Casting aluminum bar smelting device for aluminum profile production

An aluminum profile and aluminum rod technology, which is applied in the field of aluminum material smelting, can solve the problems of uneven mixing of additives, consumption of long heating time, and low thermal melting efficiency of aluminum rods, so as to reduce hidden dangers in production safety, promote heating efficiency, and shorten the effect of time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

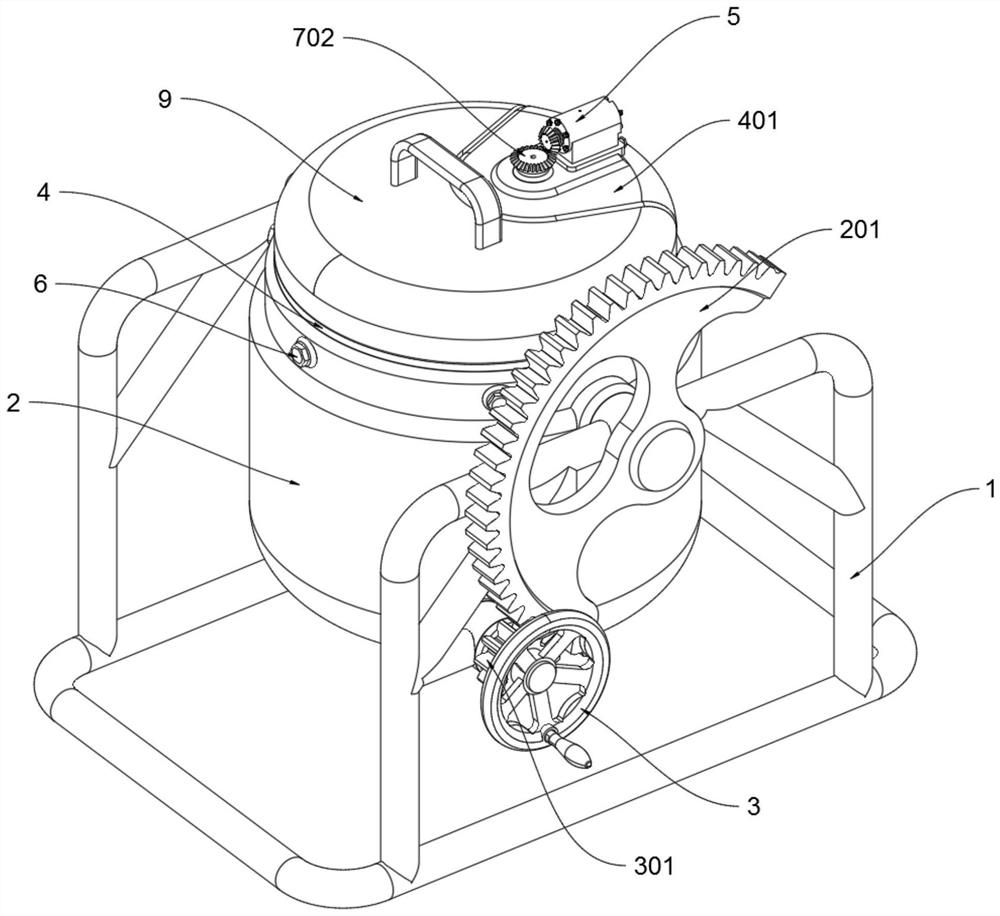

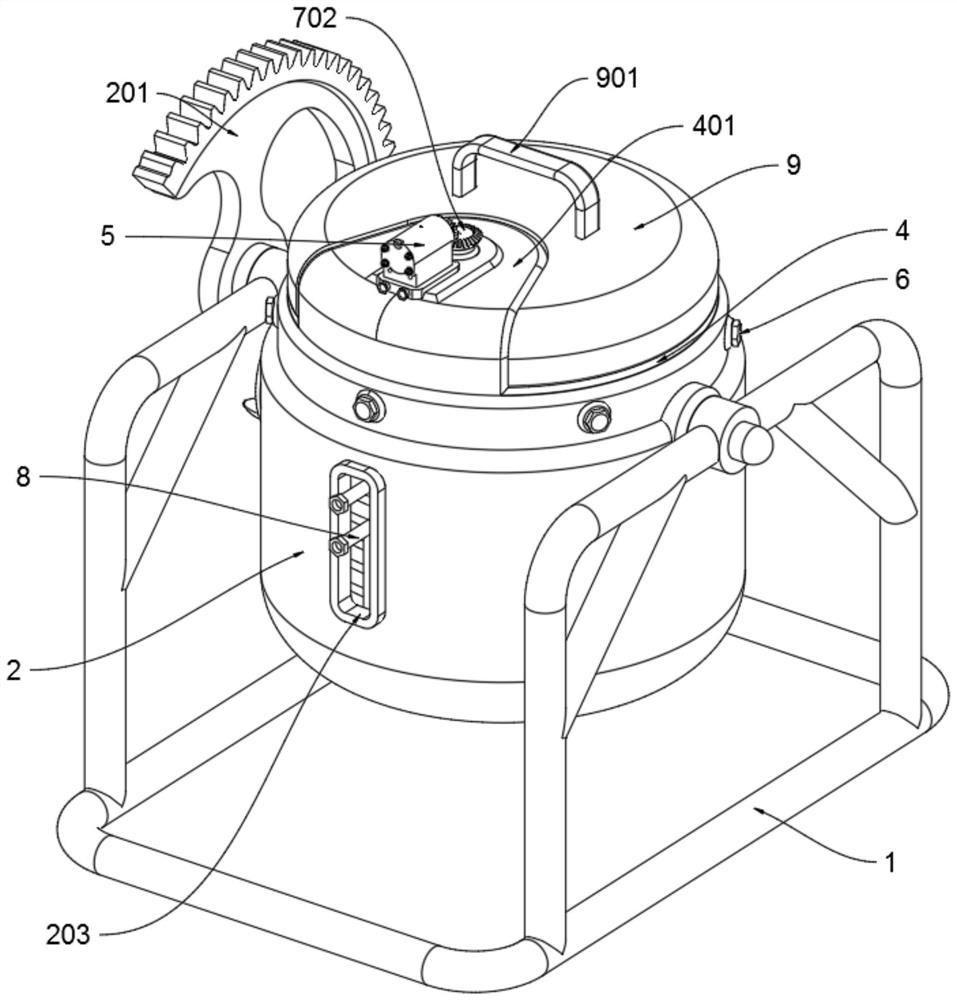

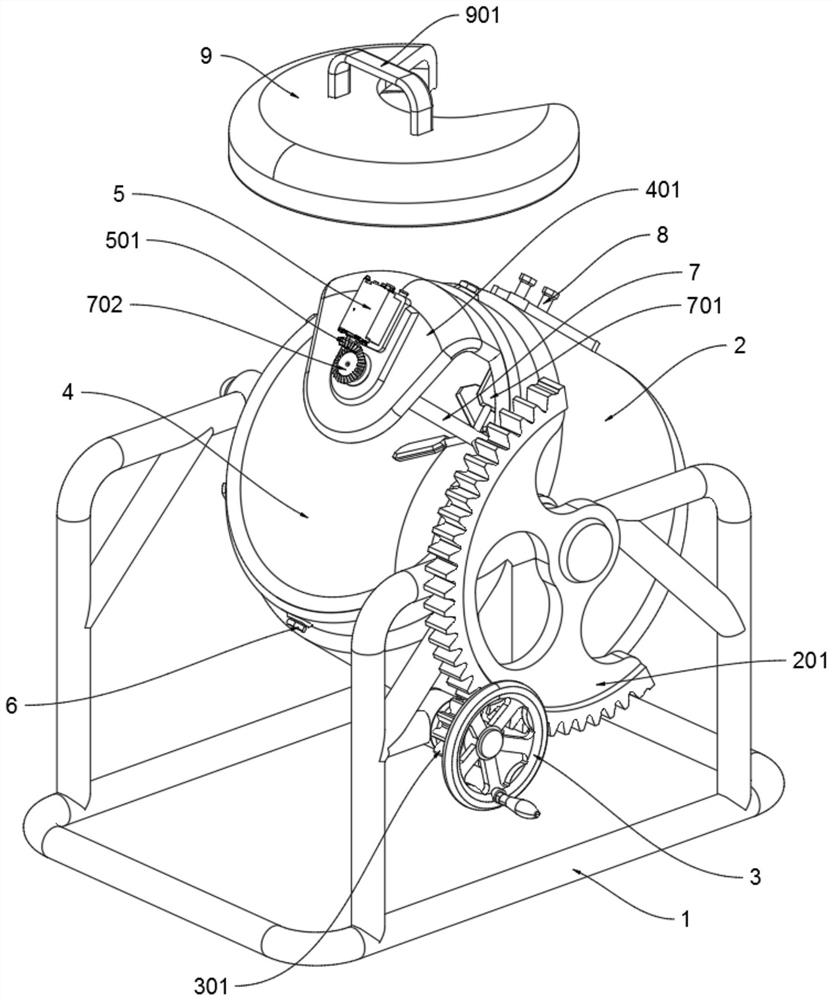

[0031] as attached figure 1 To attach Figure 8 Shown:

[0032] The present invention provides a casting aluminum bar smelting device for aluminum profile production, which includes a support frame 1, a hot-melt barrel 4, an air motor 5 and a heat-insulating sealing cover 9; the support frame 1 is a frame structure, and the heat-insulating outer barrel 2 is connected to the Inside the top of the support frame 1; an external connection port 203 is opened on the rear side of the heat-insulating outer barrel 2, and the right end of the heat-insulating outer barrel 2 is connected to the handwheel 3; the hot-melt barrel 4 is connected to the inside of the heat-insulating outer barrel 2, and the A top connecting plate 401 is provided on the top of the barrel 4; the air motor 5 is connected to the top of the stirring shaft 7, and the stirring shaft 7 is located inside the hot-melt barrel 4, and the hot-melt barrel 4 is fixedly connected to the heat-insulating outer barrel 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com