Patents

Literature

58results about How to "Avoid missing parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

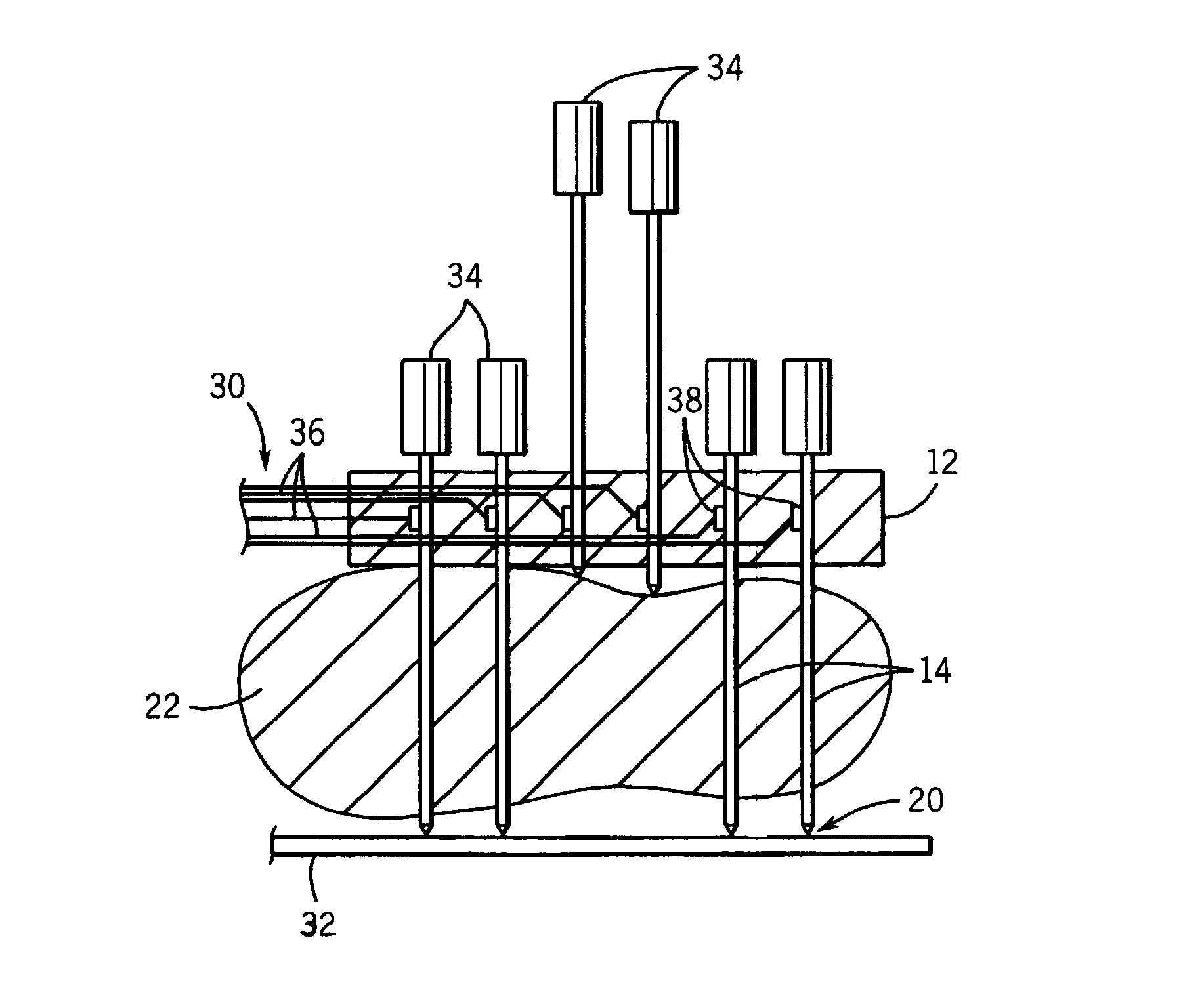

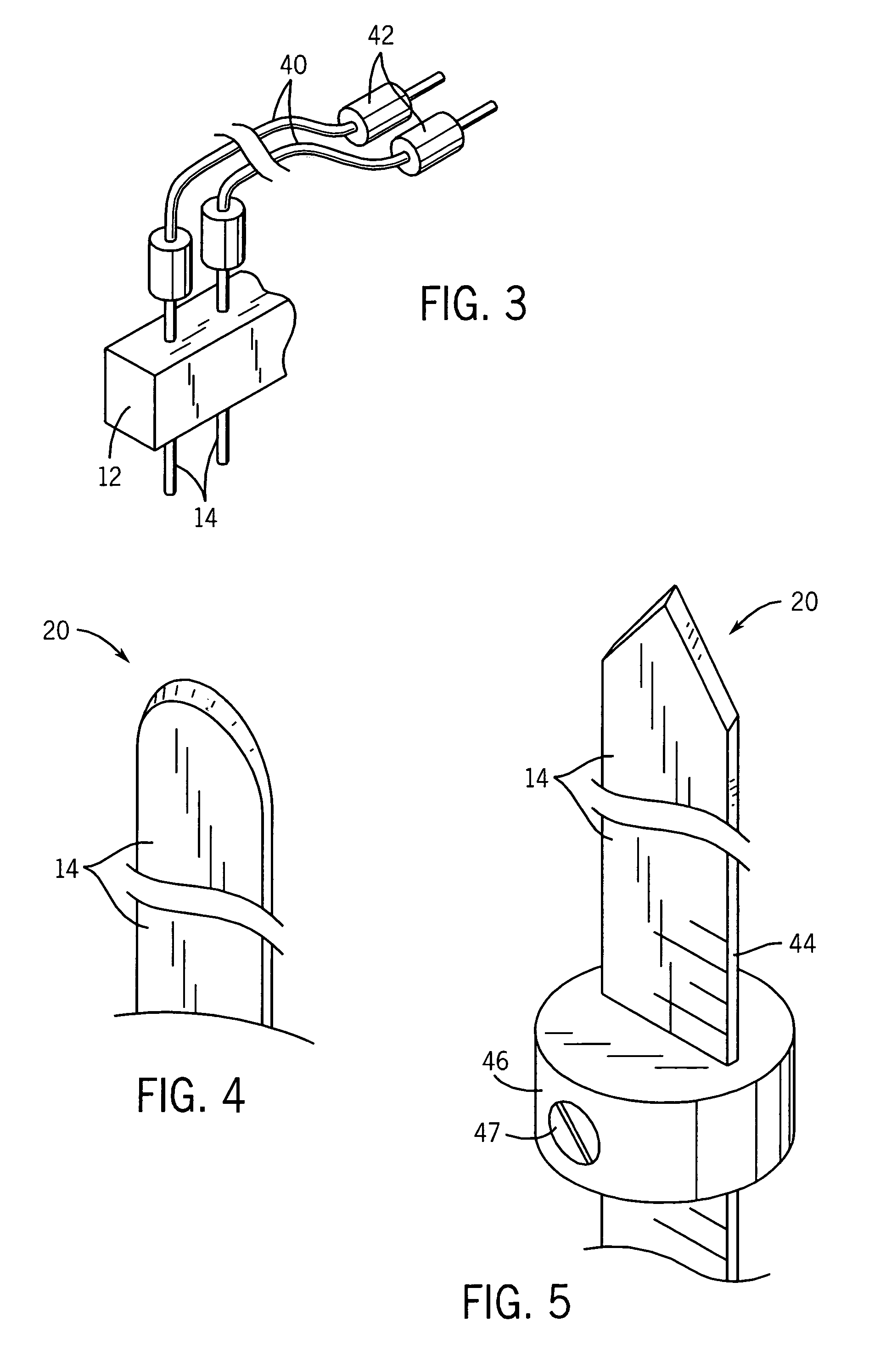

Electrode array for tissue ablation

ActiveUS7367974B2Fast ablationFlow of bloodDiagnosticsSurgical needlesElectrode arrayTissue ablation

An electrode array allows for rapid ablation of a strip of tissue in an organ providing a barrier to blood loss during resection operations.

Owner:WISCONSIN ALUMNI RES FOUND

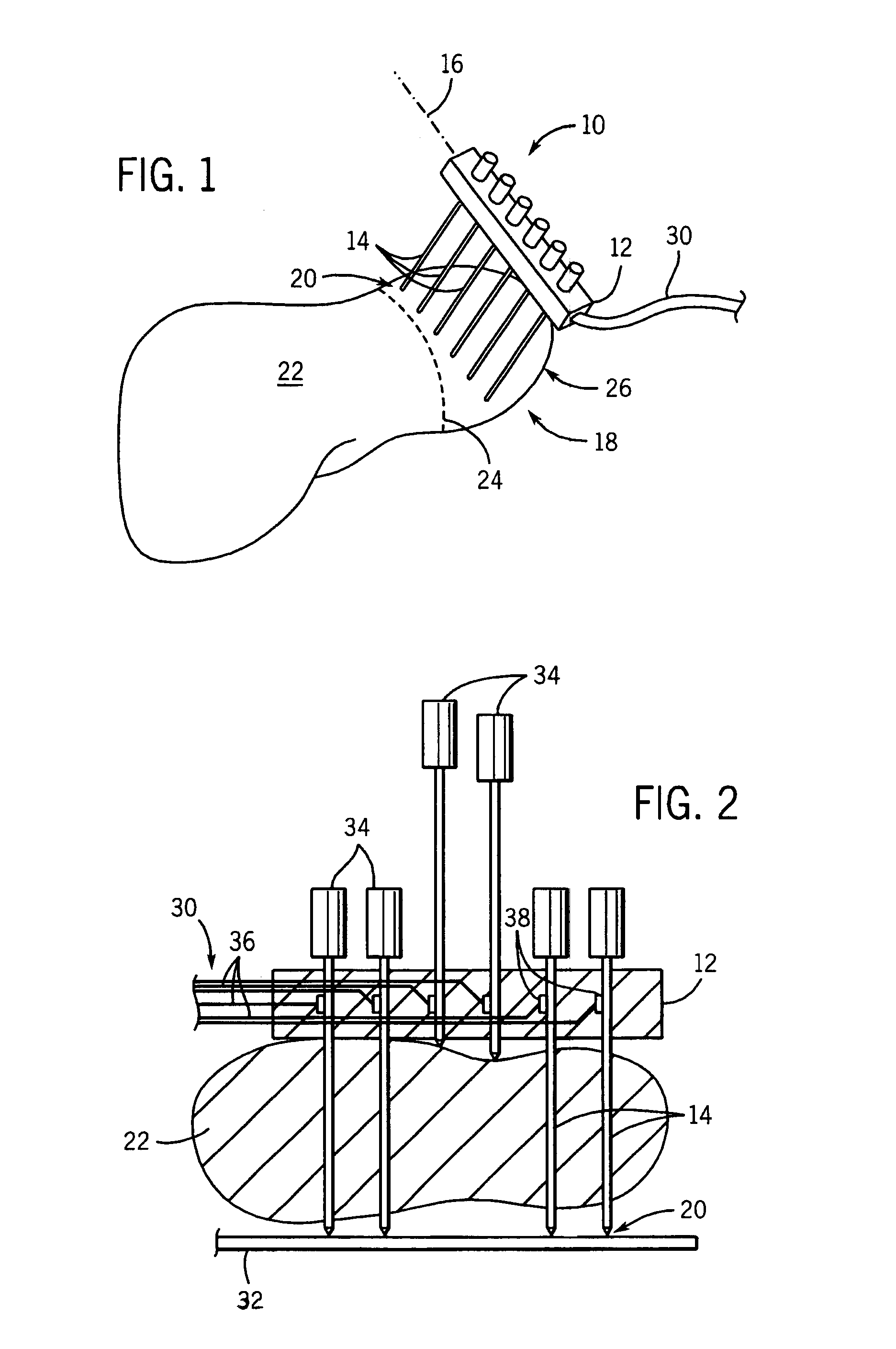

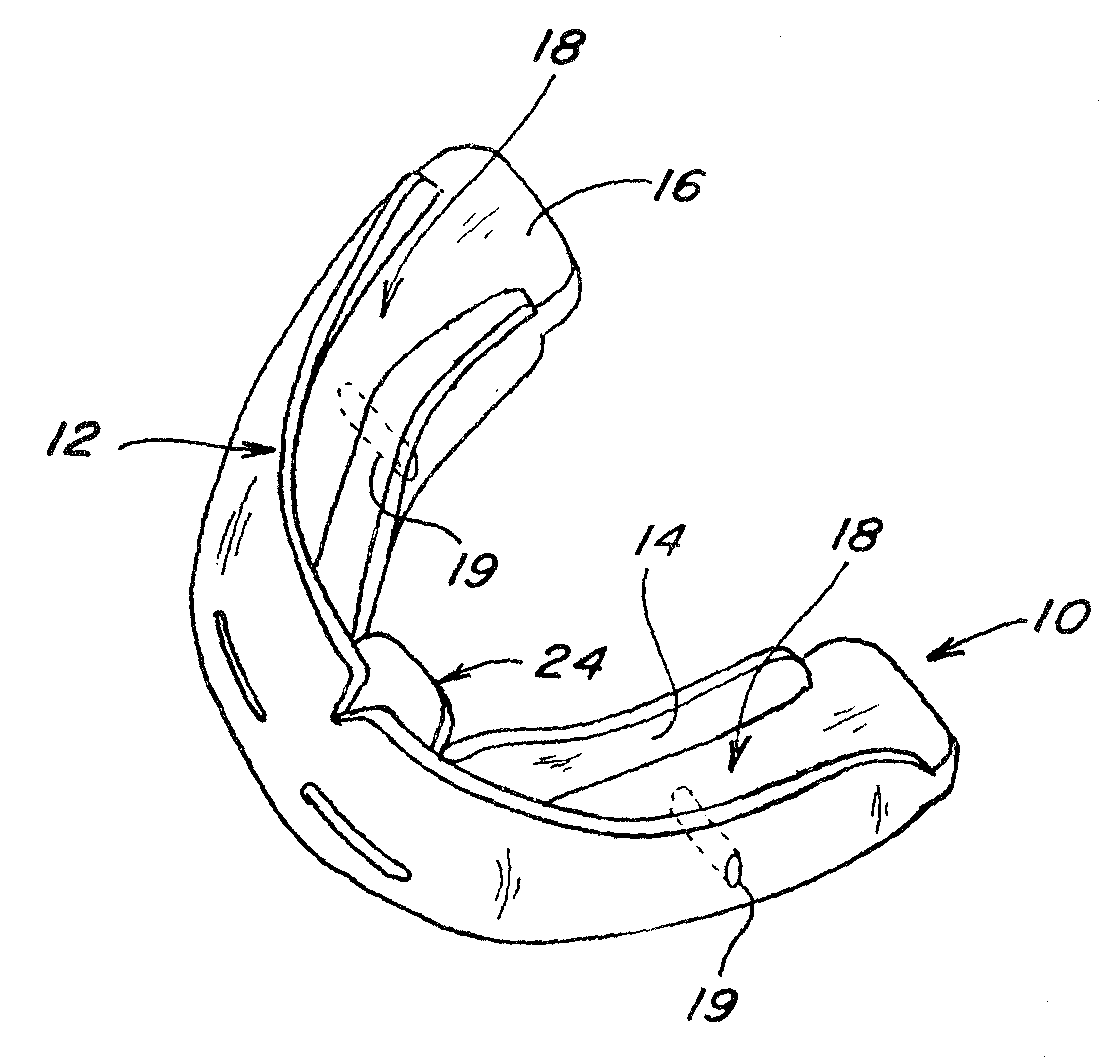

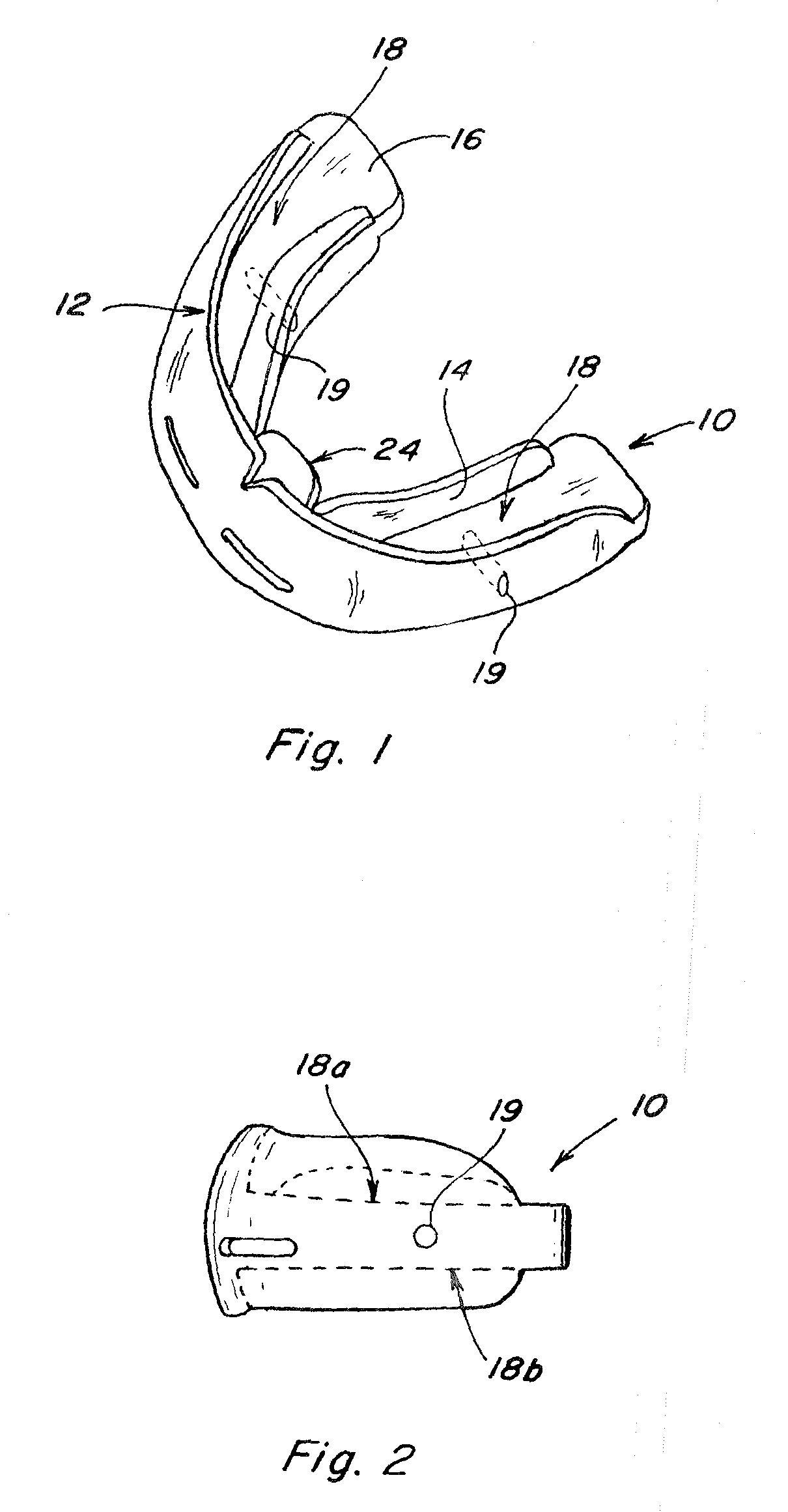

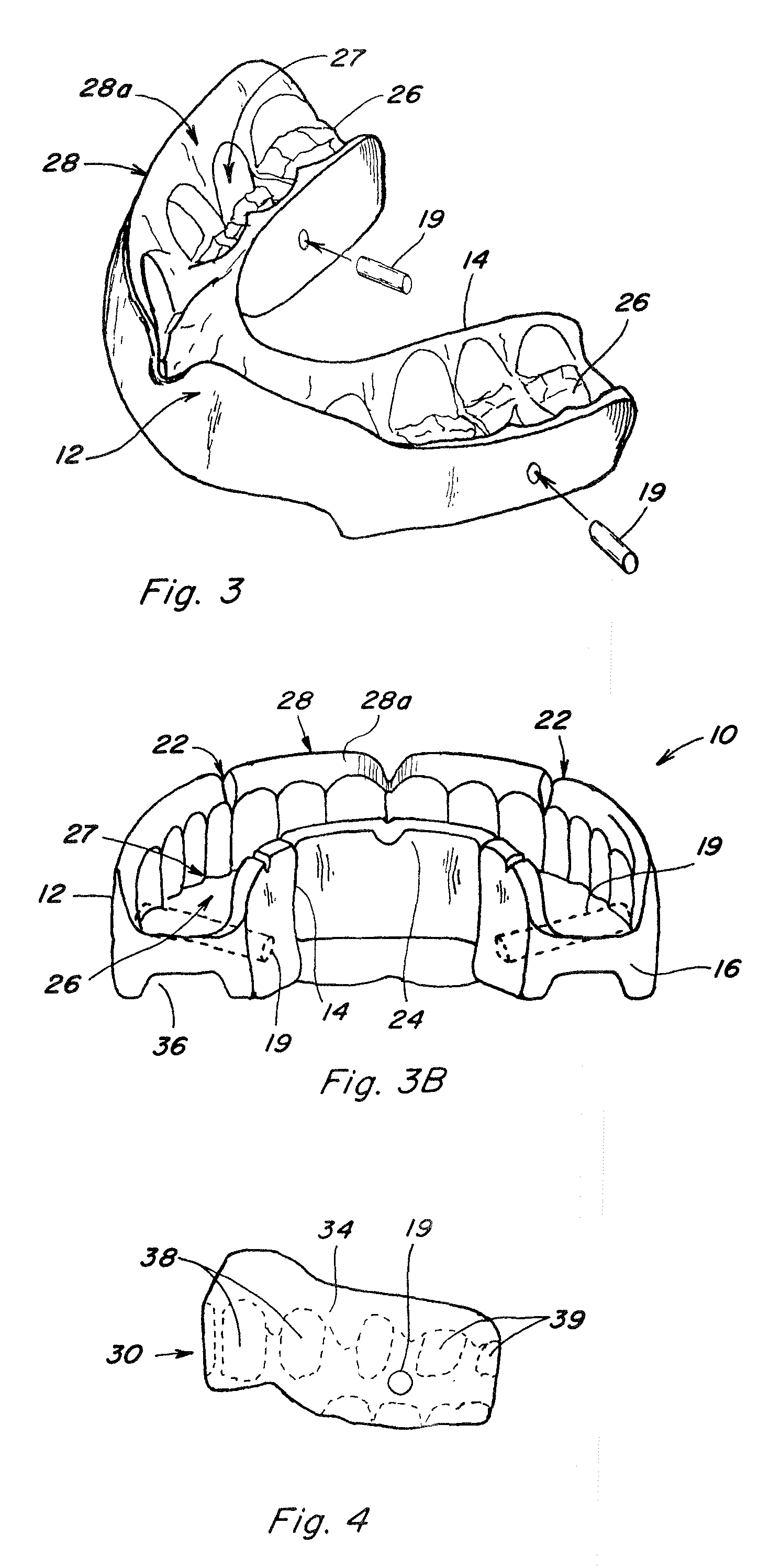

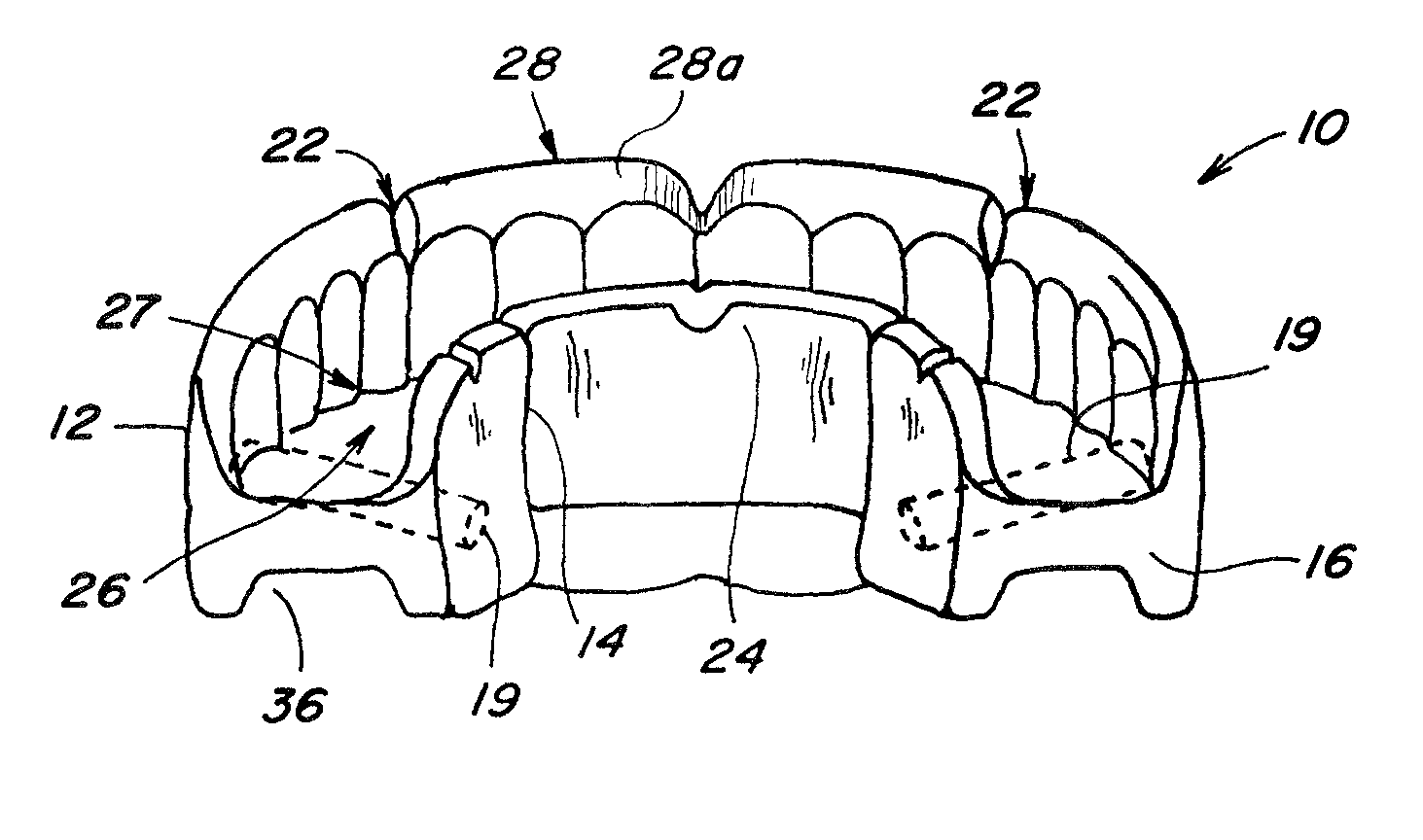

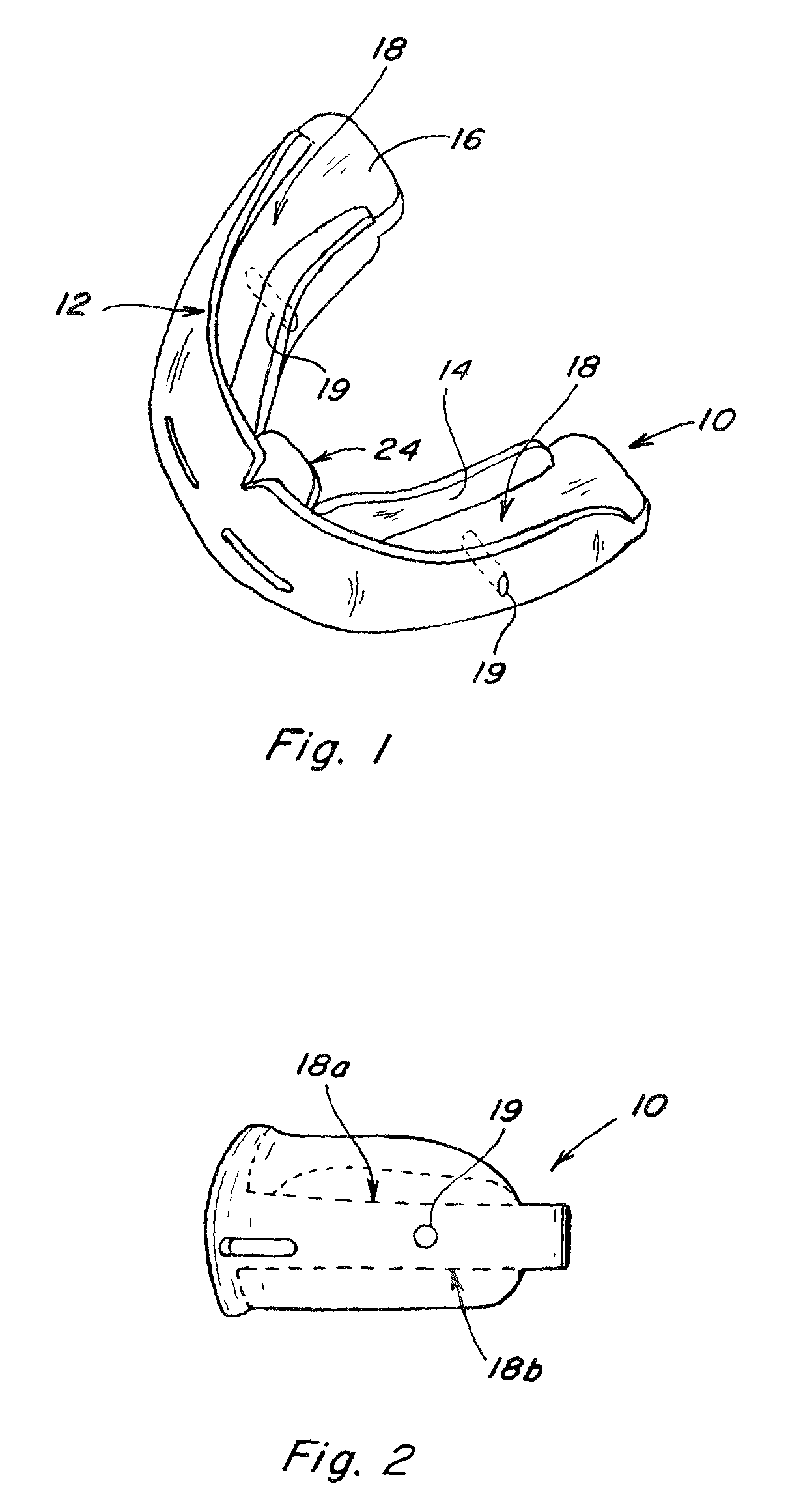

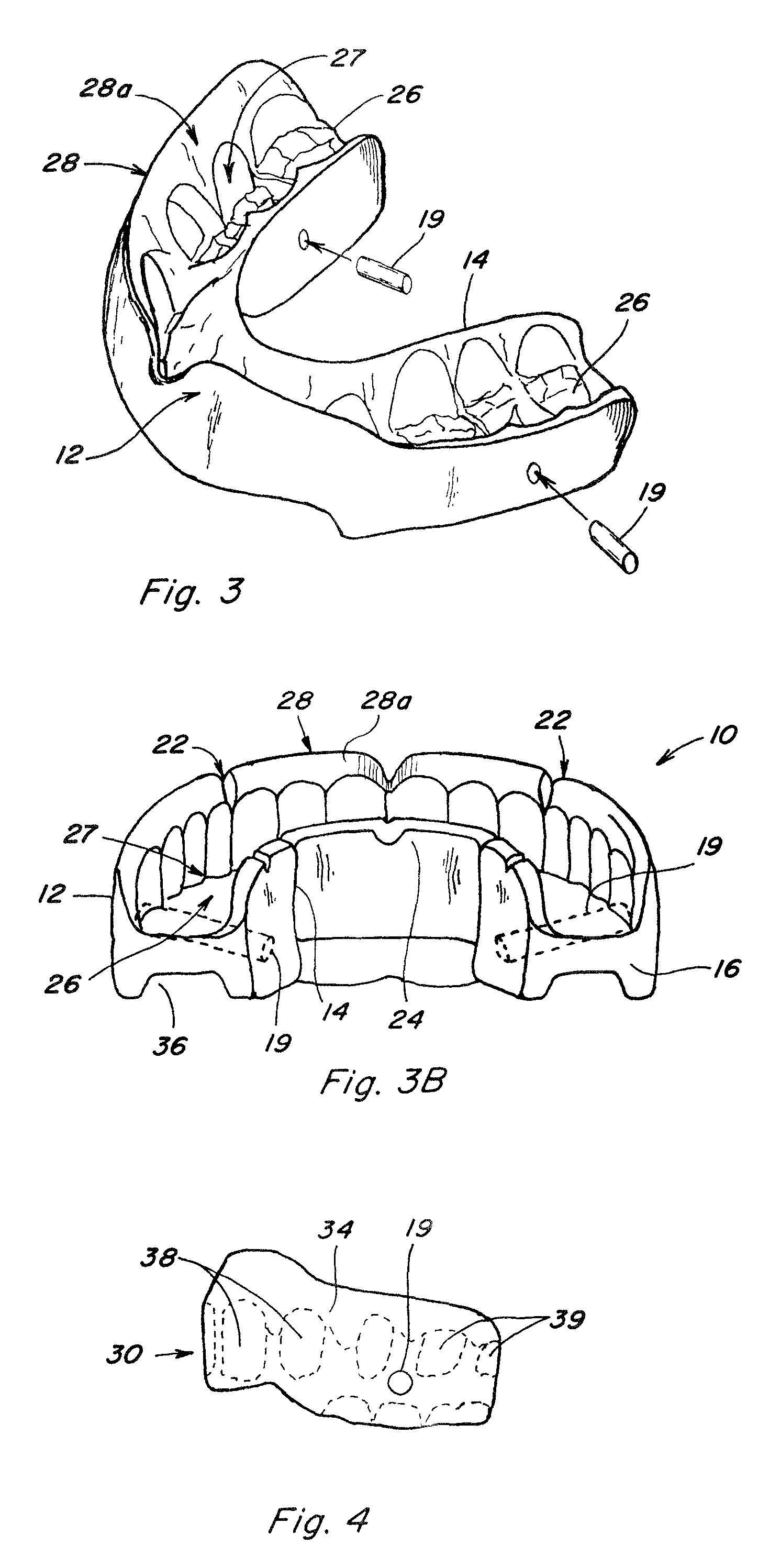

Dental bite construction for performance enhancing mouth guards

An improved performance enhancing mouth guards having transverse pins embedded in the right and left posterior occlusal base portion of the mouth guard, is disclosed.

Owner:QUIGLESS KIRK C

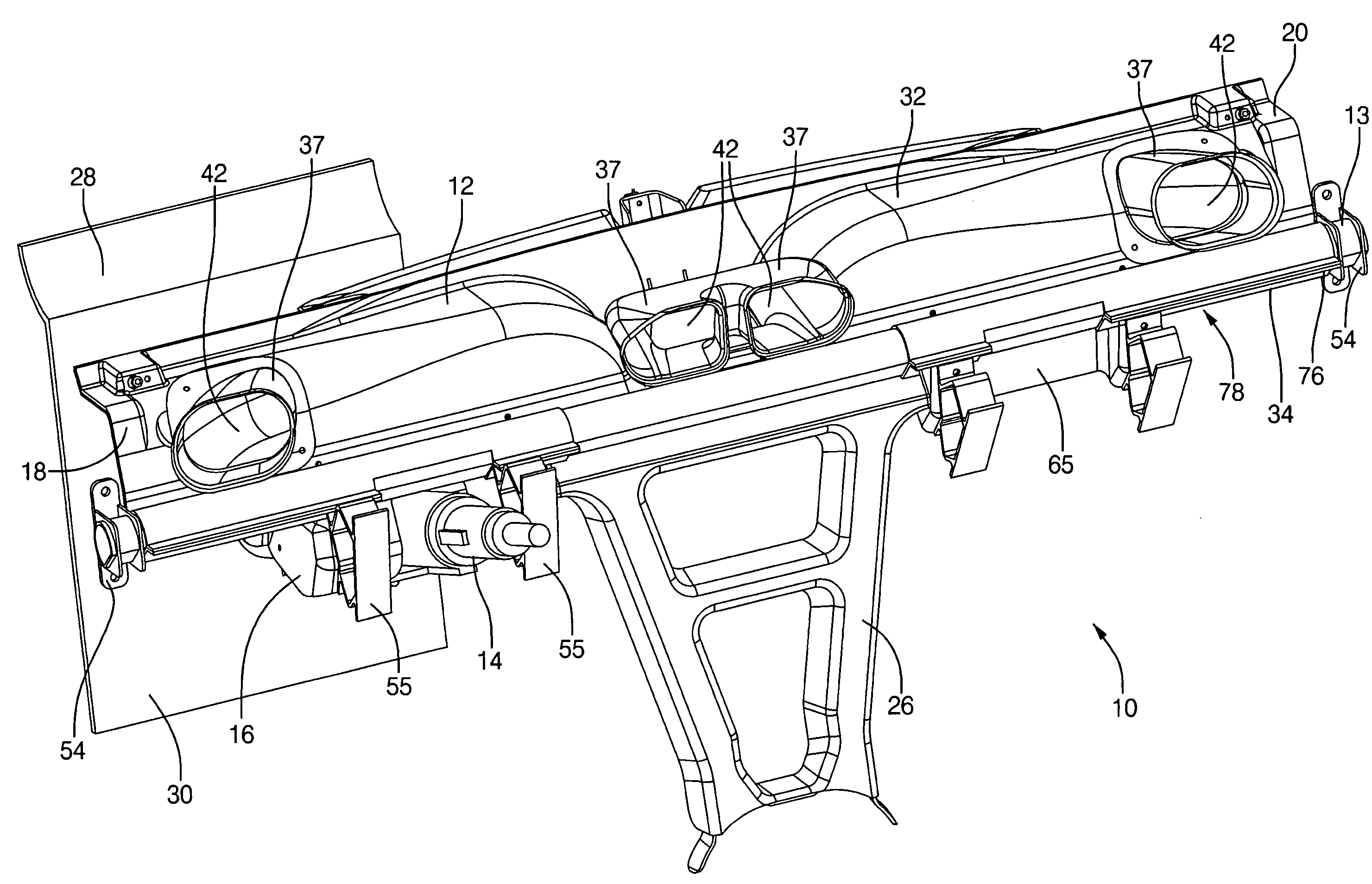

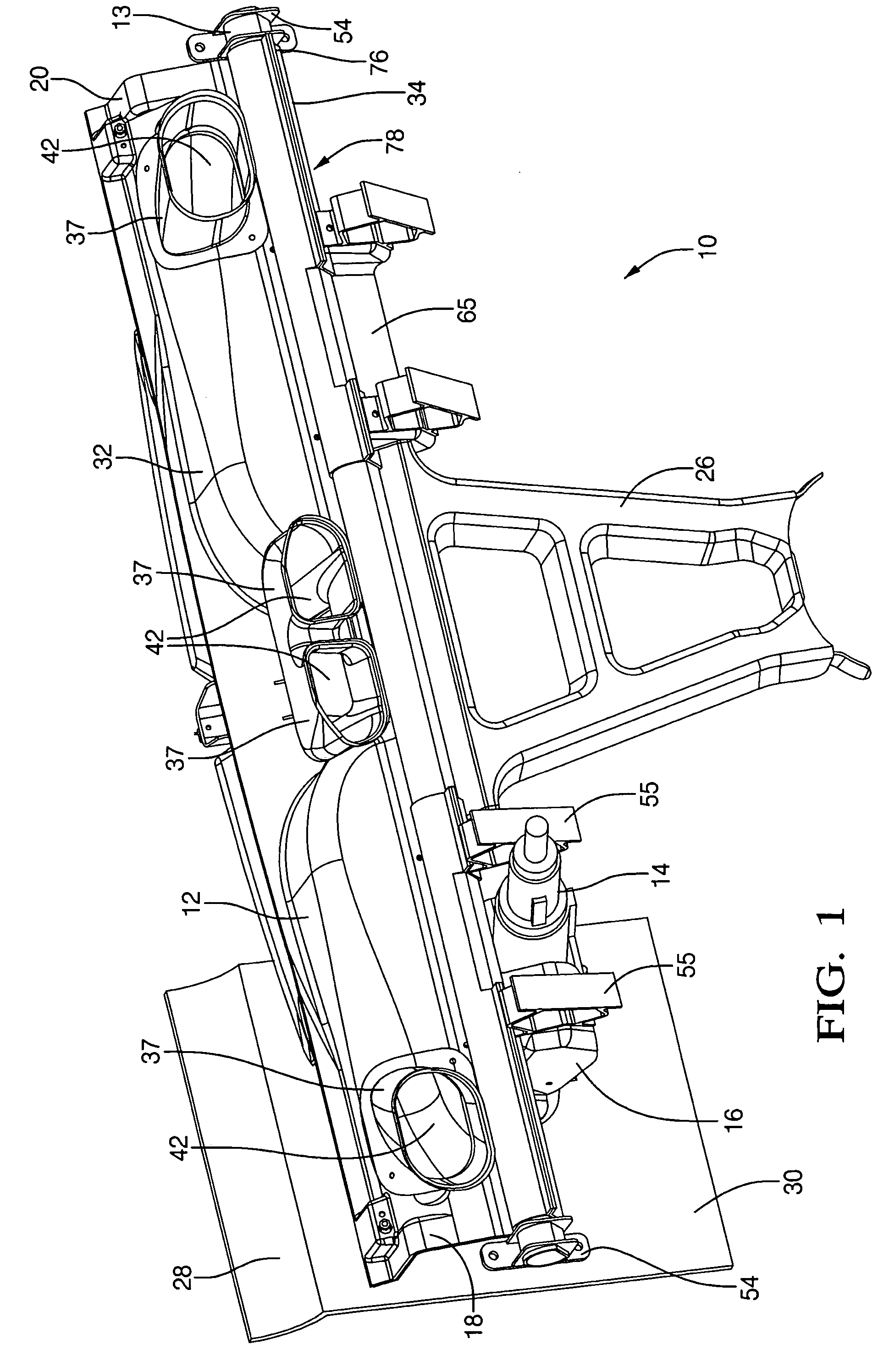

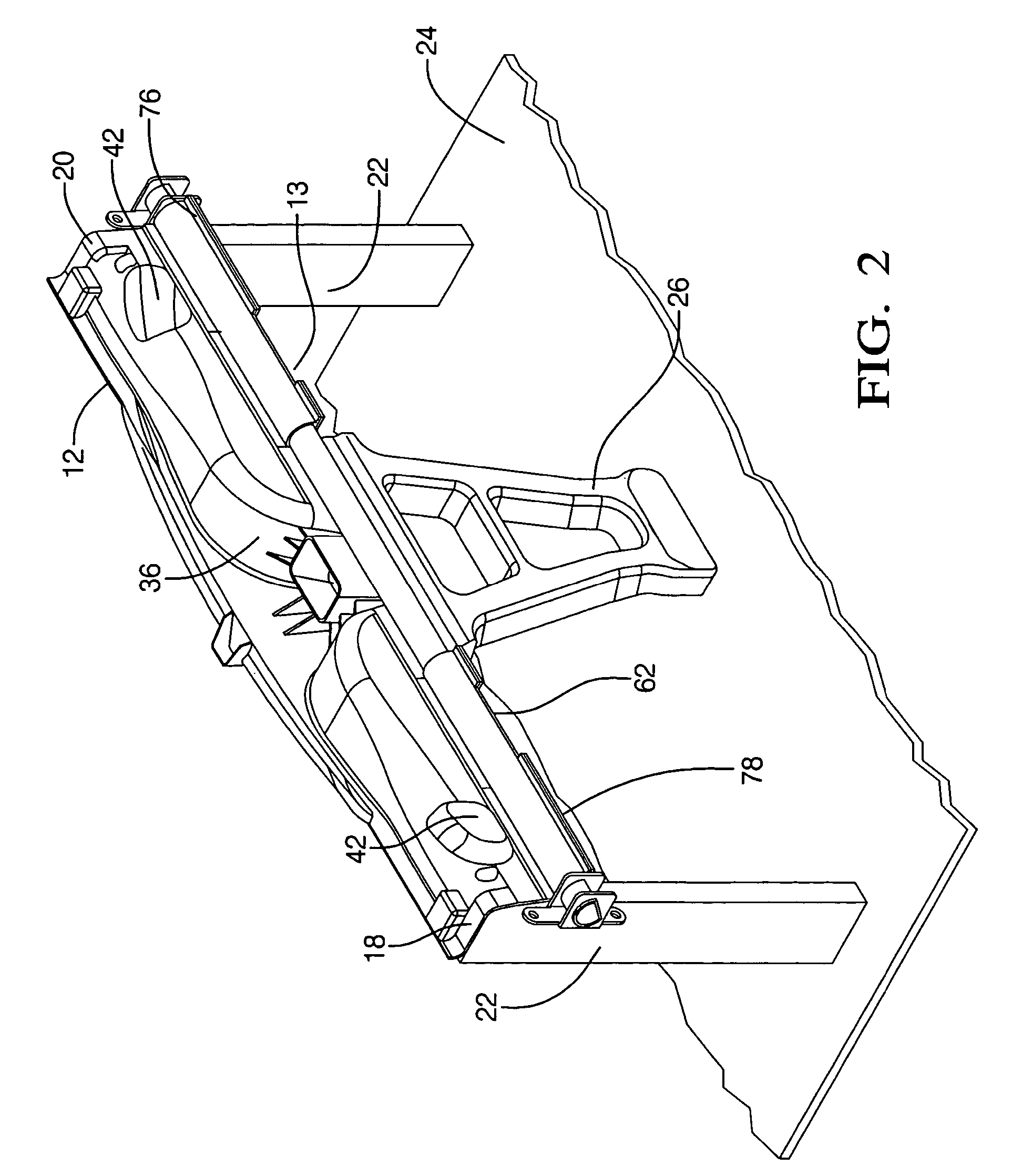

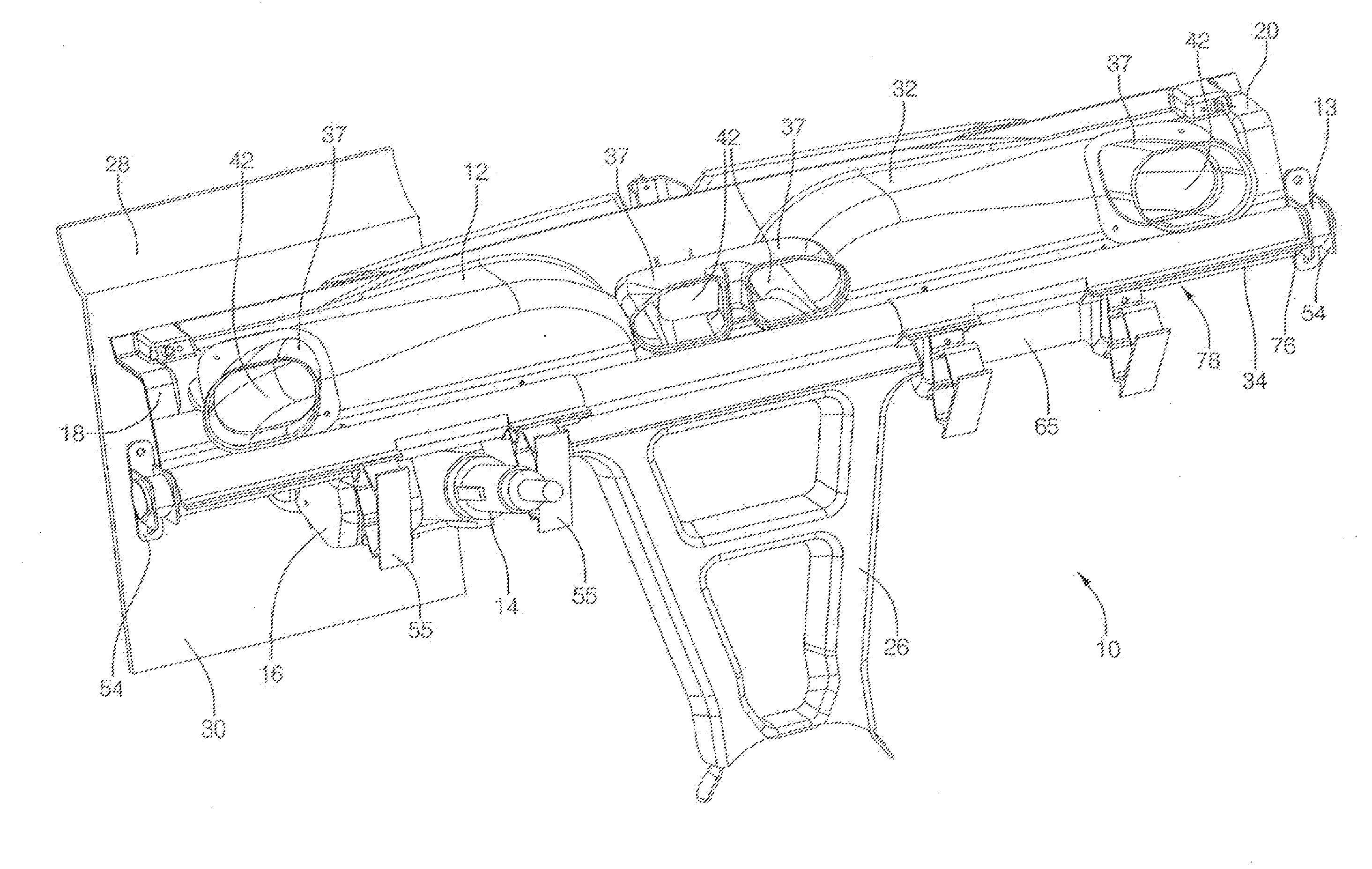

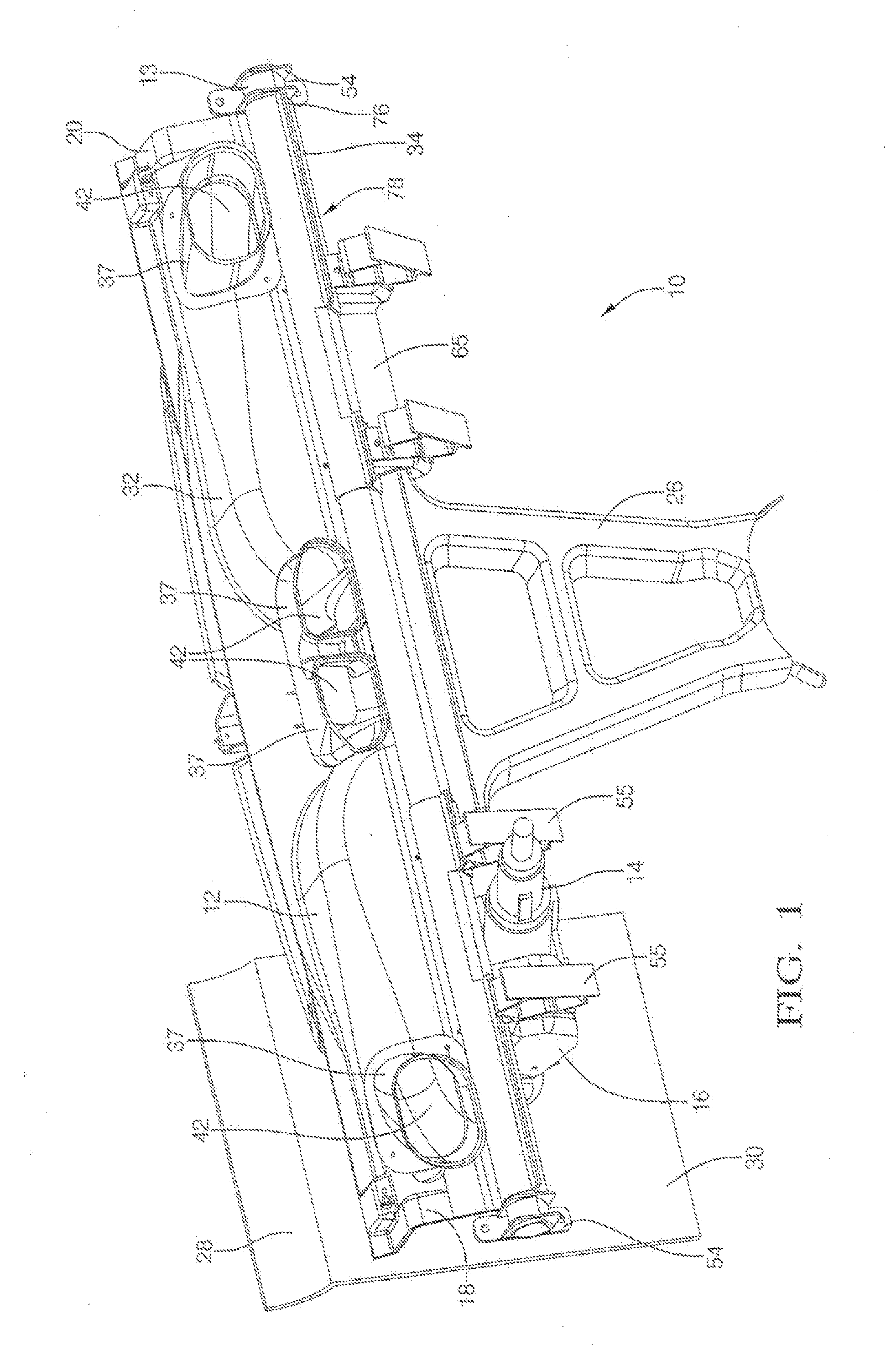

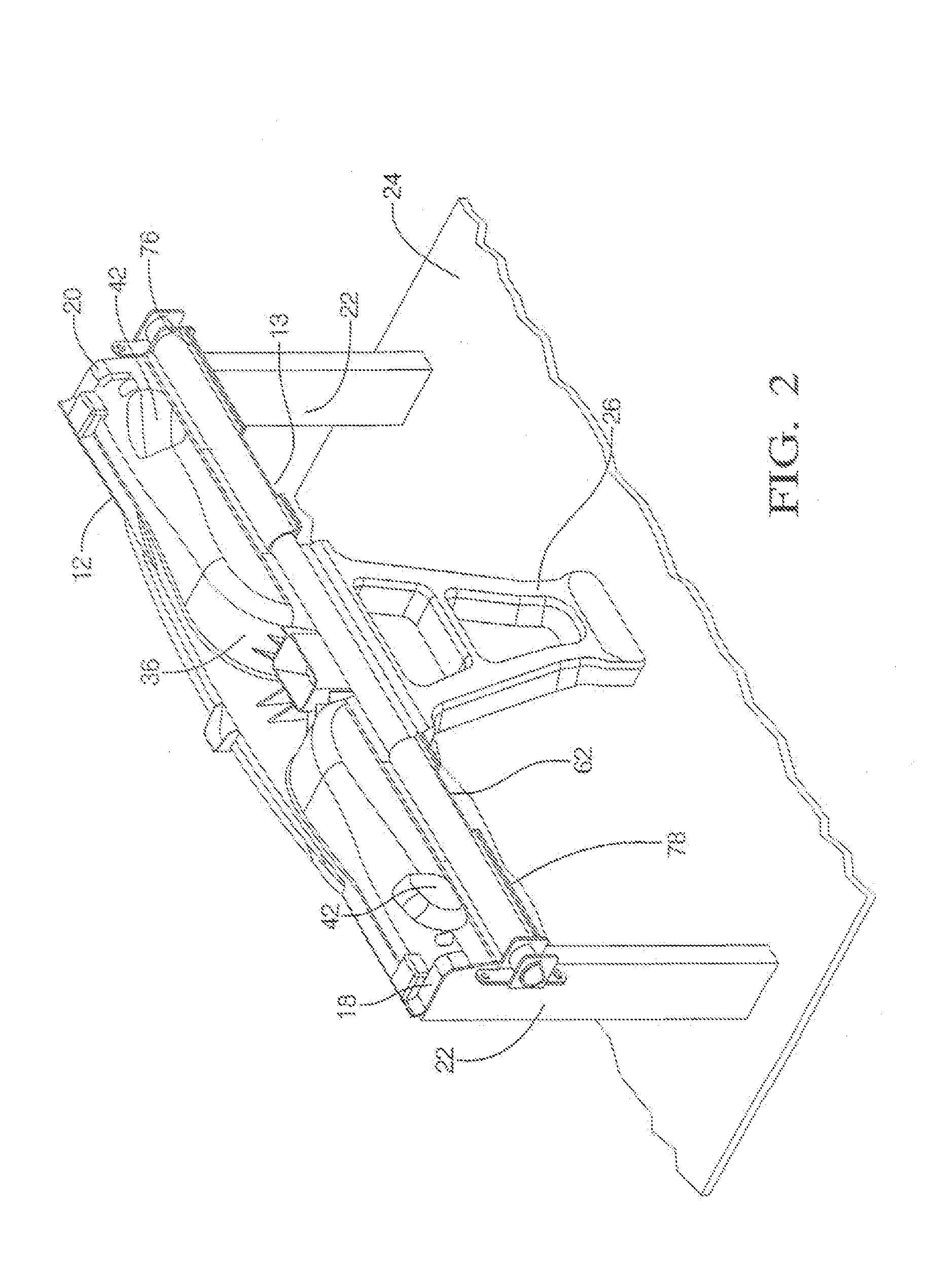

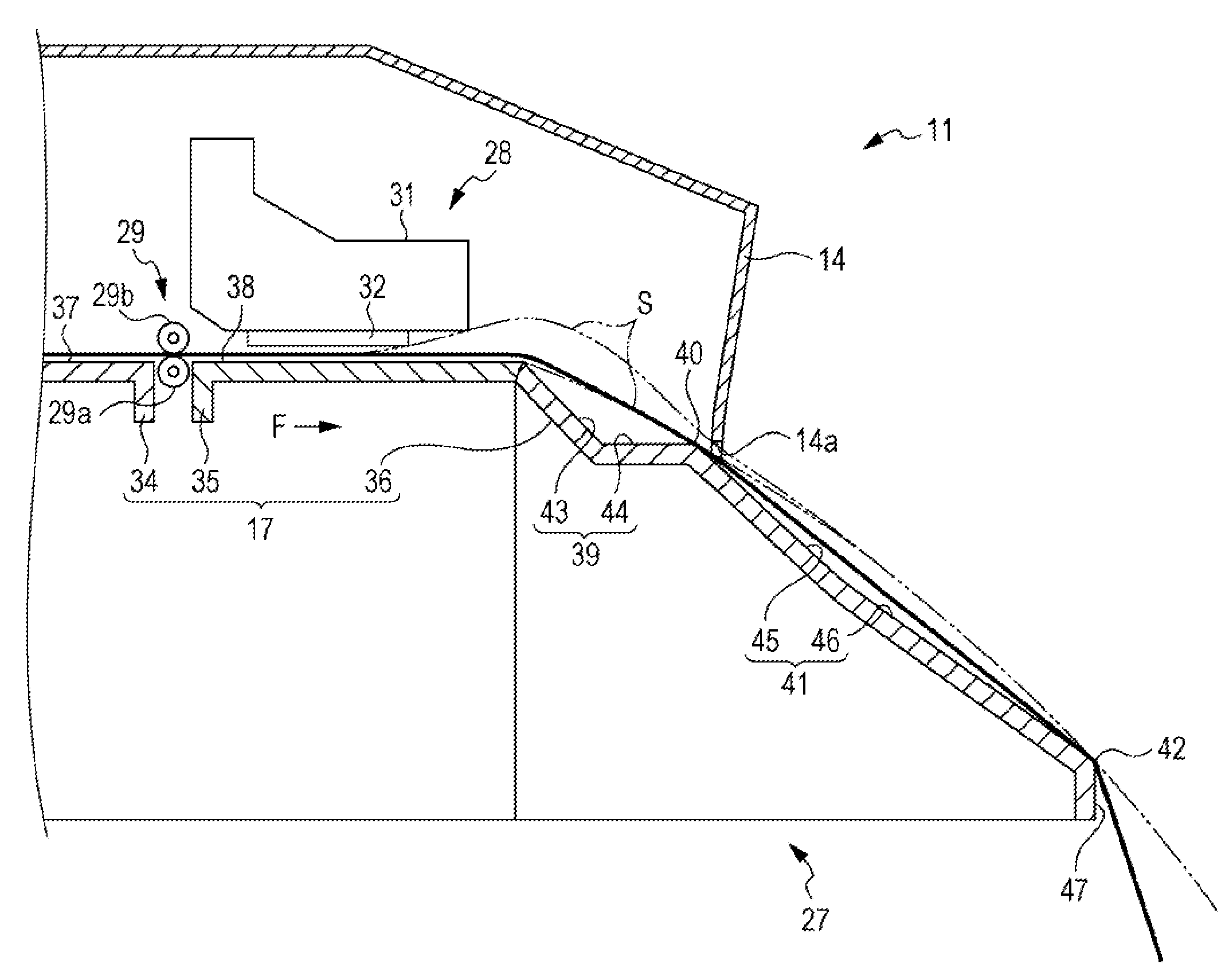

Structural hybrid attachment system and method

InactiveUS7128360B2Effective distribution of loadEffective distributionSuperstructure subunitsDomestic articlesStructural loadEngineering

An integrated structural system for a vehicle is provided. The integrated structural system includes a molded duct system configured to guide airflow having a first section and a second section and configured to operably attach a vehicle component thereto. The integrated structural system also includes a metal structure integrated with the molded duct system by means for integrating the metal structure with the molded duct system forming an integrated structural load path assembly. The integrated structural load path assembly is configured as a load bearing area to distribute a load of the vehicle component operably attached thereto. The means for integrating the metal structure with said molded duct system include, but not limited to, at least one of, sonic welding, heat staking, insert molding, and gluing.

Owner:INTEVA PRODUCTS LLC

Structural hybrid attachment system and method

InactiveUS20090008956A1Effective distributionReduce the total massMetal-working apparatusSuperstructure subunitsStructural loadEngineering

An integrated structural system for a vehicle is provided. The integrated structural system includes a molded duct system configured to guide airflow having a first section and a second section and configured to operably attach a vehicle component thereto. The integrated structural system also includes a metal structure integrated with the molded duct system by means for integrating the metal structure with the molded duct system forming an integrated structural load path assembly. The integrated structural load path assembly is configured as a load bearing area to distribute a load of the vehicle component operably attached thereto. The means for integrating the metal structure with said molded duct system include, but not limited to, at least one of, sonic welding, heat staking, insert molding, and gluing.

Owner:INTEVA PRODUCTS LLC

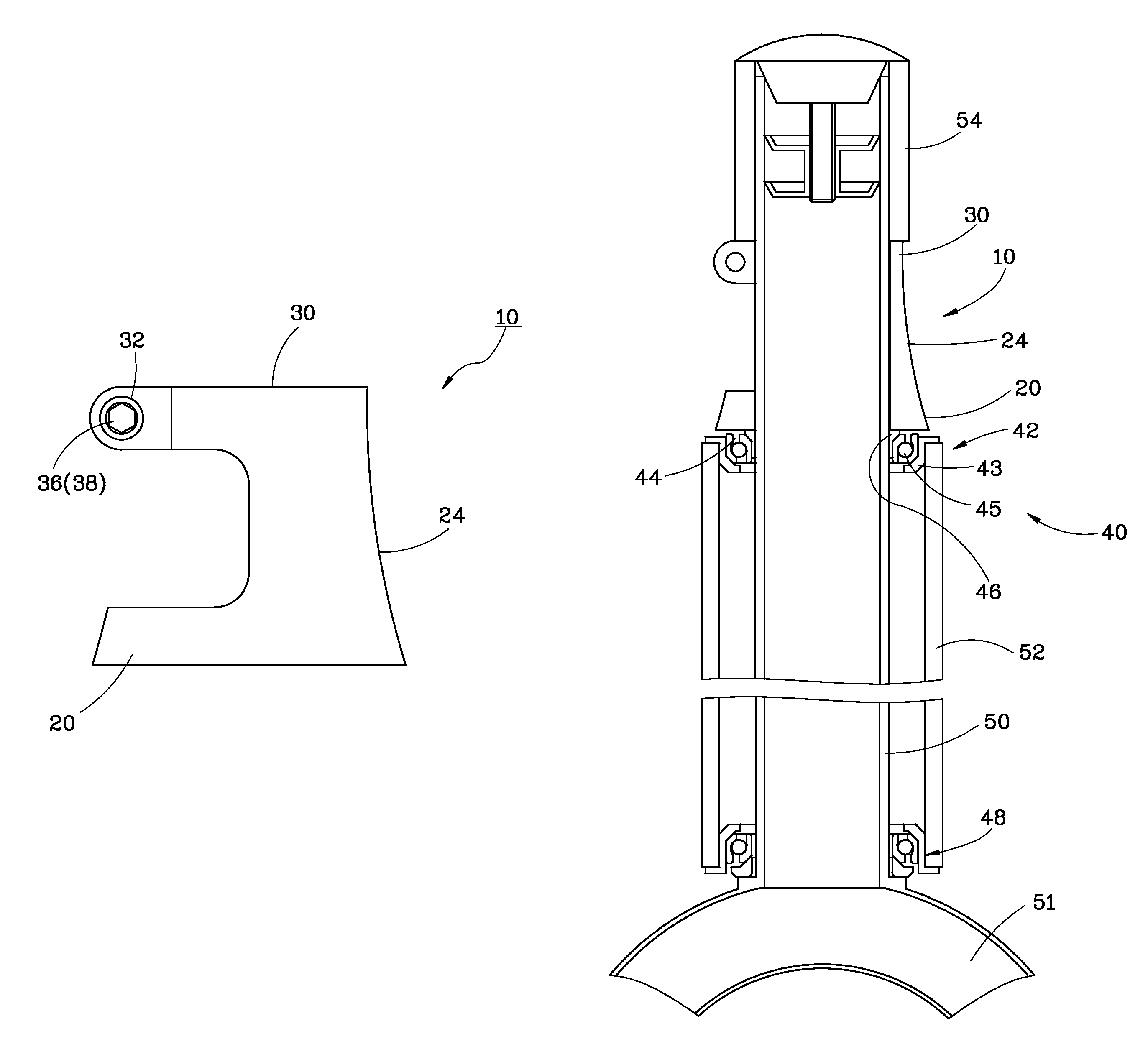

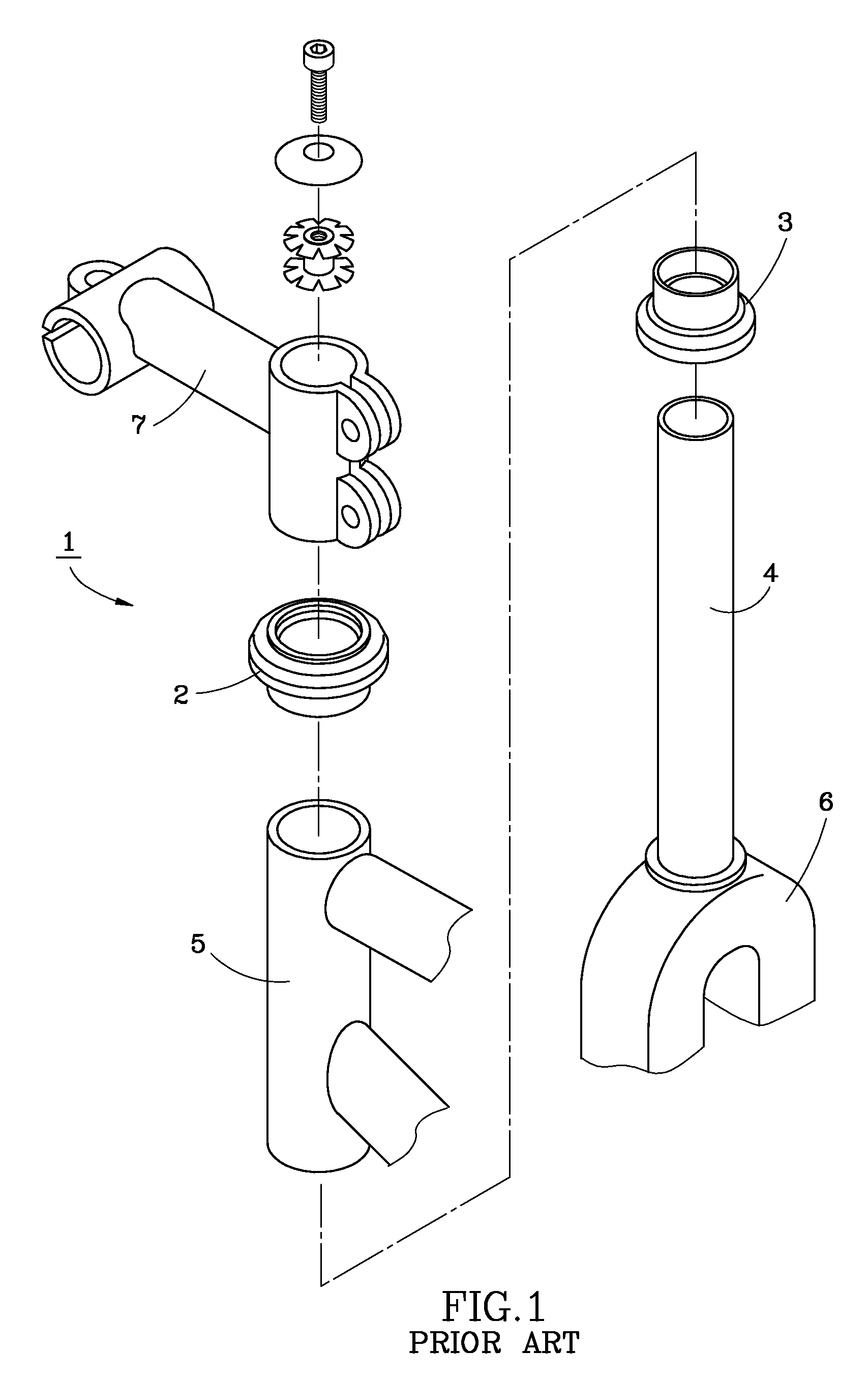

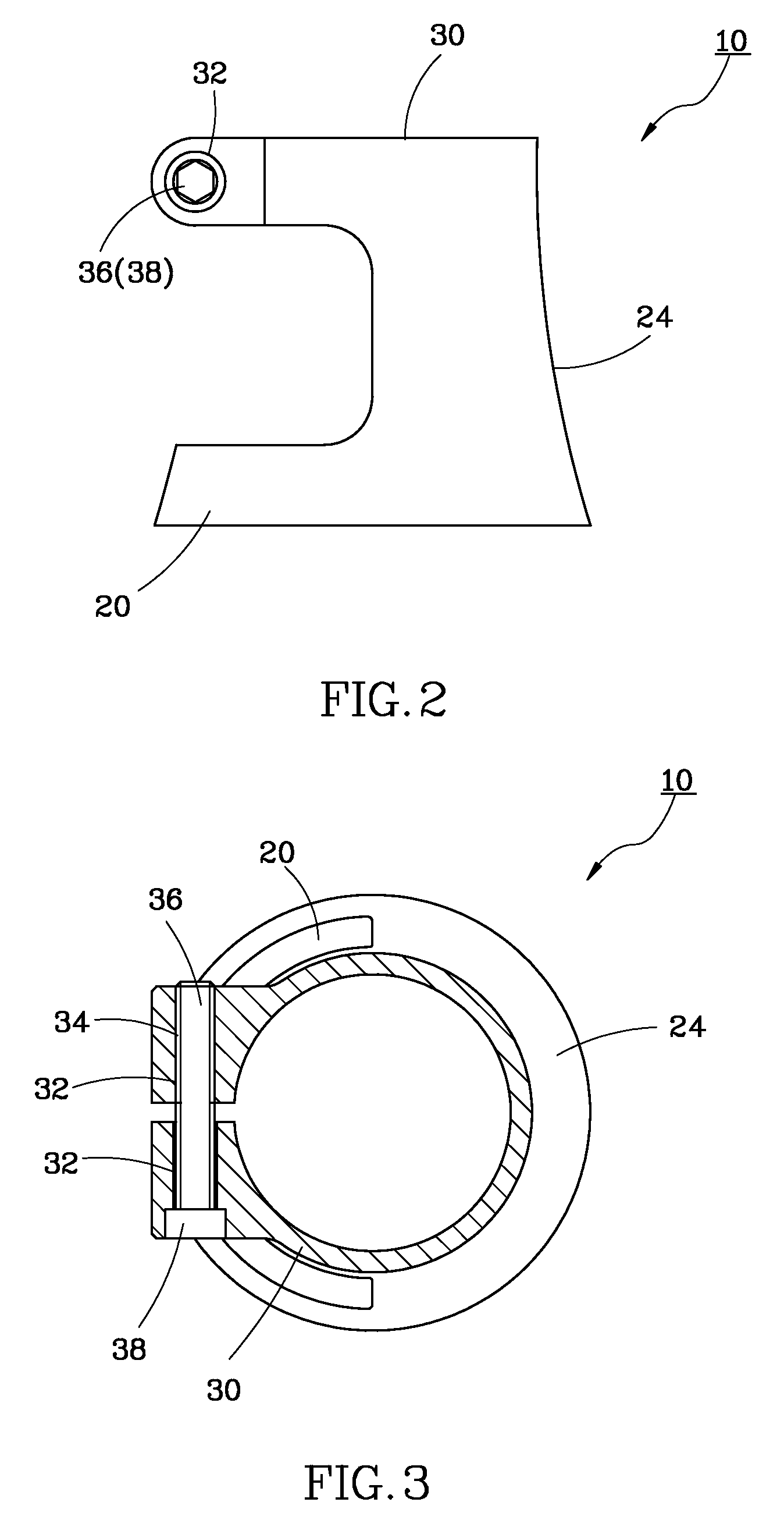

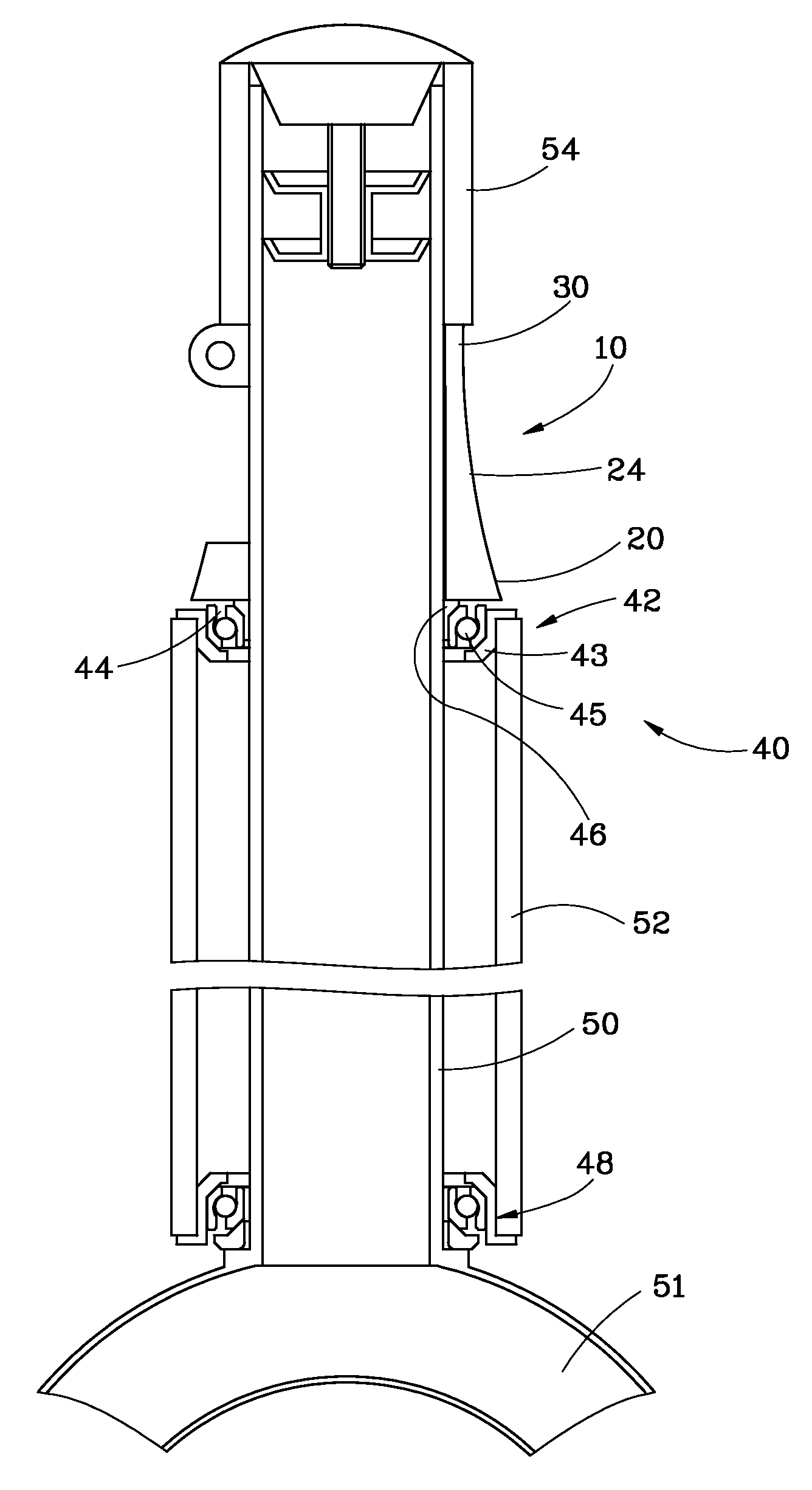

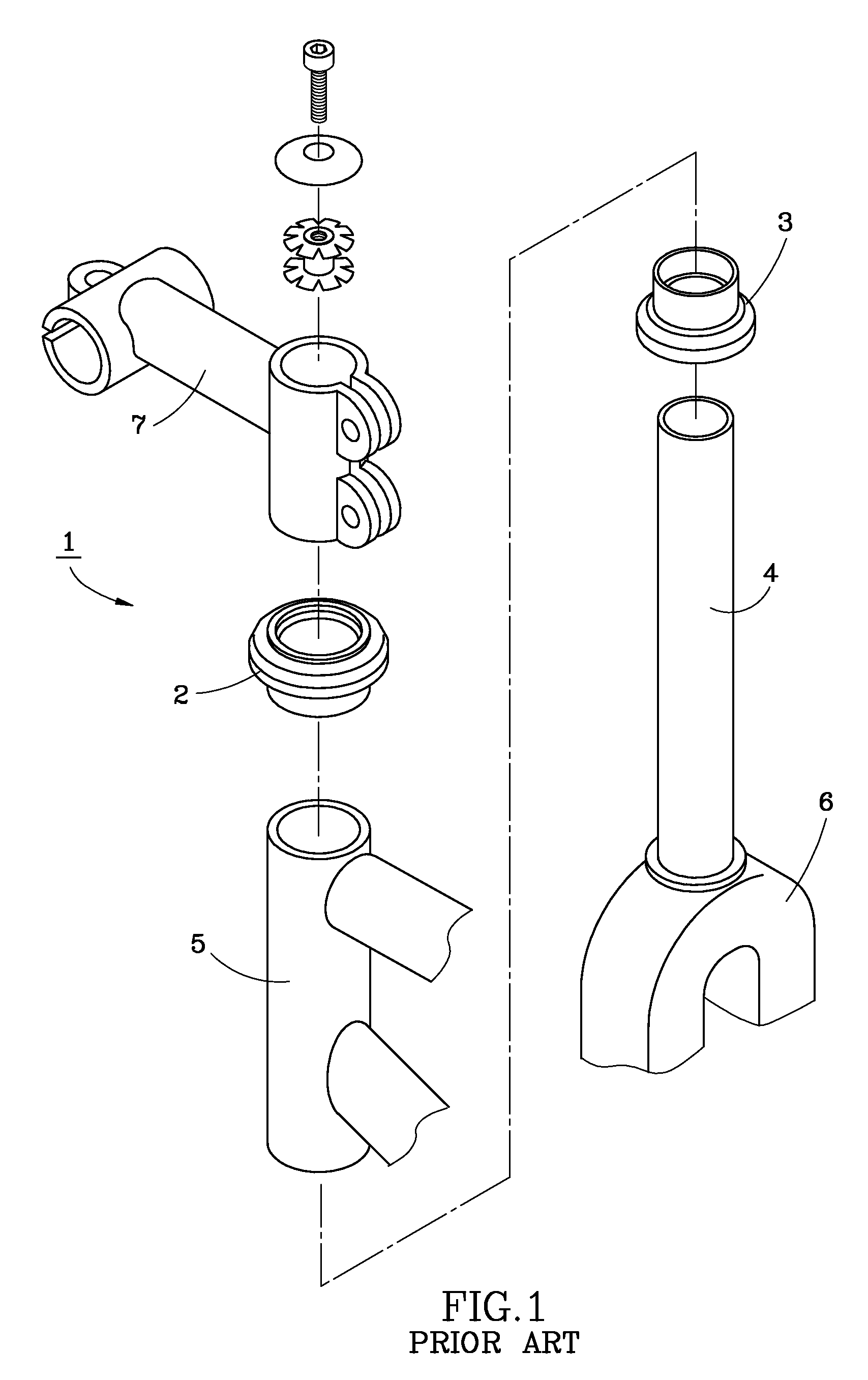

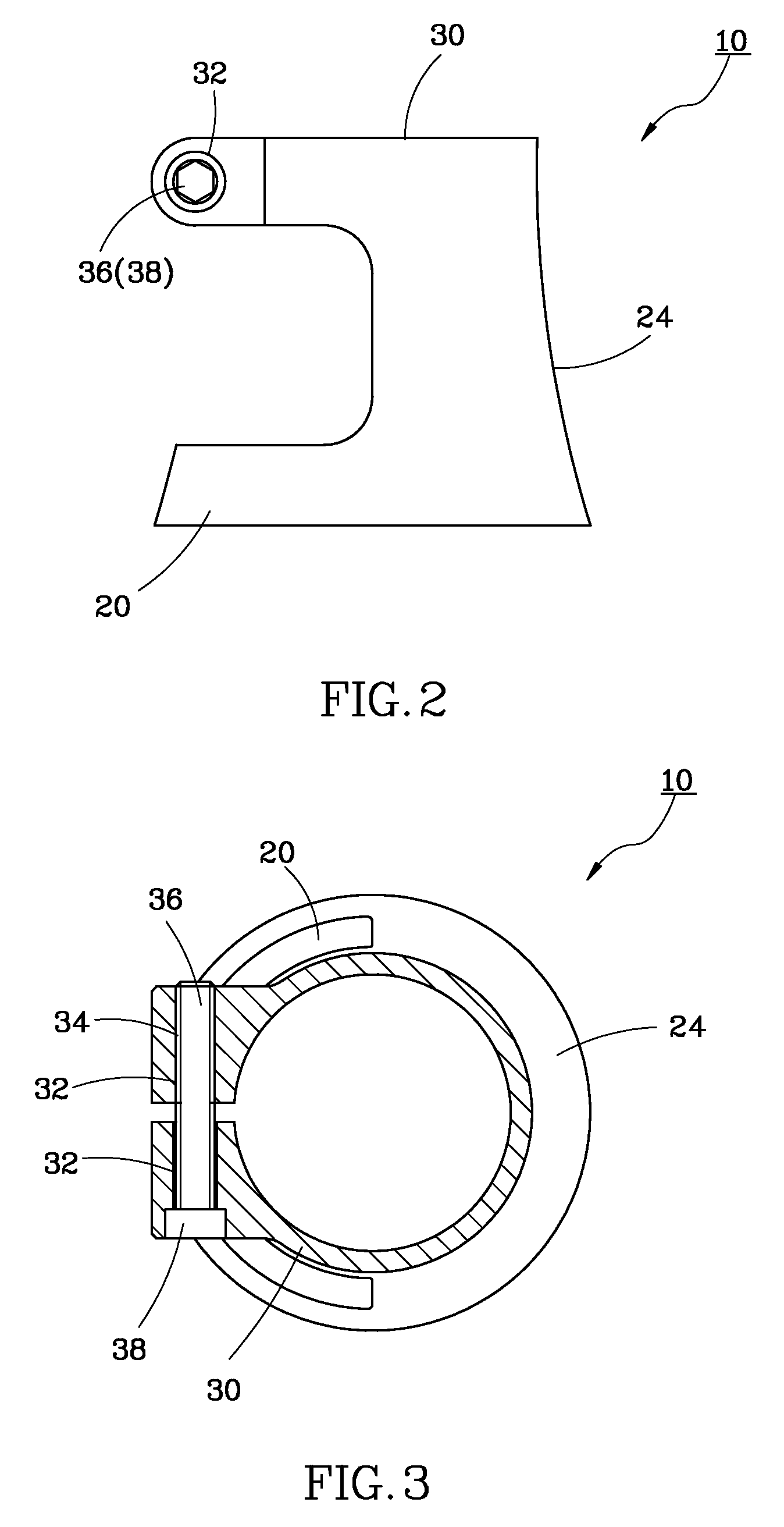

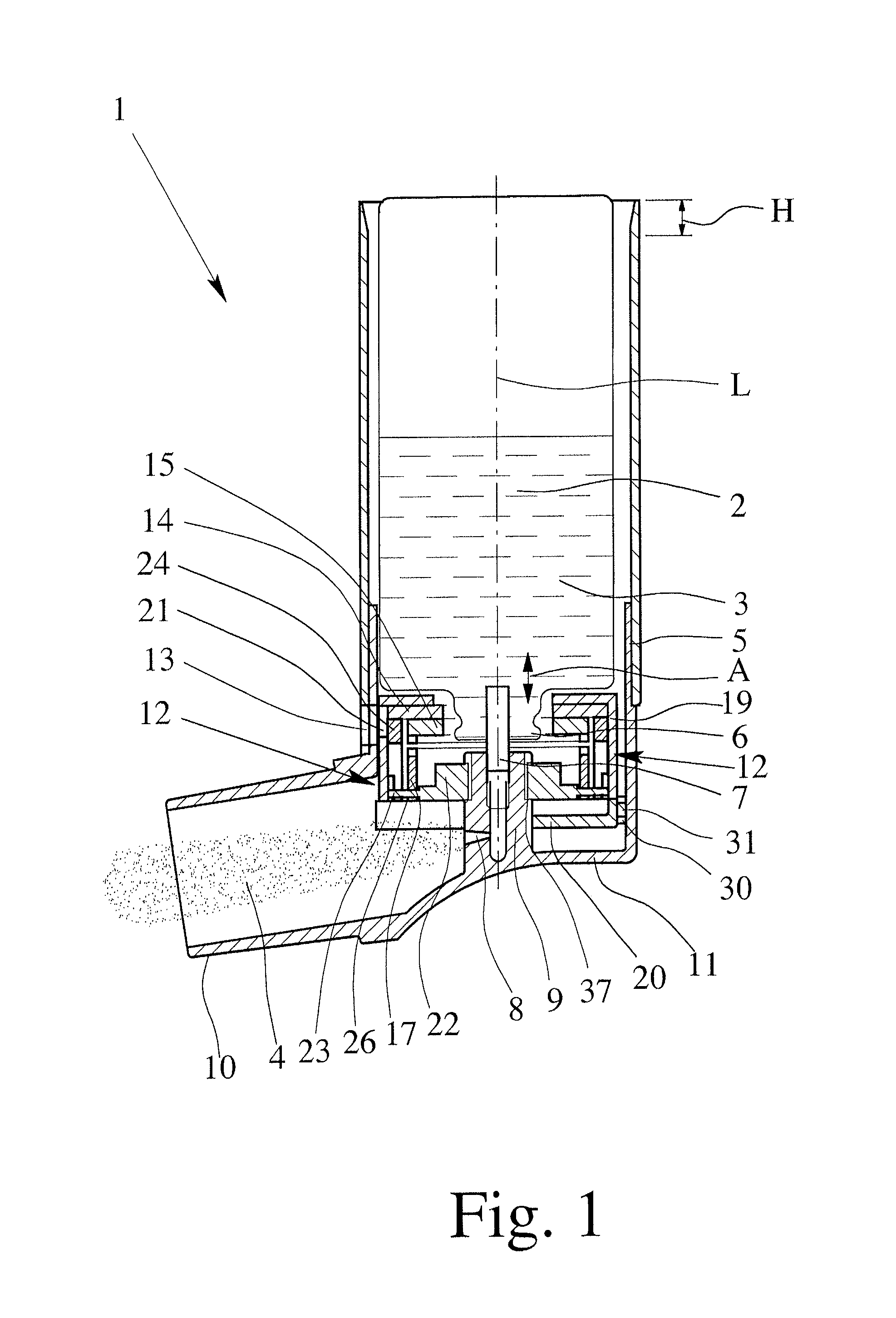

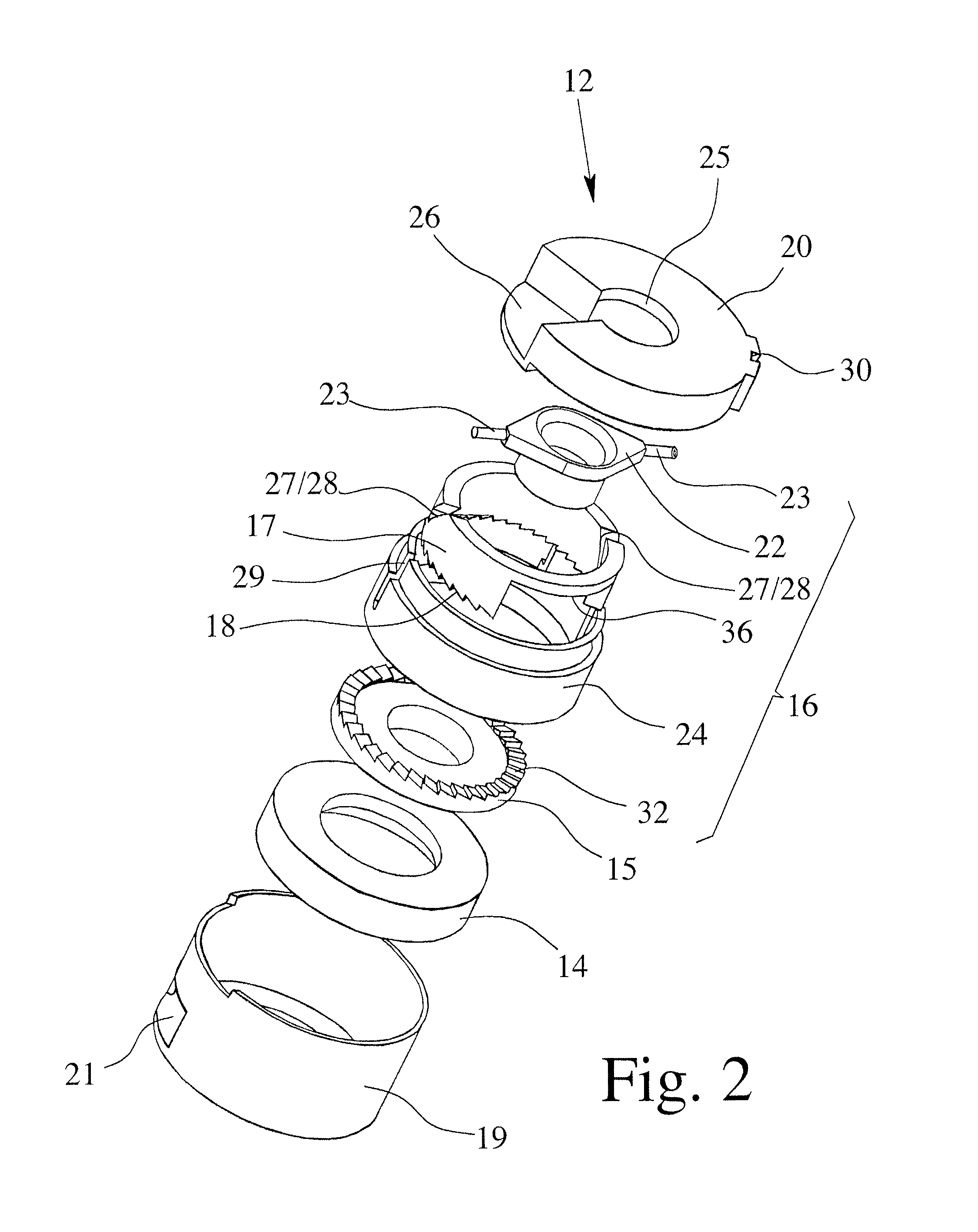

Top cover for headset of bicycle

InactiveUS7896380B2Improve convenienceAvoid componentsFoot-driven leversWheel based transmissionEngineeringHeadphones

A top cover for a headset of a bicycle includes a bottom ring, a side wall, a C-shaped clip and a fastening unit. The side wall extends upwards from the bottom ring. The C-shaped clip extends upwards from a top end of the side wall and has a through hole at each of two distal ends thereof. The fastening unit passes through the through holes of the C-shaped clip for tightening the C-shaped clip. Thus, the top cover of the present invention can enhance convenience of assembly and disassembly of the bicycle, and prevent components of the headset from getting lost during assembly and disassembly of the bicycle.

Owner:TANGE SEIKI TAICHUNG

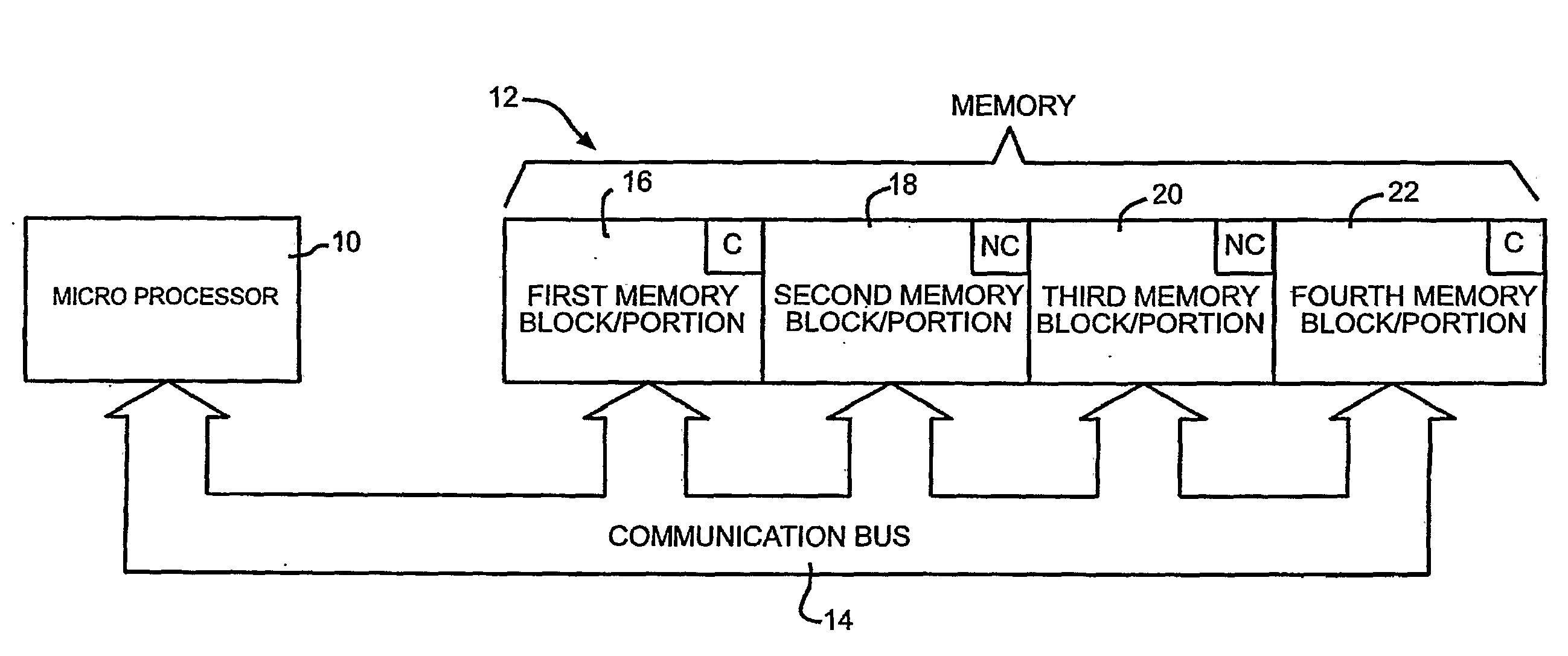

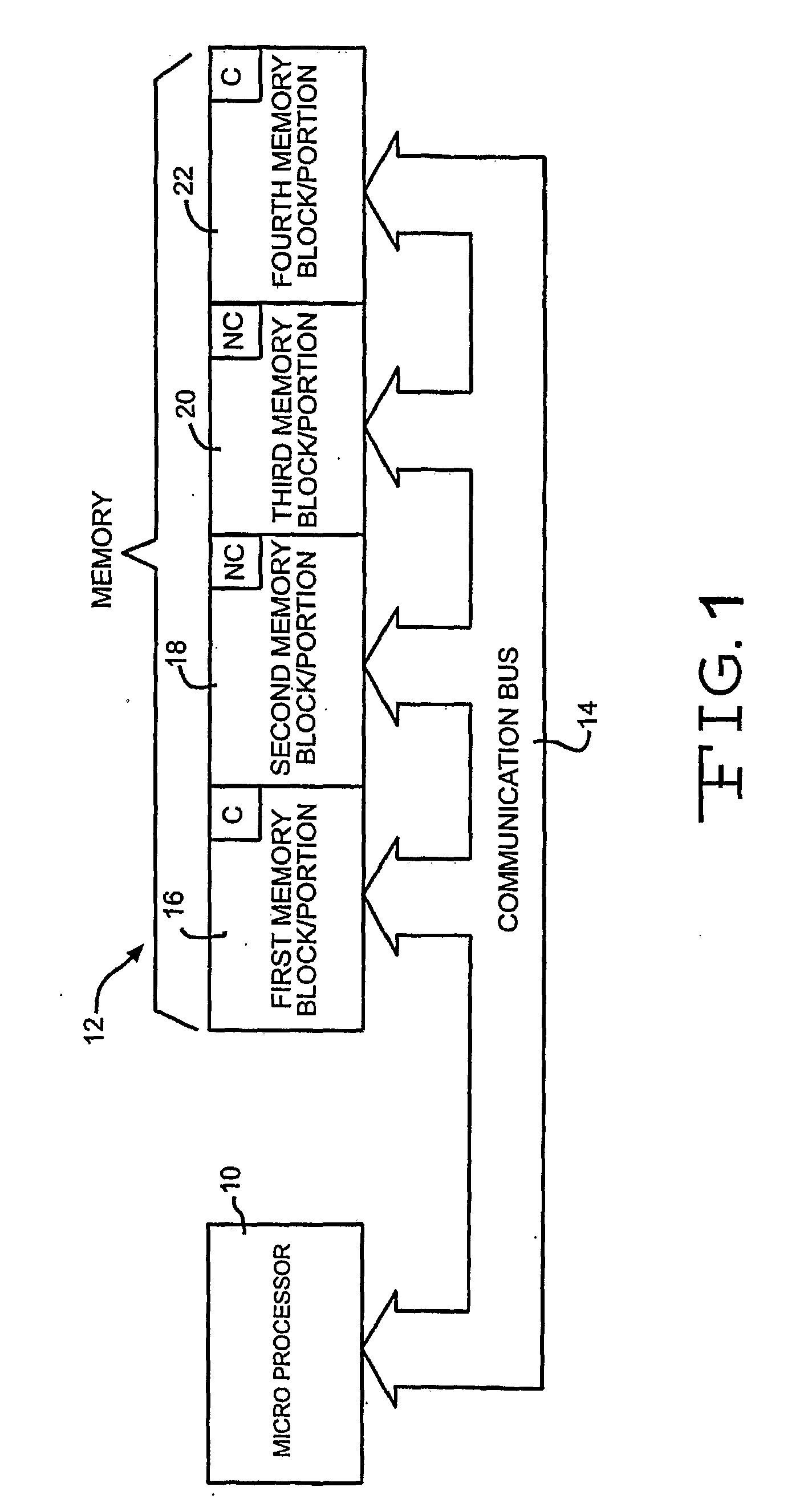

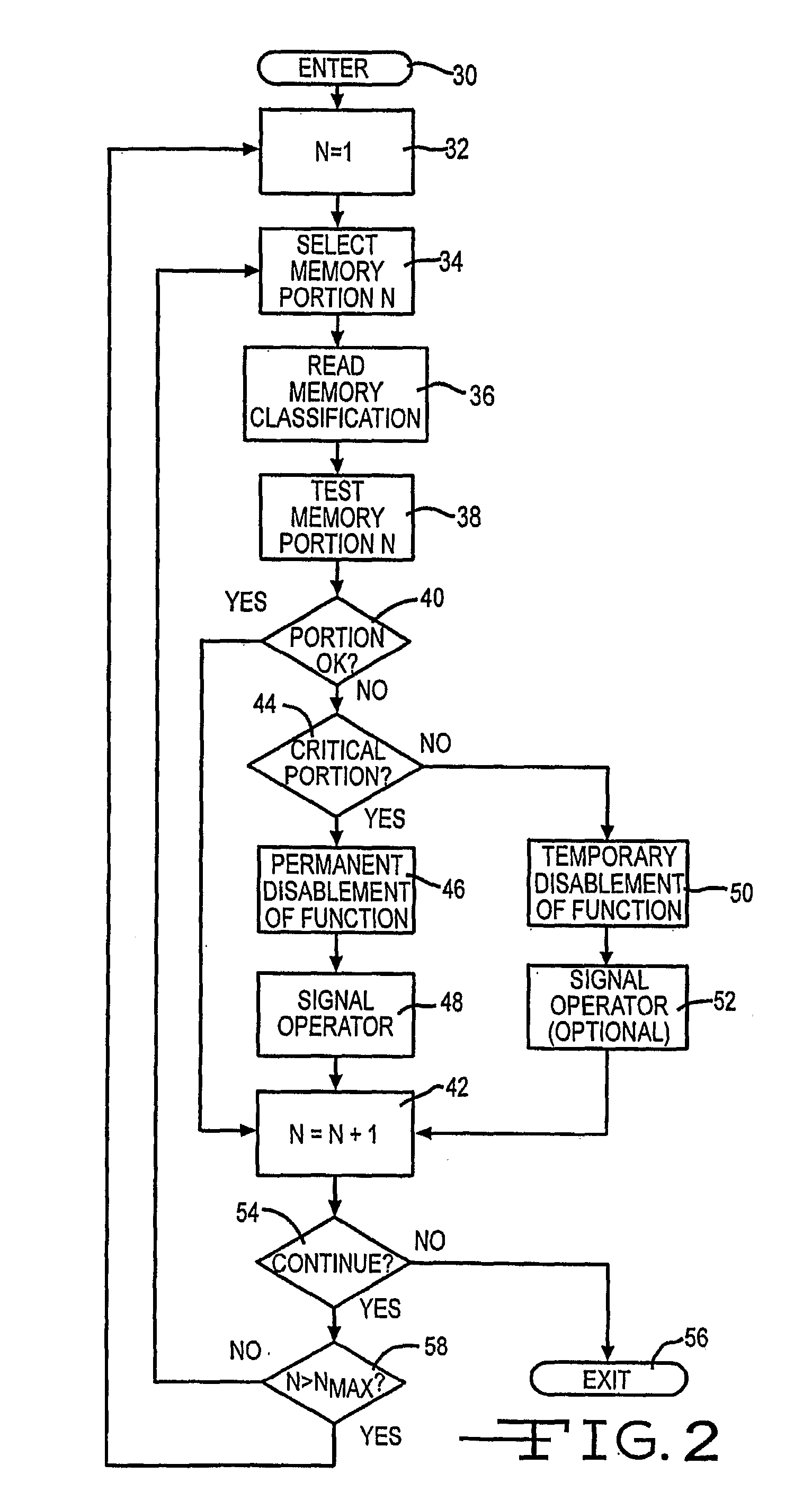

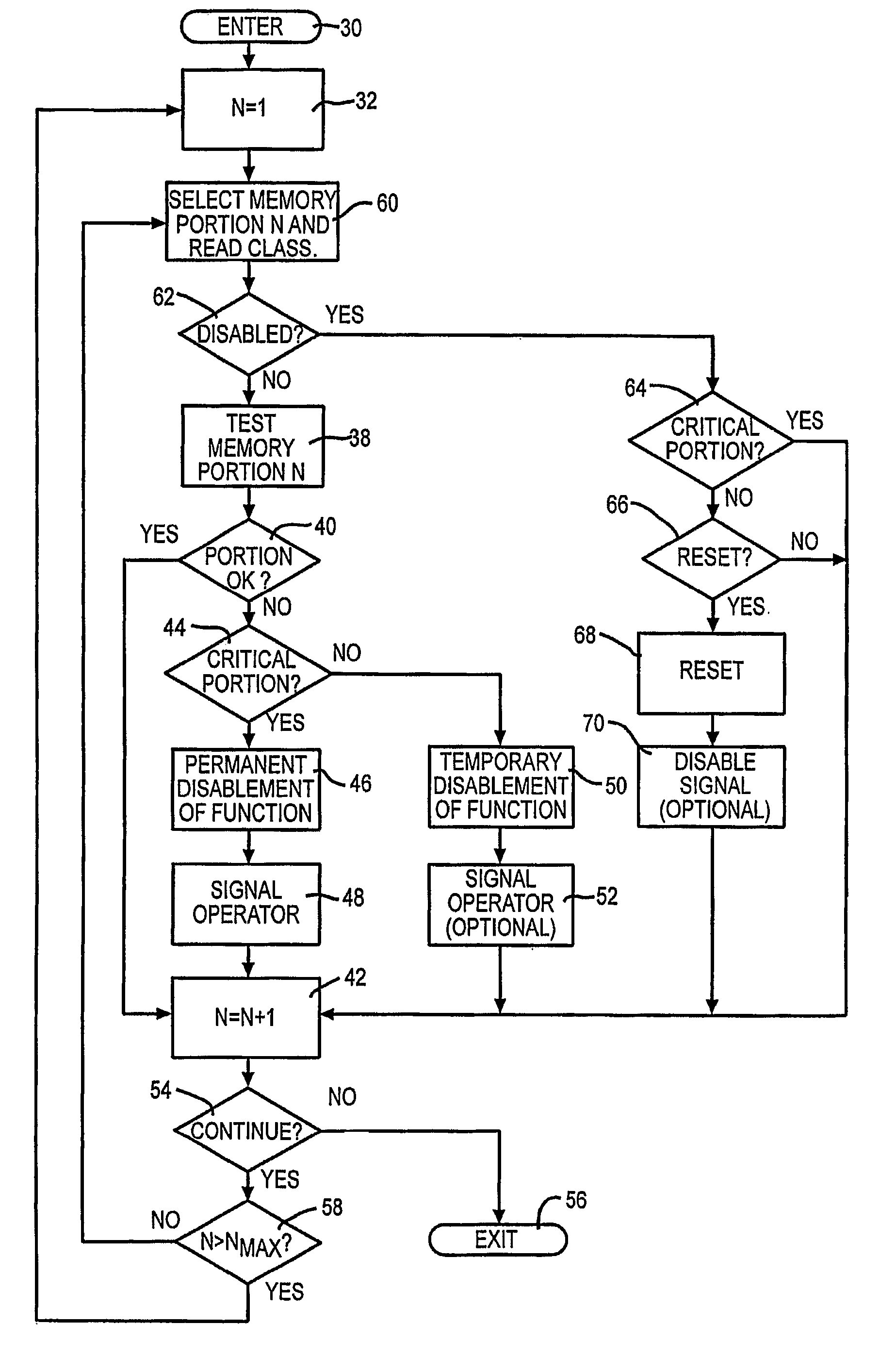

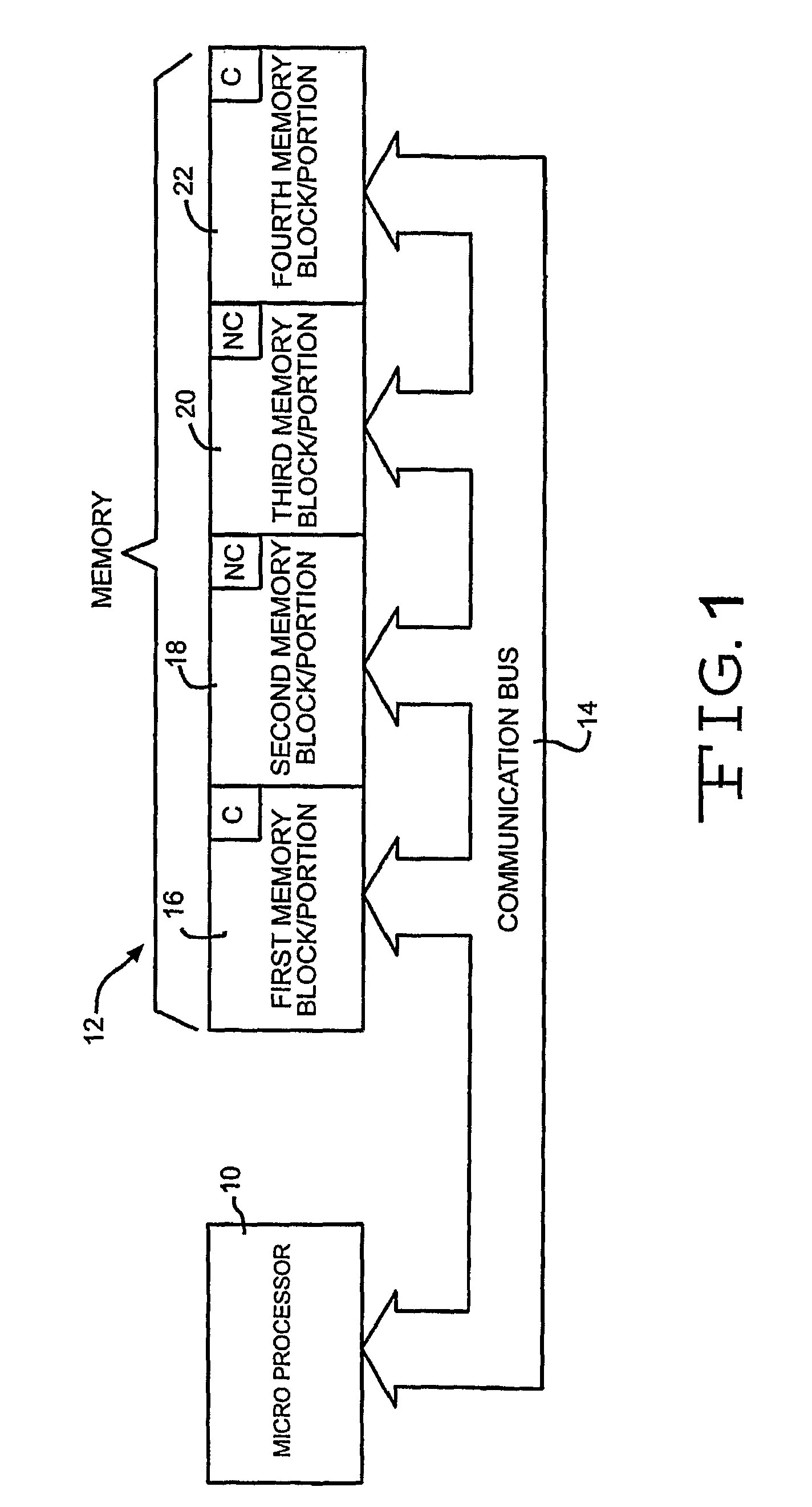

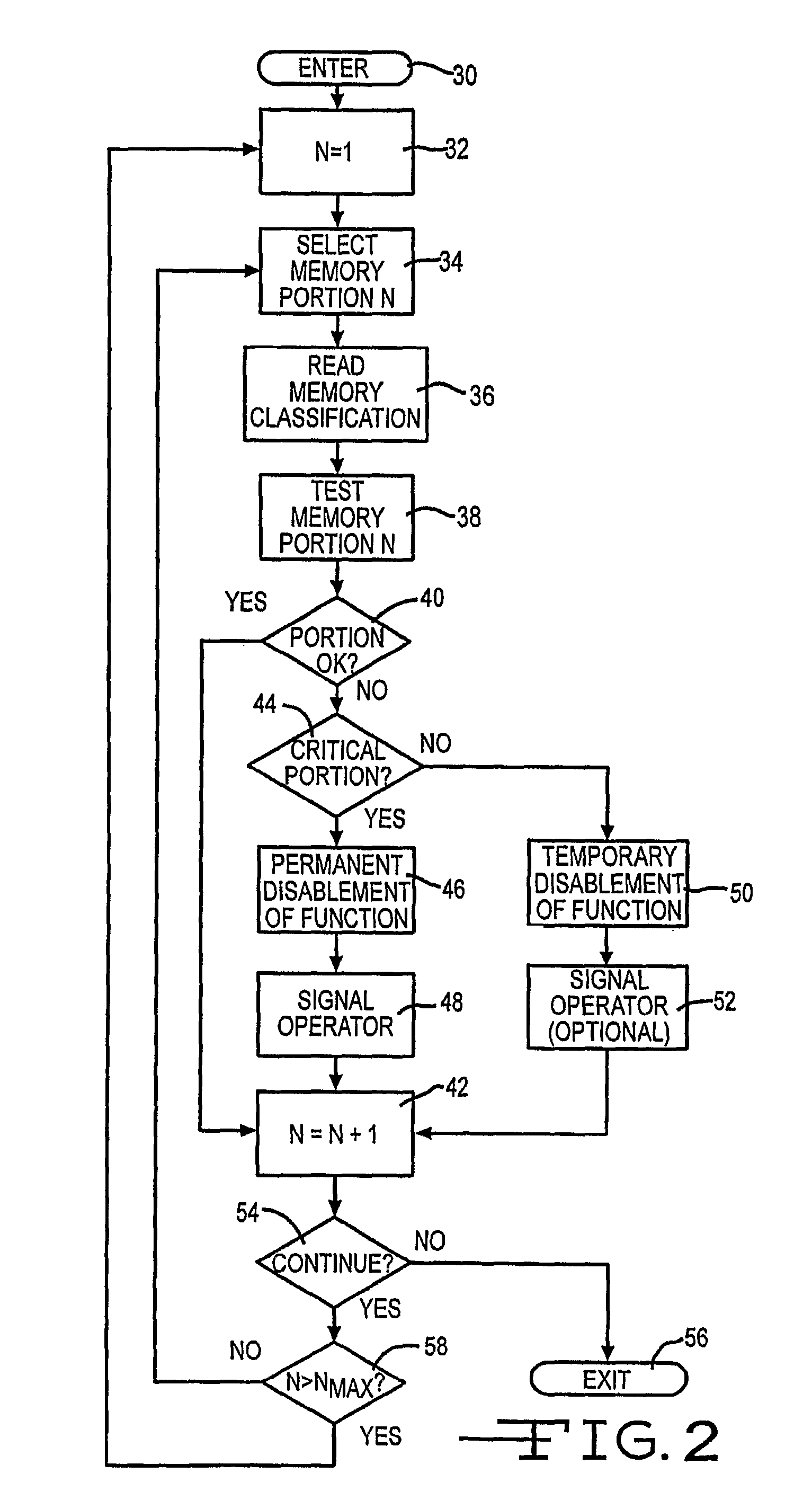

Microprocessor Memory Management

ActiveUS20090164838A1Avoid missing partsRead-only memoriesFunctional testingControl systemBraking system

A memory for an electronic brake control system is divided into portions that are classified as critical and non-critical. Each portion is periodically tested for faults. Upon detection of a fault, the memory is reconfigured with any operations of the brake system associated with a critical memory portion permanently disabled and any operations of the brake system associated with a non-critical memory portion temporarily disabled.

Owner:KELSEY HAYES CO

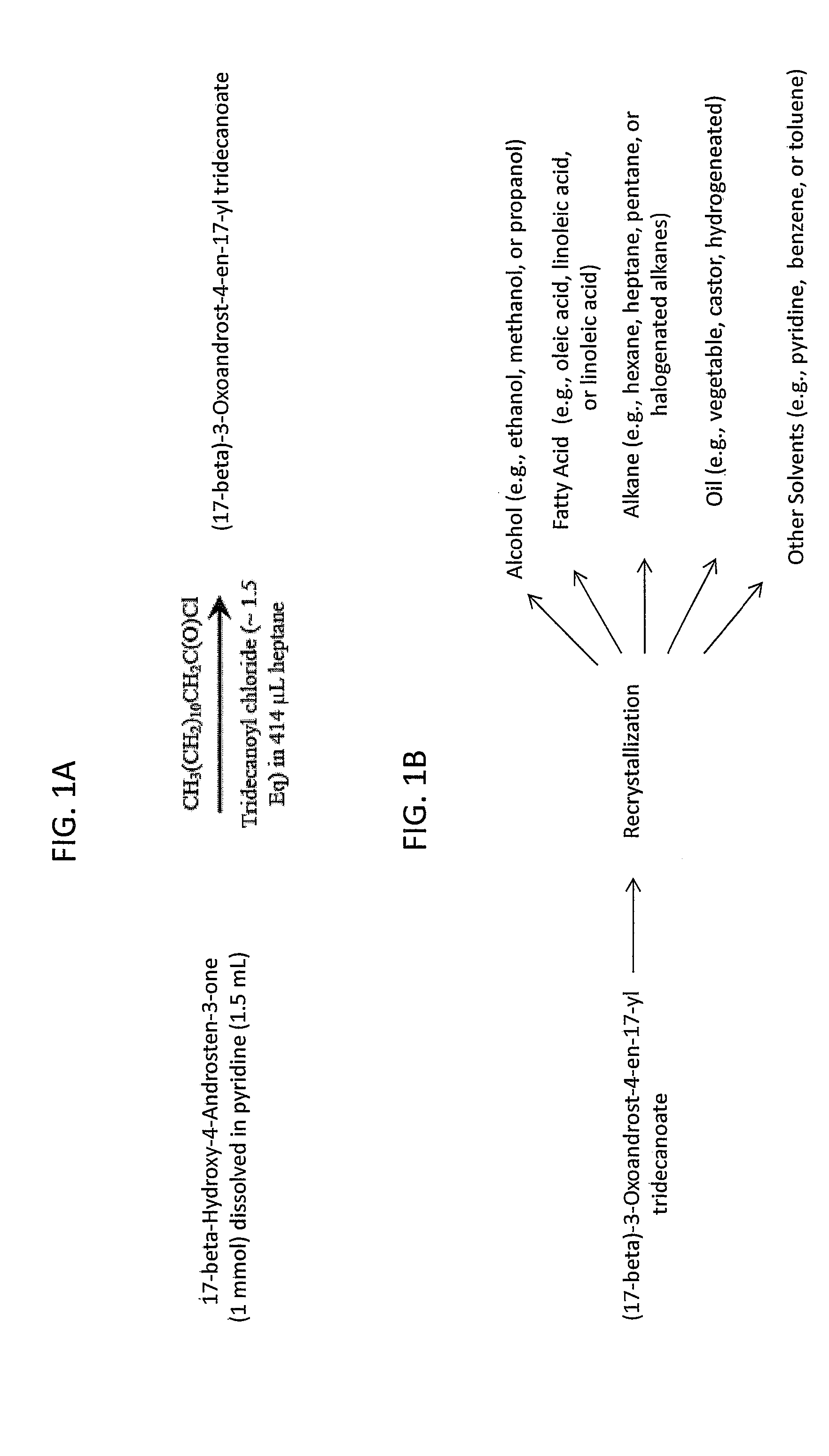

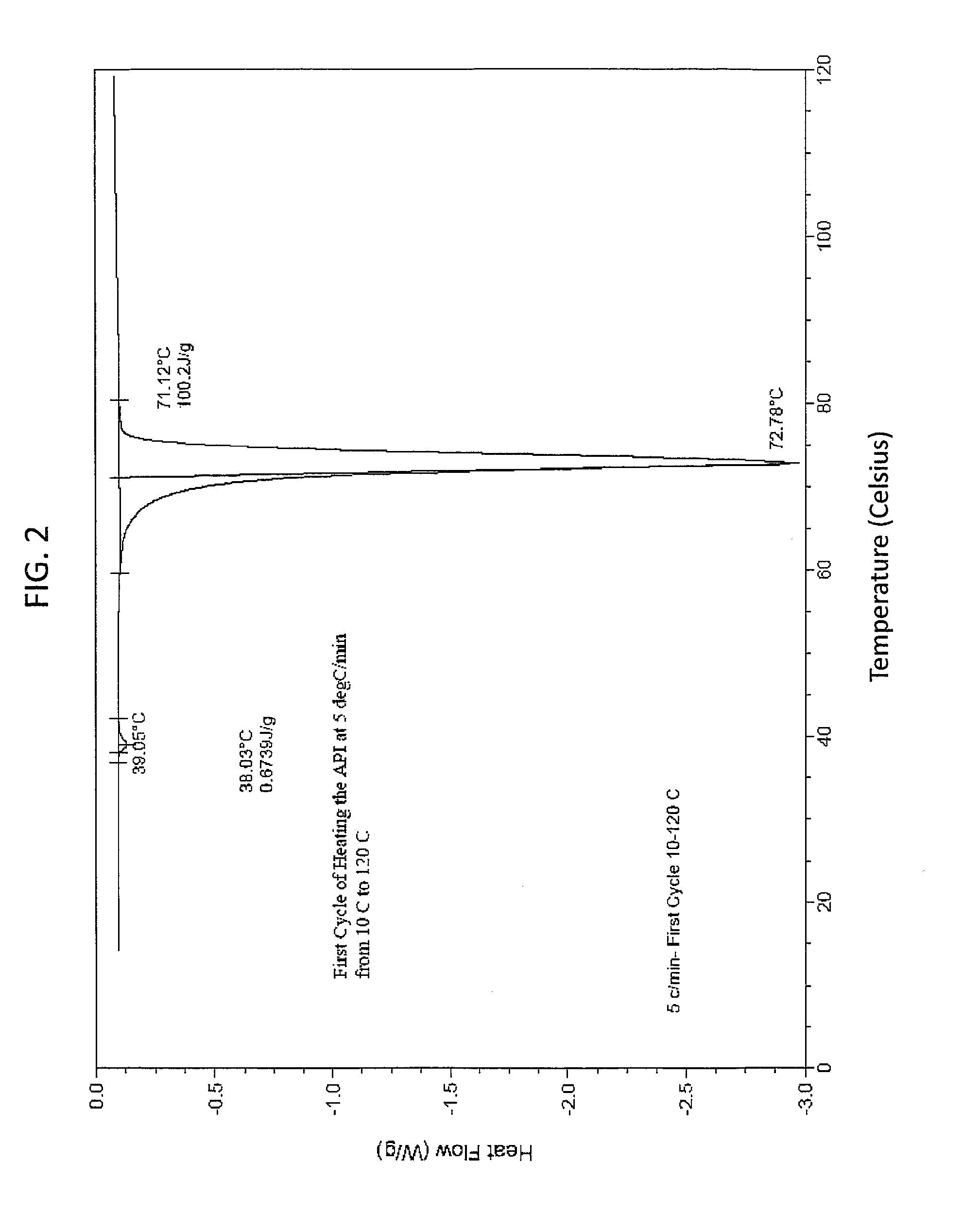

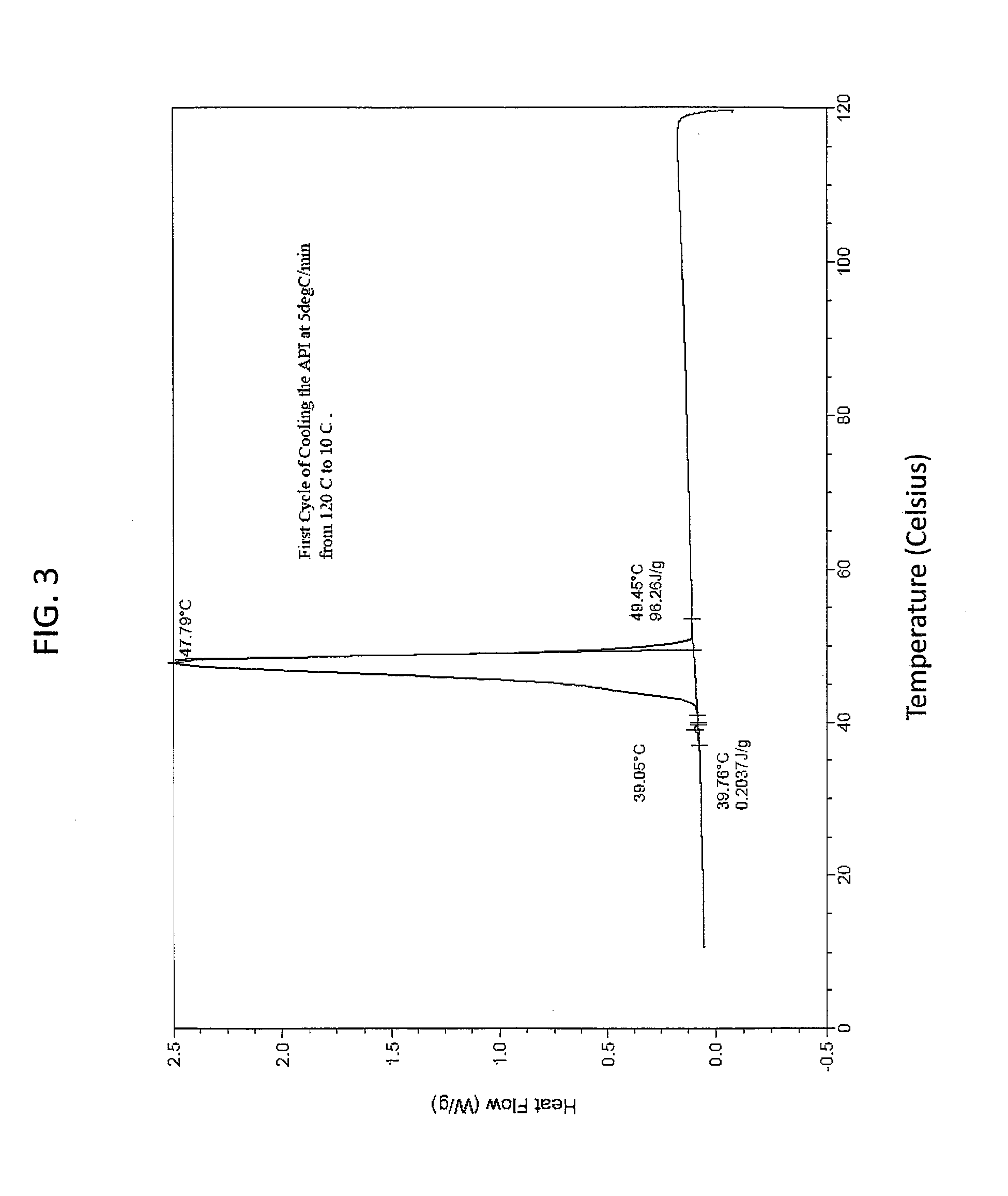

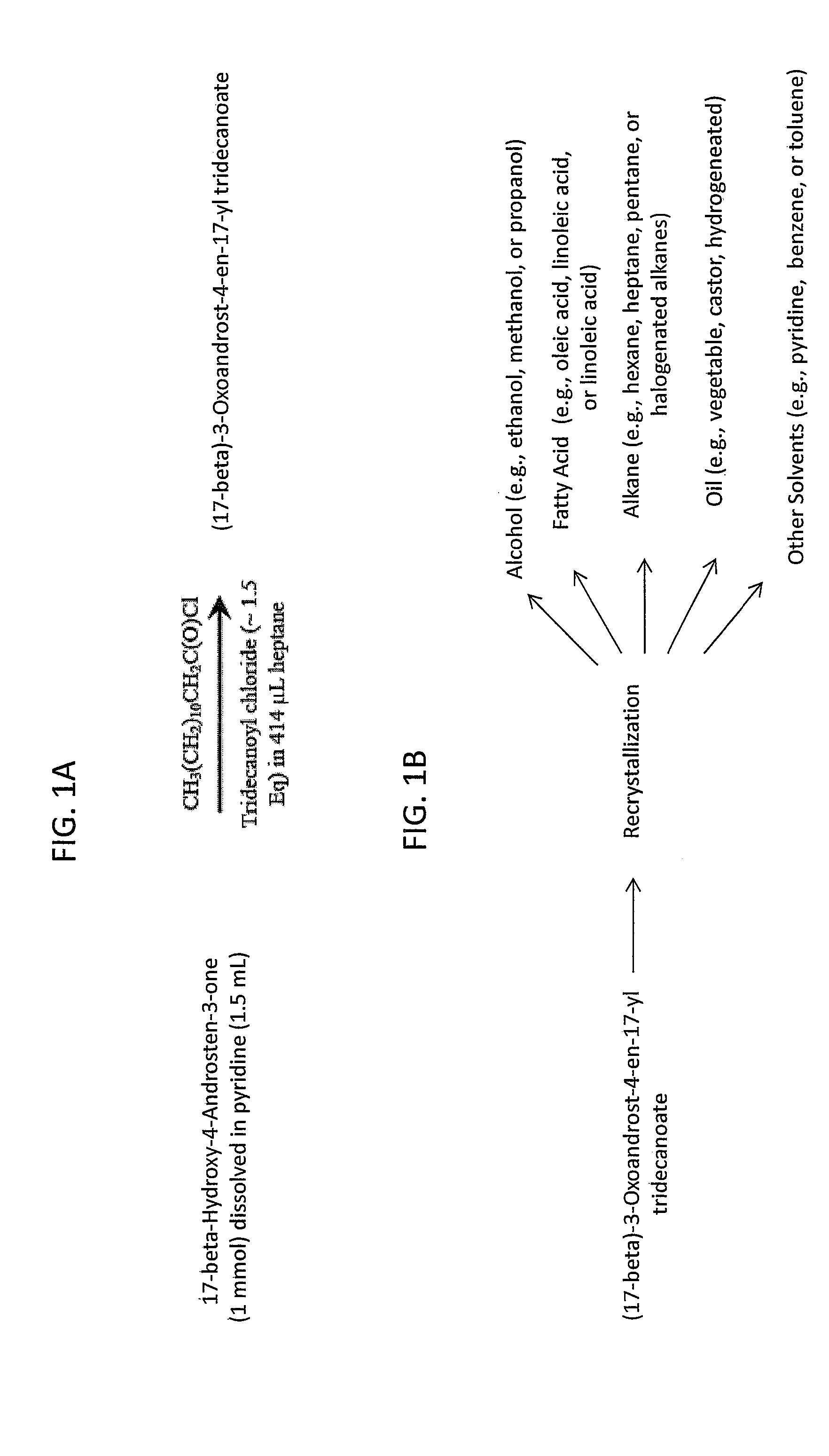

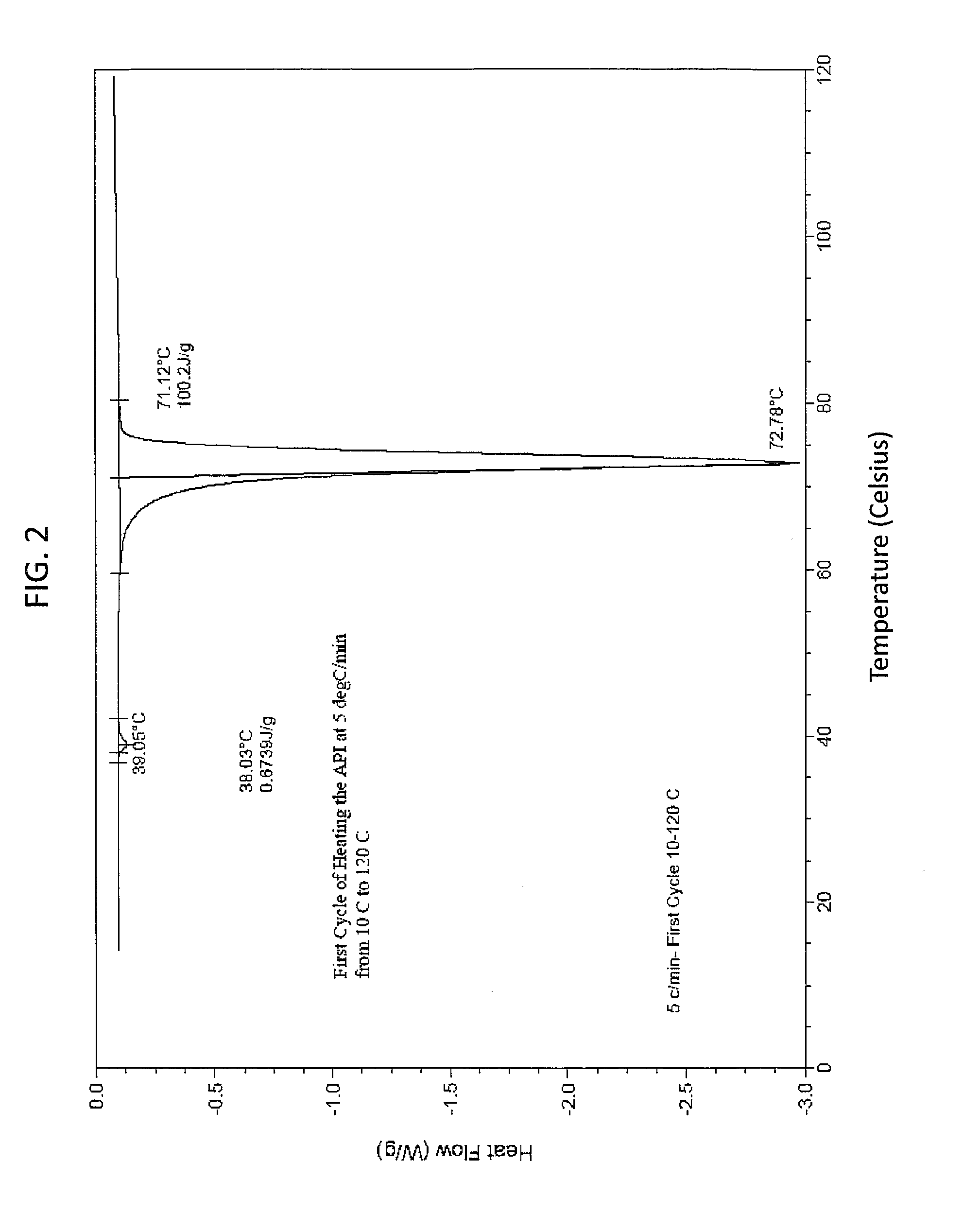

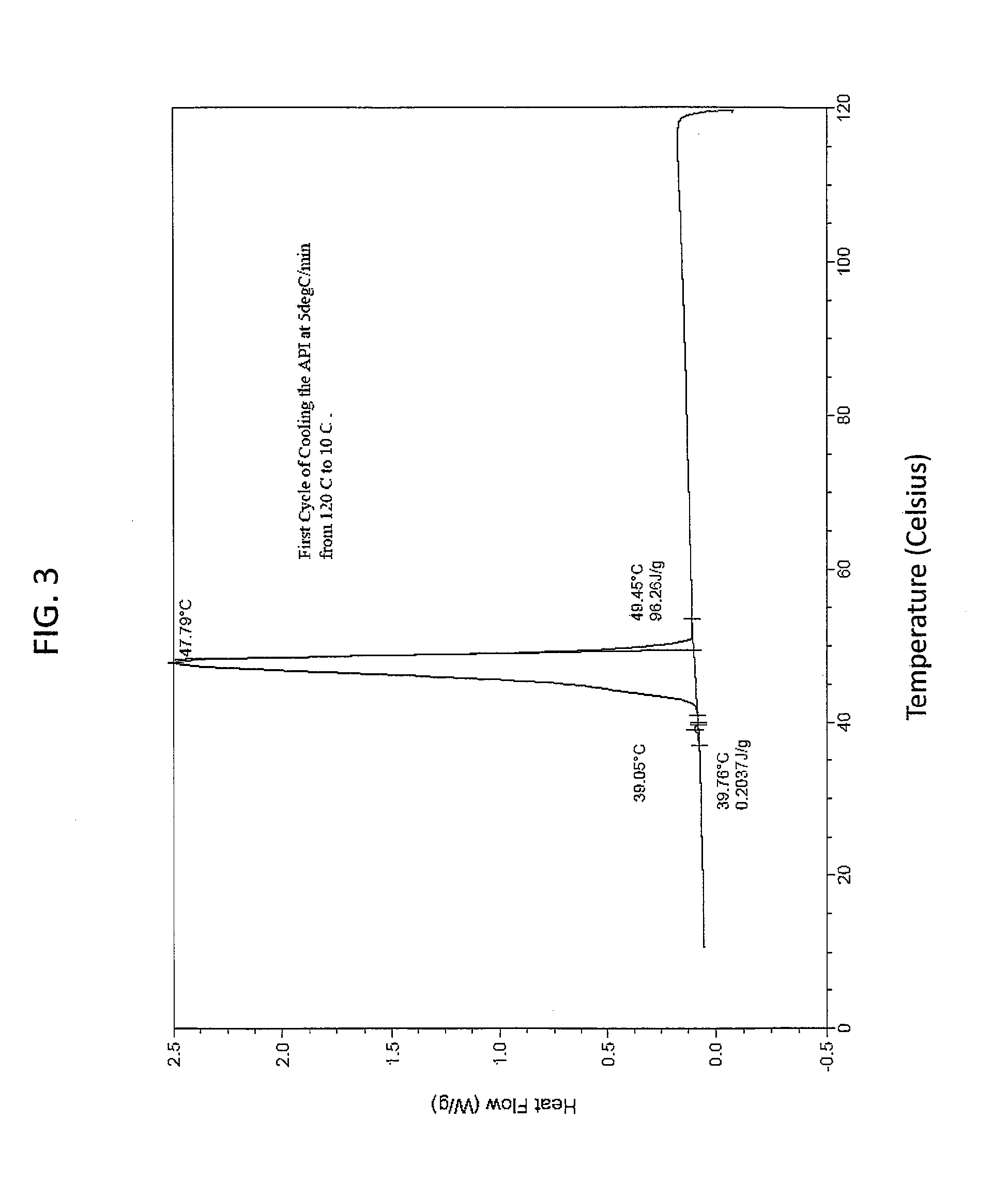

Bioavailable solid state (17-β)-hydroxy-4-androsten-3-one esters

ActiveUS9498485B2Avoid missing partsEffective oral bioavailabilityOrganic active ingredientsGranular delivery4-androsten-3-oneKetone

Disclosed are bioavailable solid state (17-β)-Hydroxy-4-Androsten-3-one esters suitable for pharmaceutical uses and administration to mammals in need of (17-β)-Hydroxy-4-Androsten-3-one.

Owner:LIPOCINE

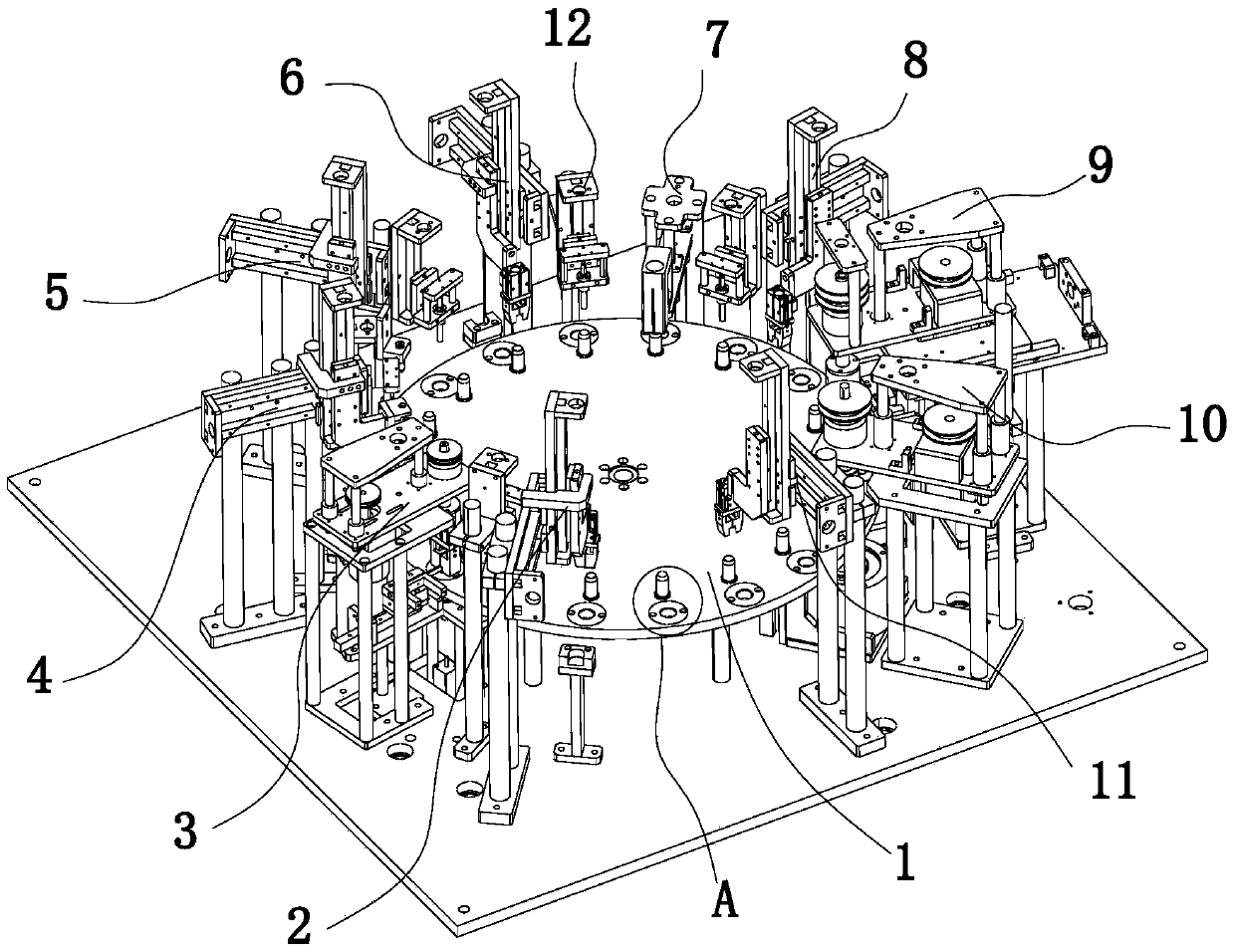

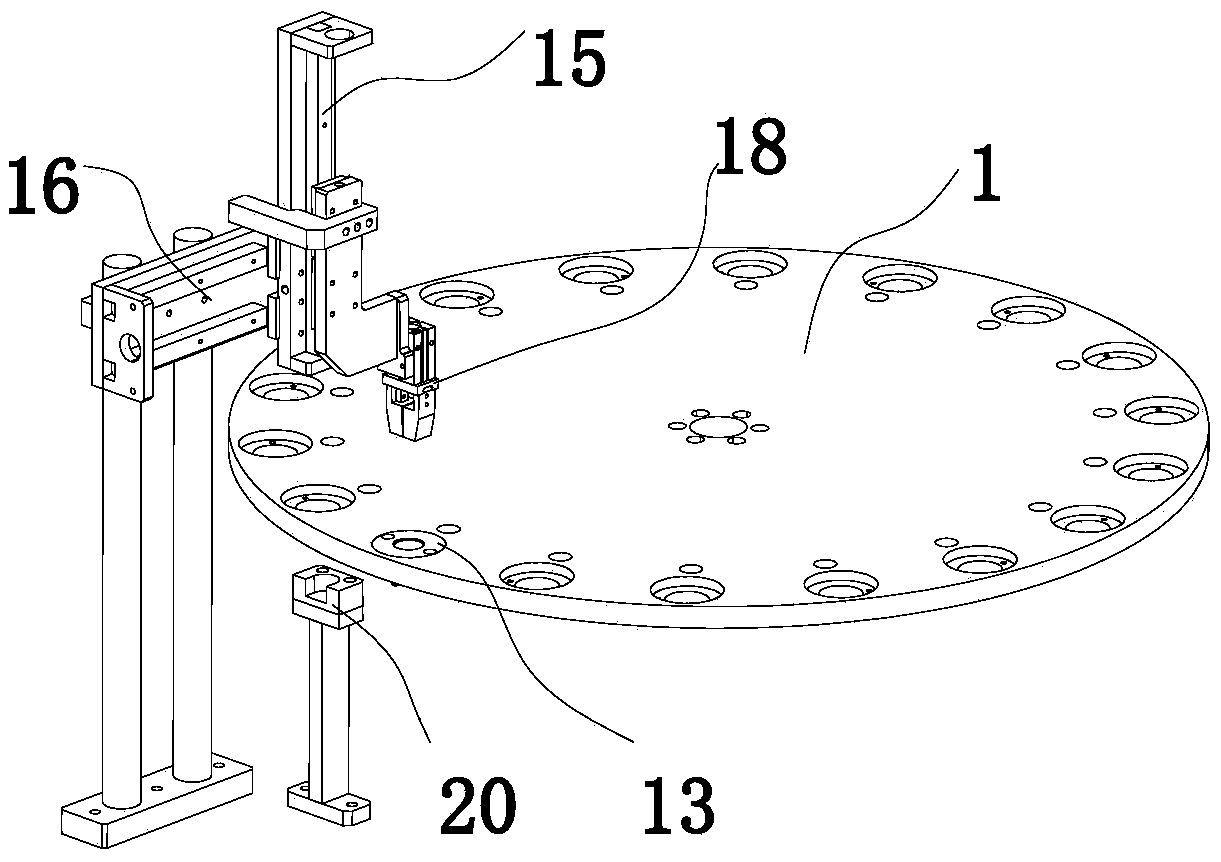

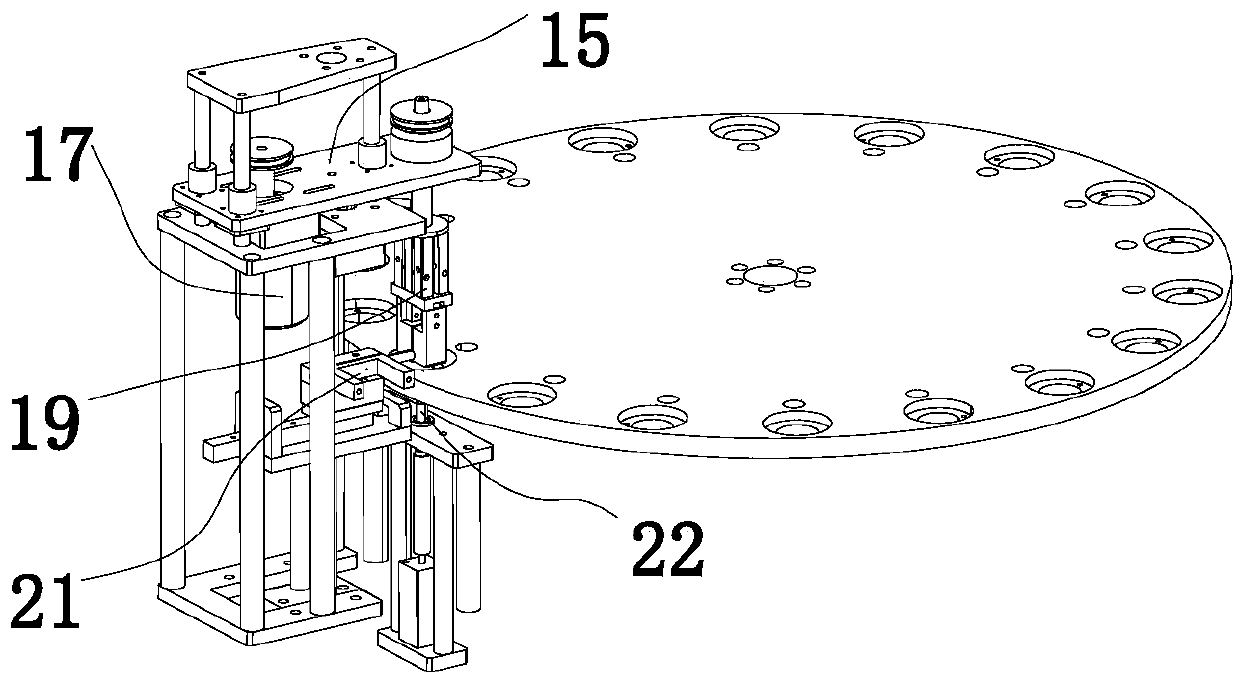

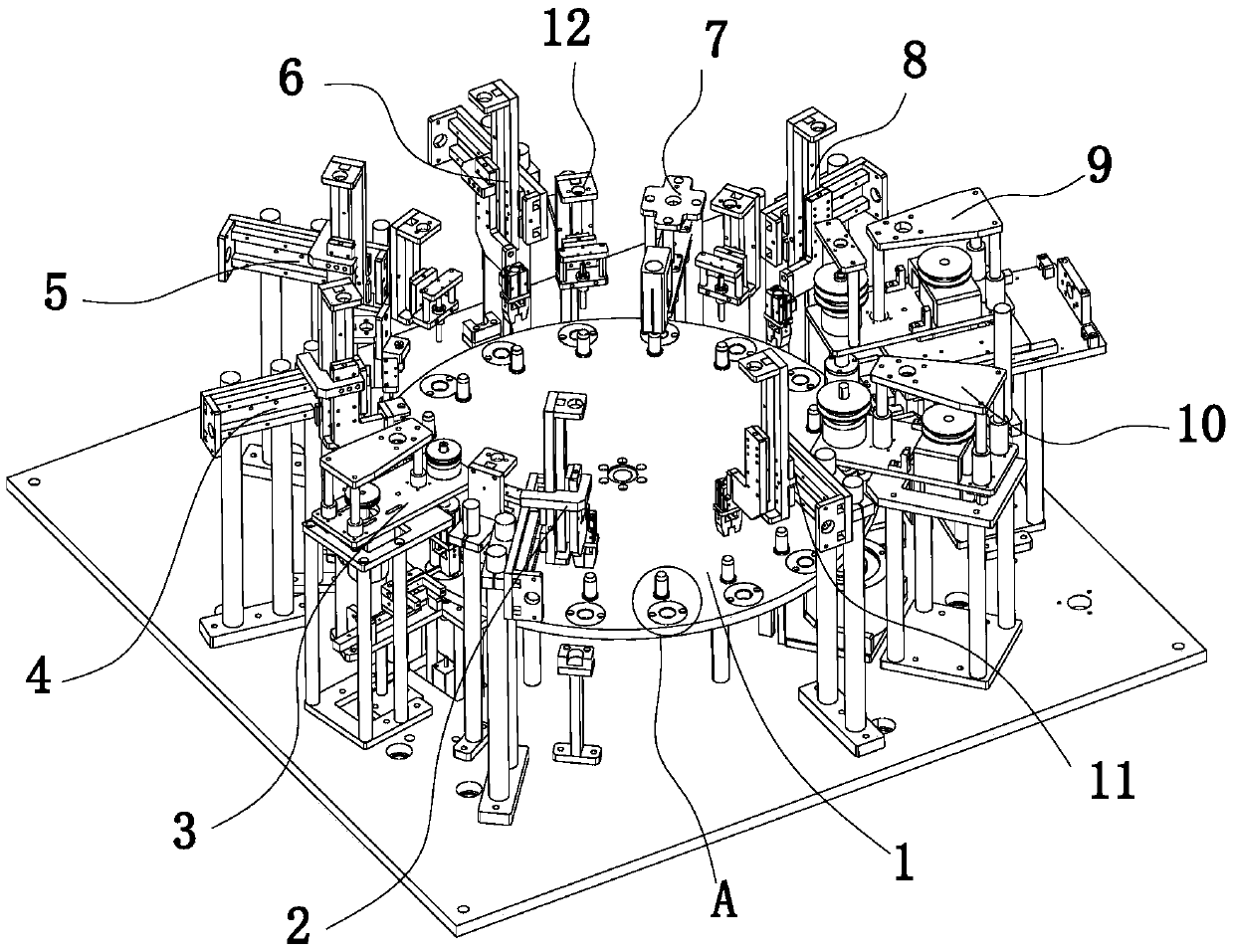

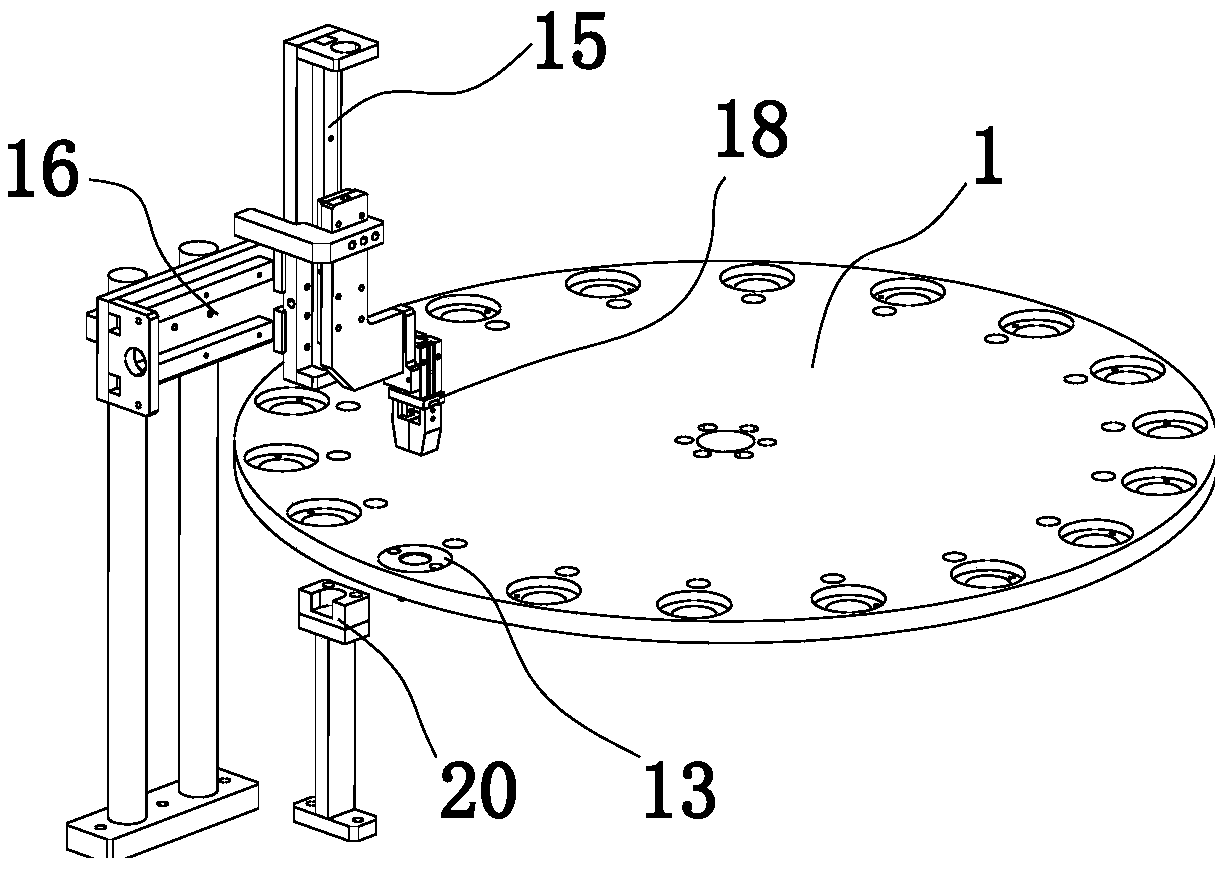

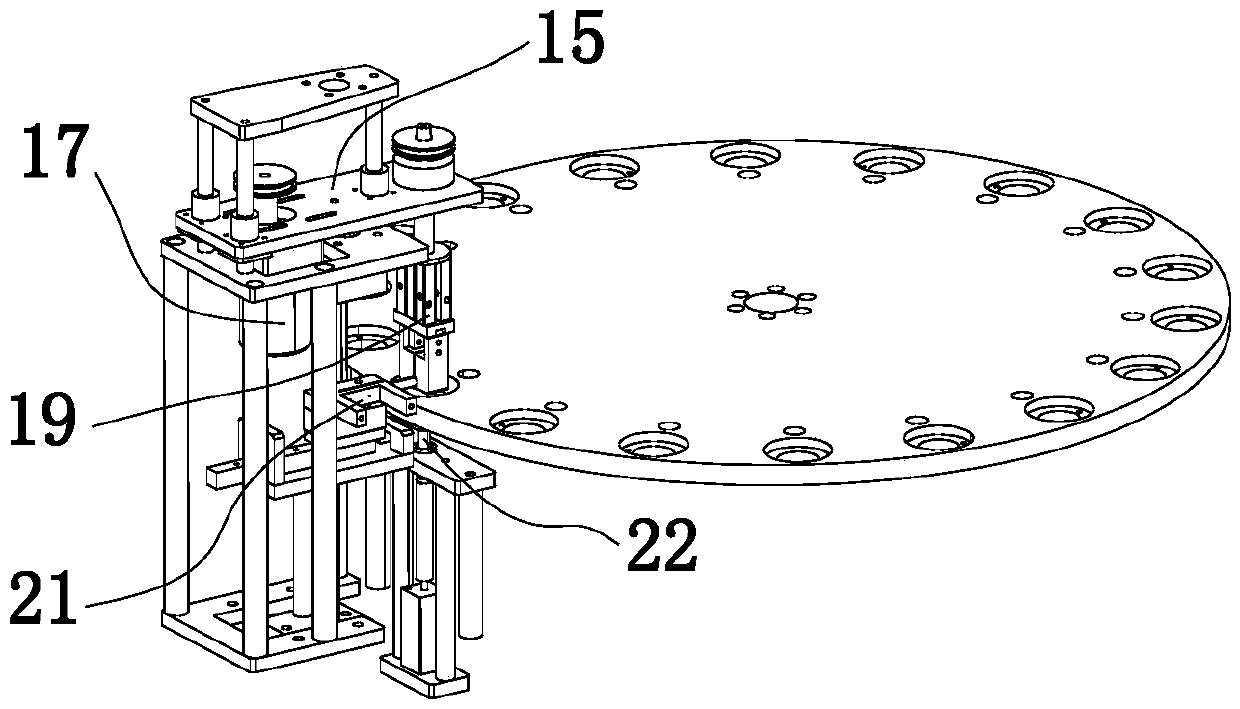

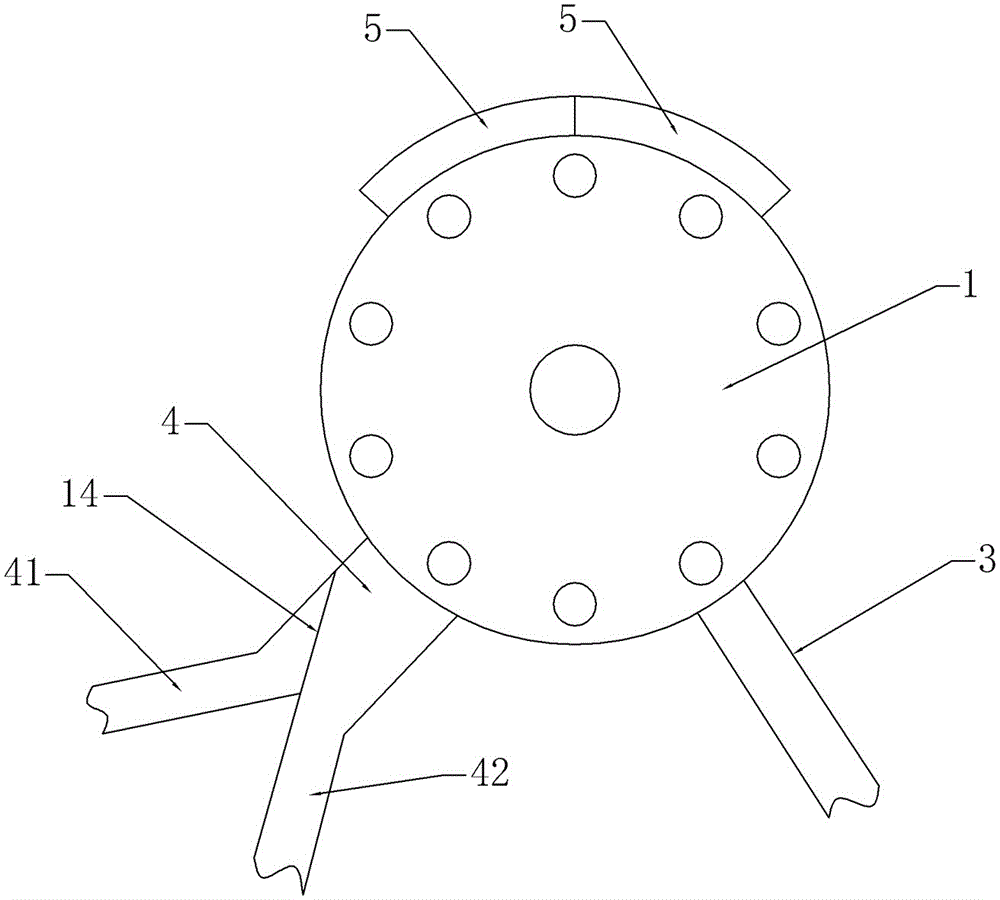

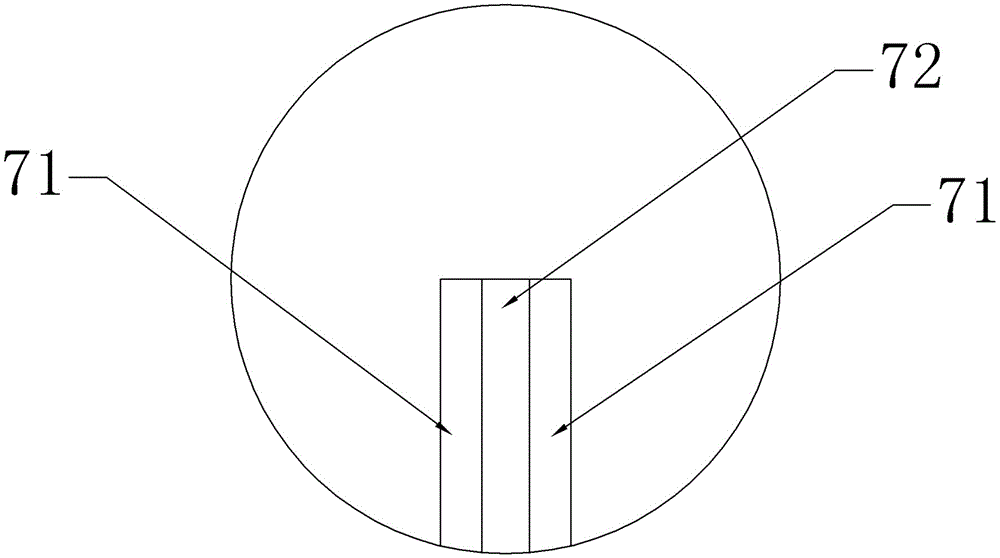

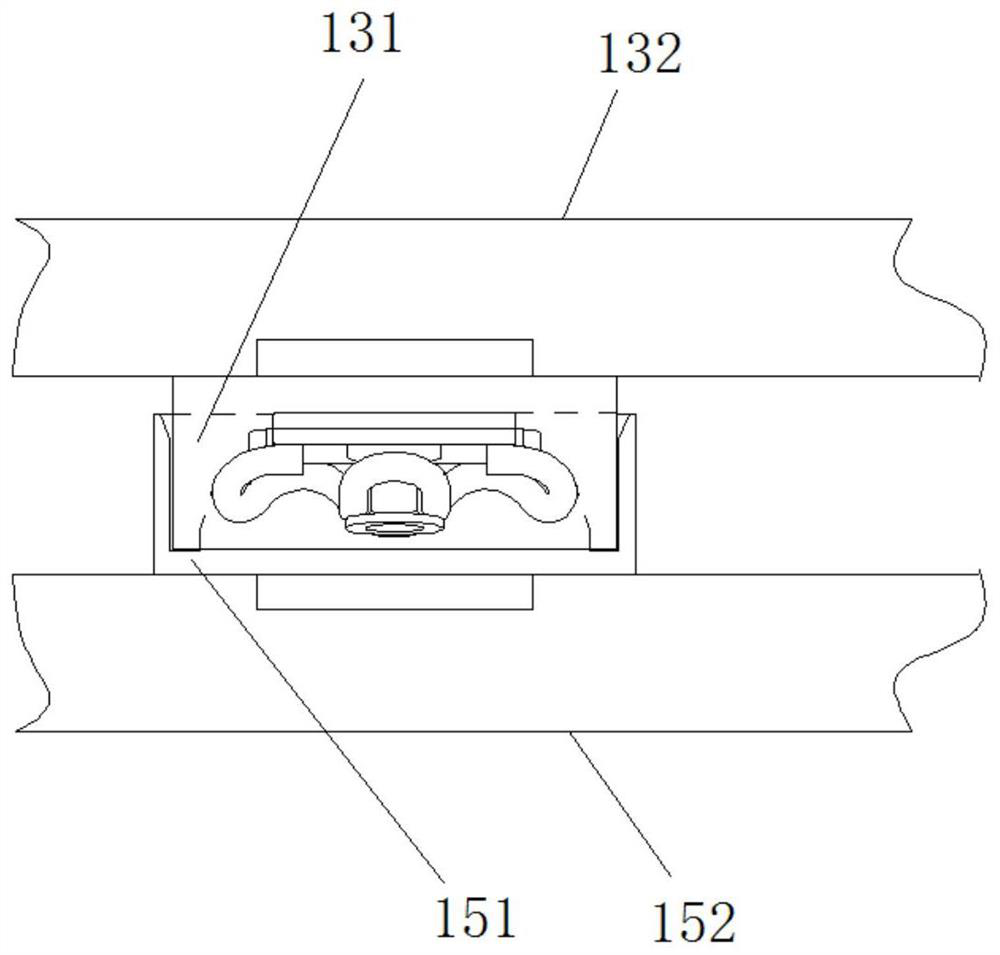

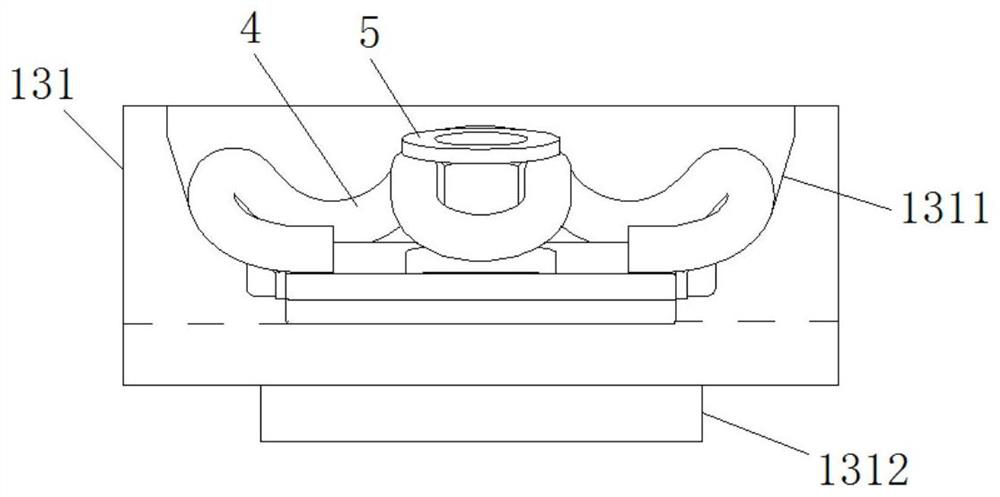

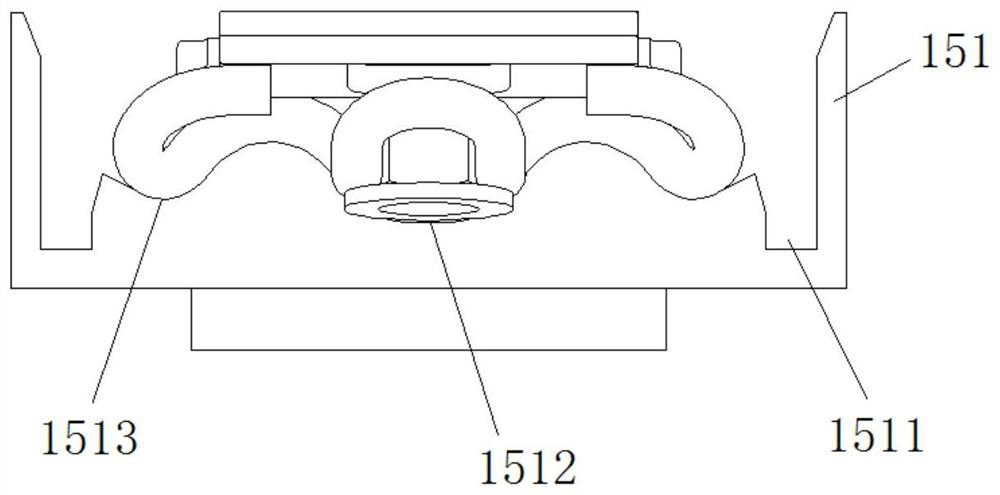

Rotating disc type rapid connector assembling machine

ActiveCN105499991ARealize automated assemblyImprove assembly efficiencyAssembly machinesEngineeringAssembly machine

The invention relates to the technical field of rapid connector assembling equipment, in particular to a rotating disc type rapid connector assembling machine. The machine comprises an index plate. A plurality of automatic assembling stations are arranged on the periphery of the index plate. Inner ring workpiece installation stations and outer ring workpiece installation stations are arranged in the circumferential direction of the index plate. The inner ring workpiece installation stations are columnar parts arranged at equal intervals. The outer ring workpiece installation stations are positioning blocks arranged at equal intervals. Each columnar part and the corresponding positioning block which correspond to the same automatic assembling station correspond to each other in the radial direction of the index plate. The automatic assembling stations, the inner ring workpiece installation stations and the outer ring workpiece installation stations are arranged in the circumferential direction of the index plate. Rapid connector assembling comprises three steps of assembling of a center assembly, assembling of an outer sleeve assembly and nut screwing. Automatic assembling of a rapid connector is achieved, the assembling efficiency is high, and the problem that an outer sleeve spring is large in installation difficulty is solved; the phenomenon of missed assembling of components in the automatic assembling process is effectively avoided through the multiple installation detection stations.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

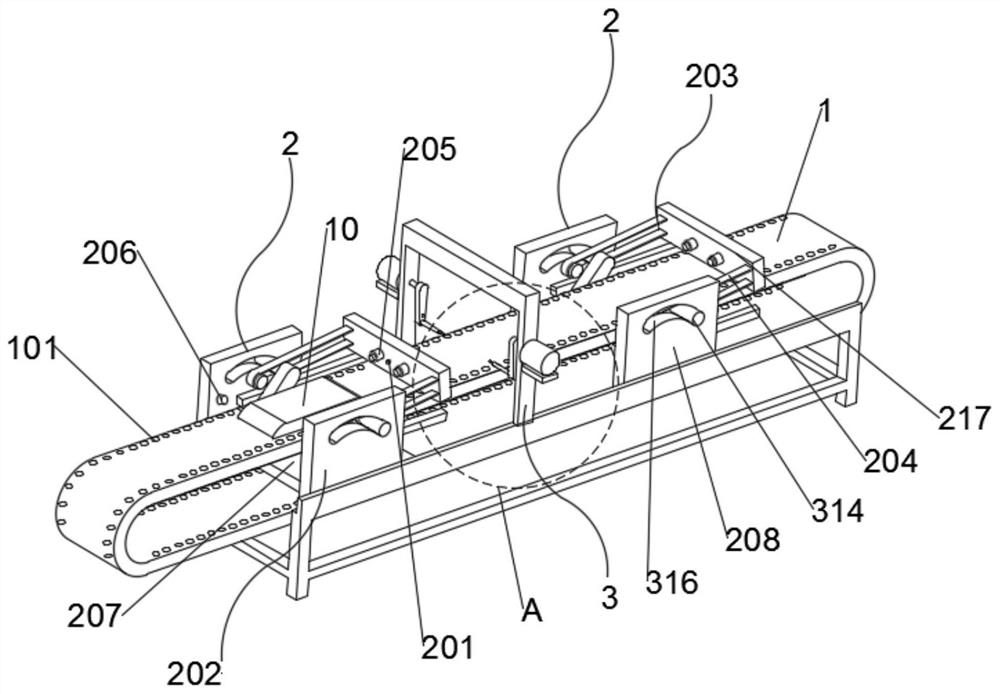

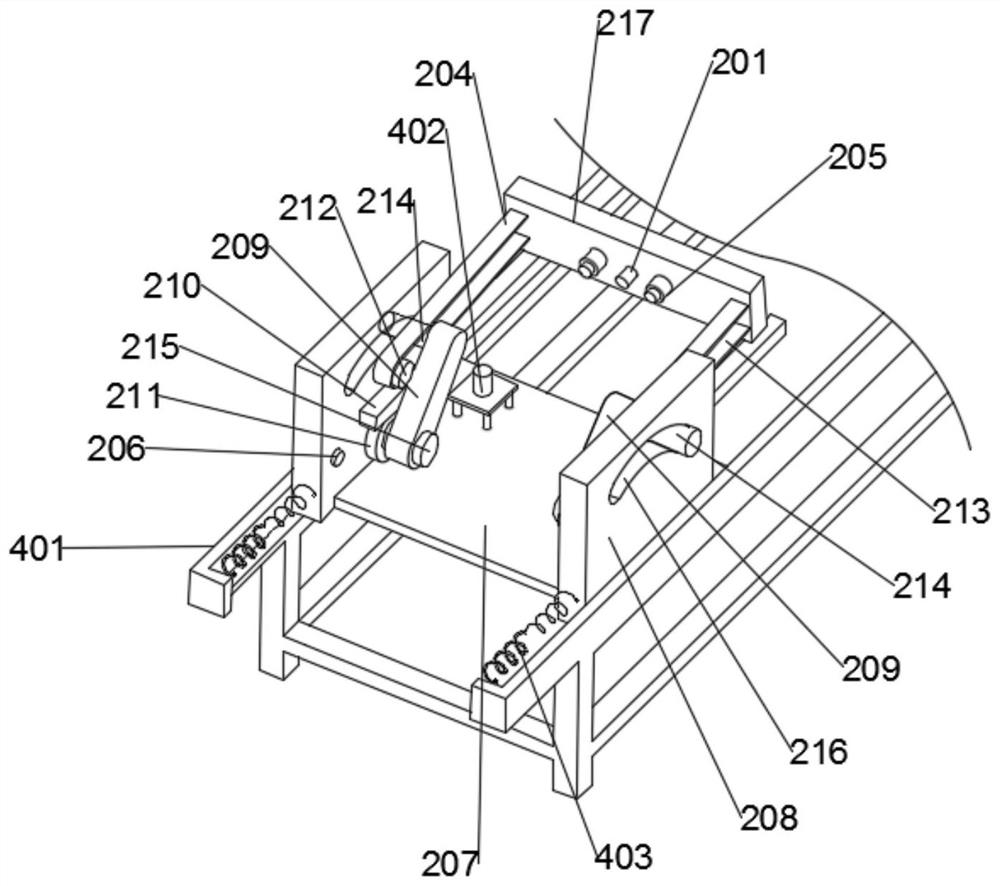

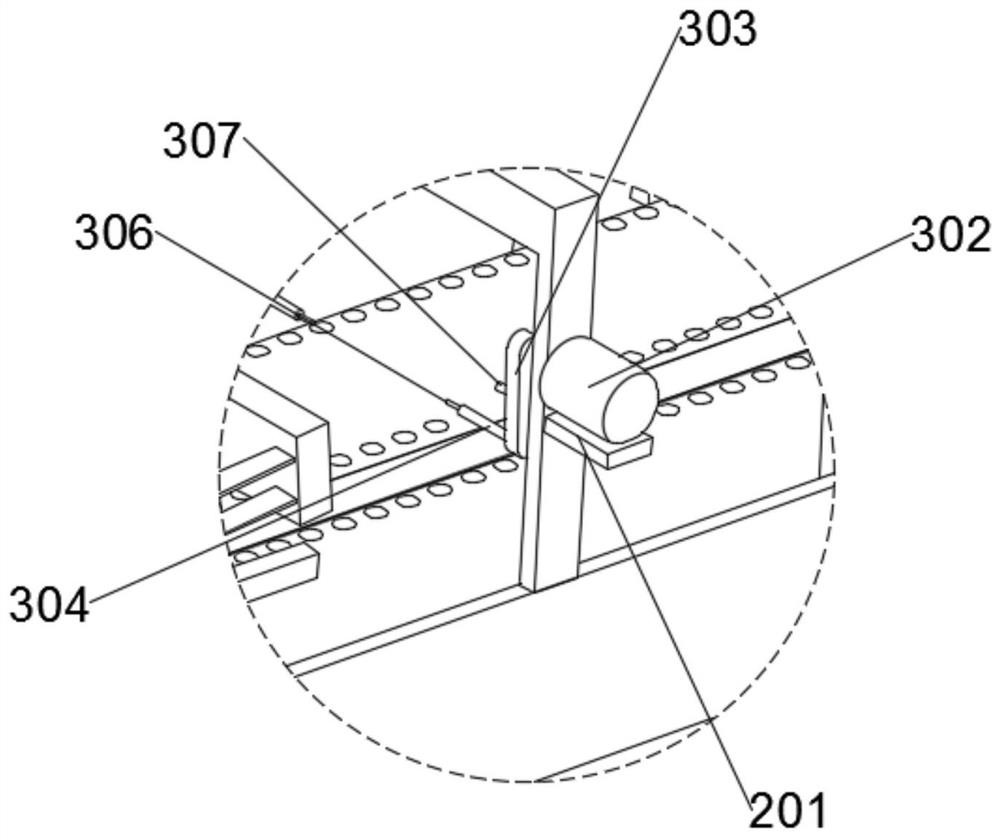

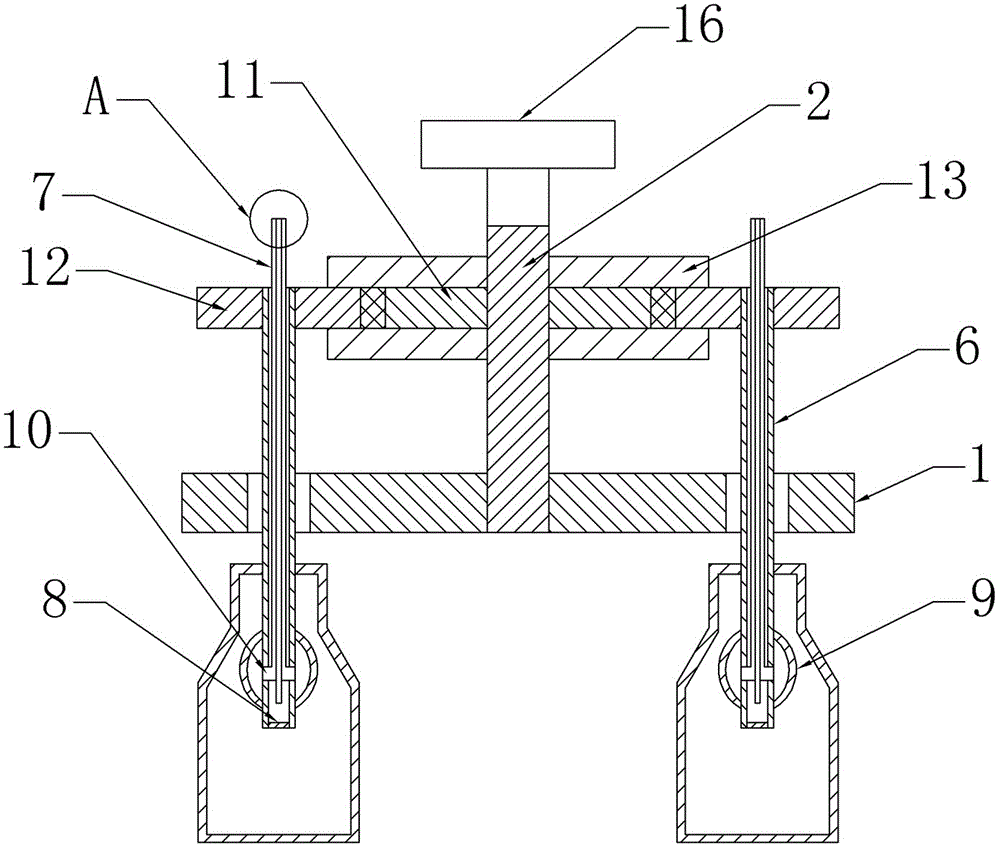

Multi-station quick coupling assembling machine

ActiveCN105499992ARealize automated assemblySolve the difficulty of installationAssembly machinesCouplingEngineering

The invention relates to the technical field of quick coupling assembling equipment, in particular to a multi-station quick coupling assembling machine. The multi-station quick coupling assembling machine comprises a material conveying table capable of moving step by step and multiple automatic assembling stations which are arranged in the moving direction of the material conveying table, the material conveying table is provided with workpiece installation stations corresponding to the all the automatic assembling stations, and each workpiece installation station is provided with a positioning block used for central component assembling and a column-shaped leaning nut used for wrap component assembling. According to the multi-station quick coupling assembling machine, assembling of a quick coupling is divided into central component assembling, wrap component assembling and nut tightening, automatic assembling of the quick coupling is achieved, and the assembling efficiency is high; wrap components and central components are assembled through material shifting stations, and the problem that the wrap springs are difficult to install is solved; the situation that parts are missed in the automated assembly process is effectively avoided by means of multiple installation detection stations.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

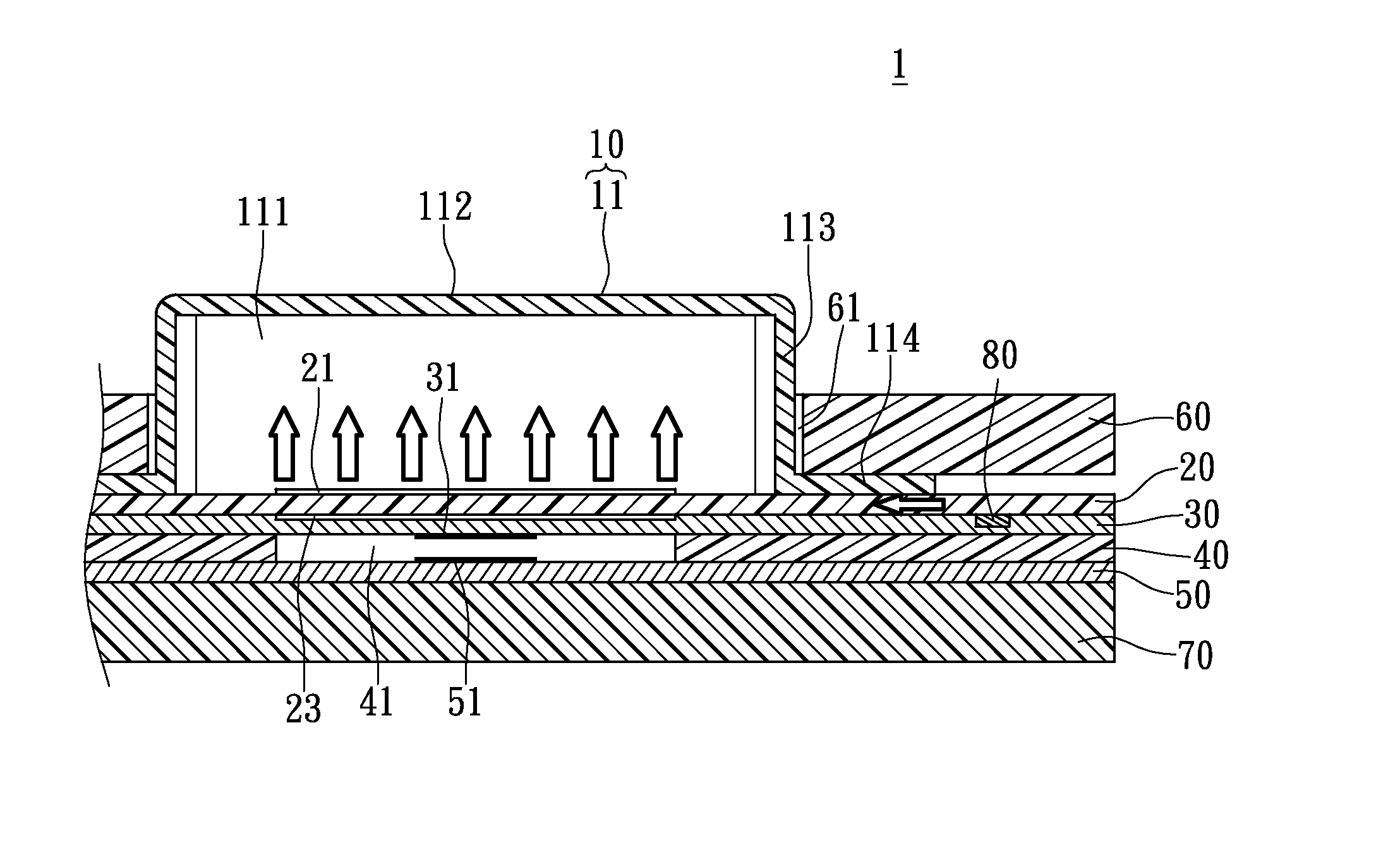

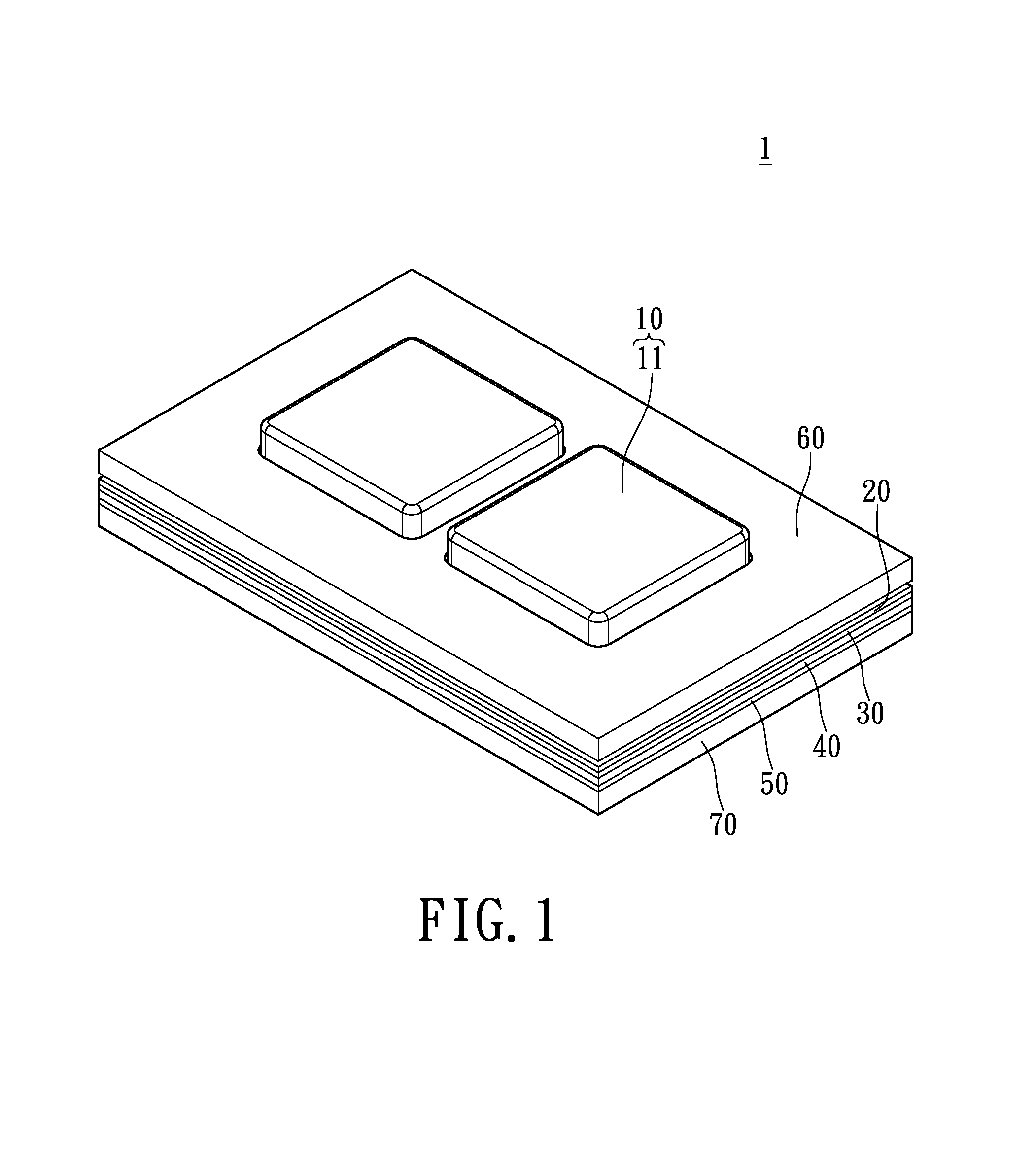

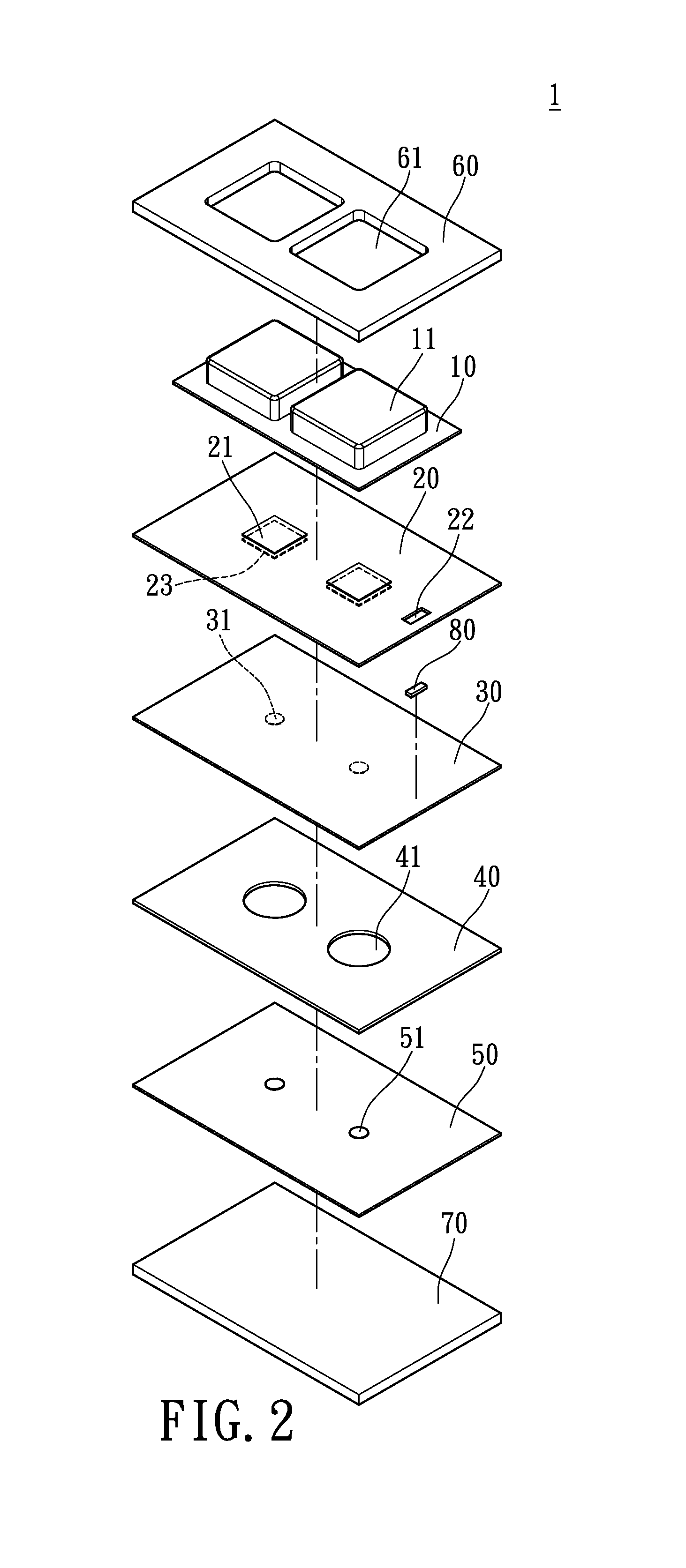

Resilient pressing member structure

InactiveUS20140042005A1Display clearIncrease backlight brightnessEmergency actuatorsOperation facilitationLight guideEngineering

The instant disclosure is a resilient pressing member structure having a pressing unit disposed on top of a translucent insulated layer, an upper cover, a light-emitting unit, two conductive layers and a spacer. The pressing unit includes a plurality of pressing members while the cover is formed with a cavity filled with a fluid to achieve the effect of pressure dispersion. A light guiding structure and a light reflecting structure are disposed on the topside and the backside of the insulated layer, respectively. The insulated layer is formed by at least one light unit opening which extends through the insulated layer. The light-emitting unit is hosted inside the light unit opening. Light from the light-emitting unit penetrates the insulated layer and reaches the pressing member. Then the guiding structure directs light while the reflecting structure reflects light towards the pressing member, thus illuminates the pressing member.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

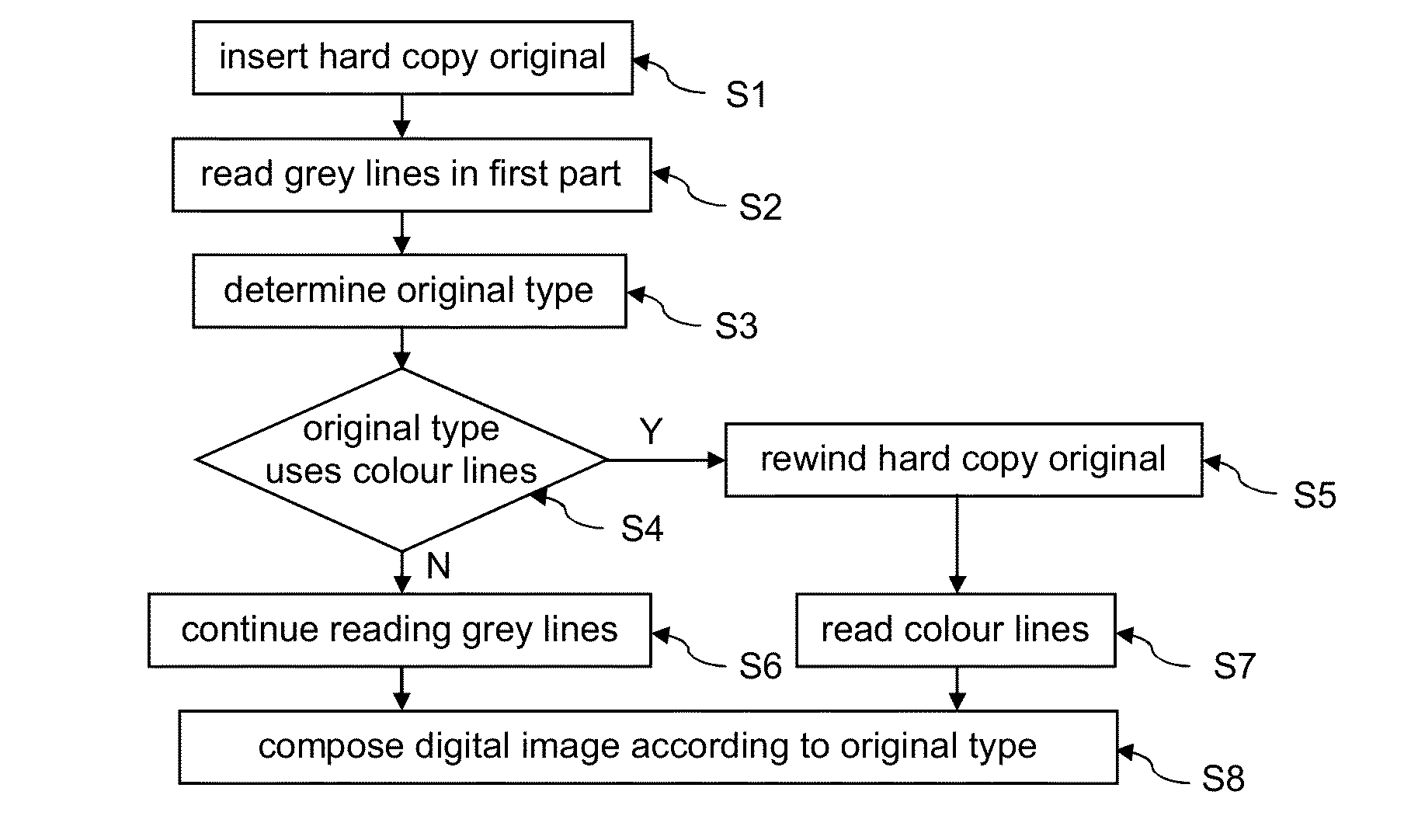

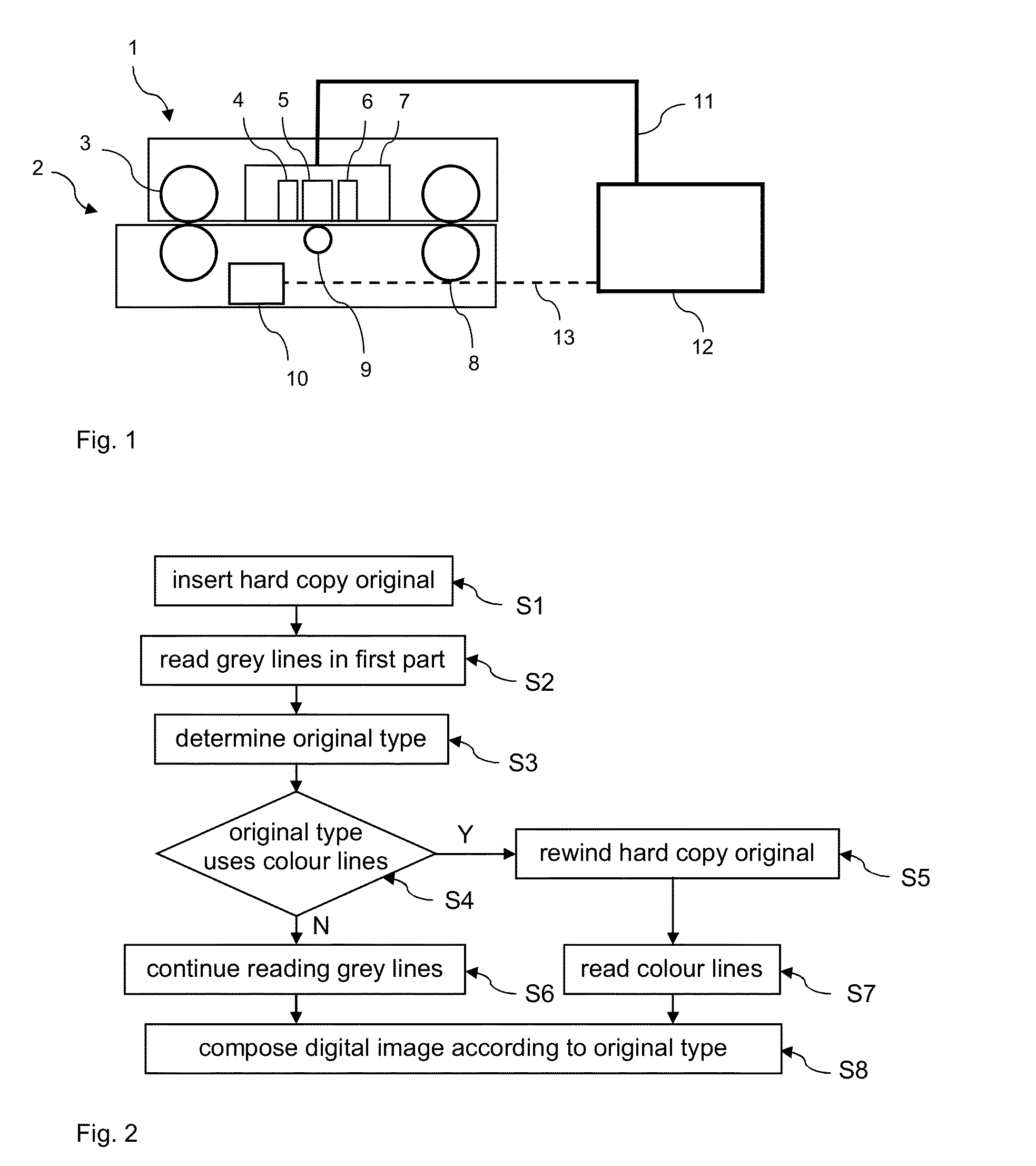

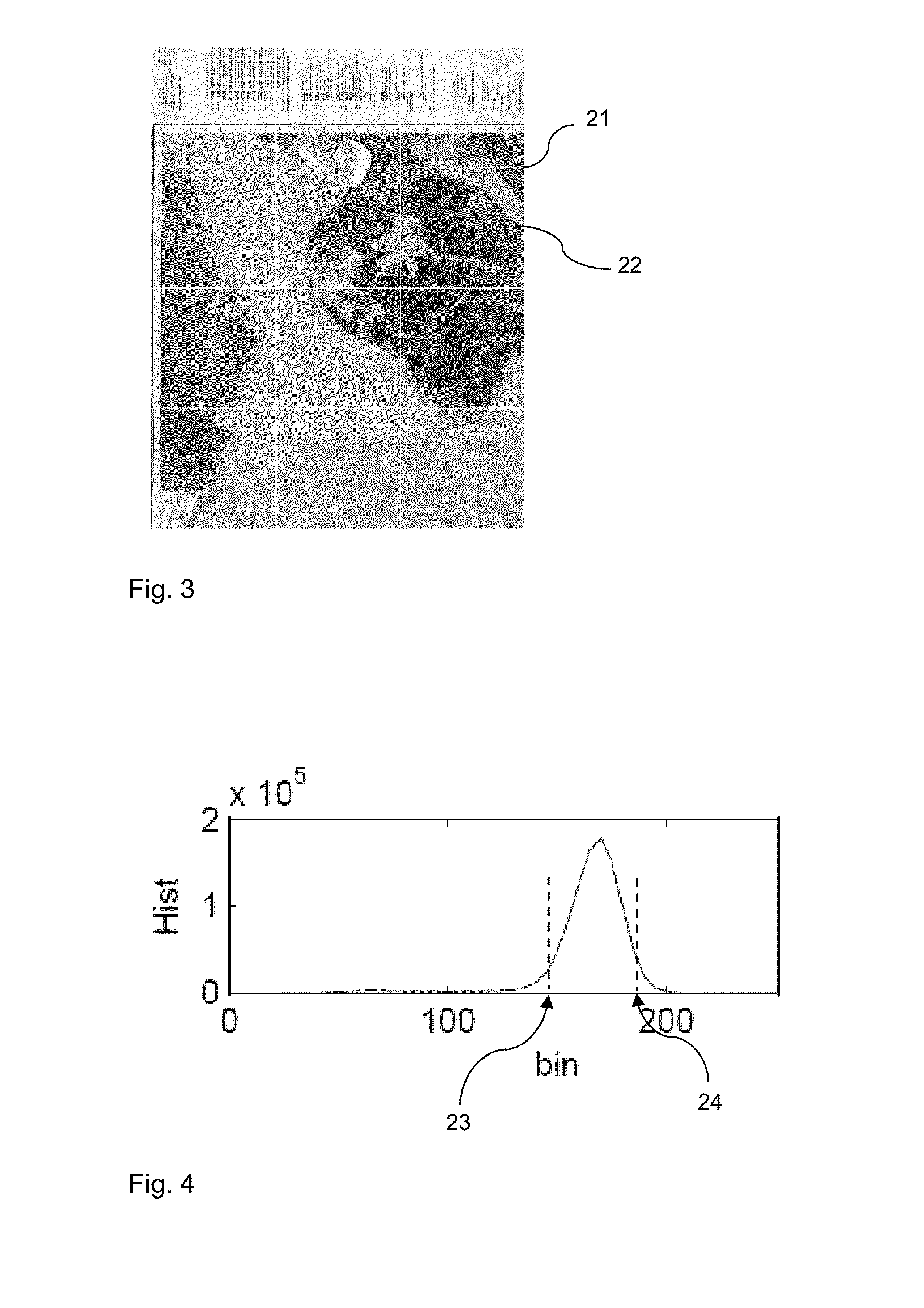

Method for scanning hard copy originals

InactiveUS20130278980A1Increase transfer speedAvoid missing partsPictoral communicationLine sensorTransport system

A method for converting a hard copy original to a digital image by a scanner system having an image line sensor and a transport system for transporting the hard copy original across the image line sensor are provided. The scanner system has several modes of operation, each mode being associated with a predefined original type and each mode assembling either grey lines or color lines for composing the digital image. The method includes determining an optimal mode of operation for converting the hard copy original by transporting a first part of the hard copy original across the image line sensor. Grey lines from the image line sensor are used in the determination, because this allows the hard copy original to be transported three times as fast across the image line sensor. It is still possible to discern originals with color information from scanned originals with only black-and-white information.

Owner:OCE TECH

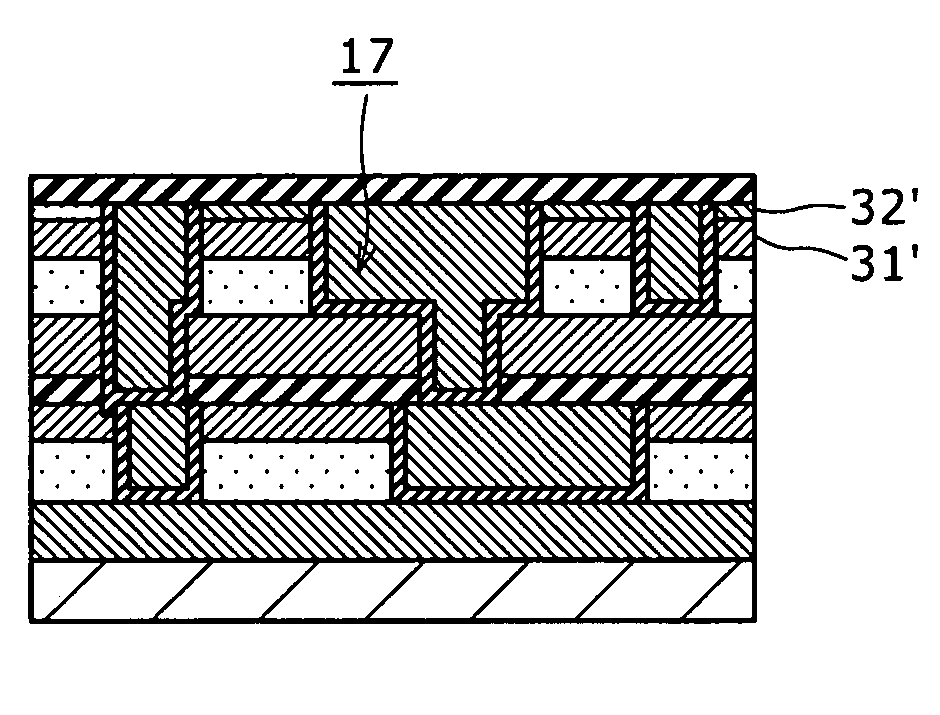

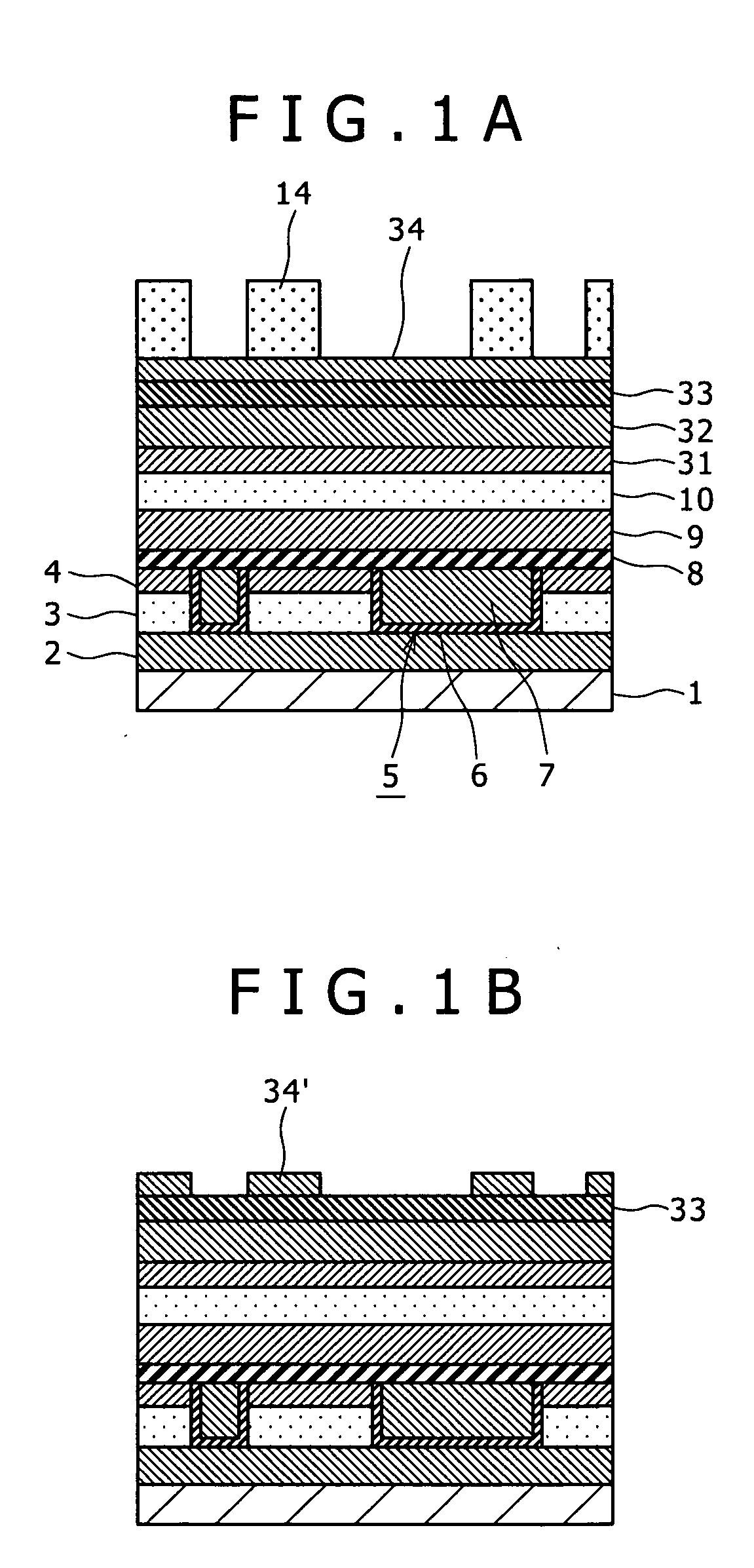

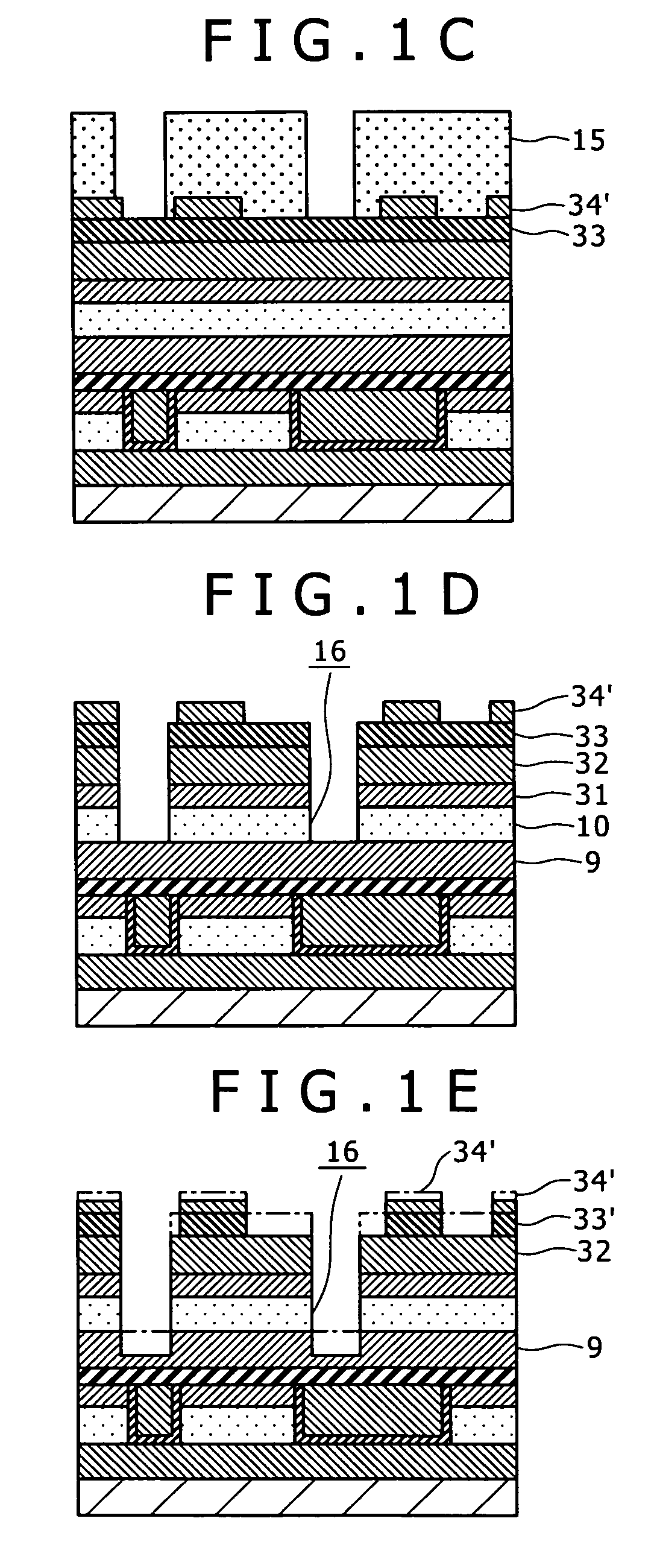

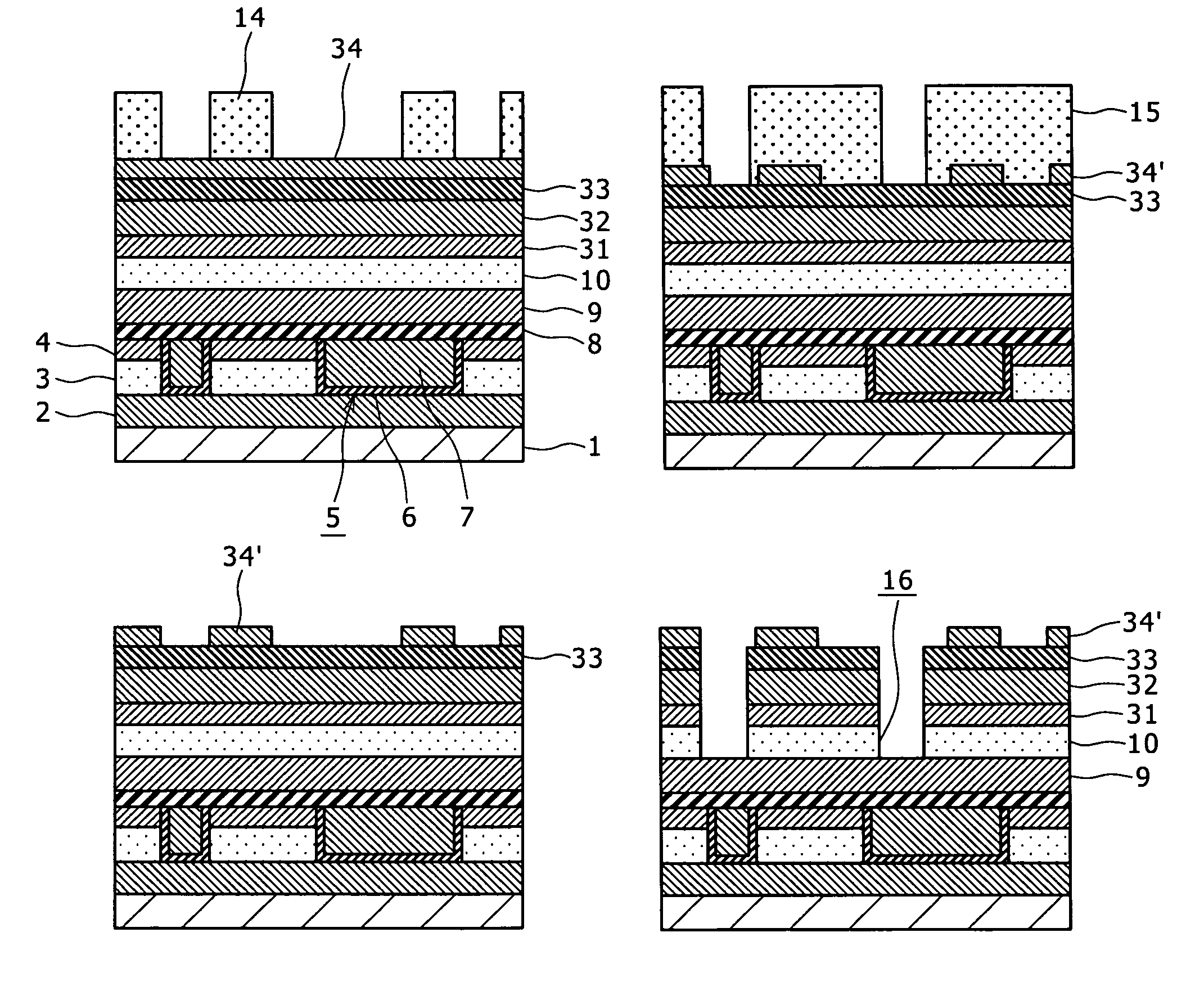

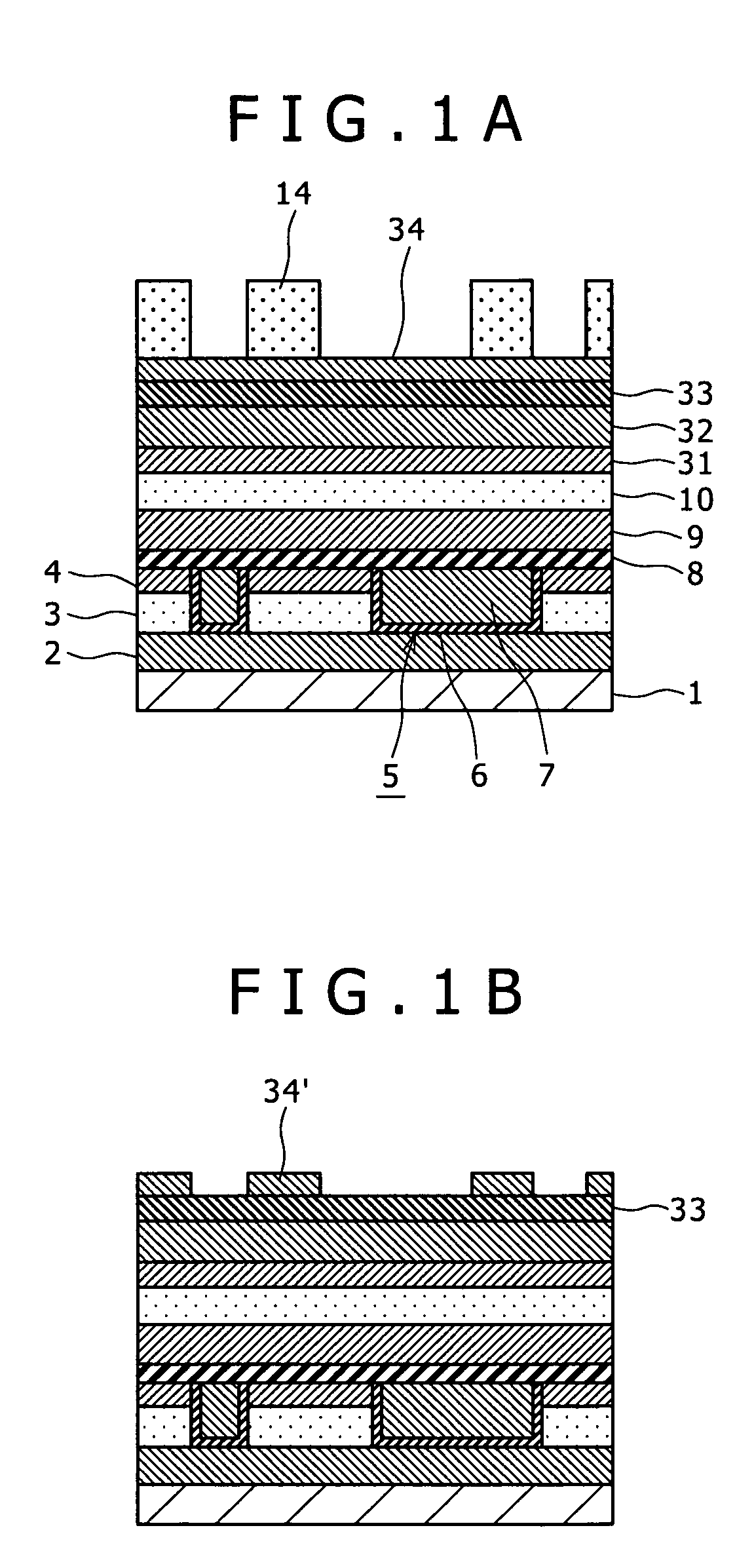

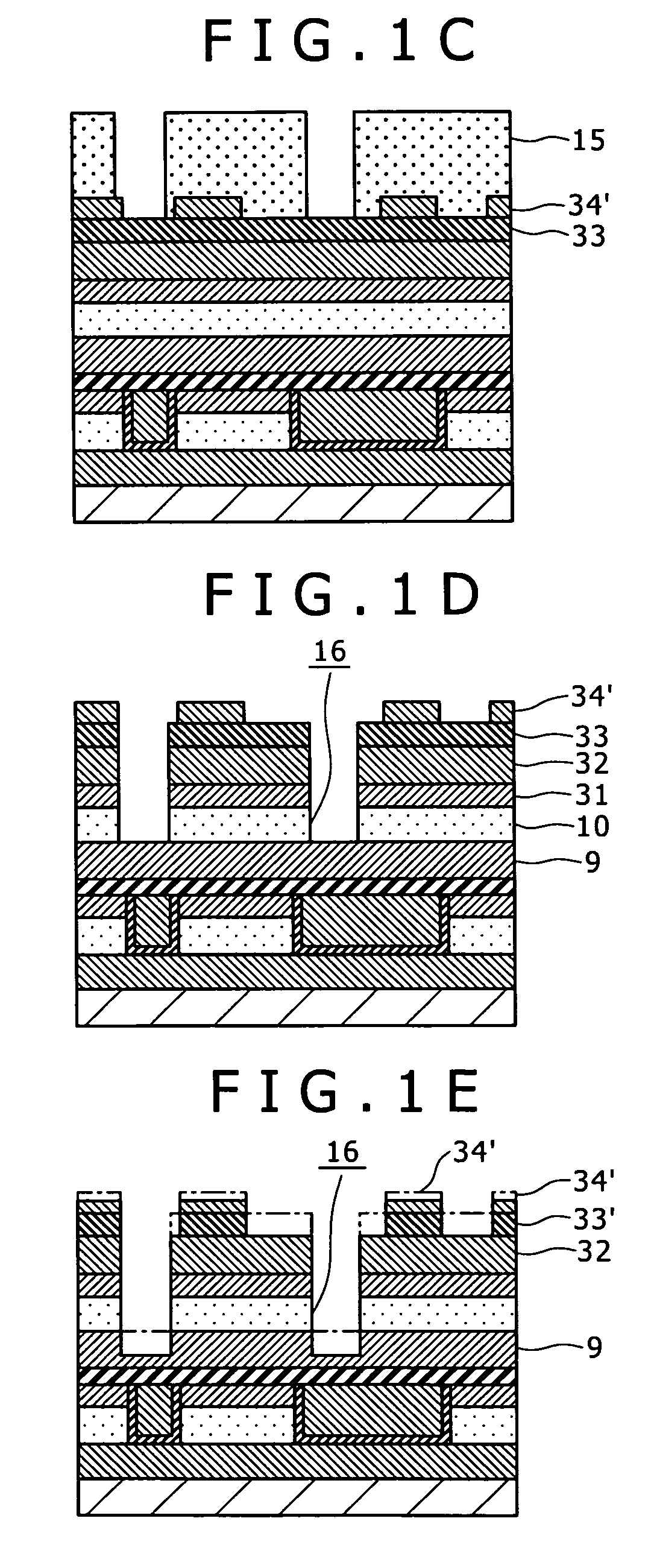

Method of manufacturing semiconductor device and semiconductor device

InactiveUS20060186548A1Improve interconnect reliabilityImprove controllabilitySemiconductor/solid-state device detailsSolid-state devicesResistDevice material

The present invention provides a method of manufacturing a semiconductor device and a semiconductor device that allow use of interlayer and interconnect insulating films having a low dielectric constant in forming a dual damascene structure. A first insulating film, a second insulating film, a first-mask forming layer, a second-mask forming layer, a third-mask forming layer, and a fourth-mask forming layer are sequentially deposited over a substrate. The fourth-mask forming layer is patterned to form a fourth mask having an interconnect trench pattern. After a resist mask is formed on the fourth mask, the layers to the second insulating film are etched to open via holes. The third-mask forming layer is etched through the fourth mask to thereby form a third mask having the interconnect trench pattern and to extend the via holes downward partway across the first insulating film. The second-mask forming layer is etched through the fourth mask to thereby form a second mask having the interconnect trench pattern, and the first insulating film that remains under the bottoms of the via holes is removed. Subsequently, the second insulating film is etched through the second mask to thereby form an interconnect trench, and then the second mask is removed.

Owner:SONY CORP

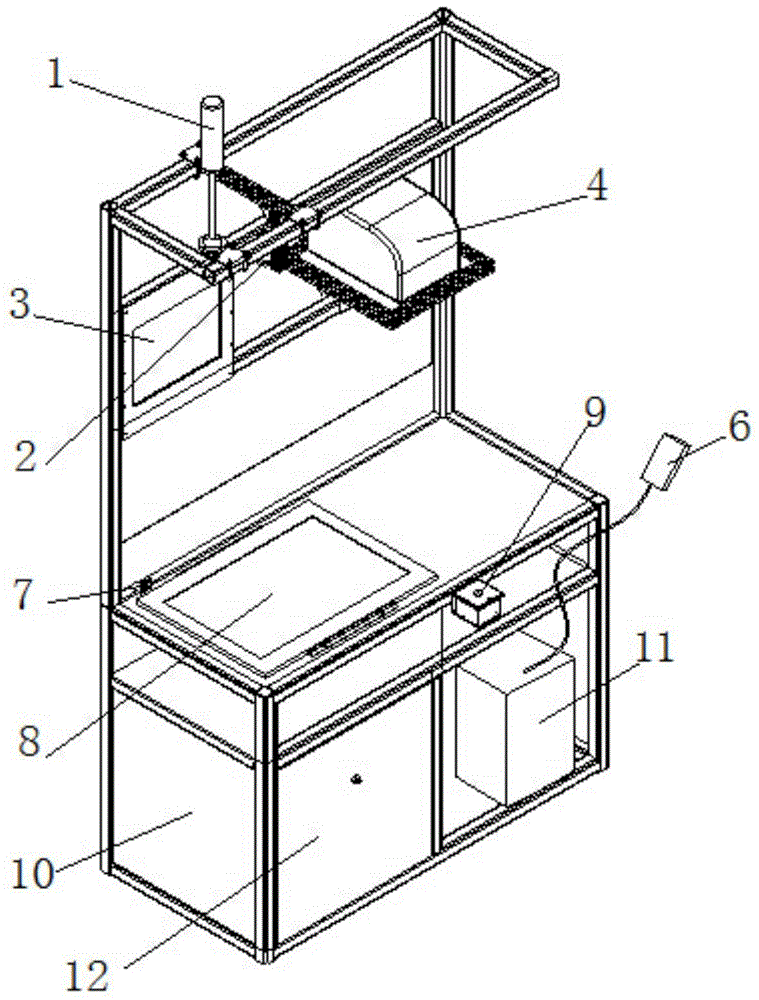

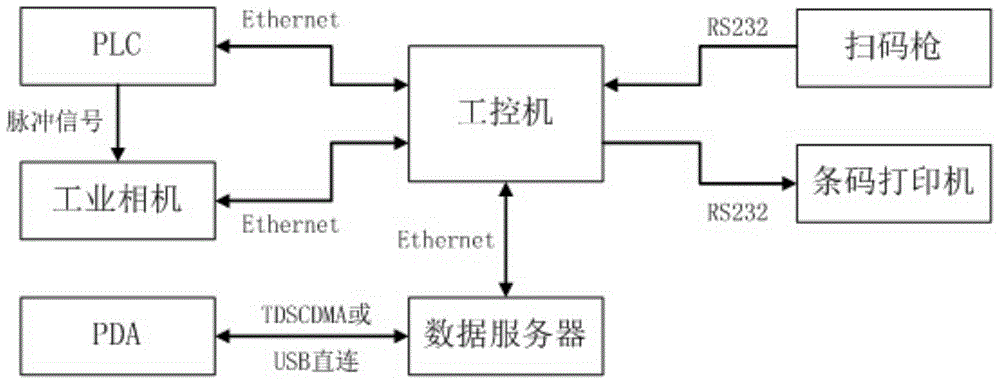

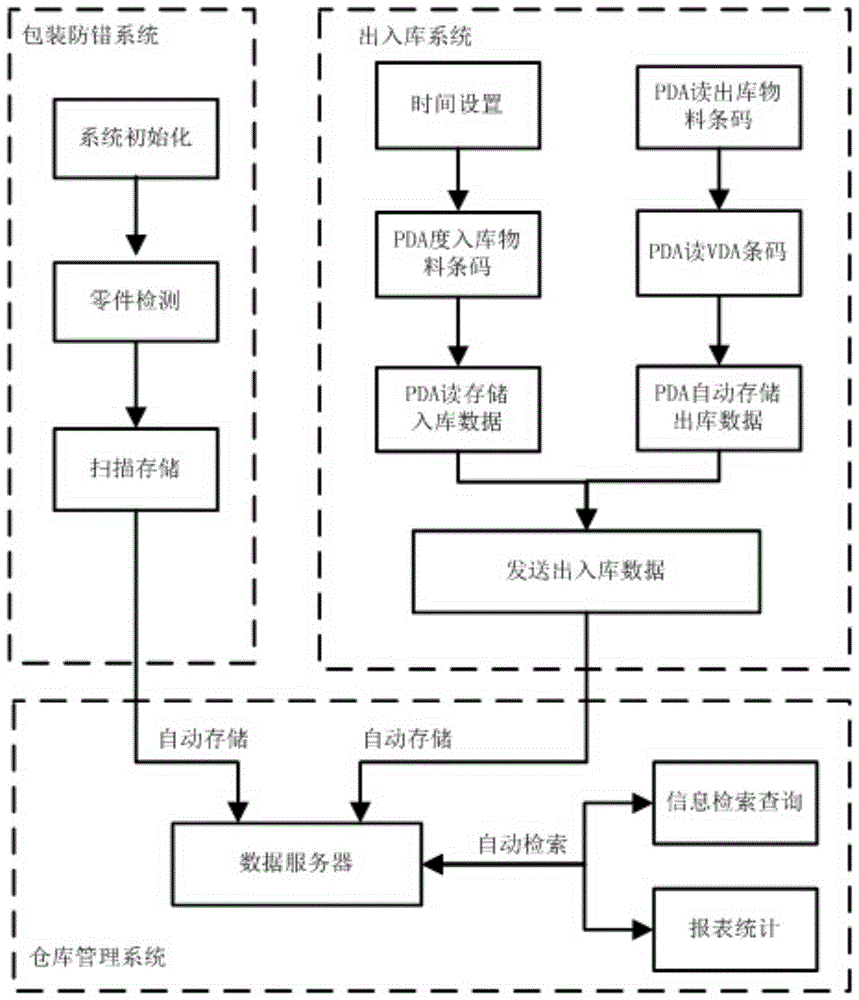

Bearing cover packaging system and control method of bearing cover packaging system

The invention relates to a bearing cover packaging system and a control method of the bearing cover packaging system. The bearing cover packaging system comprises a work table, a packaging mistake proofing system, a warehouse-discharging and warehouse-entering system and a warehouse management system, wherein the left lower part of the work table is provided with an electric control box; a PLC (Programmable Logic Controller) and an industrial personal computer are arranged in the electric control box; the right lower part of the work table is provided with a data server; the right side of the middle part of the work table is provided with a button box; the left side of the middle part of the work table is provided with a light source; the back side of the light source is fixedly provided with an electro-optic switch; the left upper side of the work table is provided with a touch display connected with the industrial personal computer; the right upper side of the work table is provided with a barcode printer; the upper end of the work table is provided with a warning lamp and an industrial camera; the data server is connected with a PDA (Personal Digital Assistant); and the data server is connected with the industrial personal computer. Various bearing covers in different models can be detected, packaged and managed. The bearing cover packaging system and the control method of the bearing cover packaging system have the advantages that the operation is simple; the reliability is high; and the effective management and control on the material warehouse-discharging and warehouse-entering operation and the material warehouse by enterprises are guaranteed.

Owner:WUHU HIT ROBOT TECH RES INST

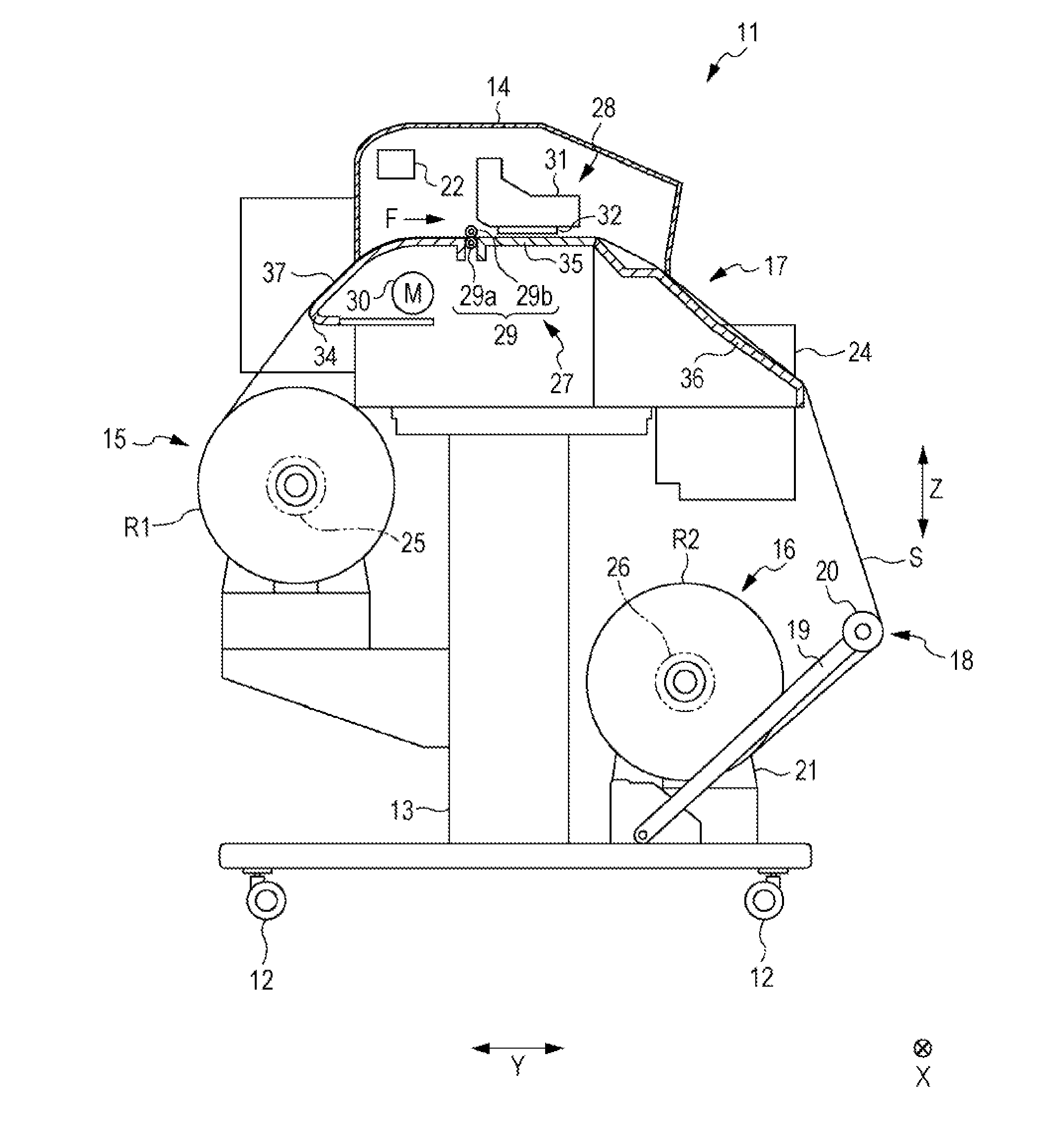

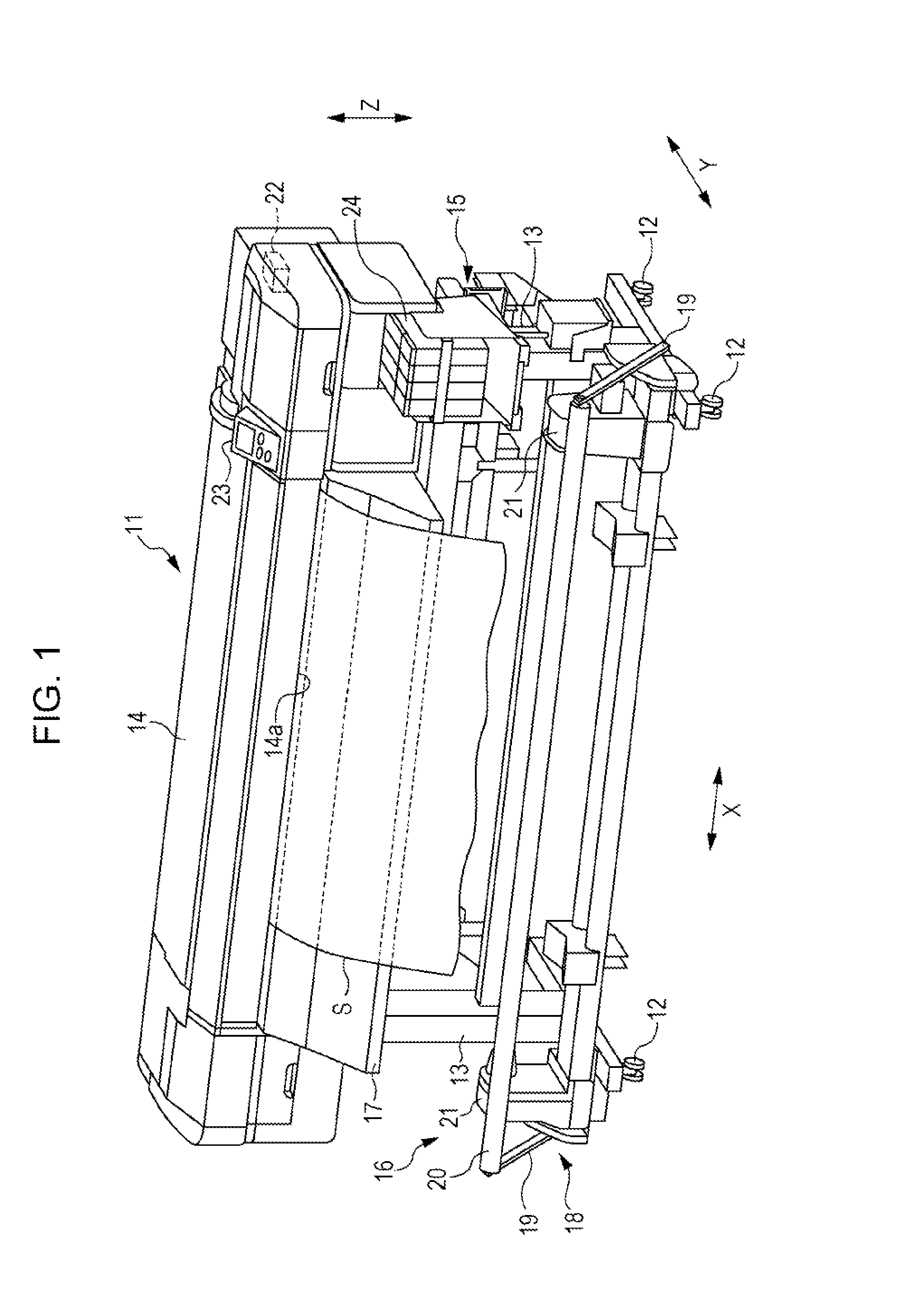

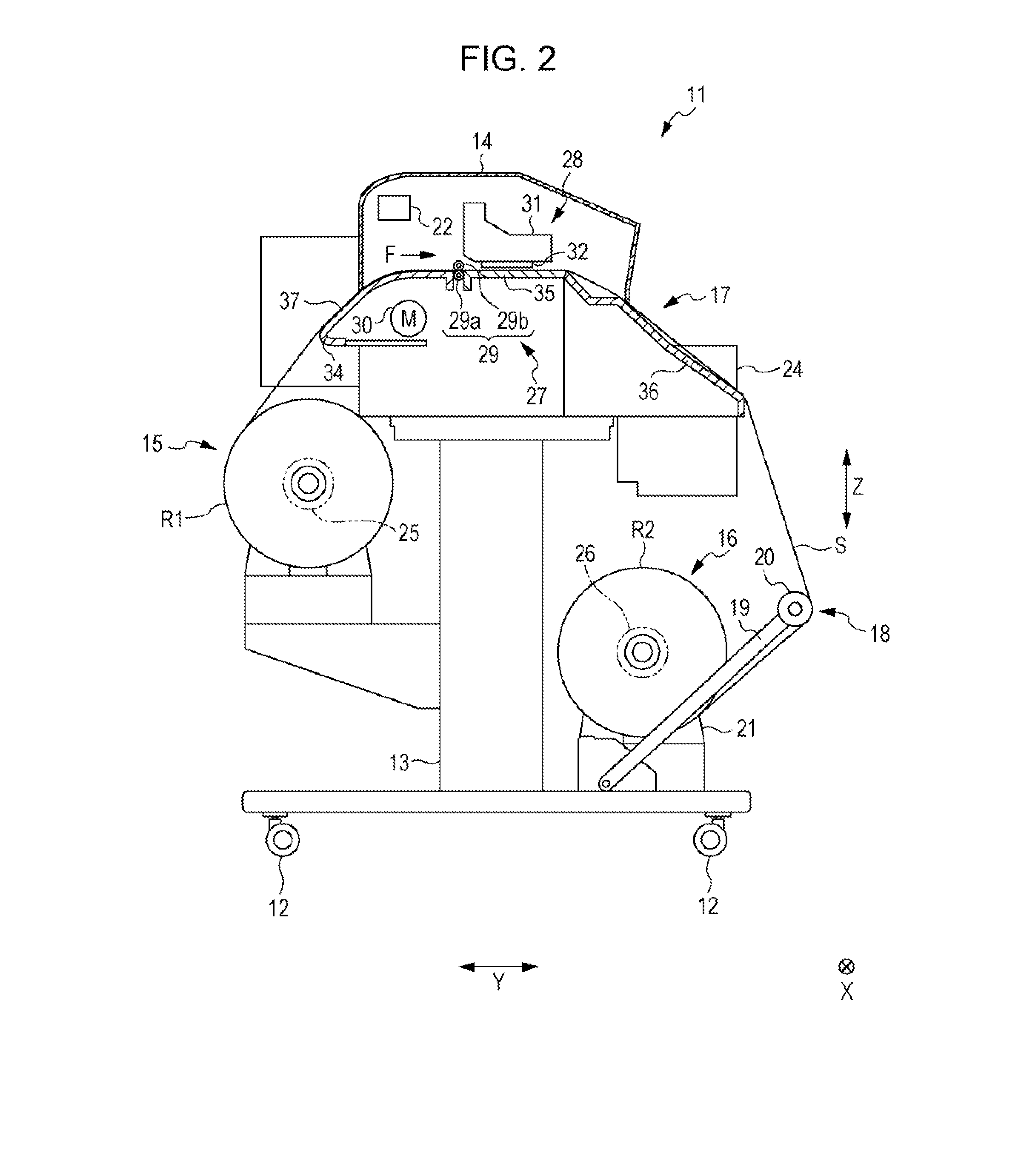

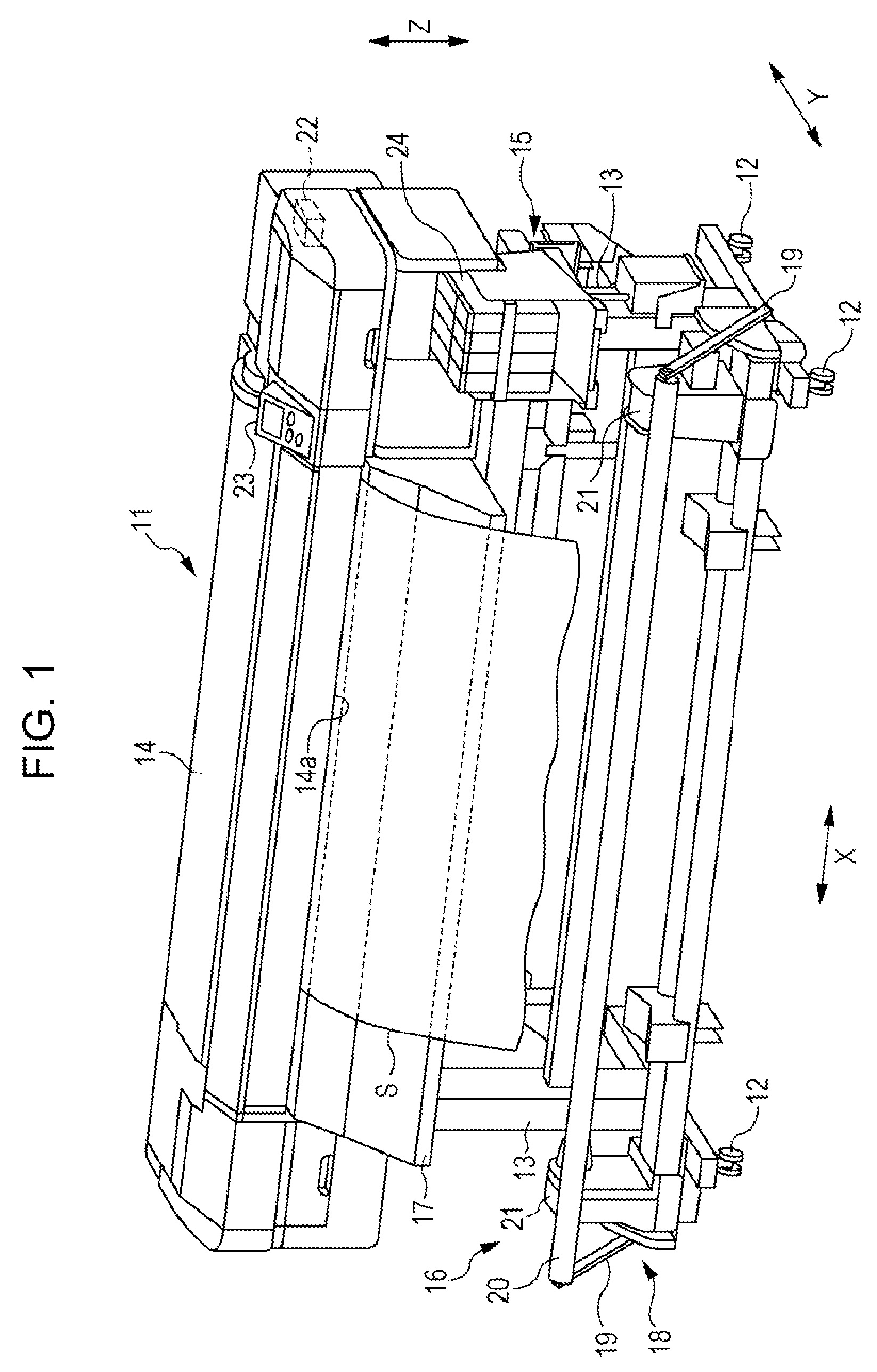

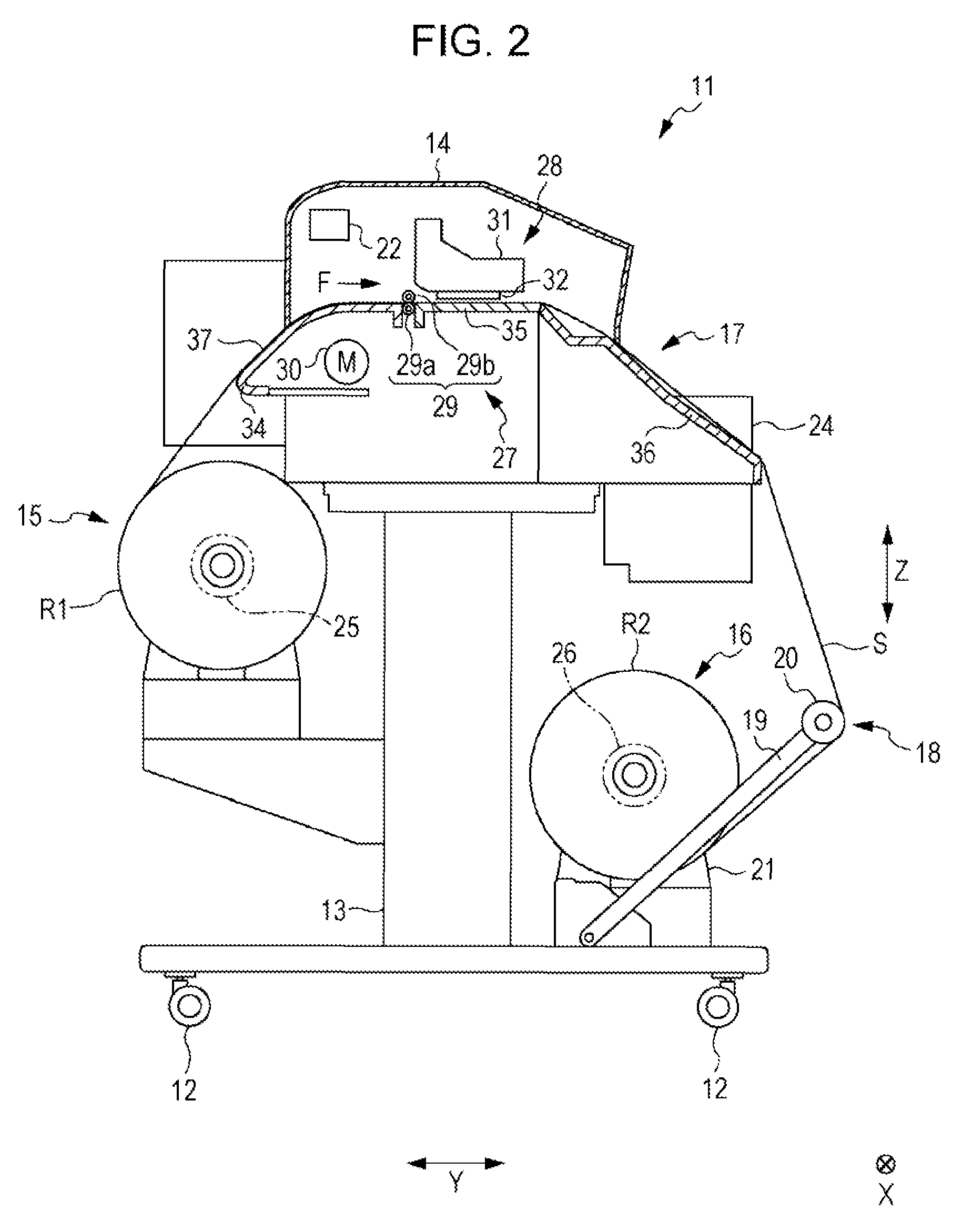

Transporting apparatus and recording apparatus

ActiveUS20140132689A1Suppress generationAvoid contactOther printing apparatusArticle feedersEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Top cover for headset of bicycle

InactiveUS20100096830A1Improve convenienceAvoid componentsFoot-driven leversWheel based transmissionEngineeringHeadphones

A top cover for a headset of a bicycle includes a bottom ring, a side wall, a C-shaped clip and a fastening unit. The side wall extends upwards from the bottom ring. The C-shaped clip extends upwards from a top end of the side wall and has a through hole at each of two distal ends thereof. The fastening unit passes through the through holes of the C-shaped clip for tightening the C-shaped clip. Thus, the top cover of the present invention can enhance convenience of assembly and disassembly of the bicycle, and prevent components of the headset from getting lost during assembly and disassembly of the bicycle.

Owner:TANGE SEIKI TAICHUNG

Industrial data acquisition device and system

ActiveCN111797957AAvoid missing partsClear scanning angleCo-operative working arrangementsElectromagnetic wave reradiationLogistics managementSoftware engineering

The invention discloses an industrial data acquisition device. The industrial data acquisition device comprises a conveying platform, follow-up corner code scanning devices and a material overturningdevice, two groups of follow-up corner code scanning devices are arranged on the conveying platform front and back, and each follow-up corner code scanning device comprises a first infrared distance measuring sensor, a movable mounting bracket and an arc code scanning assembly, each arc code scanning assembly comprises a code scanning swing arm capable of doing arc motion, an upper edge code scanning gun is arranged at the swing arm end of each code scanning swing arm, a side end code scanning gun is further arranged on each movable mounting bracket, when the first infrared distance measuringsensors sense that materials pass through the stroke range of the movable mounting brackets, the movable mounting brackets and the materials are synchronously conveyed, and the code scanning swing arms scan codes of the materials around the materials by means of the upper edge code scanning gun by half a circle. The material turnover device is arranged between the two follow-up corner code scanning devices and used for turning over materials on the conveying platform, and the system further comprises a logistics database and a data processing module. Te express delivery code scanning precisioncan be improved, and the express delivery missing phenomenon in the express delivery statistics process is avoided.

Owner:南京信云智能制造科技有限公司

Dental bite construction for performance enhancing mouth guards

An improved performance enhancing mouth guards having transverse pins embedded in the right and left posterior occlusal base portion of the mouth guard, is disclosed.

Owner:QUIGLESS KIRK C

Transporting apparatus and recording apparatus

ActiveUS9308748B2Suppress generationAvoid contactOther printing apparatusArticle feedersMechanical engineering

Owner:SEIKO EPSON CORP

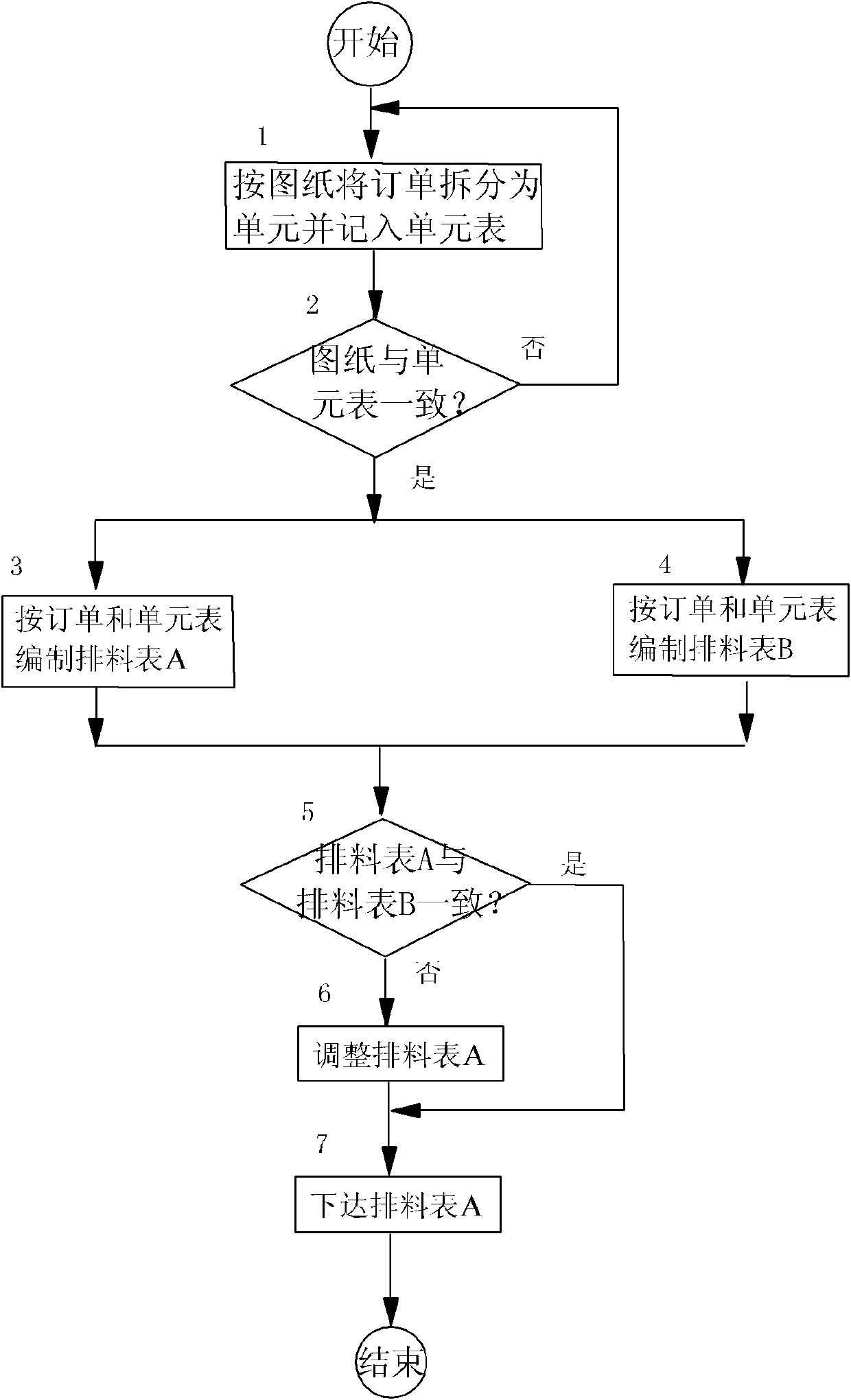

Method for splitting and arranging material for scale customized cupboard order

The invention discloses a method for splitting and arranging material of a scale customized cupboard order, relating to a processing method for production information. The method comprises the following steps: a cupboard order is split into cupboard units pre-stored with an information center based on a drawing; the cupboard units are recorded into an unit table of the cupboard order; a material arranging table A and a material discharging table B are worked out by two different terminals according to the board types, hardware and each standard board information used by all cupboard units of each type with different styles stored in the information center based on the cupboard order and the unit table; whether the material arranging table A is consistent with the material discharging table B is checked by one terminal; if not, the inconsistent items in the material discharging table A and the material arranging table B are checked; the error items in the material arranging table A are corrected and adjusted; the error items are reported to the material arranging table A and the operation is finished. According to the method, the splitting and material arranging process of the order can be managed and controlled in a collective manner completely and accurately by the computer and network communication technology.

Owner:เซี่ยเหมิน โกลเด้นโฮม โค

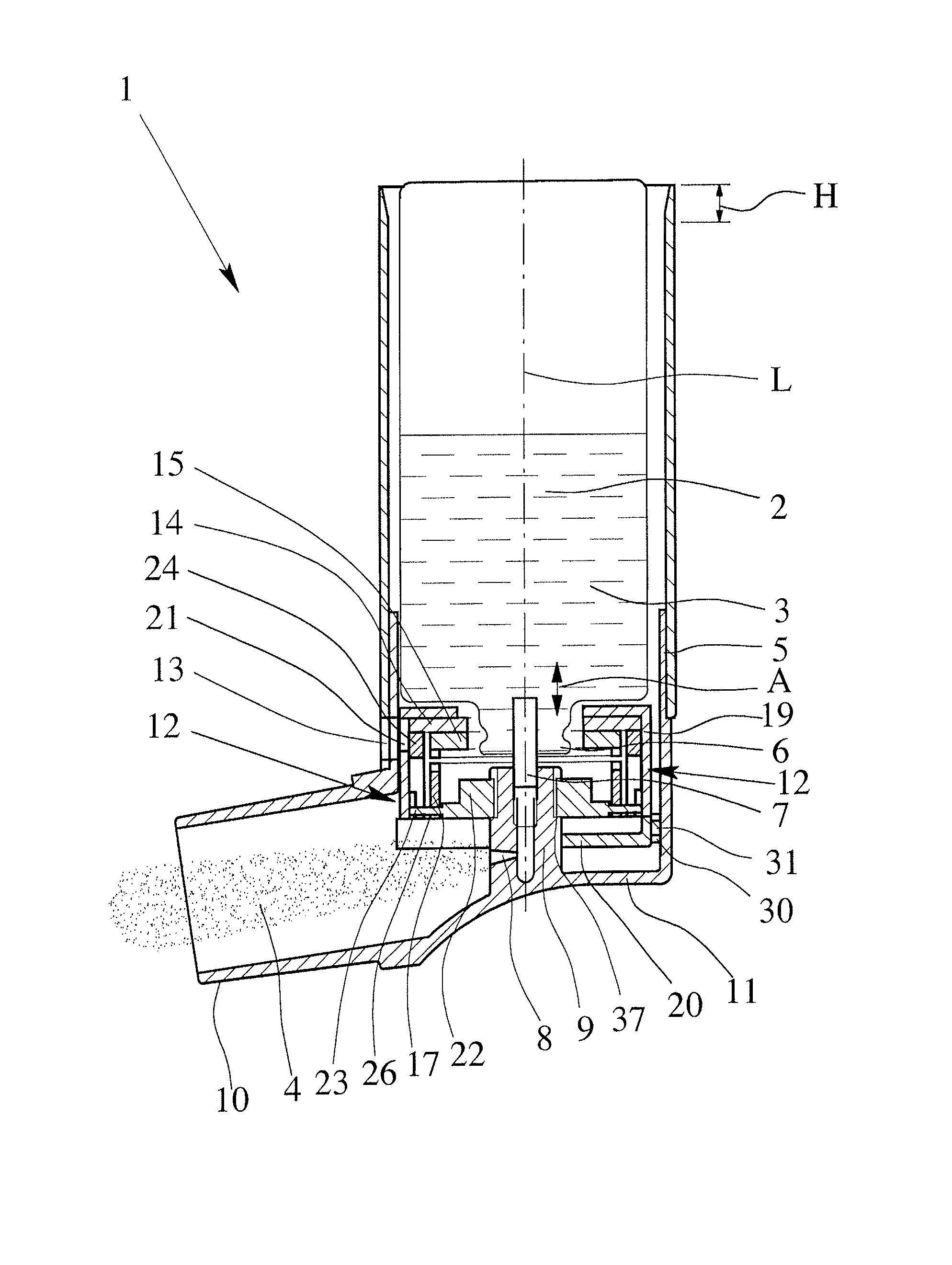

Drive unit for dosage counter

ActiveUS9027547B2Avoid elastic deformationGuaranteed uptimeRespiratorsLiquid transferring devicesNebulizerMedicine

A nebulizer which is a metered dose inhaler for use in administering medicaments with an associated does counter, which can, by way of a guide track or inclined plane and an associated guide element, cause an axial movement occurring on actuation of the nebulizer to be partly converted into a rotary movement for driving a counting ring, which can count both complete and incomplete actuations.

Owner:BOEHRINGER INGELHEIM INT GMBH

Multifunctional equipment used for glass bottle

The invention relates to the technical field of glass bottle detecting, in particular to multifunctional equipment used for a glass bottle. The multifunctional equipment comprises a rotating plate, a rotating motor, a feeding channel, a discharging channel and photographing devices and further comprises a computer detecting system and a control device. The upper end of the rotating motor is connected with a lifting mechanism connected with the control device. A driving mechanism is arranged on a rotating shaft. A plurality of through holes are formed in the rotating plate in the circumferential direction. A fixing cylinder of which the two ends are located outside each through hole is arranged in each through hole. The fixing cylinders are connected with the rotating shaft through the driving mechanism. A water inlet pipe of which the lower end is located in each fixing cylinder is arranged on each fixing cylinder. Water bags covering the outer side walls of the fixing cylinders are arranged on the fixing cylinders. A plurality of water outlet holes communicating with the interiors of the fixing cylinders and the water bags are formed in the side walls of the fixing cylinders. Water pressure control valves are further arranged at the lower ends of the fixing cylinders. The problem that an existing mechanical arm can be only applied to a glass bottle of a specific type can be solved through the multifunctional equipment.

Owner:CHONGQING CONGBO ENERGY SAVING GLASS CO LTD

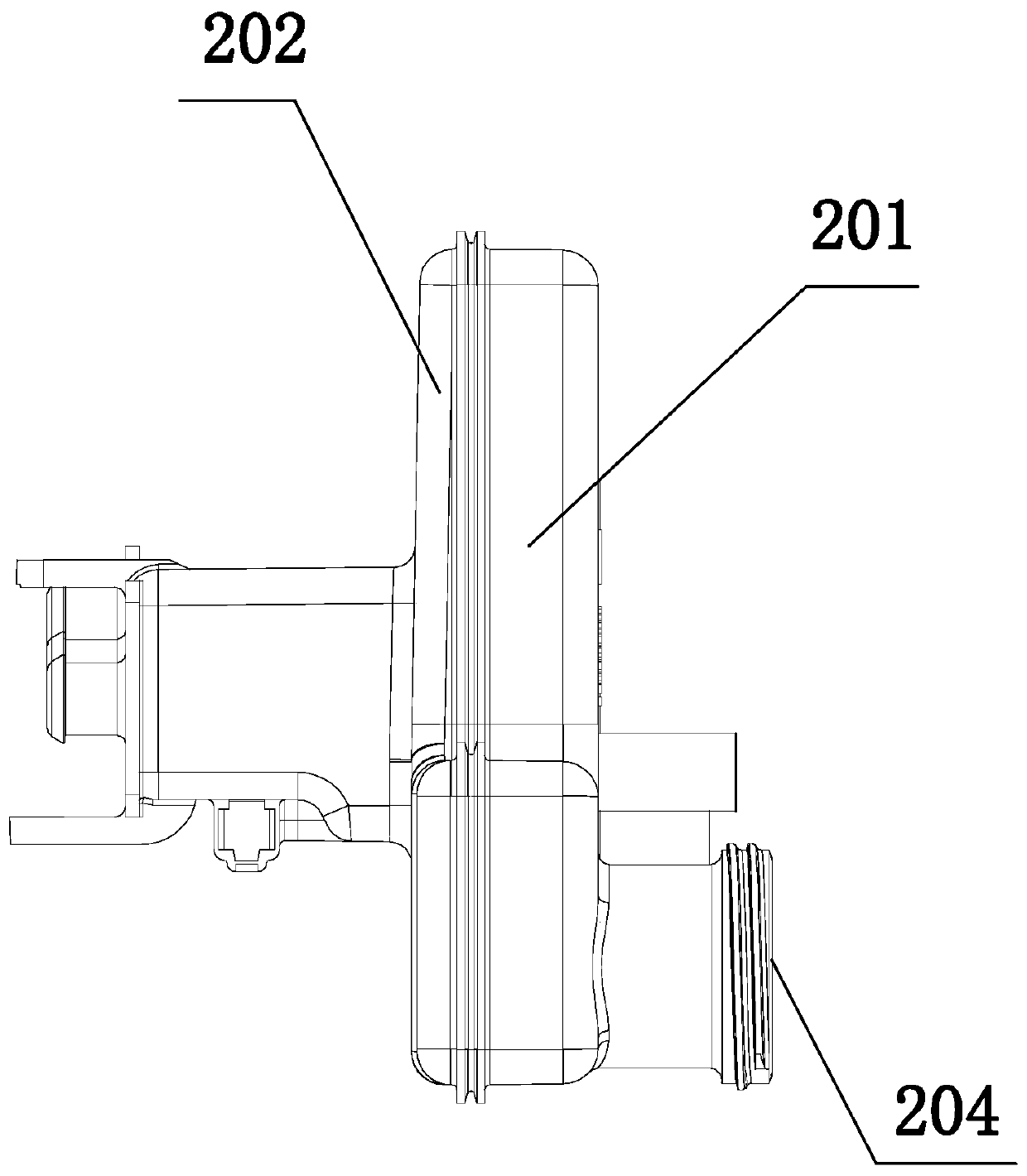

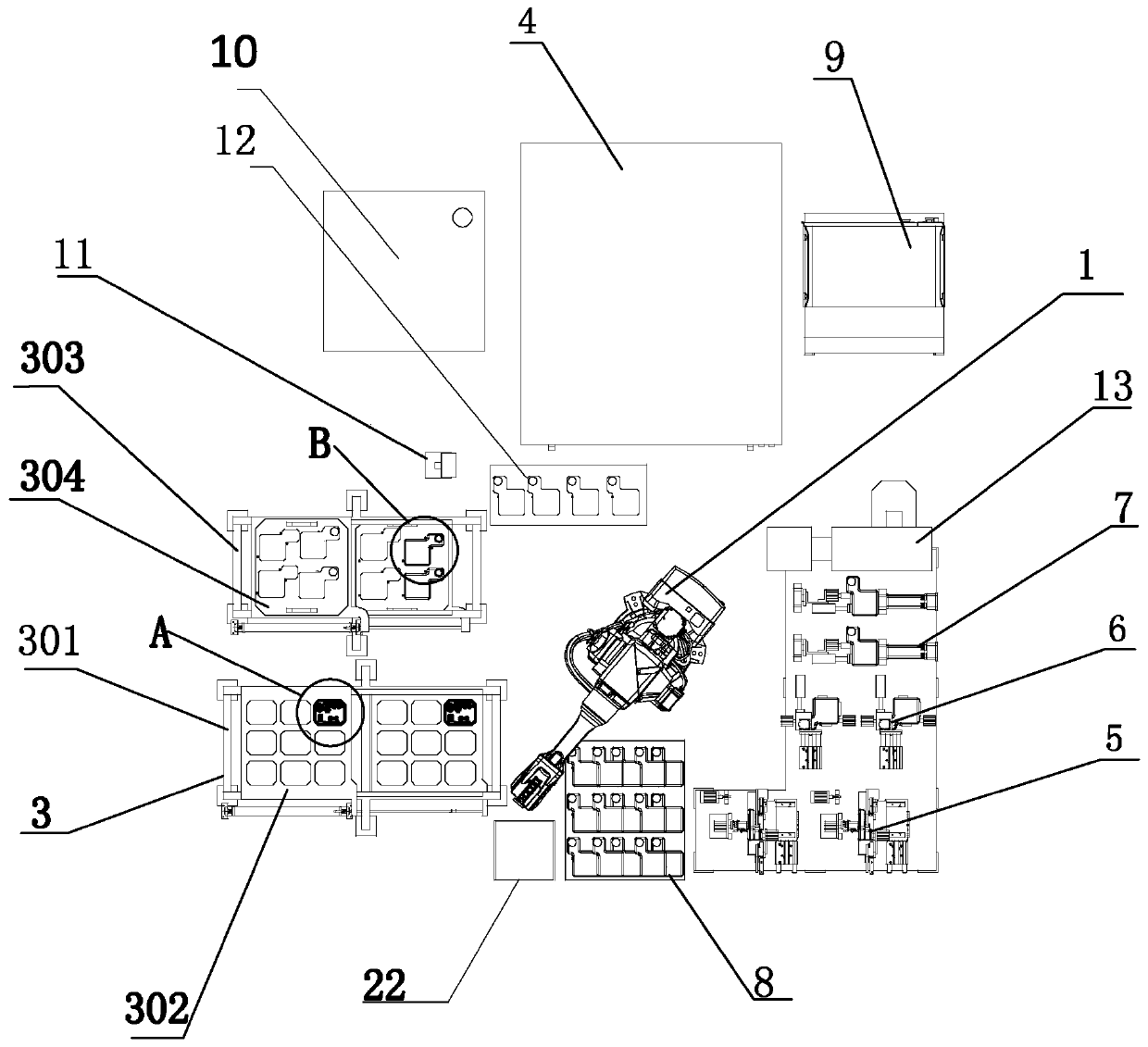

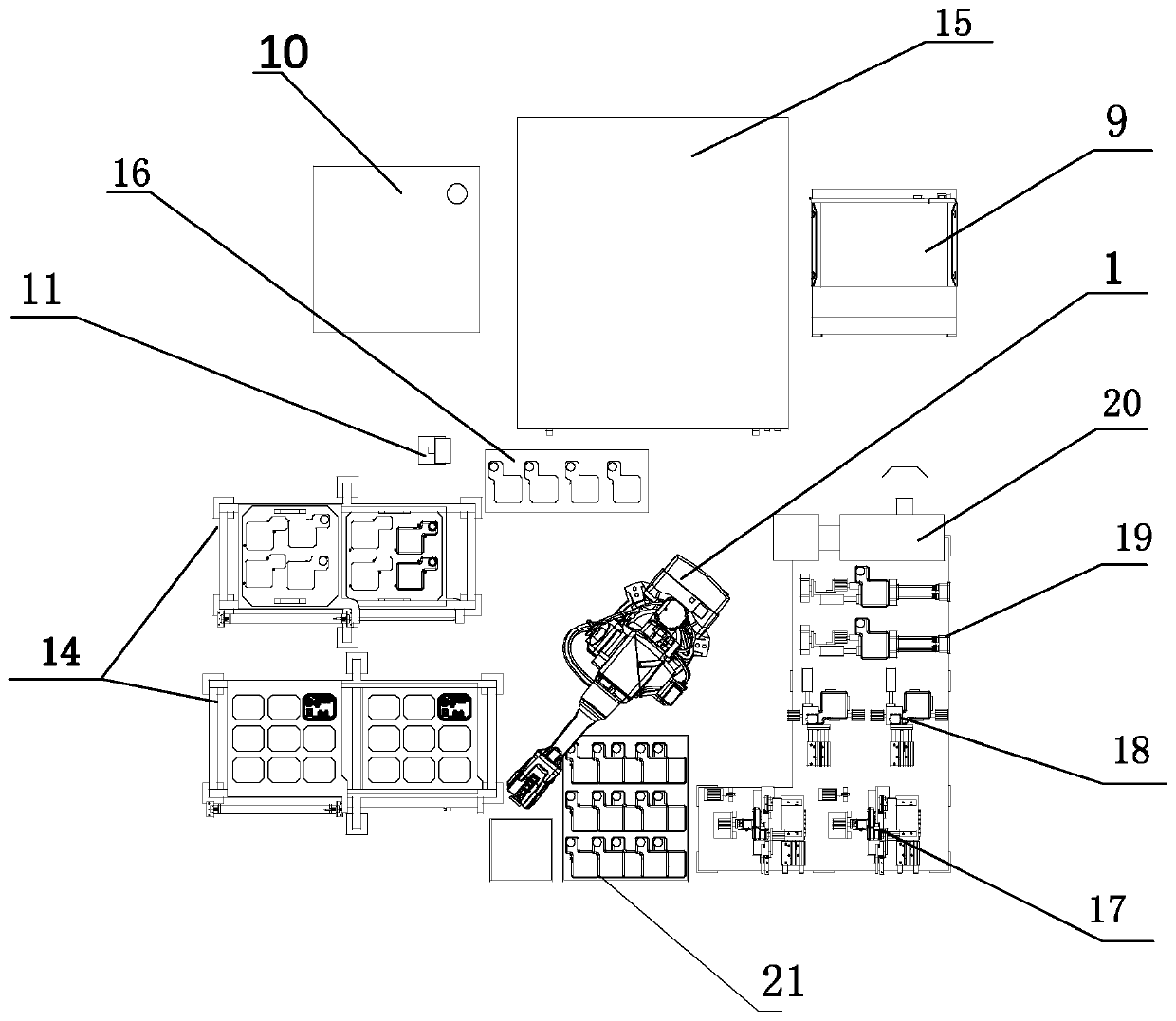

Automatic oil pot assembly detection production line

PendingCN110103480AIncrease productivityReduce labor costsMachine part testingMeasurement of fluid loss/gain rateProduction lineRobotic systems

The invention discloses an automatic oil pot assembly detection production line, and belongs to the technical field of automatic oil pot assembly detection. The production line comprises a product robot system, a feeding system, a servo welding machine, two air tightness detection machines, two sensor drawing force test machines and two overturning on-off test machines, wherein the product robot system is arranged at the middle of the production line; the feeding system is arranged at the left side of the robot system; the servo welding machine is arranged behind the robot system; the air tightness detection mechanisms, the sensor drawing force test mechanisms and the overturning on-off test mechanisms are arranged at the right side of the robot system; a material receiving frame system isarranged in front of the robot system; and the robot system is used for clamping workpieces and delivering the workpieces among station devices so as to achieve automatic operation. The production line has the beneficial effects that the production efficiency is improved, the labor cost is reduced, the risk of gouges and damage by man is reduced, the situations of manual missing parts, misjudgment and the like are avoided, and the production line is suitable for the requirements of mass production and modern management.

Owner:浙江乔士智能工业股份有限公司

Microprocessor memory management

ActiveUS8117490B2Avoid missing partsError detection/correctionRead-only memoriesControl systemBraking system

A memory for an electronic brake control system is divided into portions that are classified as critical and non-critical. Each portion is periodically tested for faults. Upon detection of a fault, the memory is reconfigured with any operations of the brake system associated with a critical memory portion permanently disabled and any operations of the brake system associated with a non-critical memory portion temporarily disabled.

Owner:KELSEY HAYES CO

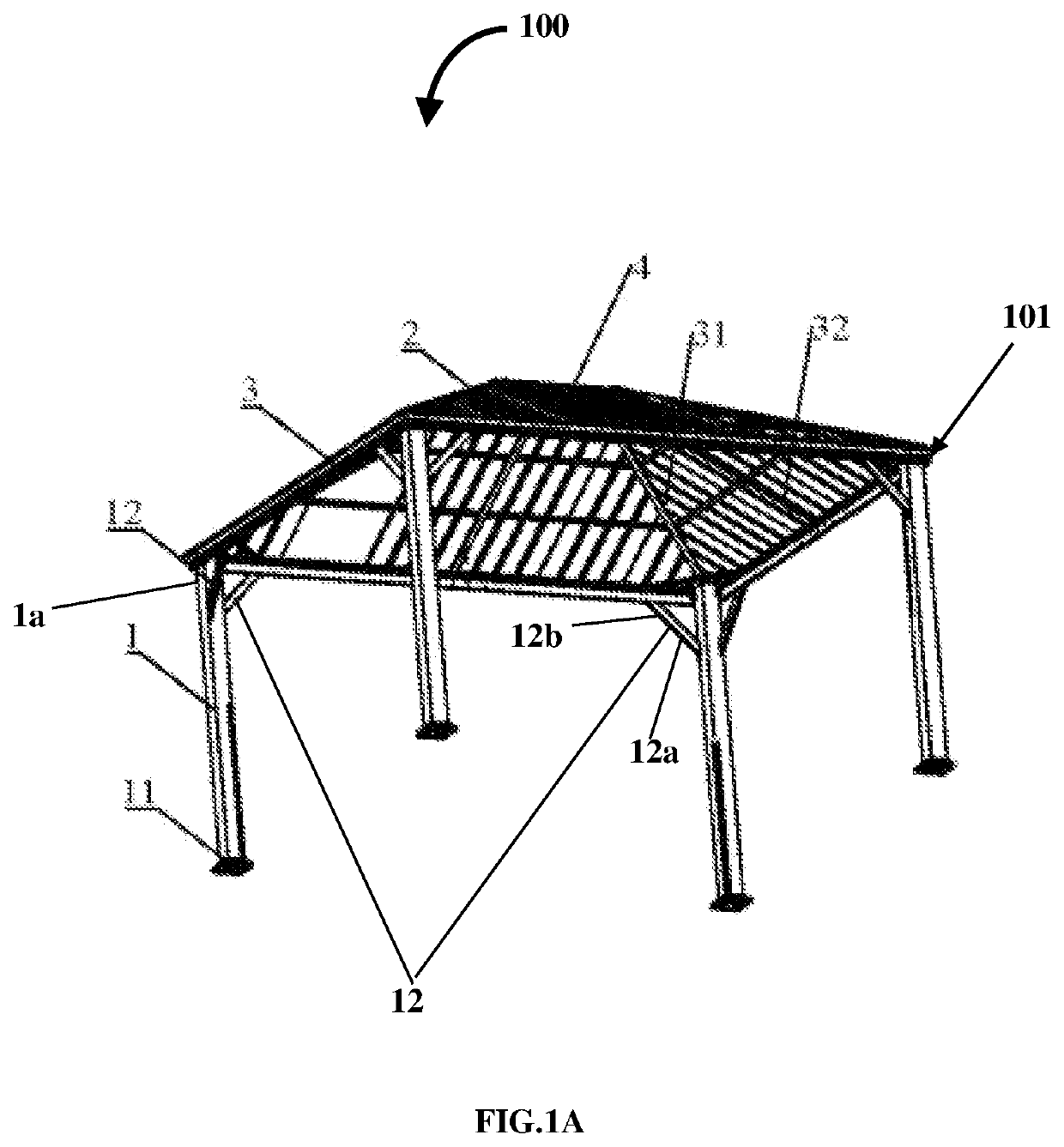

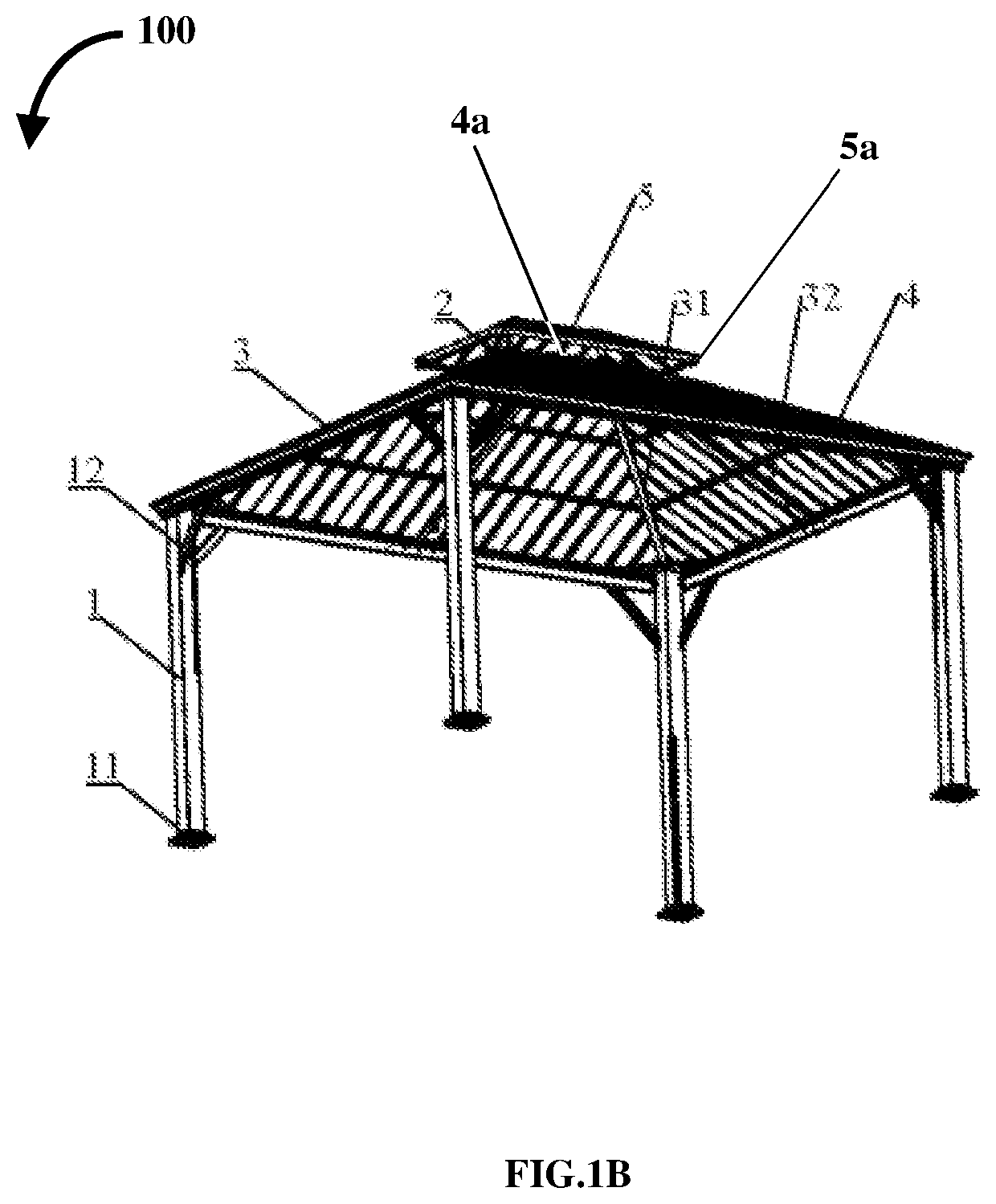

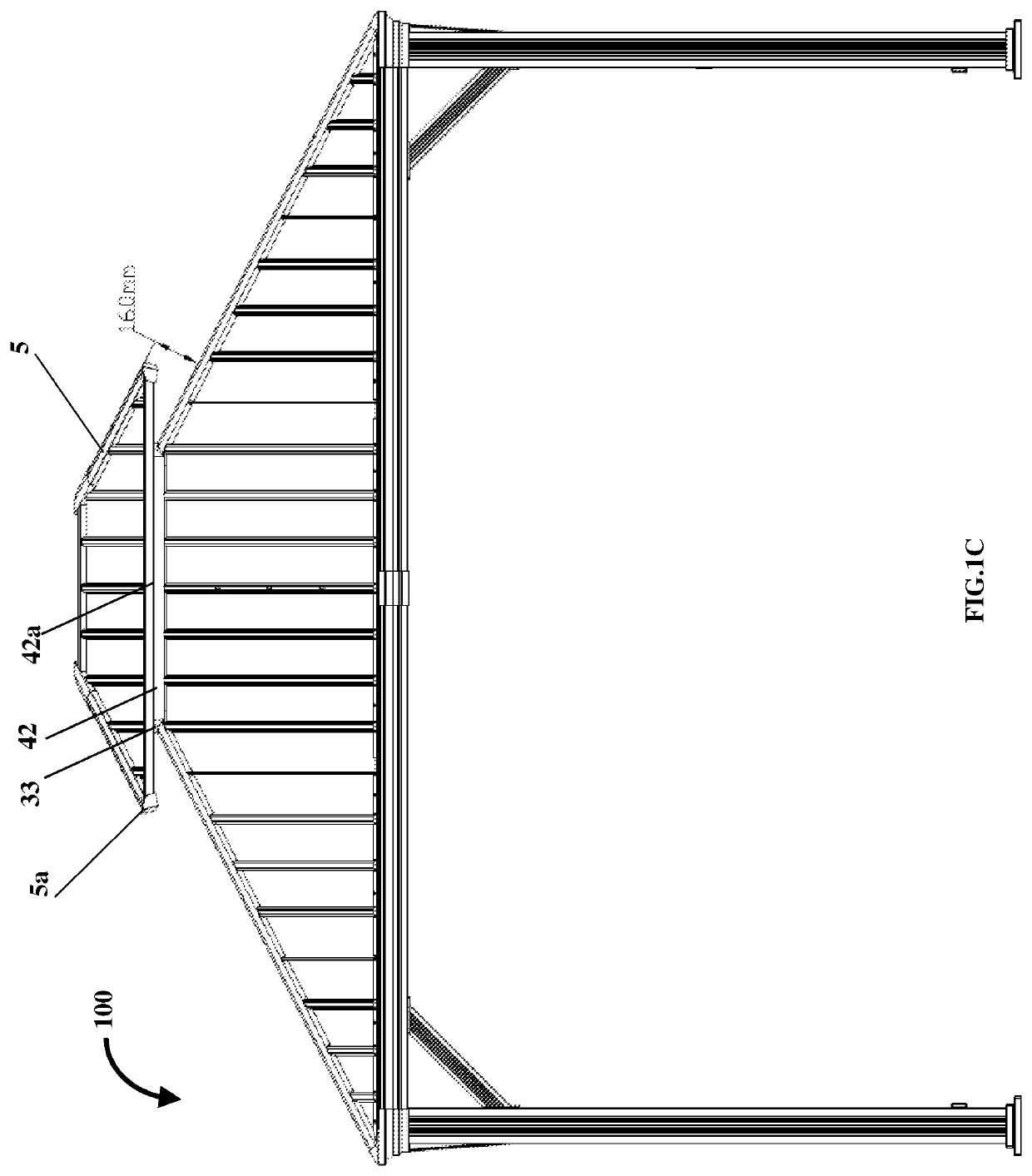

Sunshade tent

ActiveUS20210396038A1Easy to installNumber of loss and incorrectUmbrellasTents/canopiesClassical mechanicsStructural engineering

A sunshade tent comprises a frame assembly and sheet assemblies. The frame assembly comprises legs, first and second rafters. Each of the legs comprise a first connection mechanism, horizontal connecting members configured to be fixedly attached to a first end of each of the legs, and a mounting base positioned proximal a second end of each of the legs. The first rafters are detachably attached to a corresponding one of the legs via the first connection mechanism at an inclination relative to the horizontal connecting members. At least one of the second rafters is fixedly attached to a corresponding one of the horizontal connecting members via second interlocking elements. Each of the sheet assemblies comprise grooves for detachably attaching to a corresponding one of the second rafters via first interlocking elements.

Owner:ZHEJIANG YOTRIO GRP CO LTD

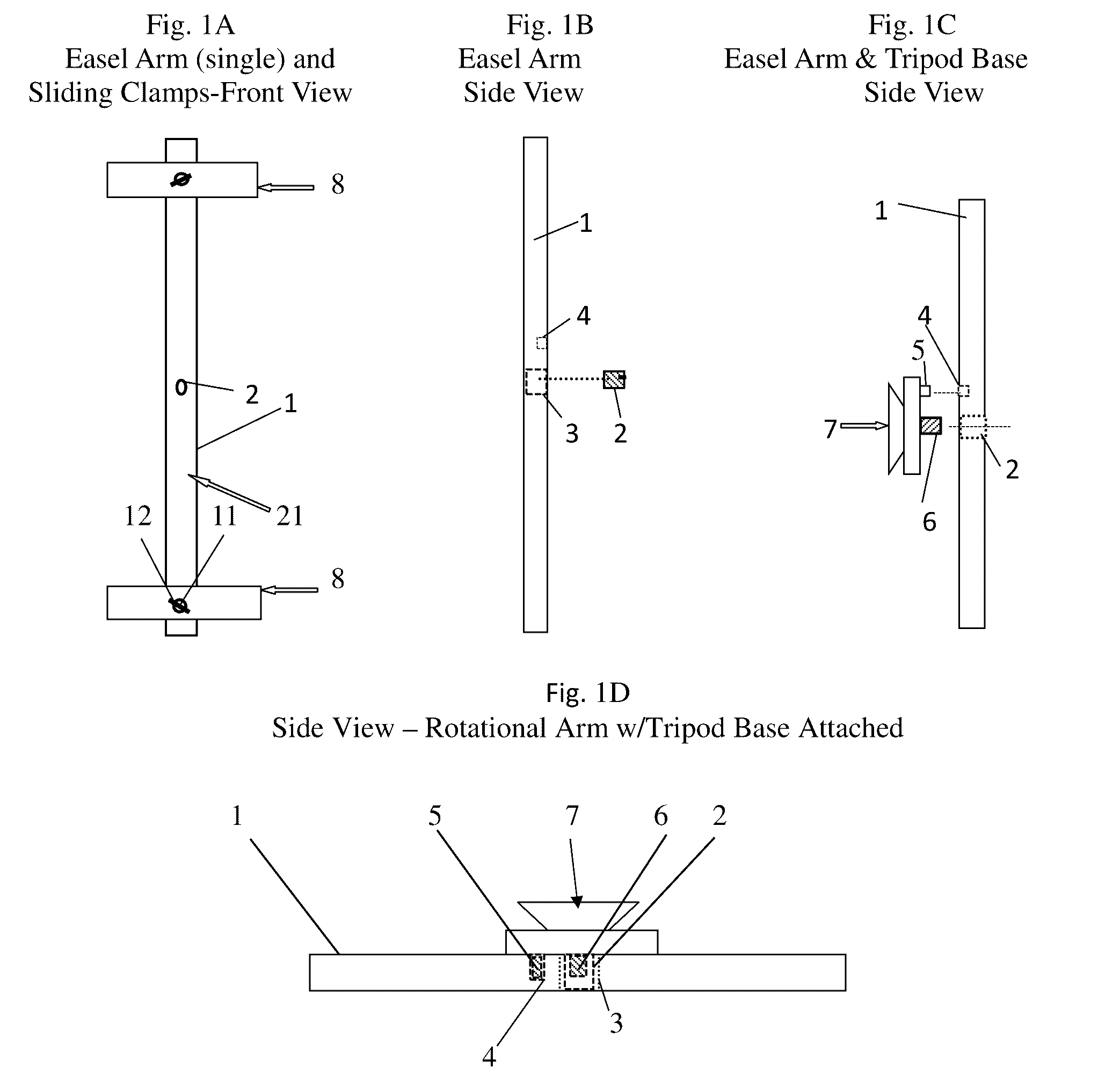

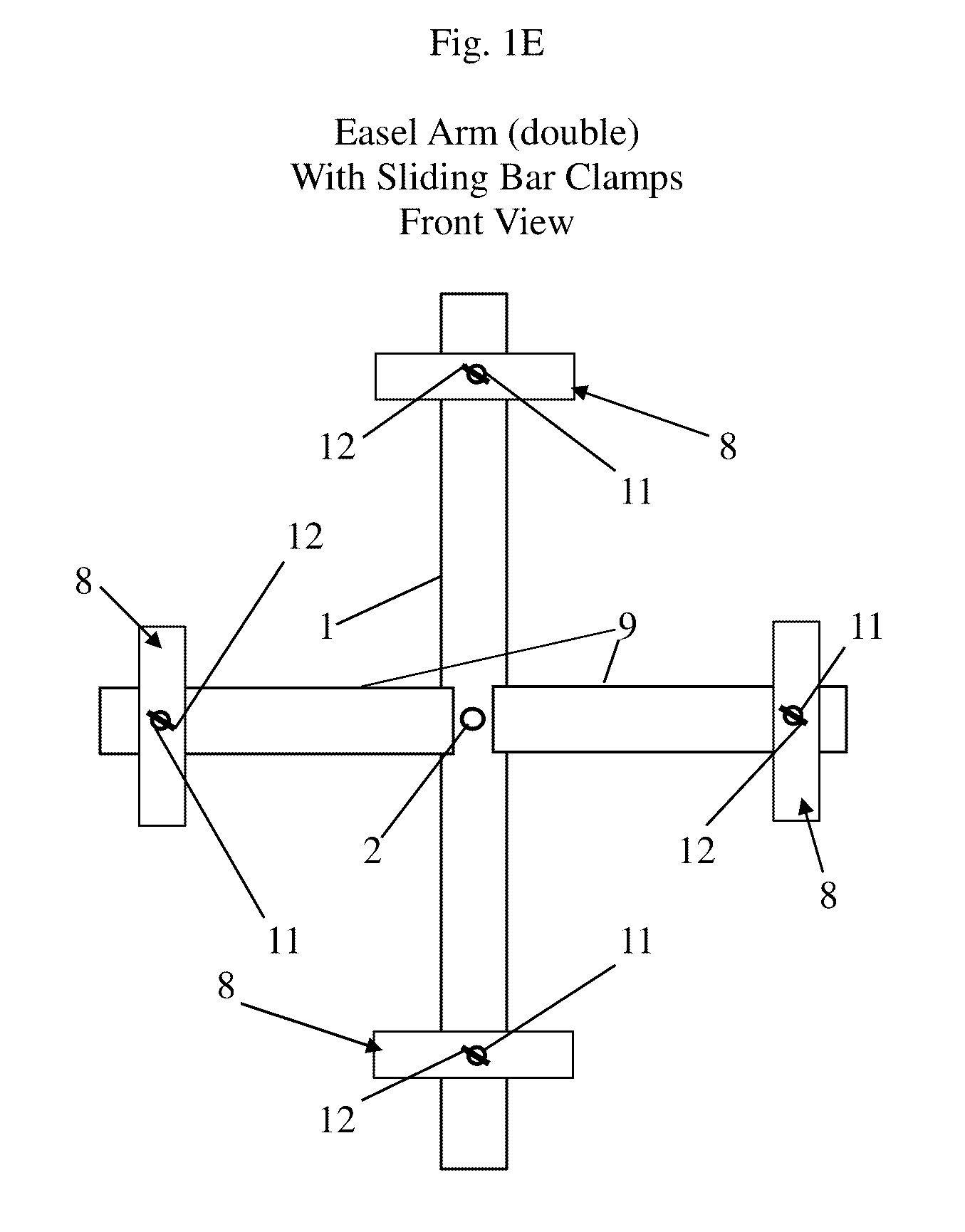

Easel with a built-in Connecting Device for a Mounting Mechanism

Owner:SELWA ROBERT ALLEN

Jig box for railway fastener bulk vehicle

ActiveCN111702733AAvoid missing partsAvoid installation deviationRail fastenersWork tools storageBulk storageFastener

The invention discloses a jig box for a railway fastener bulk vehicle. The jig box comprises an assembly jig box and a bulk storage jig box, wherein the assembly jig box comprises an assembly groove,the assembly groove comprises a side low groove formed in one side of the bottom and used for accommodating a stop block to fix the stop block, a low groove formed in the other side of the bottom andused for accommodating a base plate to fix the base plate, and side arc grooves formed in the two sides and used for accommodating elastic strips to fix the elastic strips; the bulk storage jig box comprises a bulk storage groove, the bulk storage groove comprises a tooth groove engaged with the side wall of the assembly jig box, a bottom arc groove used for accommodating the elastic strips to fixthe elastic strips and a middle arc groove formed in the middle of the bottom arc groove and used for accommodating a gasket to fix the gasket, and when the side wall of the assembly jig box is inserted into the tooth groove, the elastic strips can be tightly attached to the side arc groove and the bottom arc groove at the same time. Complete set assembling and complete set transferring of railway fasteners can be achieved, and the industrial efficiency and the operation quality are remarkably improved.

Owner:BAOJI CSR TIMES ENG MACHINERY

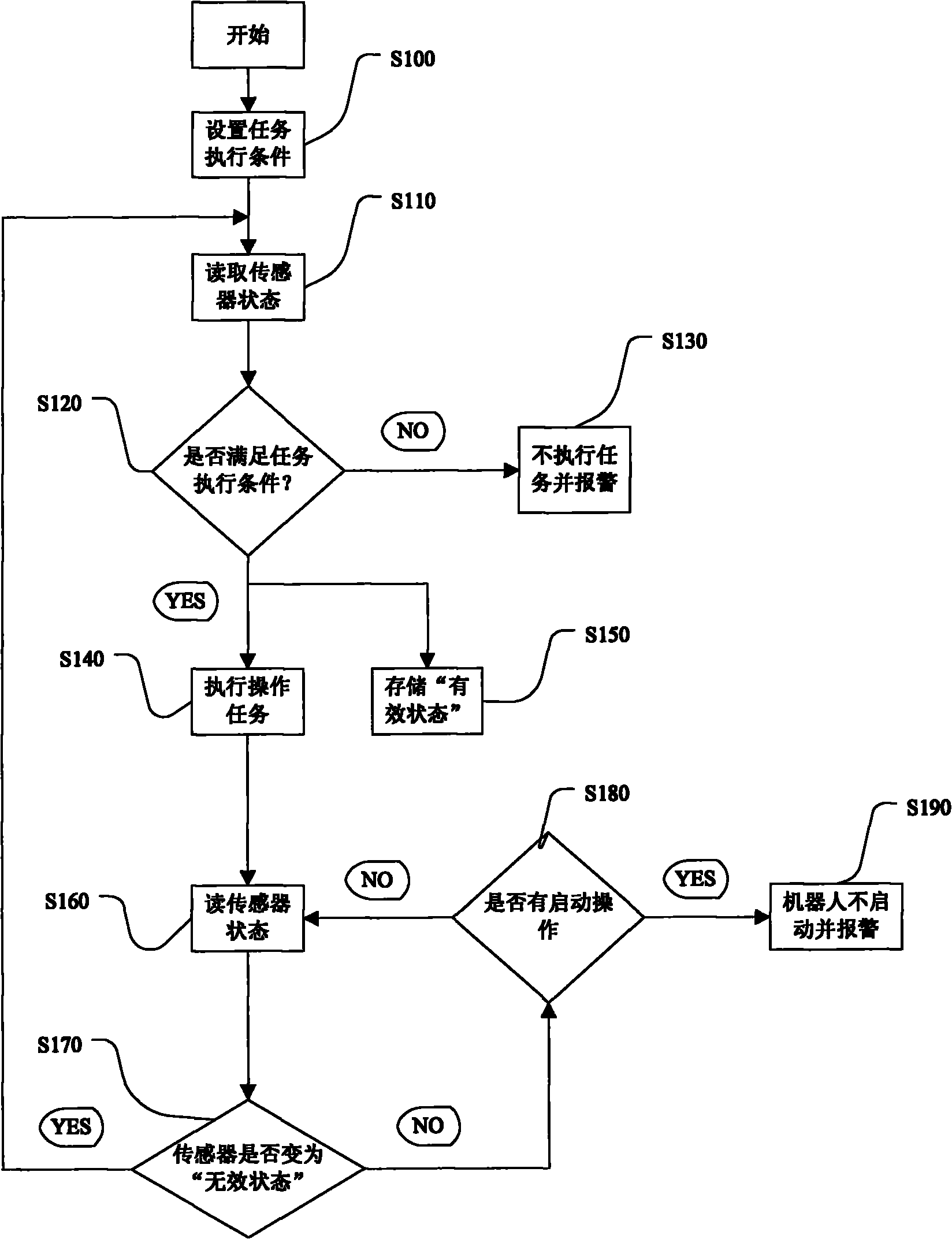

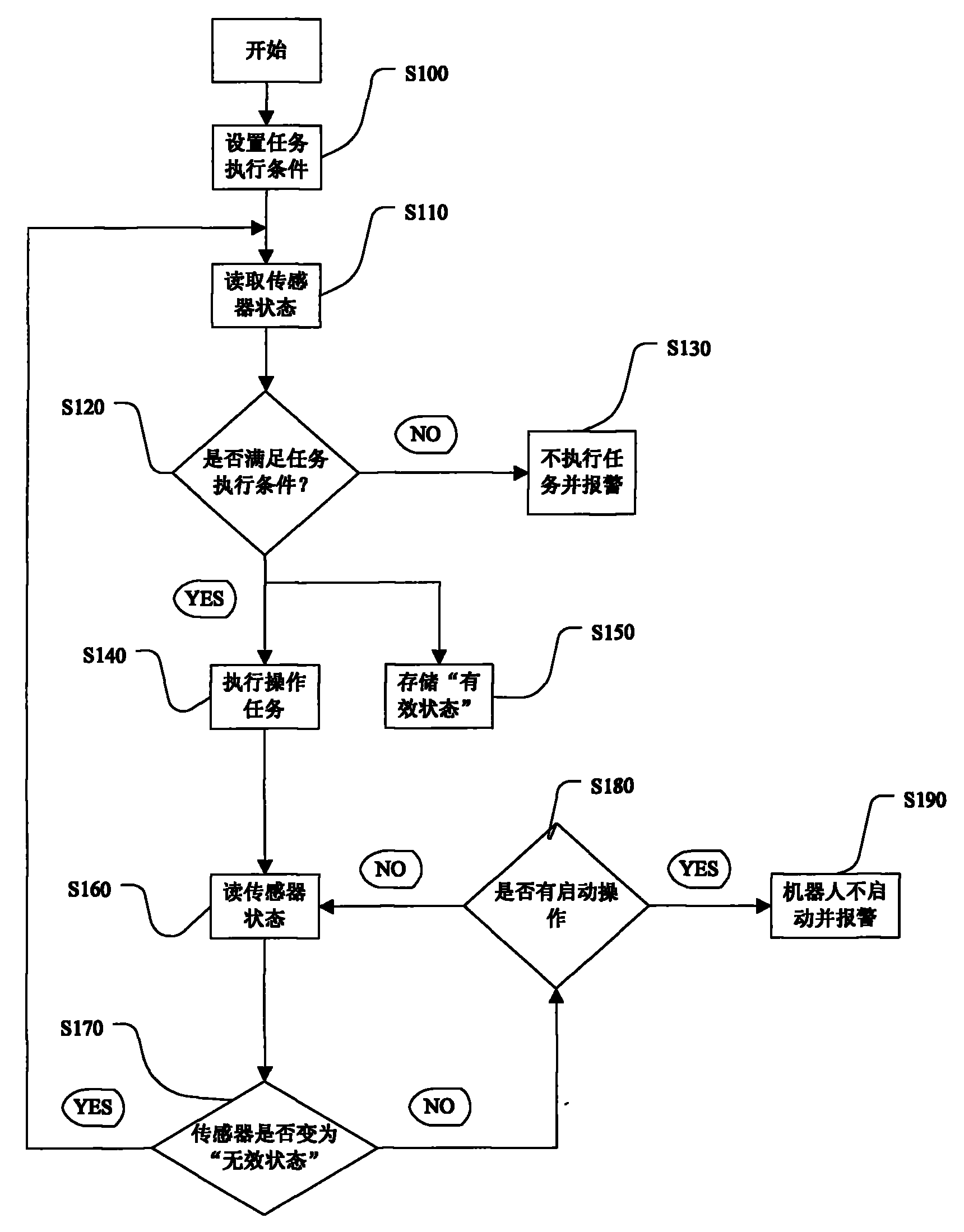

Redundancy error-proofing method of robot

InactiveCN102380874ARaise the level of error proofingImprove yieldManipulatorProgrammable logic controllerSimulation

The invention discloses a redundancy error-proofing method of a robot. The method comprises the following steps of: detecting whether a part is on a workpiece by a sensor; carrying out a corresponding operation task on the part by the robot controlled by an PLC (Programmable Logic Controller); when the robot finishes the operation task once, scanning the state of the sensor; if a conversion state from a 'part' effective state to a 'no-part' ineffective state appears in the state of the sensor, executing the next time of operation task by the robot; or else, stopping executing the next time of operation task. According to the method, the robot can be controlled to stop executing the next time of operation till faults on the sensor are eliminated, therefore the problem of part missing can be avoided, the level of part error proofing is increased, the possibility of part missing is reduced, the finished product rate of the workpiece can be also improved, and the production cost of enterprises is reduced.

Owner:SHANGHAI TRACTOR & INTERNAL COMBUSTION ENGINE

Method of manufacturing semiconductor device and semiconductor device

InactiveUS7378340B2Small thicknessAvoid missing partsSemiconductor/solid-state device detailsSolid-state devicesResistEngineering

The present invention provides a method of manufacturing a semiconductor device and a semiconductor device that allow use of interlayer and interconnect insulating films having a low dielectric constant in forming a dual damascene structure. A first insulating film, a second insulating film, a first-mask forming layer, a second-mask forming layer, a third-mask forming layer, and a fourth-mask forming layer are sequentially deposited over a substrate. The fourth-mask forming layer is patterned to form a fourth mask having an interconnect trench pattern. After a resist mask is formed on the fourth mask, the layers to the second insulating film are etched to open via holes. The third-mask forming layer is etched through the fourth mask to thereby form a third mask having the interconnect trench pattern and to extend the via holes downward partway across the first insulating film. The second-mask forming layer is etched through the fourth mask to thereby form a second mask having the interconnect trench pattern, and the first insulating film that remains under the bottoms of the via holes is removed. Subsequently, the second insulating film is etched through the second mask to thereby form an interconnect trench, and then the second mask is removed.

Owner:SONY CORP

Bioavailable solid state (17-ss;)-hydroxy-4-androsten-3-one esters

ActiveUS20160184320A1Facilitates adequate partitioningEffective oral bioavailabilityOrganic active ingredientsSteroids4-androsten-3-oneKetone

Disclosed are bioavailable solid state (17-β)-Hydroxy-4-Androsten-3-one esters suitable for pharmaceutical uses and administration to mammals in need of (17-β)-Hydroxy-4-Androsten-3-one.

Owner:LIPOCINE

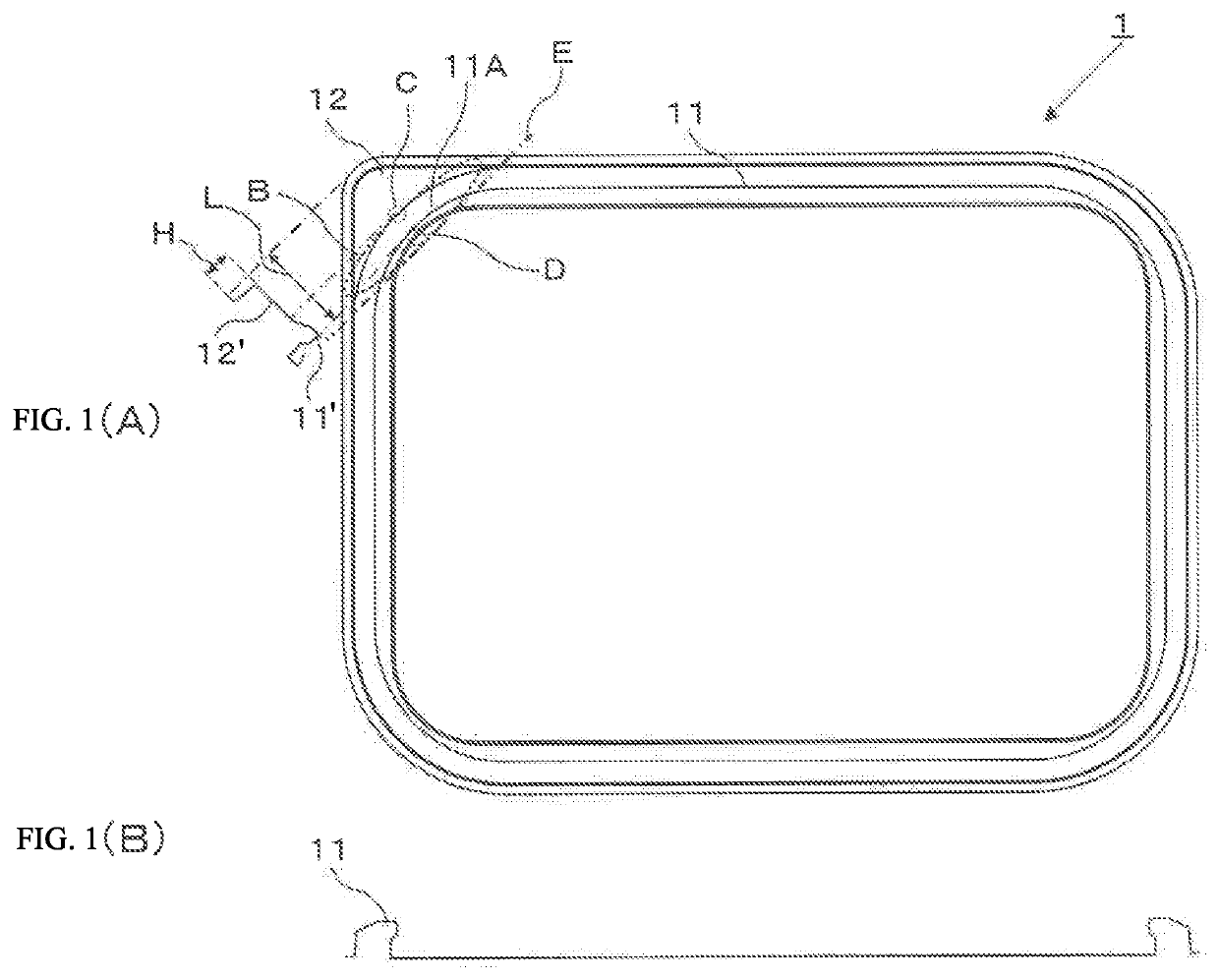

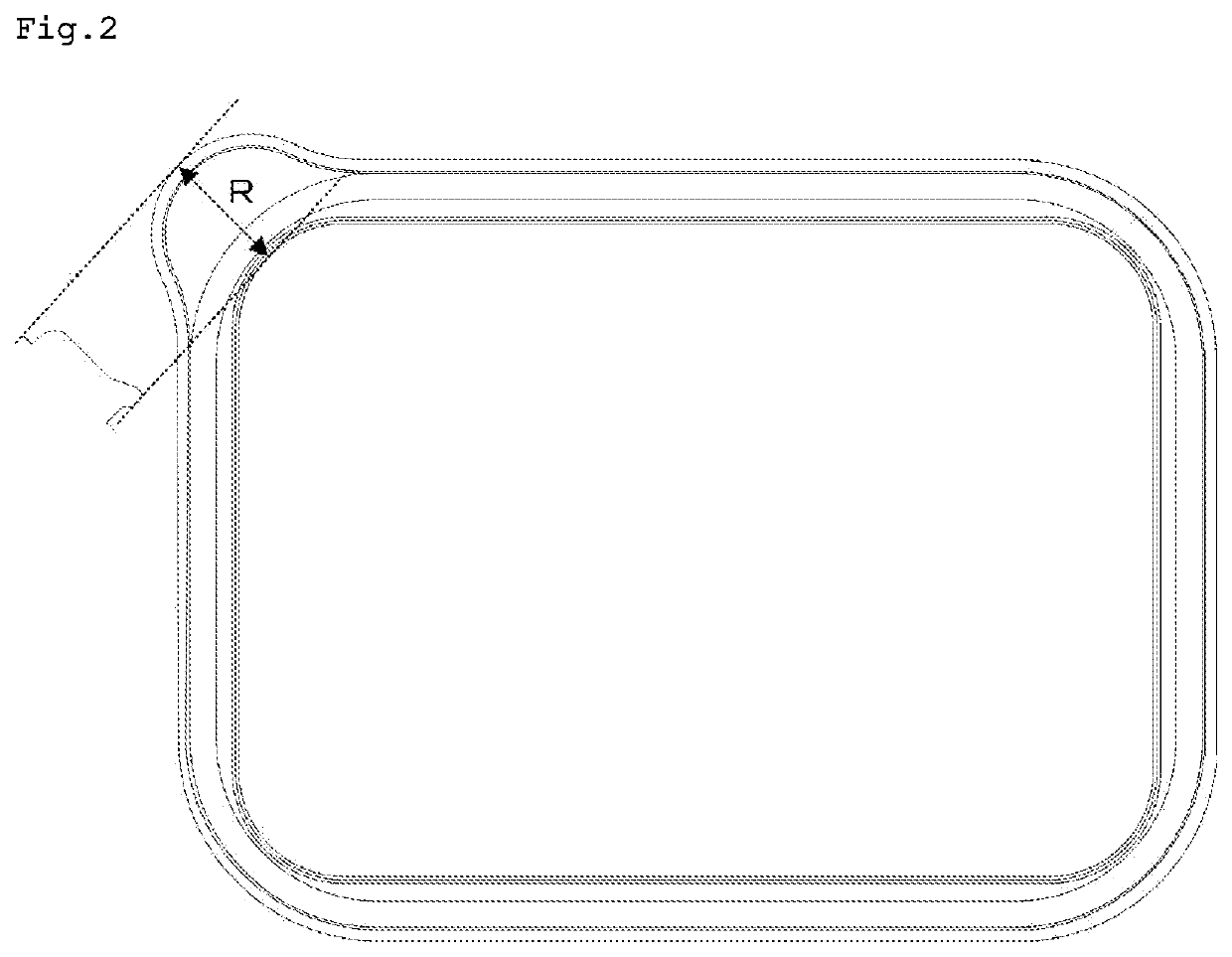

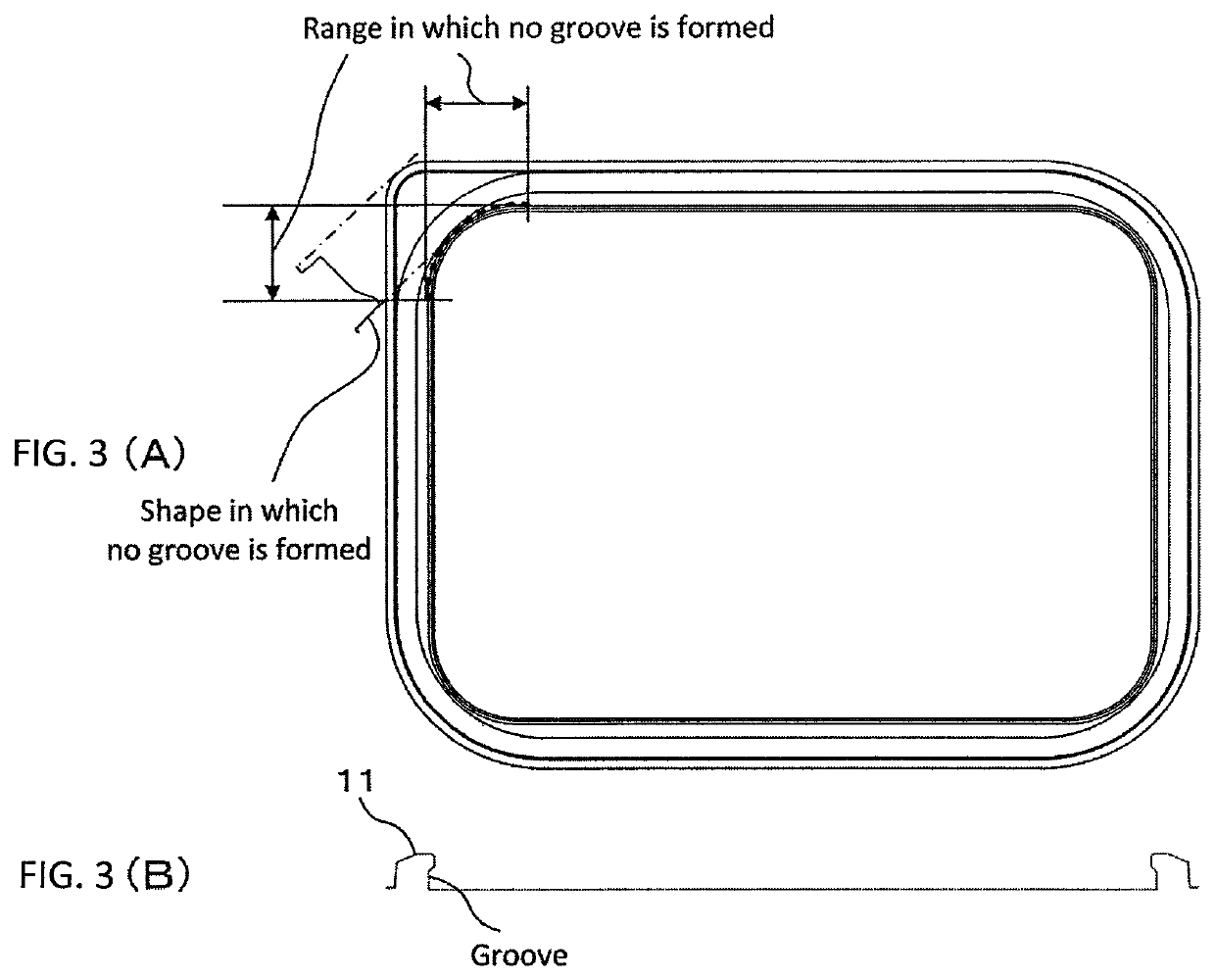

Lid for container

ActiveUS11180289B2Low flexural strengthEasy elastic deformationRemovable lids/coversLidsEngineeringMechanical engineering

Provided is a resin container lid in which a trouble such as a crack is prevented while maintaining easiness in opening even under a refrigerating or freezing environment, the resin container lid configured to be fitted to and detached from a resin container, the resin container lid including a flange part configured to be fitted to a container, the flange part being formed at a peripheral edge of the resin container lid, and an opening tab for detachment from the container, the opening tab projecting into an outer periphery from the flange part, with the tab having a flexural strength of 50 to 80 N under an environment of −30° C.

Owner:ASAHI KASEI HOME PRODS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com