Rocker-type transverse shearer

A technology of rocker arm type and coal shearer, which is applied in the direction of cutting machinery, earth drilling and mining, etc., can solve problems that hinder the implementation and implementation of resource conservation and coal resource development and protection strategies, safety hazards, narrow mining roadways, etc., and achieve Avoid direct economic losses and waste of resources, facilitate installation and disassembly, and facilitate coal mining and coal extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

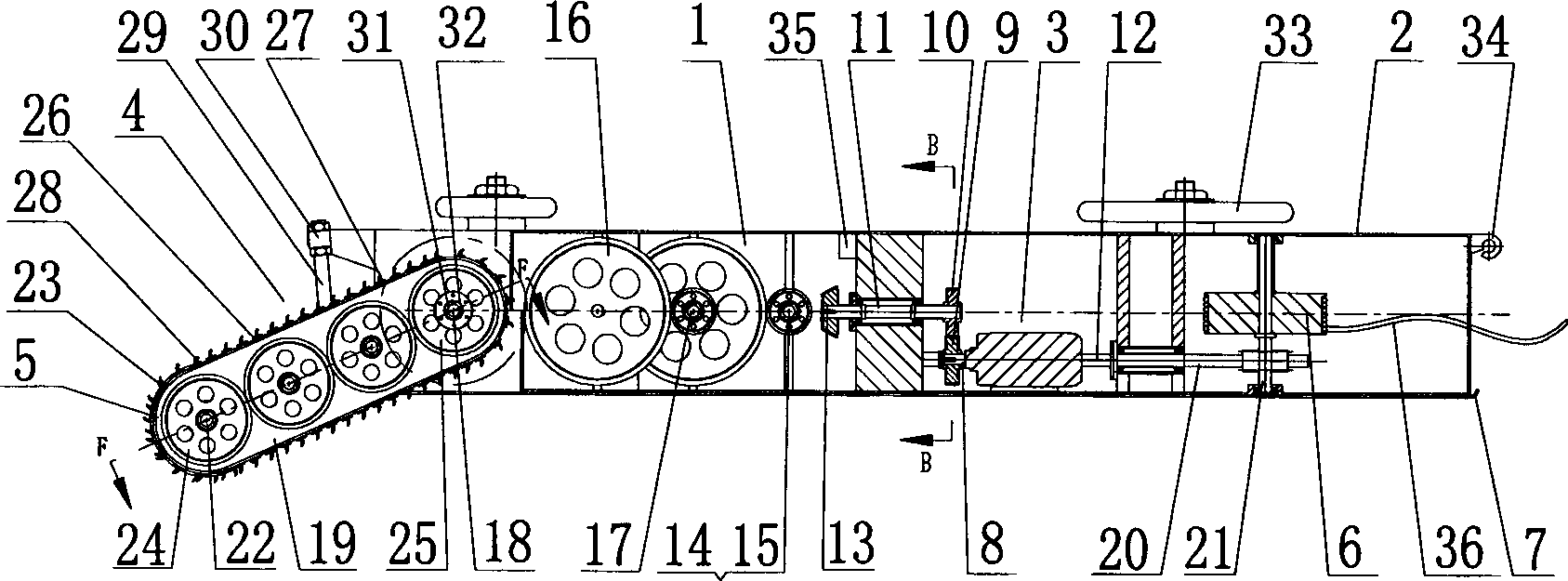

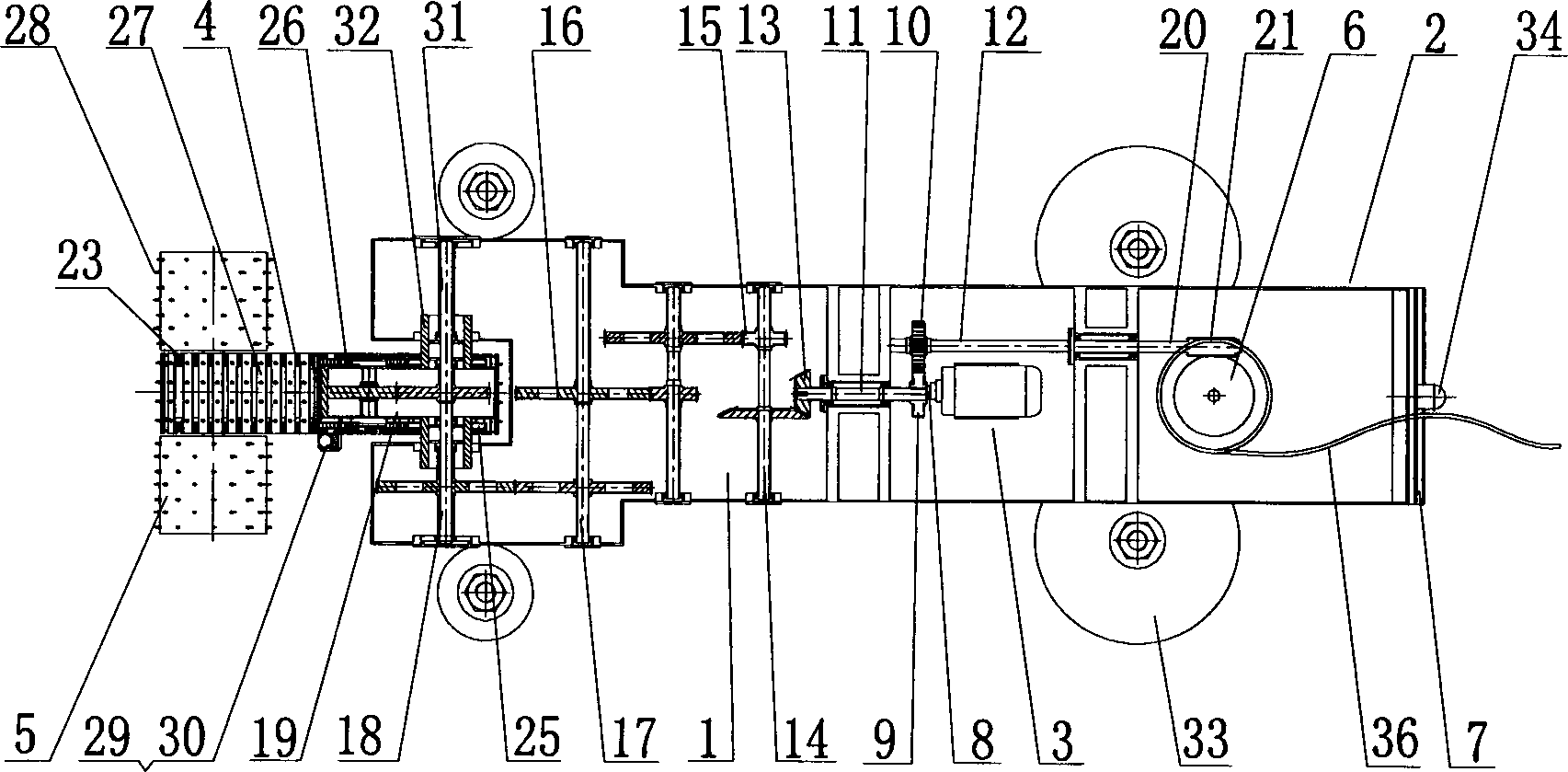

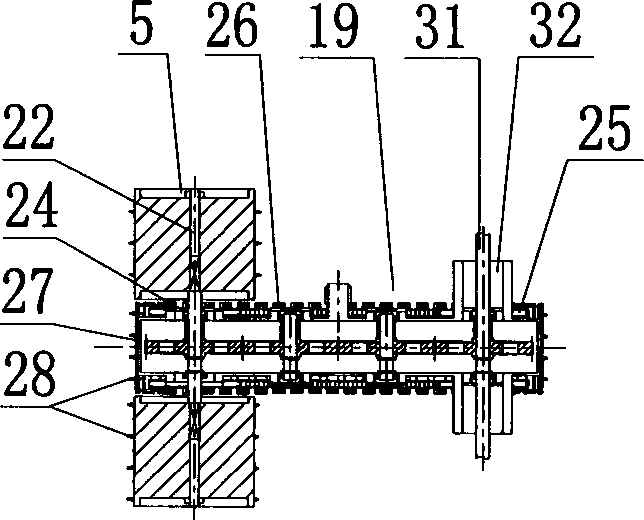

[0039] As shown in the drawings, the rocker arm type transverse drum shearer includes a body 2 composed of at least three cabinet compartments 1 and a power transmission chain 3 arranged in the cabinet compartment 1, as well as rocker arms 4, drums 5 and Drum 6, in order to improve work efficiency and be suitable for full-section mining of the thin coal seam at the bottom of the roadway structure, the lower part of the body 2 is provided with a slide plate 7, and the power transmission chain 3 includes a motor shaft 8, the main drive wheel 9 on the motor shaft 8 and a pair of auxiliary Transmission wheel 10 meshes and drives longitudinal front and rear drive shafts 11, 12 to output power, and front drive shaft 11 ends are provided with a bevel gear 13, and this bevel gear 13 drives a bevel gear shaft 14 and the spur gear 15 on the shaft thereof to rotate, and the bevel gear 13 The gear 15 drives the three-stage transmission gear 16 and the transmission gear shaft 17 of each sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com