Bush assembling mechanism

An assembly mechanism and bushing technology, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large bushing usage, inability to achieve large-scale assembly and assembly, and difficulty in unifying the effect and quality of assembly. Quantification and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

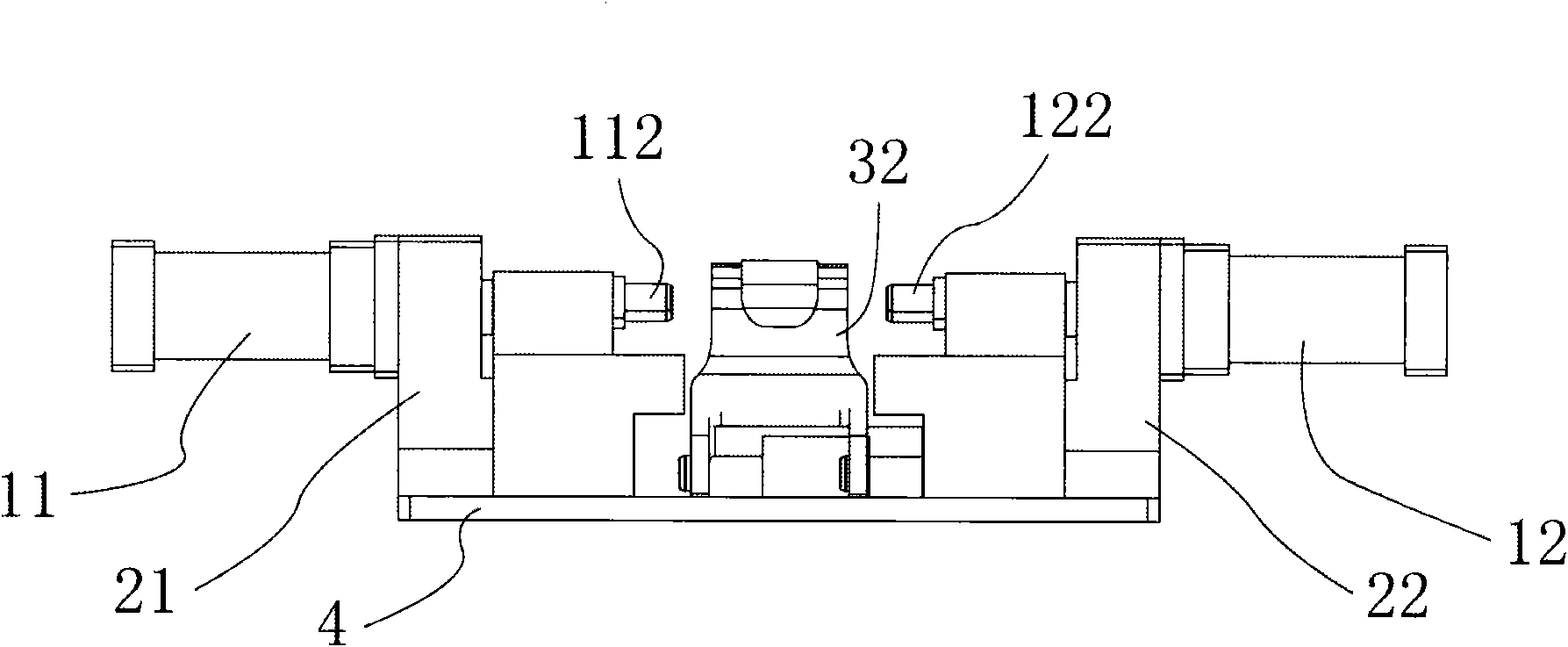

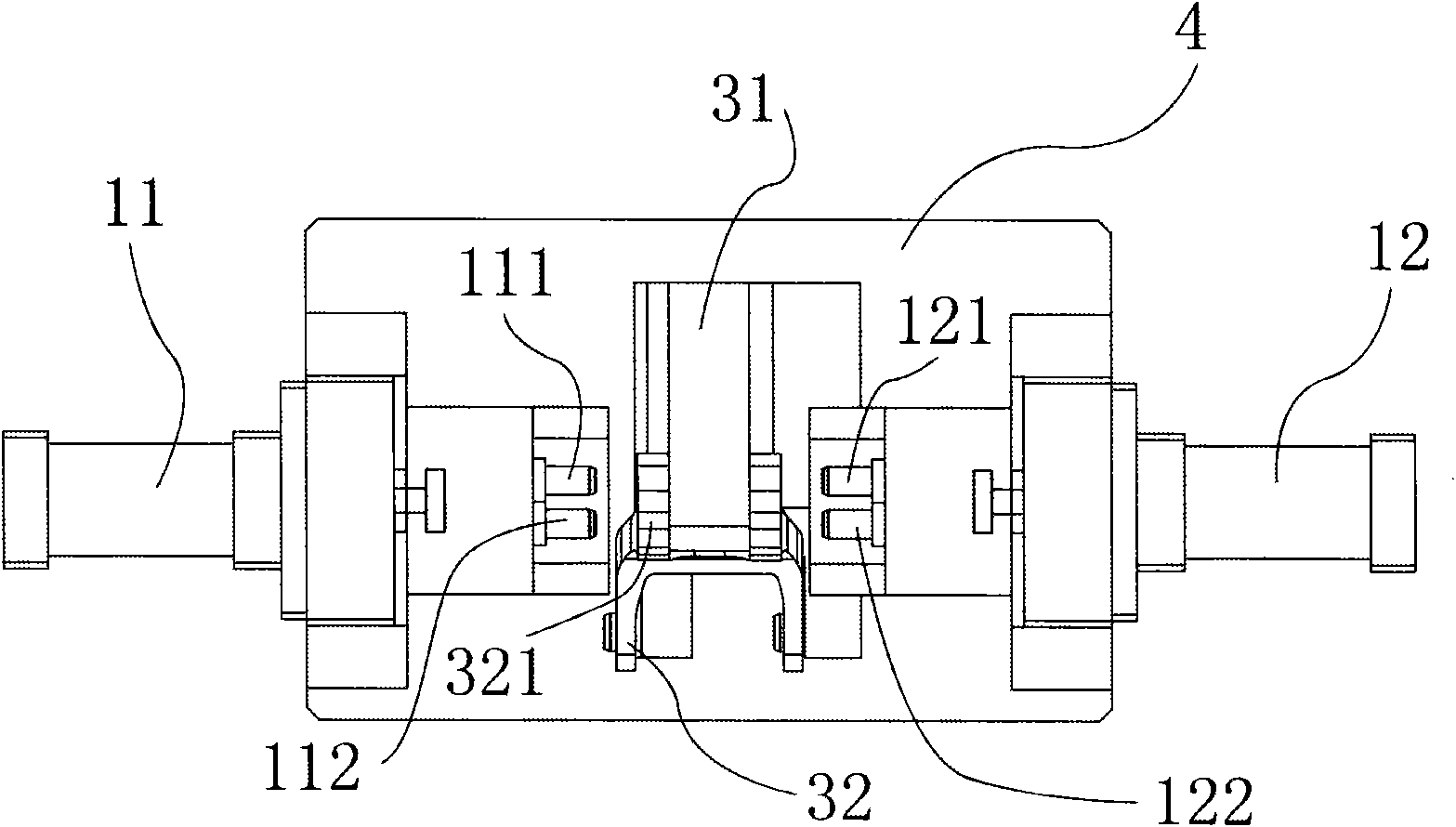

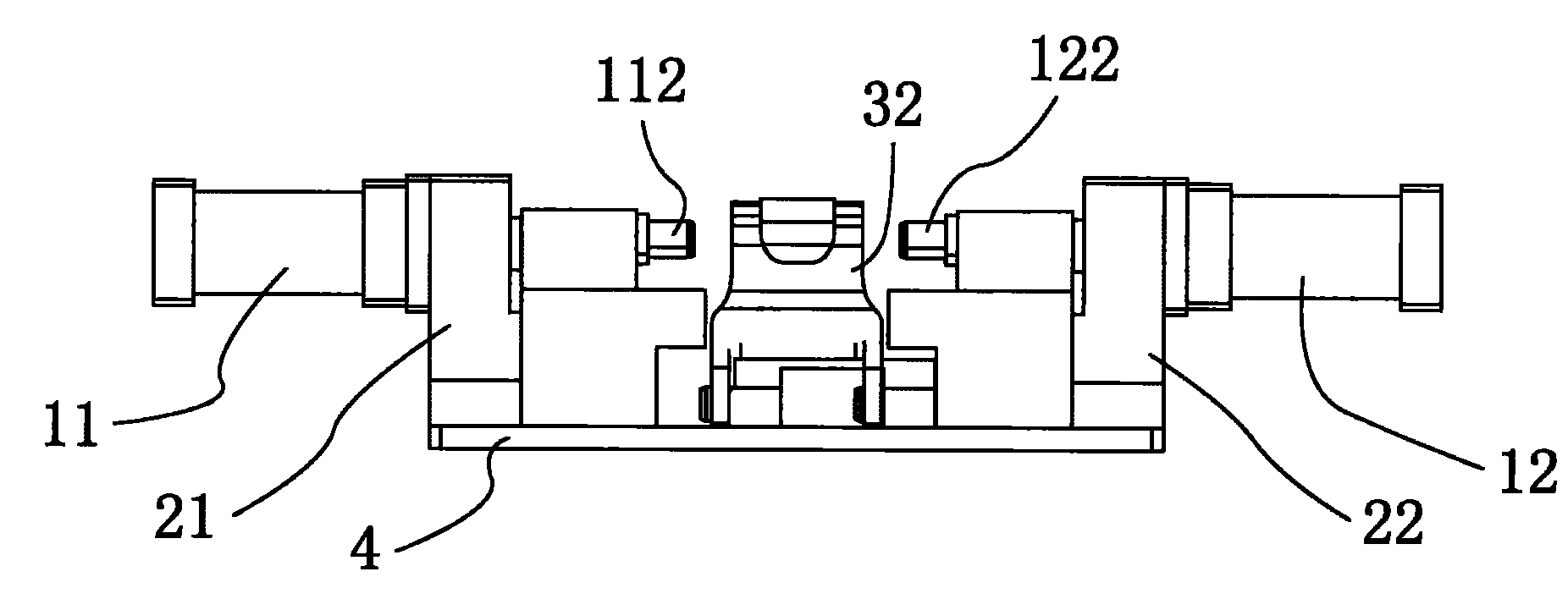

[0017] Such as figure 1 with figure 2 In the shown bushing assembly mechanism, cylinder positioning bases 21 and 22 are respectively fixed on the left and right sides of positioning plate 4, cylinders 11 and 12 are fixed on bases 21 and 22, and two piston rod heads of the two cylinders are respectively placed. A liner placement pin arranged side by side, workpieces / products 31 and 32 are placed side by side on the positioning plate 4 in the middle of the two cylinders, and each workpiece is provided with a hole similar to the liner hole 321 for inserting the liner ; wherein the heads of the bushing placement pins 111 and 112 arranged side by side correspond to the bushing holes on the left side of the workpieces 31 and 32 respectively, while the bushing placement pins 121 and 122 correspond to the positions of the bushing holes on the left side of the workpieces 31 and 32 respectively. Corresponds to the position of the bushing hole opened.

[0018] When this mechanism is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com