Industrial data acquisition device and system

A technology for collecting device and industrial data, which is applied in the field of industrial data collecting device and its system, and can solve the problems of difficult scanning by a code scanner, difficulty in obtaining a shooting angle, missing parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

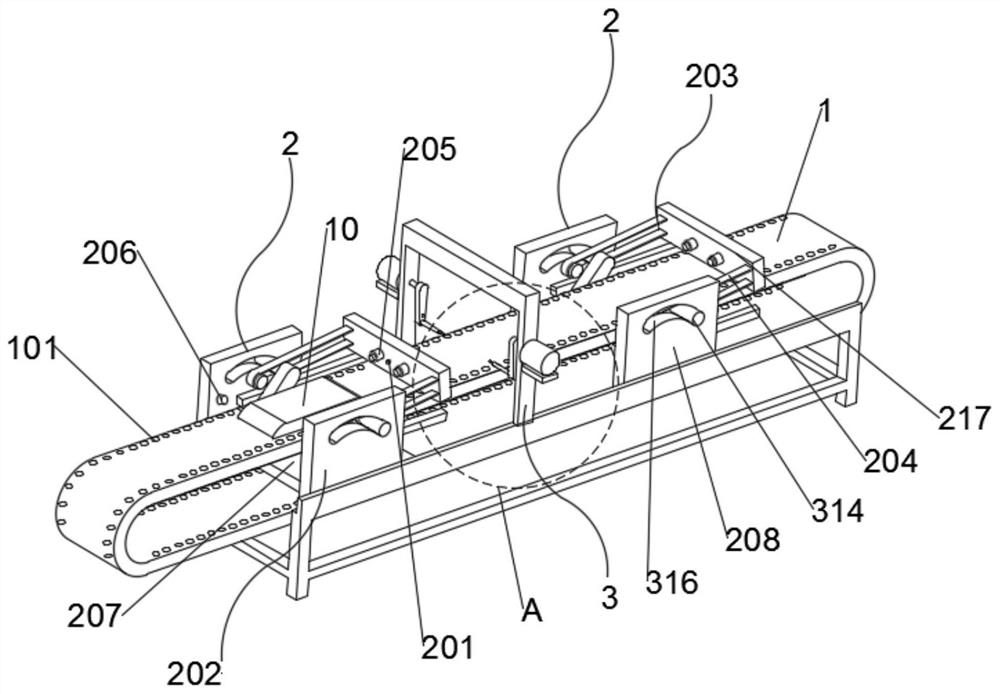

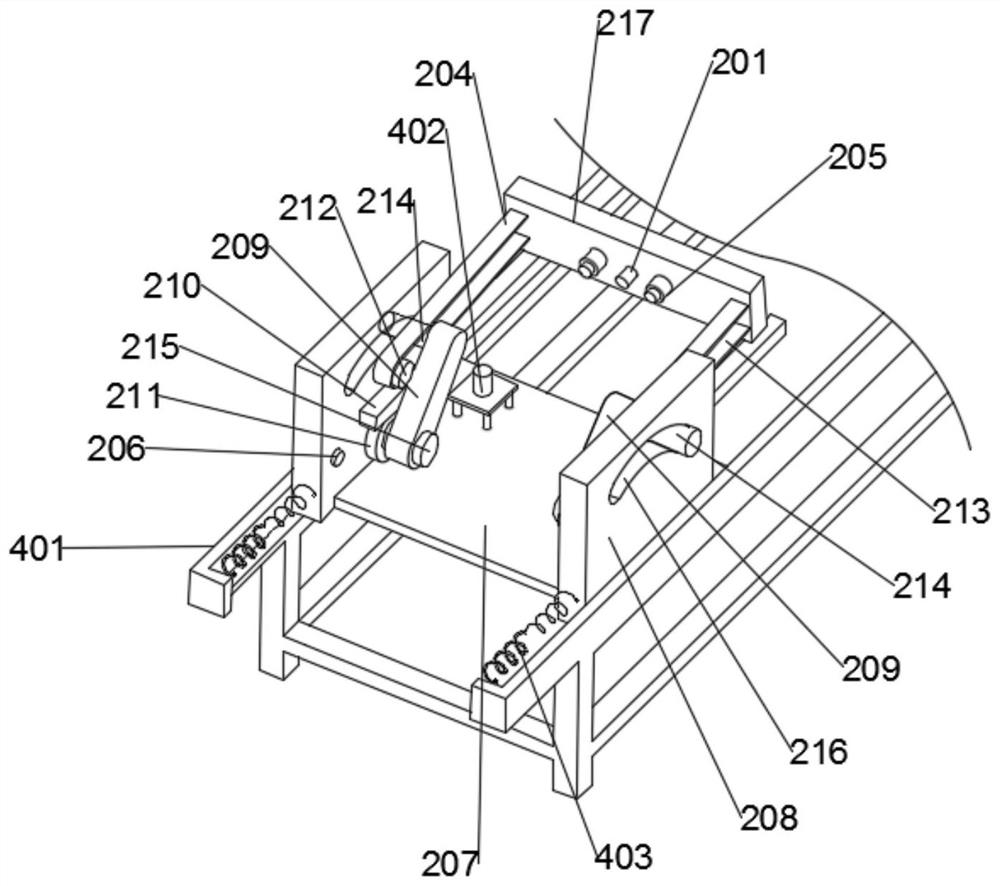

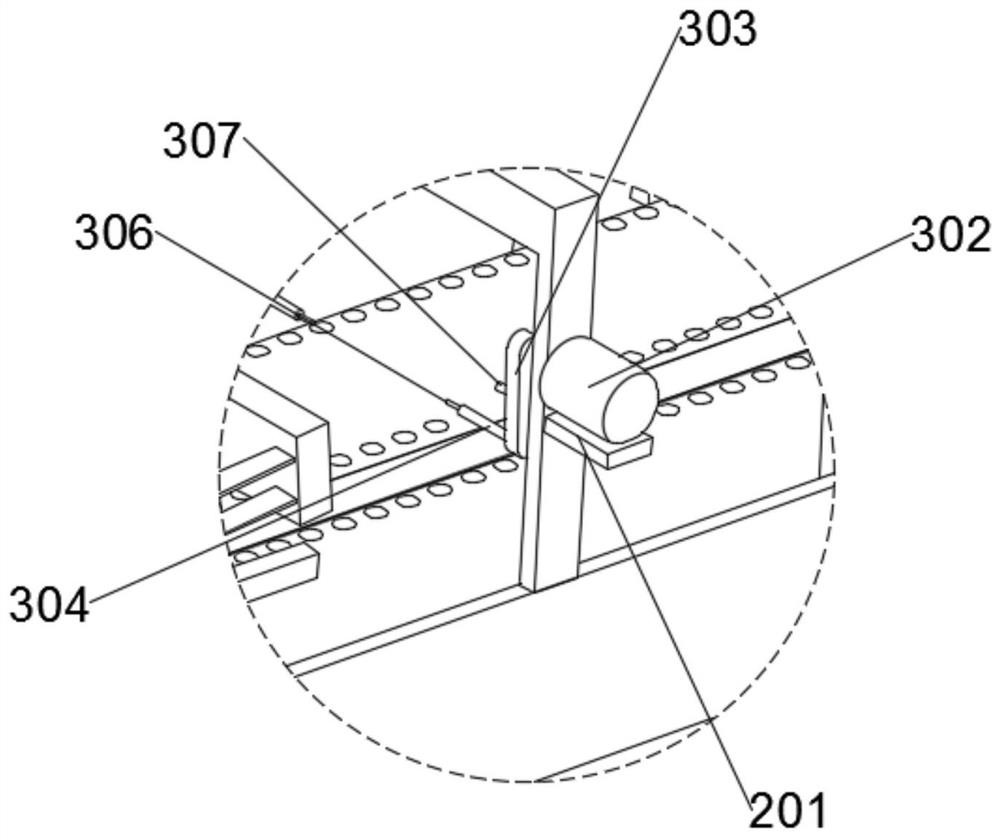

[0035] like Figure 1 to Figure 4 As shown, the present invention provides an industrial data acquisition device, including a conveying platform 1 , a follow-up angle scanning device 2 and a material turning device 3 . It can take photos and scan codes for materials without dead ends, and improve the accuracy of scanning codes and photos. specific:

[0036] Wherein, the conveying platform 1 is used for conveying the material 10 affixed with the barcode;

[0037] Jacks 101 are equidistantly arranged on the conveying belt of the conveying platform 1 . The jack 101 is arranged at a position close to the side of the conveyor belt, and will not interfere with the transmission of the material 10 .

[0038] Among them, the follow-up rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com