Multi-station quick coupling assembling machine

An assembly machine and multi-station technology, which is applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of small gap between the jacket and the central part, inconvenient installation of jacket springs, etc., to achieve high assembly efficiency and avoid missing parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

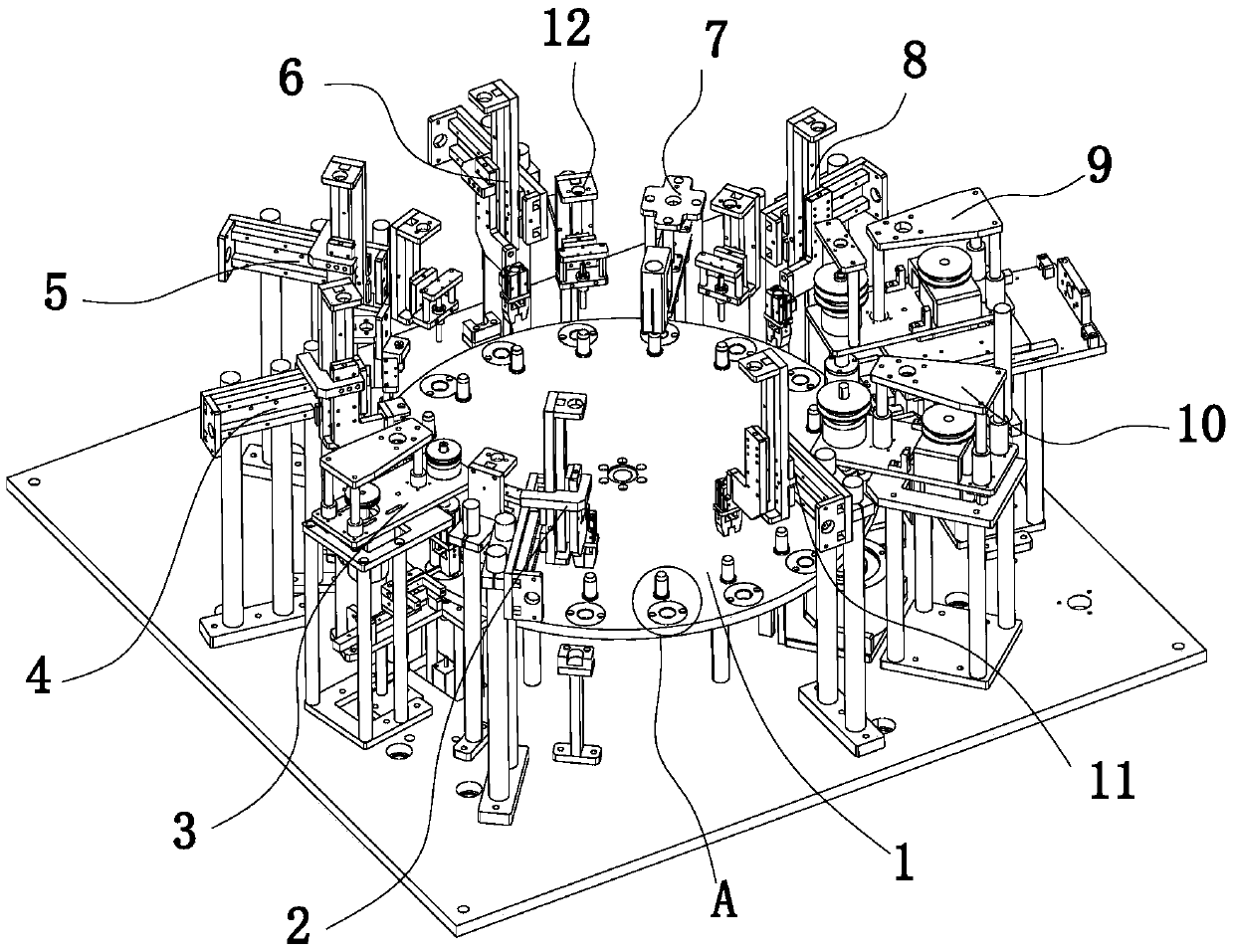

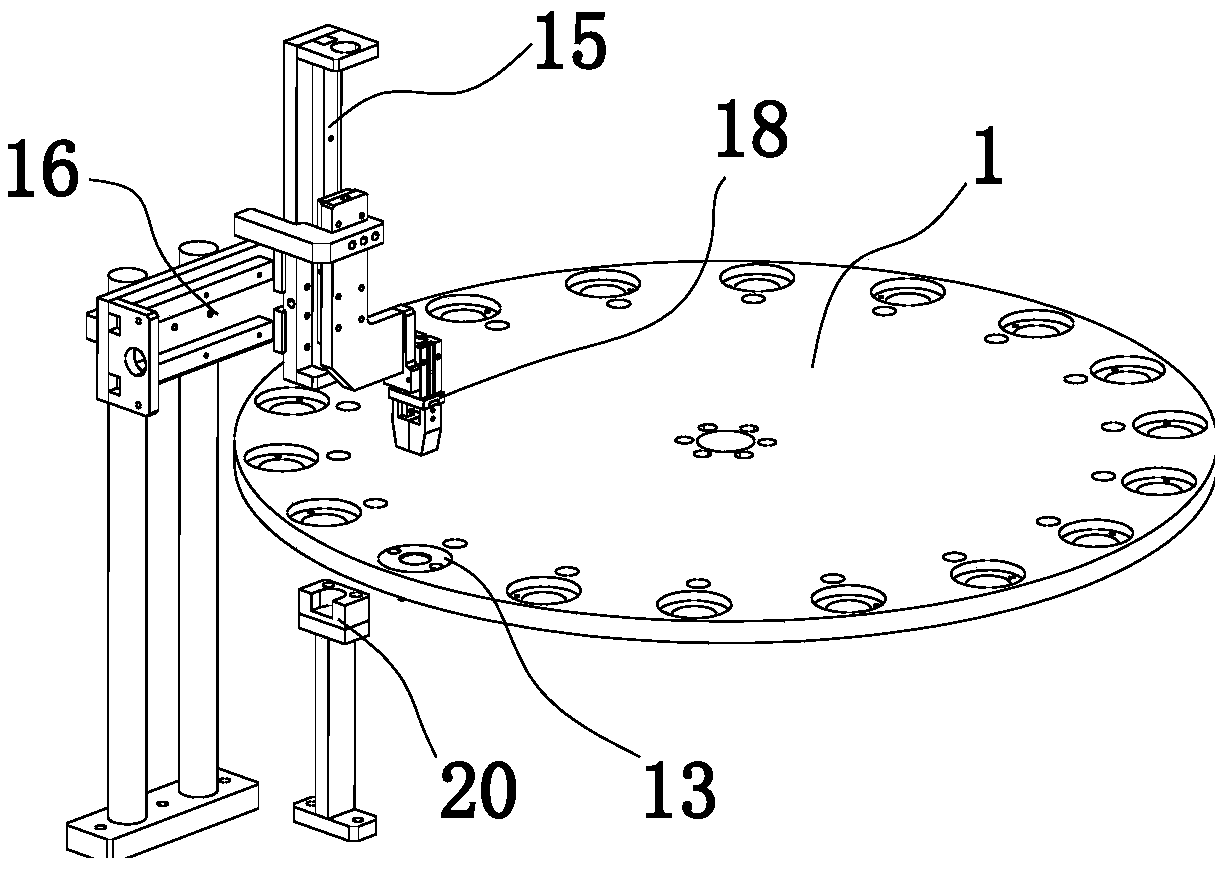

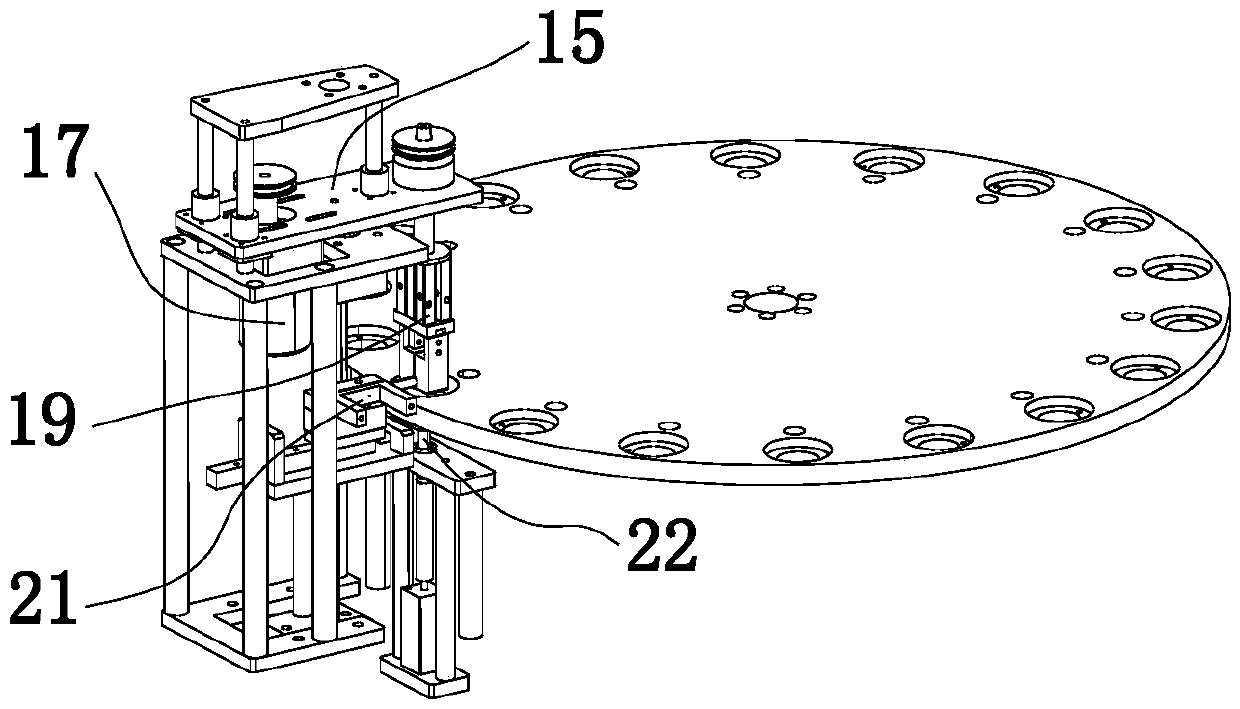

[0034] refer to figure 1 As shown, the multi-station quick joint assembly machine is a material transfer table 1 whose main body is a stepping movement, and several automatic assembly stations are set along the movement direction of the material transfer table 1, and the multi-stations operate synchronously to realize the rapid automatic assembly of the quick joint , the automatic assembly station includes in sequence along the movement direction of the material transfer table 1: the central feeding station 2, the steel ball feeding station 3, the gasket feeding station 4, the valve core feeding station 5, and the jacket feeding station 6 , spring feeding station 7, material shifting station 8, nut glue pre-tightening station 9, nut tightening station 10, reclaiming station 11 and related installation and testing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com