Assembly line for transformers

A transformer and production line technology, applied in the direction of inductance/transformer/magnet manufacturing, transportation and packaging, electrical components, etc., can solve problems such as inability to realize automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

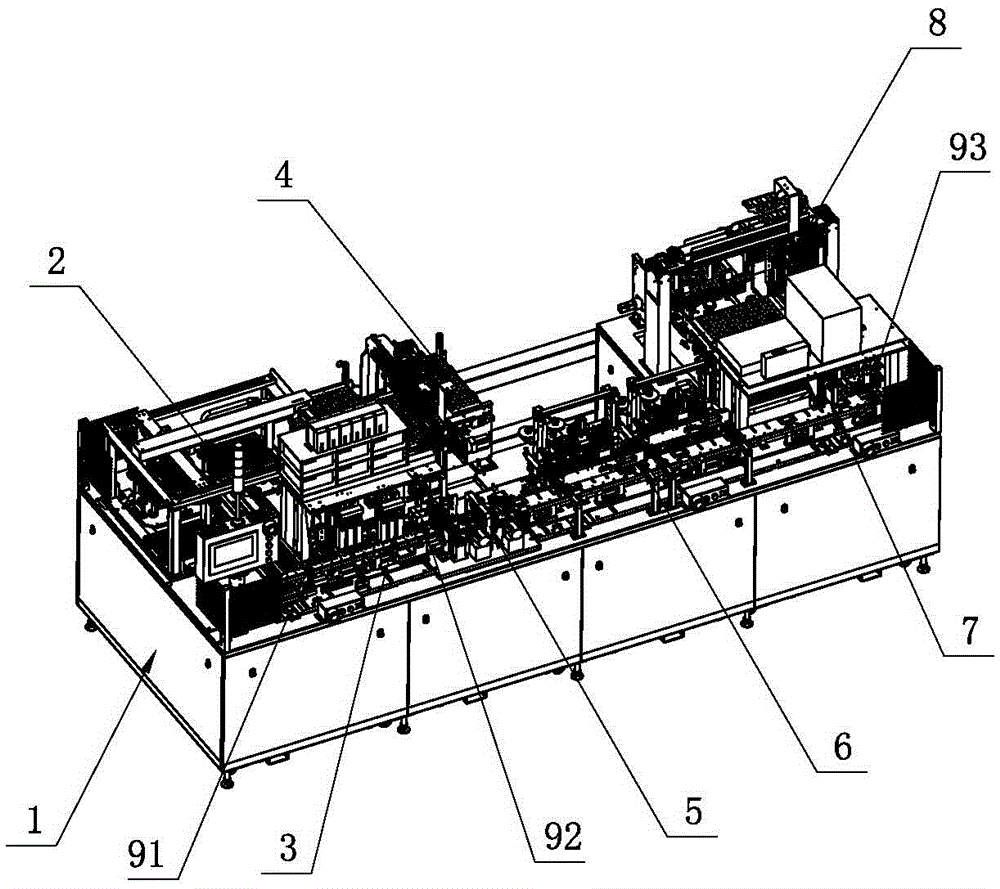

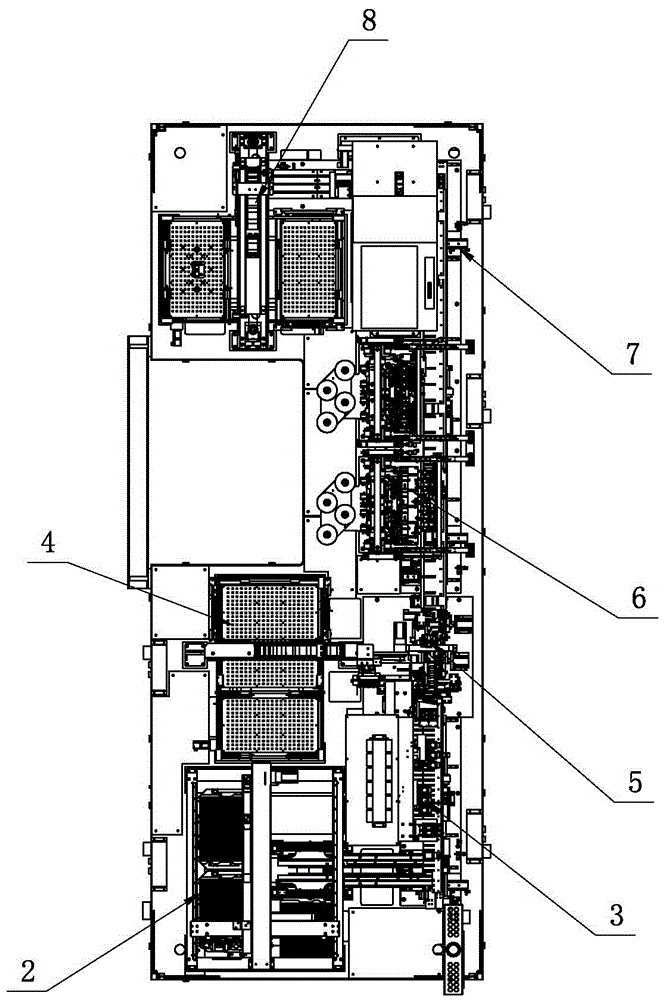

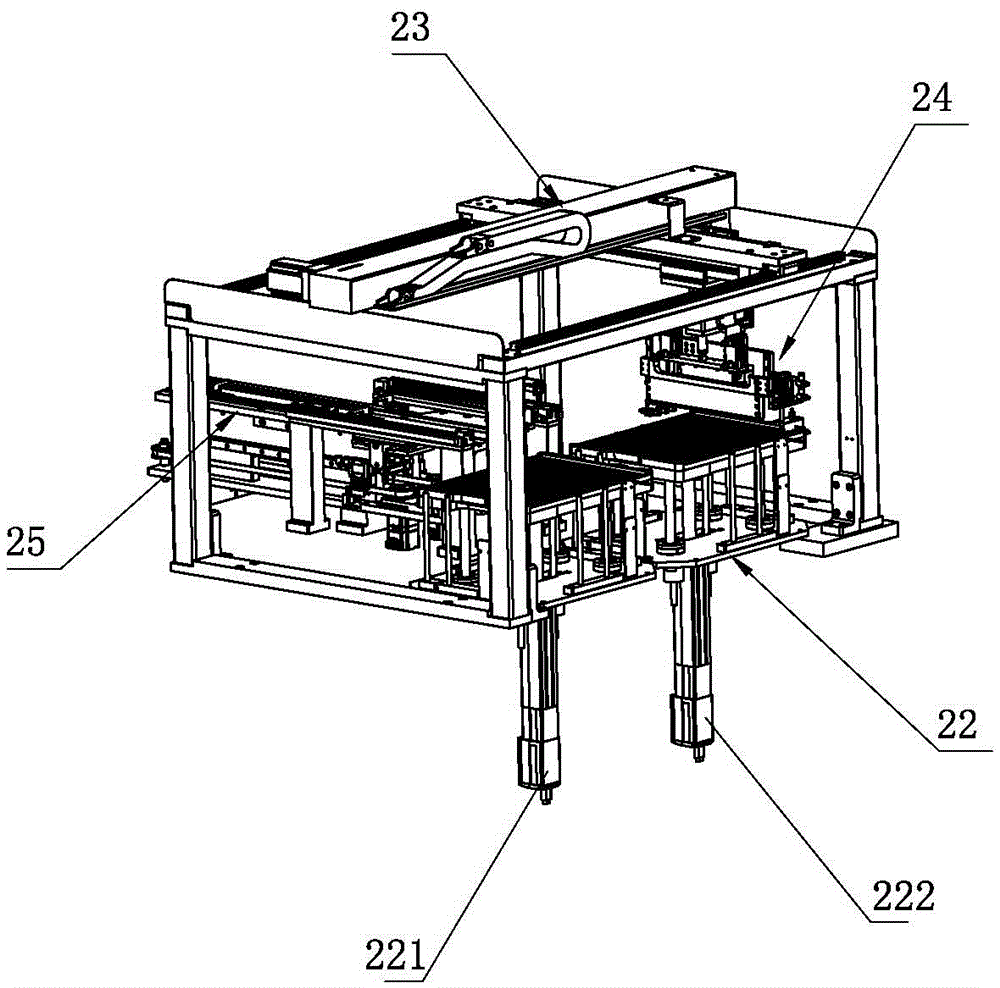

[0033] Such as Figure 1 to Figure 14 As shown, a transformer assembly production line of the present invention includes a production line frame 1, and the production line frame 1 is provided with a magnetic core feeding device 2 for loading magnetic cores, for feeding the loaded Magnetic core dispensing device 3 for dispensing magnetic cores, wire package feeding device 4 for feeding wire packages, magnetic cores and wire packages for flipping and combining loaded magnetic cores and wire packages combination mechanism 5; the production line frame 1 is provided with a transformer encapsulation device 6 for encapsulating the combined magnetic core and wire bag; An electrical testing device 7 for electrical testing; the production line frame 1 is provided with a sorting manipulator 8 for sorting good and bad transformers. The operator feeds the tray with the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com