The production process of converting deep pickling yellow phosphorus into electronic grade red phosphorus, the specific method is:

[0037] (1) Deep pickling: Dilute the nitric acid with a mass fraction of 68% to a mass fraction of 20%, add it into a glass-lined cast iron kettle filled with industrial yellow phosphorus, and continue to stir mechanically, and circulate hot water in the outer interlayer of the kettle to keep it warm. Fully react nitric acid with impurities including As, S and C in industrial yellow phosphorus, and then wash the reaction product with pure water, the mass ratio of nitric acid and industrial yellow phosphorus is 1:3.

[0038] (2) Chlorination: The yellow phosphorus after deep pickling is transferred to the chlorination kettle, and chlorine gas is introduced to react with the yellow phosphorus to form phosphorus trichloride. The mass ratio of chlorine gas and yellow phosphorus is 1:0.29.

[0039] (3) Rectification: Control the temperature in ...

Embodiment 2

[0043] The production process of converting deep pickling yellow phosphorus into electronic grade red phosphorus, the specific method is:

[0044](1) Deep pickling: dilute nitric acid with a mass fraction of 68% to a mass fraction of 20%, then add it into a glass-lined cast iron kettle filled with industrial yellow phosphorus, and carry out continuous mechanical stirring, and the outer interlayer of the kettle is circulated for heat Water insulation is used to fully react the impurities including As, S and C in nitric acid and industrial yellow phosphorus, and then the reaction product is washed with pure water. The mass ratio of nitric acid and industrial yellow phosphorus is 1:3.

[0045] (2) Chlorination: The yellow phosphorus after deep pickling is transferred to the chlorination kettle, and chlorine gas is introduced to react with the yellow phosphorus to form phosphorus trichloride. The mass ratio of chlorine gas and yellow phosphorus is 1:0.29.

[0046] (3) Rectificatio...

Embodiment 3

[0050] The production process of converting deep pickling yellow phosphorus into electronic grade red phosphorus, the specific method is:

[0051] (1) Deep pickling: dilute nitric acid with a mass fraction of 68% to a mass fraction of 20%, then add it into a glass-lined cast iron kettle filled with industrial yellow phosphorus, and carry out continuous mechanical stirring, and the outer interlayer of the kettle is circulated for heat Water insulation is used to fully react the impurities including As, S and C in nitric acid and industrial yellow phosphorus, and then the reaction product is washed with pure water. The mass ratio of nitric acid and industrial yellow phosphorus is 1:3.

[0052] (2) Chlorination: The yellow phosphorus after deep pickling is transferred to the chlorination kettle, and chlorine gas is introduced to react with the yellow phosphorus to form phosphorus trichloride. The mass ratio of chlorine gas and yellow phosphorus is 1:0.29.

[0053] (3) Rectificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com