Aging manufacturing technology for aluminum electrolytic capacitor and detecting device

An aluminum electrolytic capacitor and manufacturing process technology, applied in the field of capacitors, can solve the problems of workers' visual fatigue, safety accidents, capacitor burning, etc., and achieve the effects of improving product qualification rate, prolonging service life and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

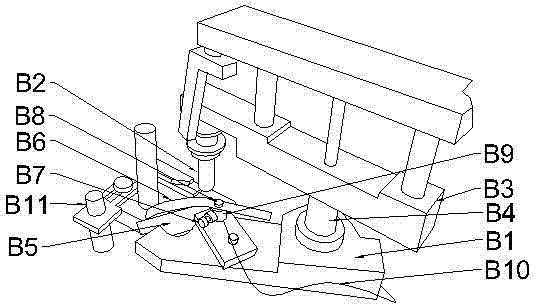

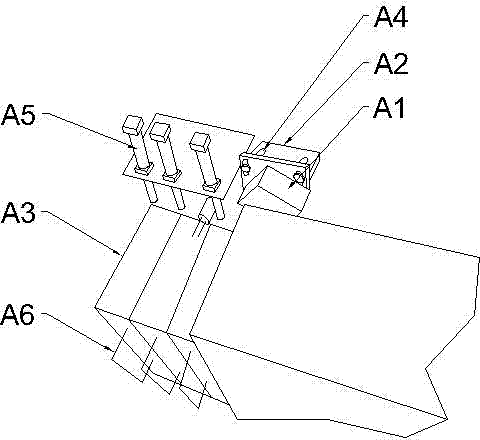

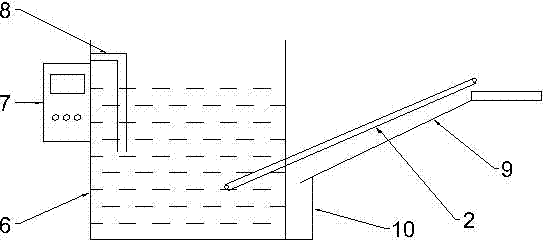

[0023] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Figure 4 , the aging manufacturing process of a kind of aluminum electrolytic capacitor described in the present embodiment, it comprises the following steps:

[0024] 1) Connect the positive and negative lead pins to the positive and negative electrode foils respectively through rivets;

[0025] 2) The positive and negative electrode foils and electrolytic paper are stacked in staggered layers and then rolled into a core body, and the outer peripheral surface of the core body is sealed and bound by transparent adhesive tape;

[0026] 3) Put the bundled rough billets into the preliminary aging box for 15-25 minutes;

[0027] 4) Through the feeding belt, the rough billet after preliminary aging is introduced into the granulator for casing and granulation; the granulator is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com