Patents

Literature

41results about How to "Avoid installation deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

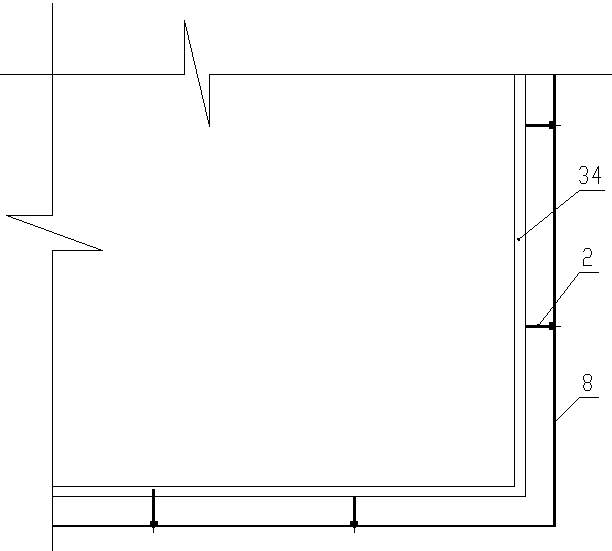

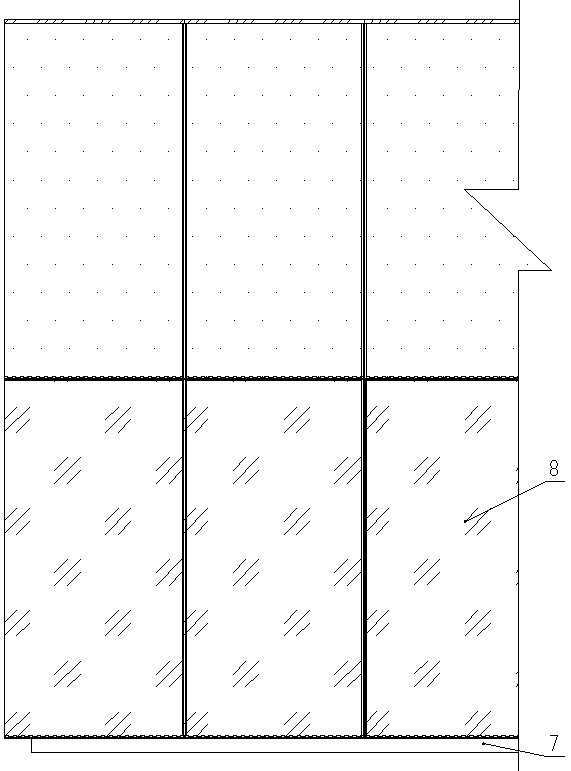

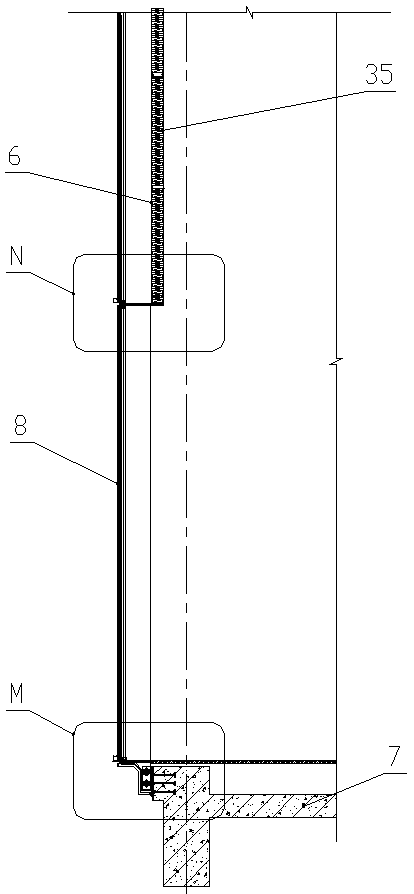

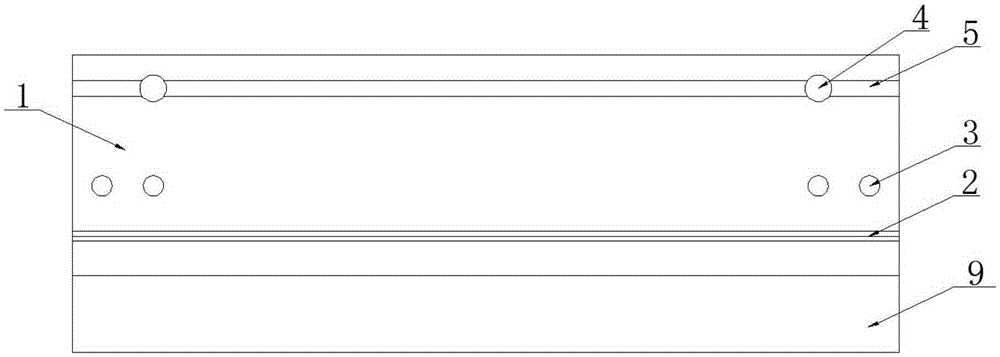

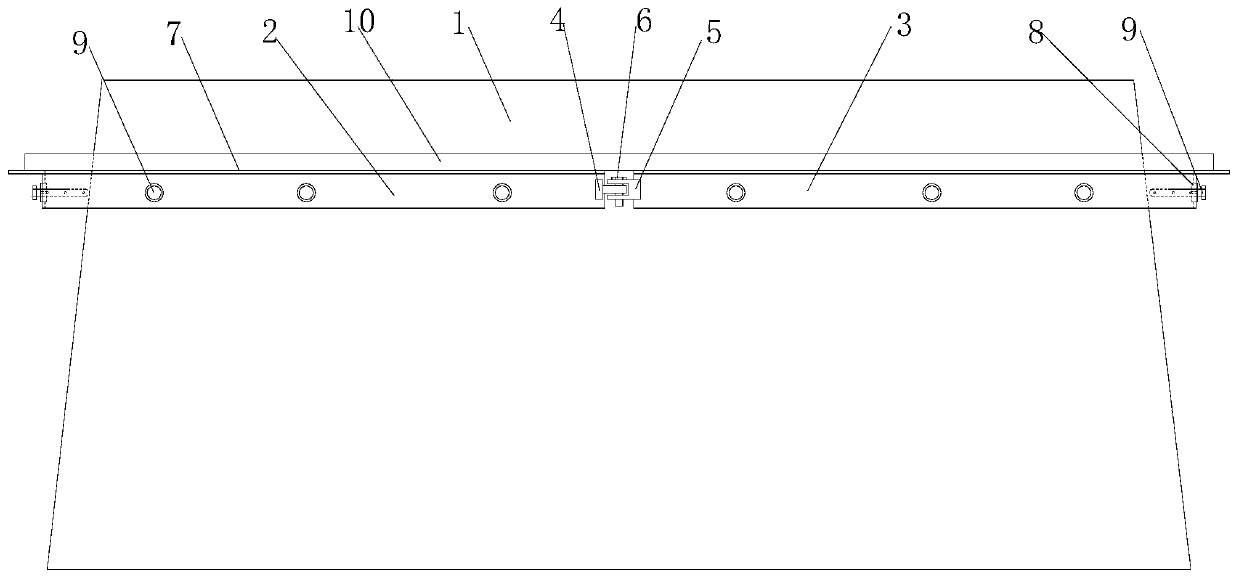

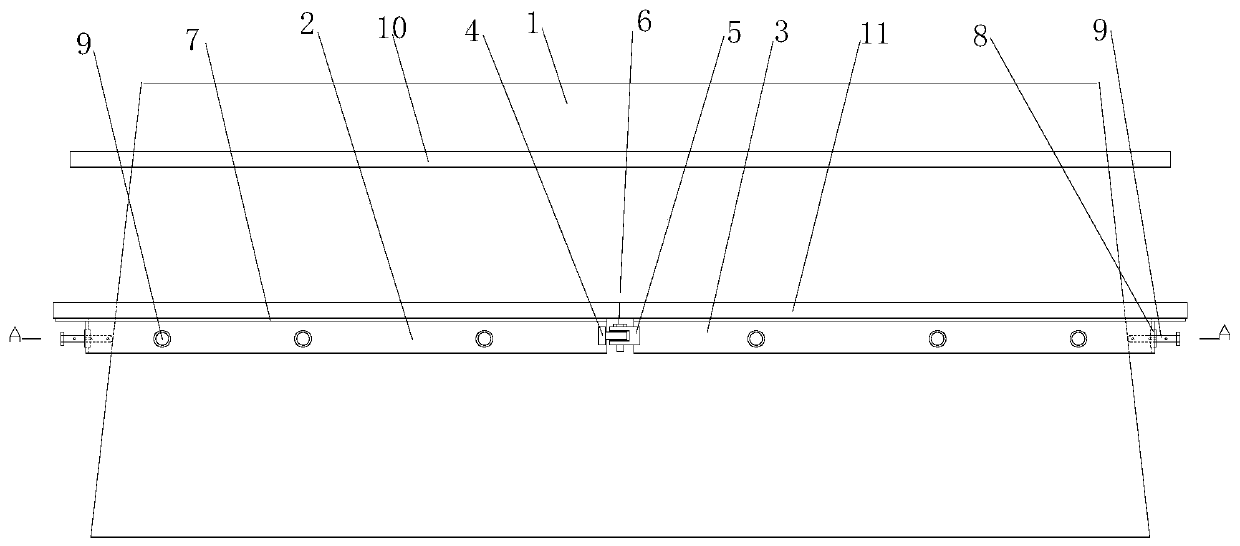

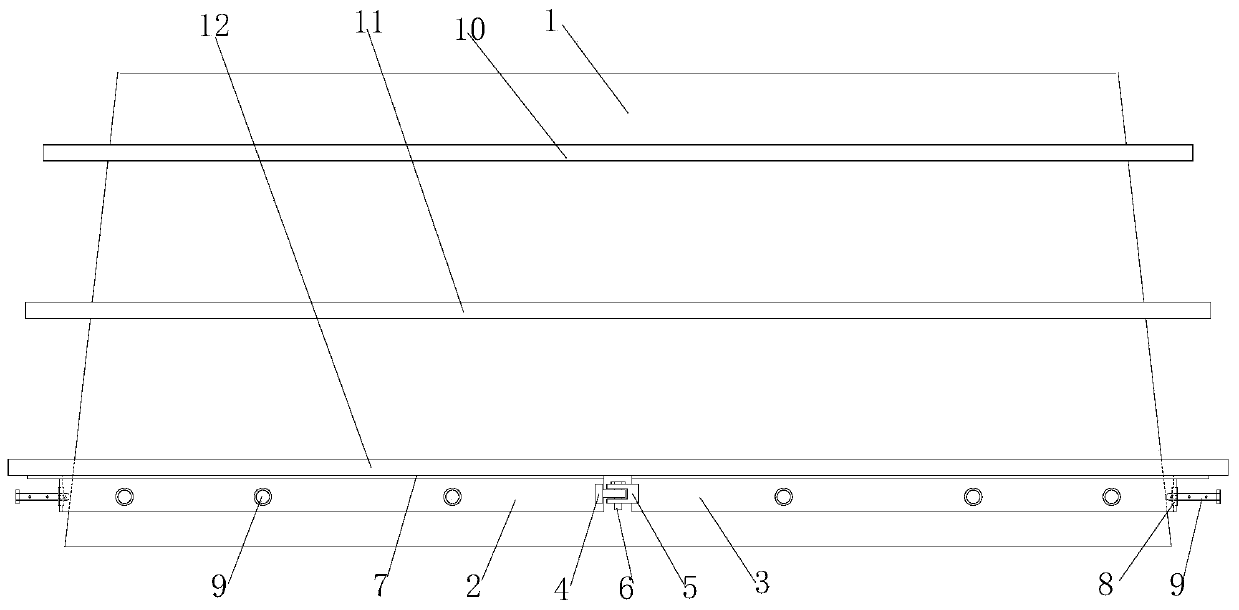

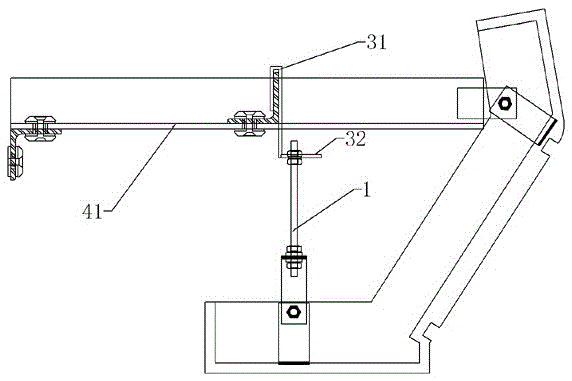

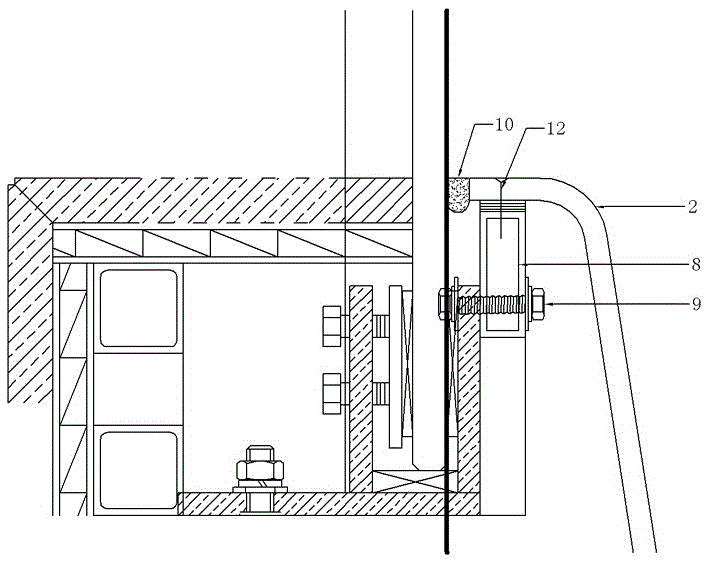

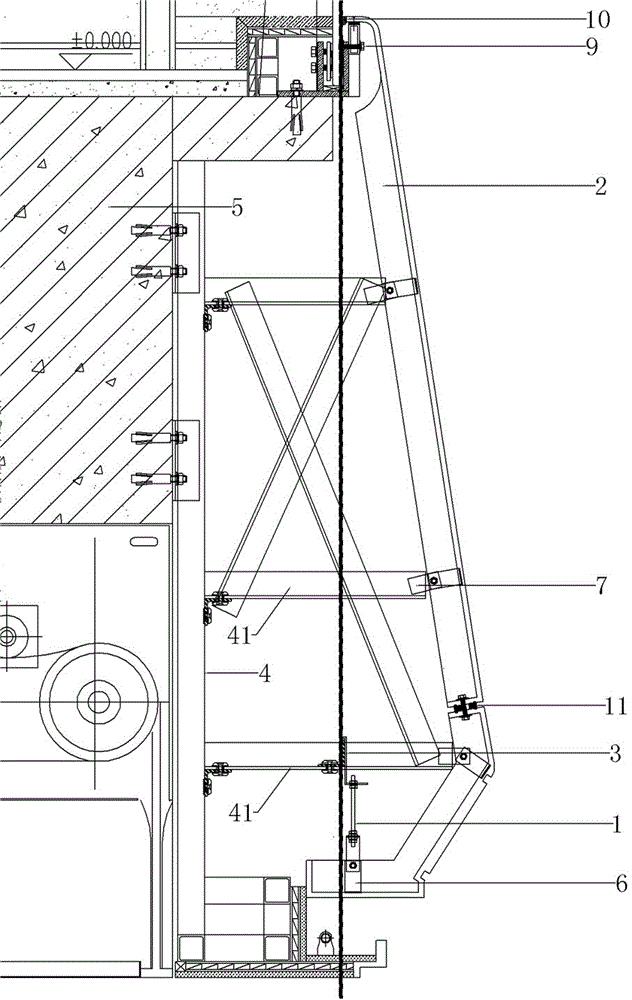

Curtain wall structure with lamp grooves and construction method thereof

ActiveCN109184056ASolve the problem of unsightly weldsImprove construction qualityWallsClimate change adaptationSteel columnsLED lamp

A curtain wall structure with lamp grooves includes a curtain wall root moisture-proof structure, T-shaped steel columns, beams, foundation embedded parts, an anodic alumina plate and a heat preservation positioning structure. The T-shaped steel columns are vertically arranged and evenly arranged along the four outer sides of a building. Multiple layers of beams are arranged between every two adjacent T-shaped steel columns. The anodic alumina plate is arranged on the outer side of the heat preservation positioning structure. A curtain wall glass component is arranged between the T-shaped steel columns and the beams. The invention further discloses a construction method of the curtain wall structure with lamp grooves. Aluminum lamp grooves are processed and fixed to the beams, and the aluminum lamp grooves provide concealed installation spaces for LED strip lamps. The overall appearance of the curtain wall glass is not affected, the lamp lines will not be exposed, and later maintenanceis facilitated. The curtain wall glass component lined with the anodic alumina plate is processed together with heat preservation cotton and galvanized steel sheets and then transported to the construction site for integral hoisting installation. The operation is faster and more accurate, installation deviation is avoided, and the construction cost can be saved.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

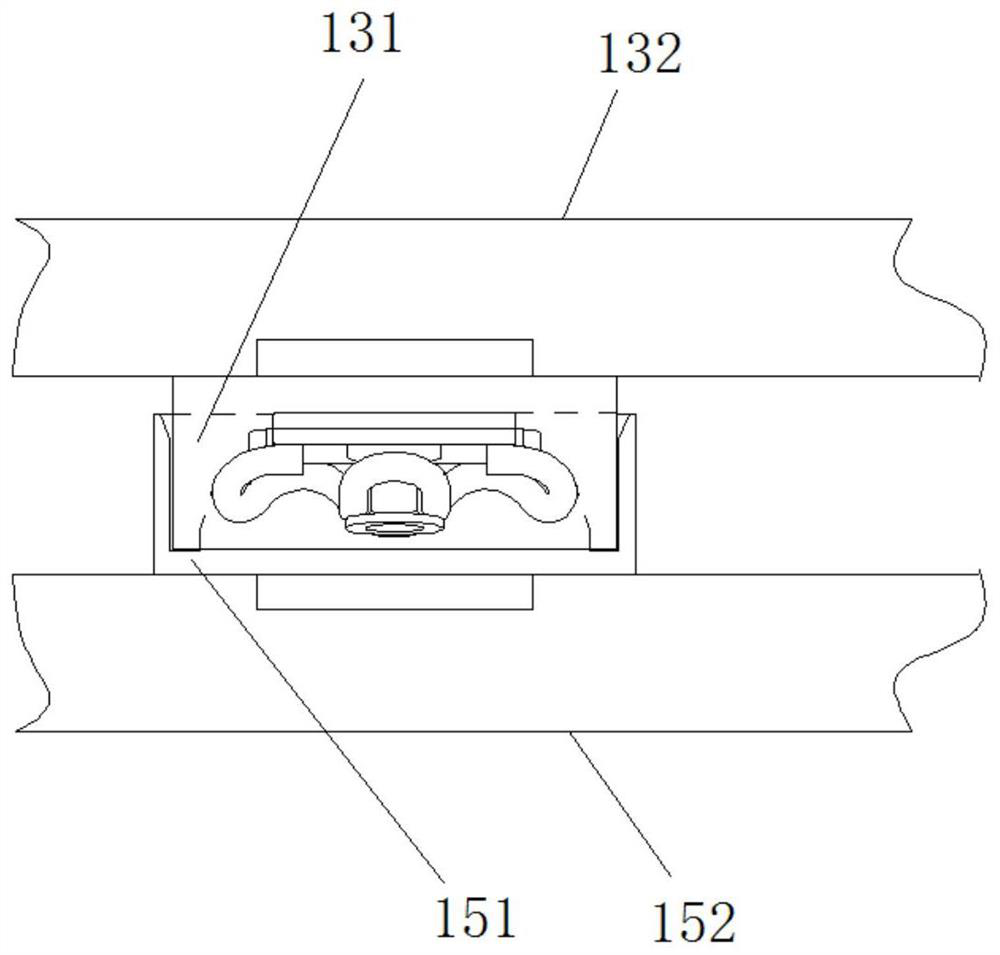

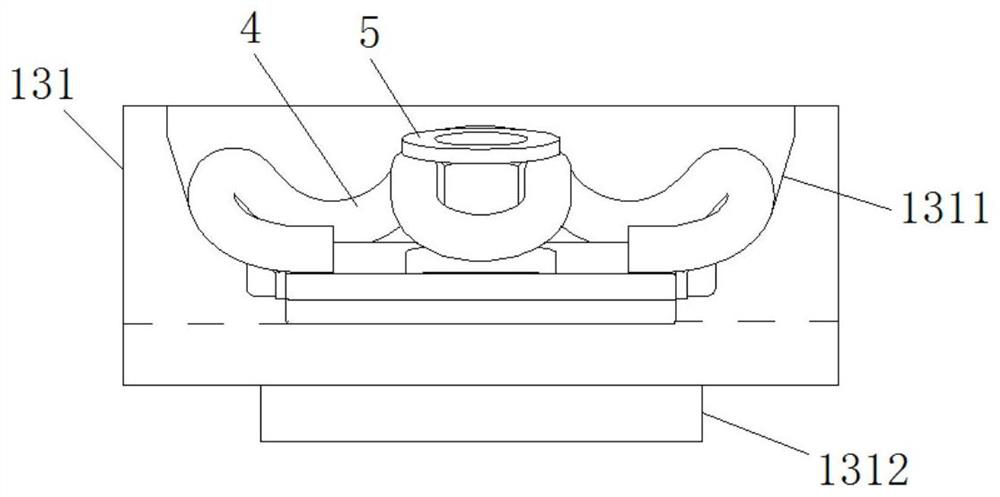

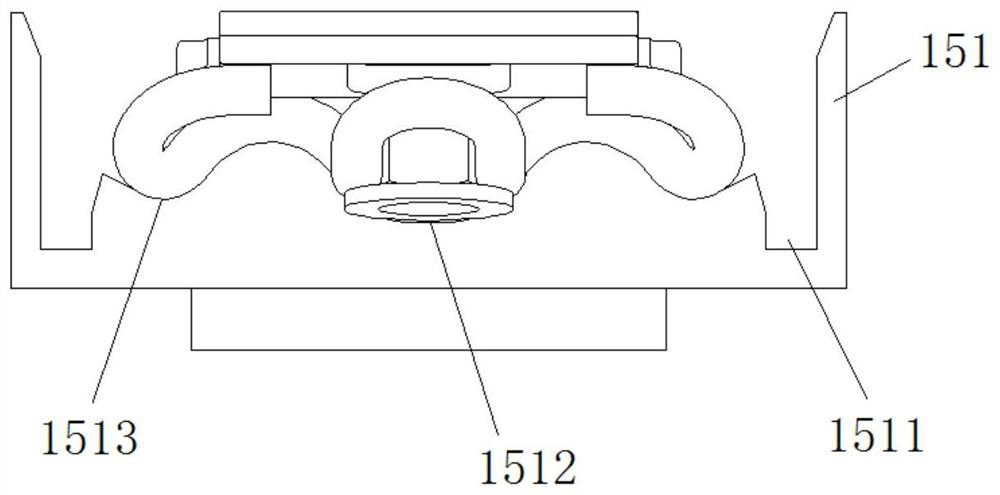

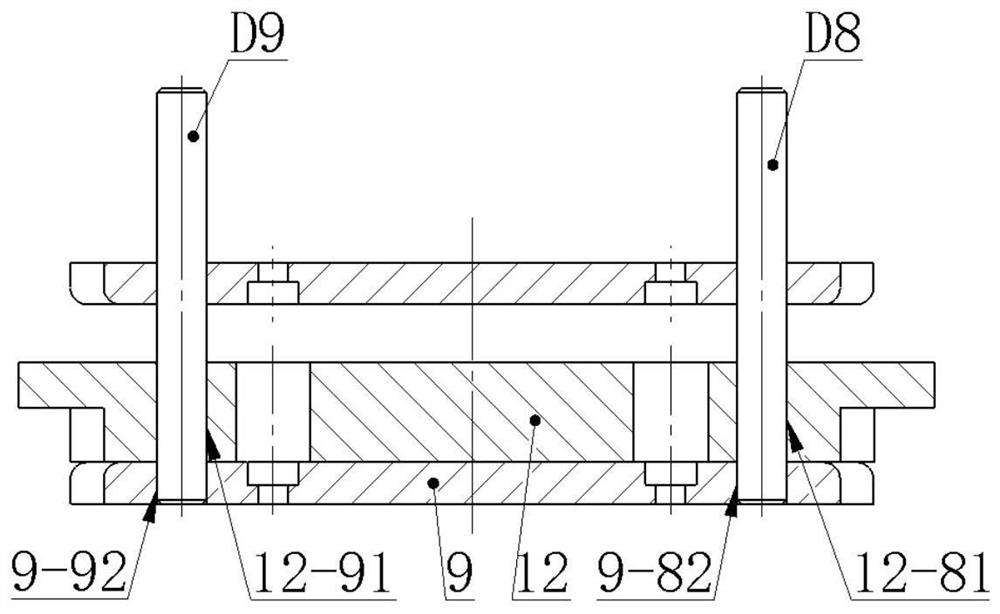

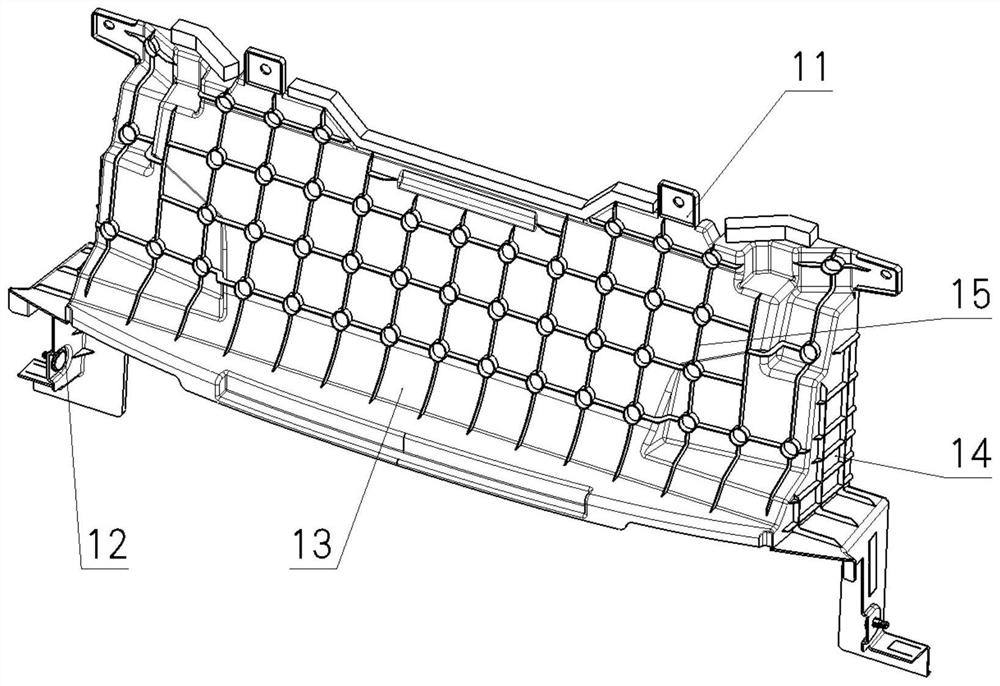

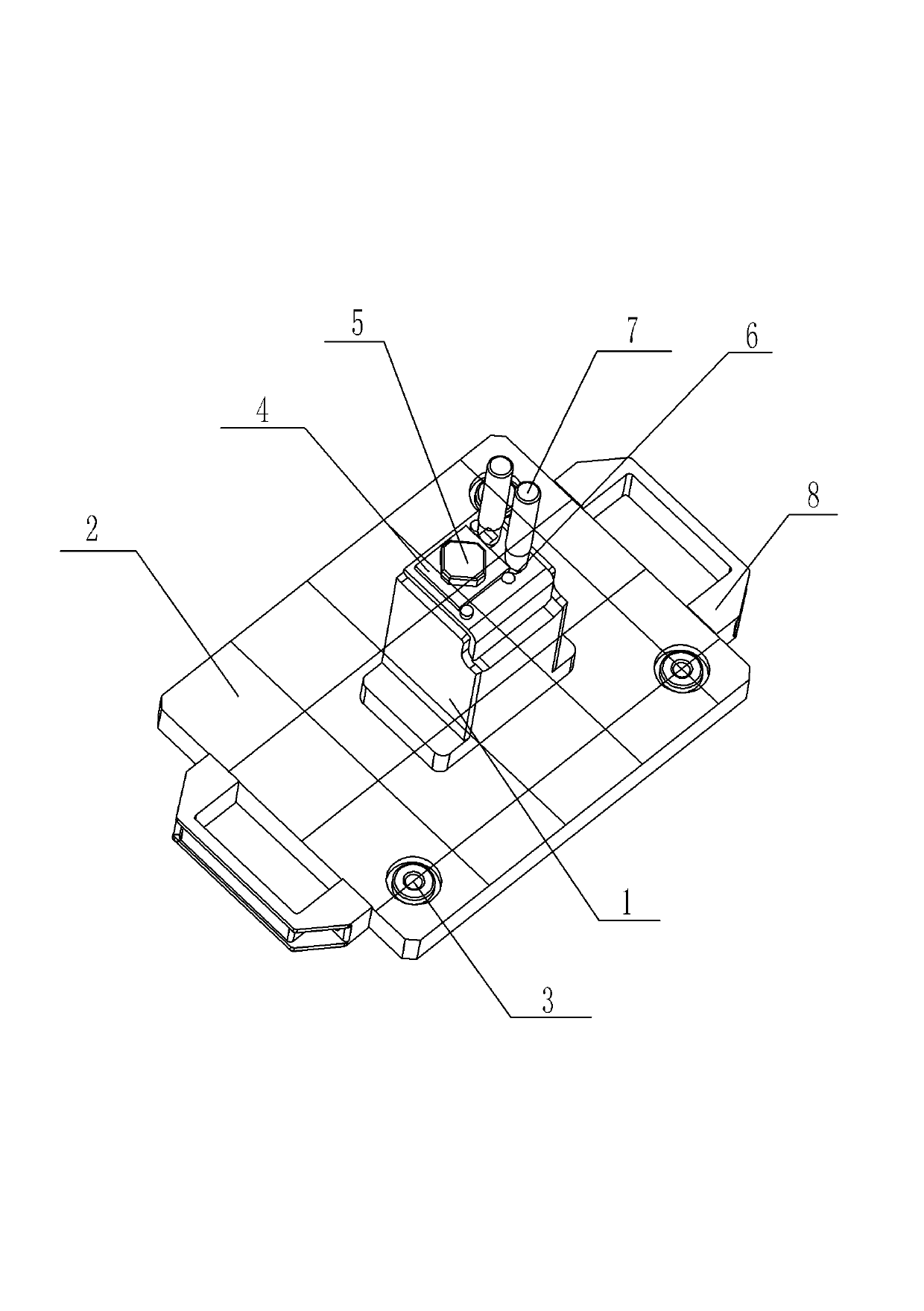

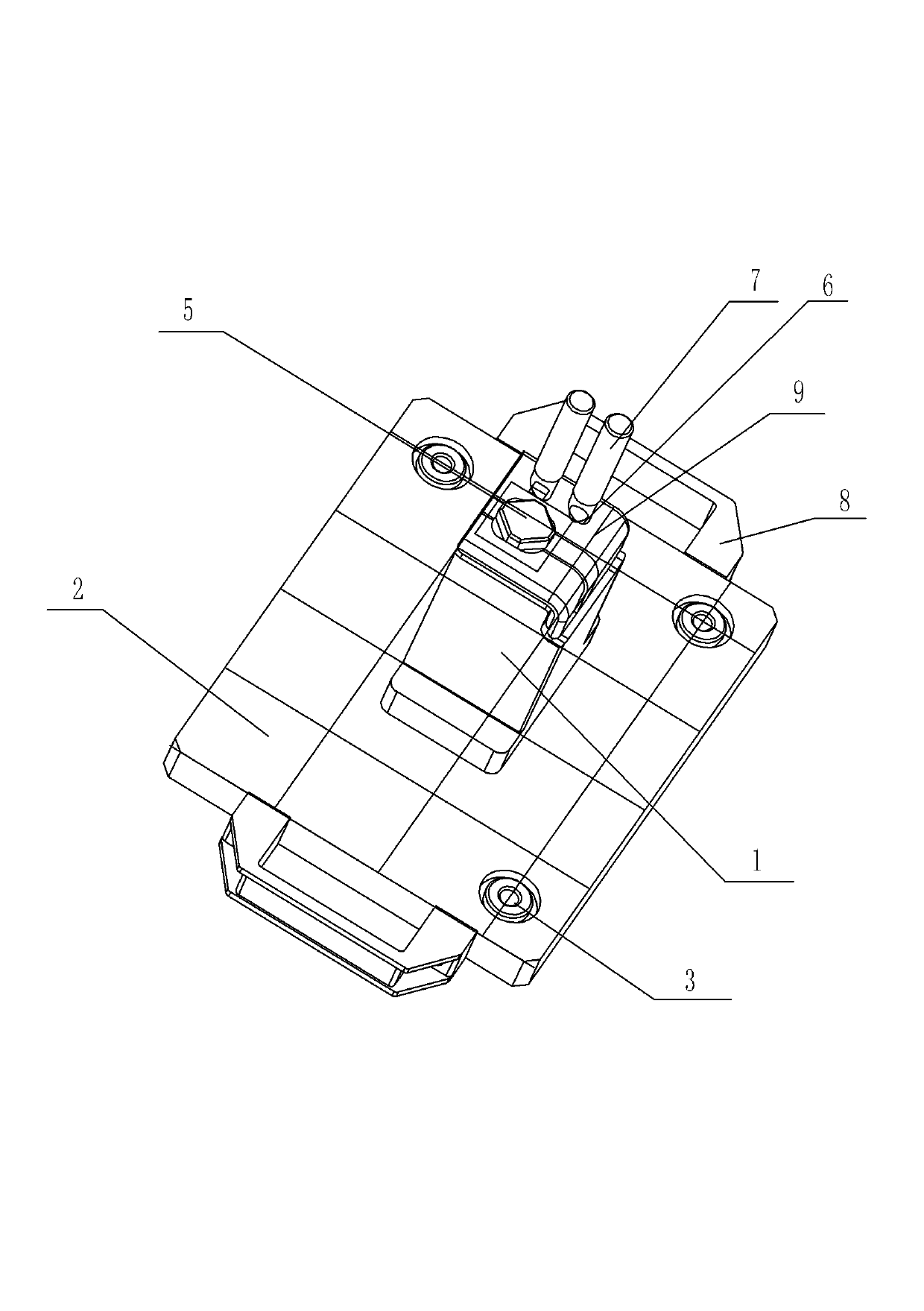

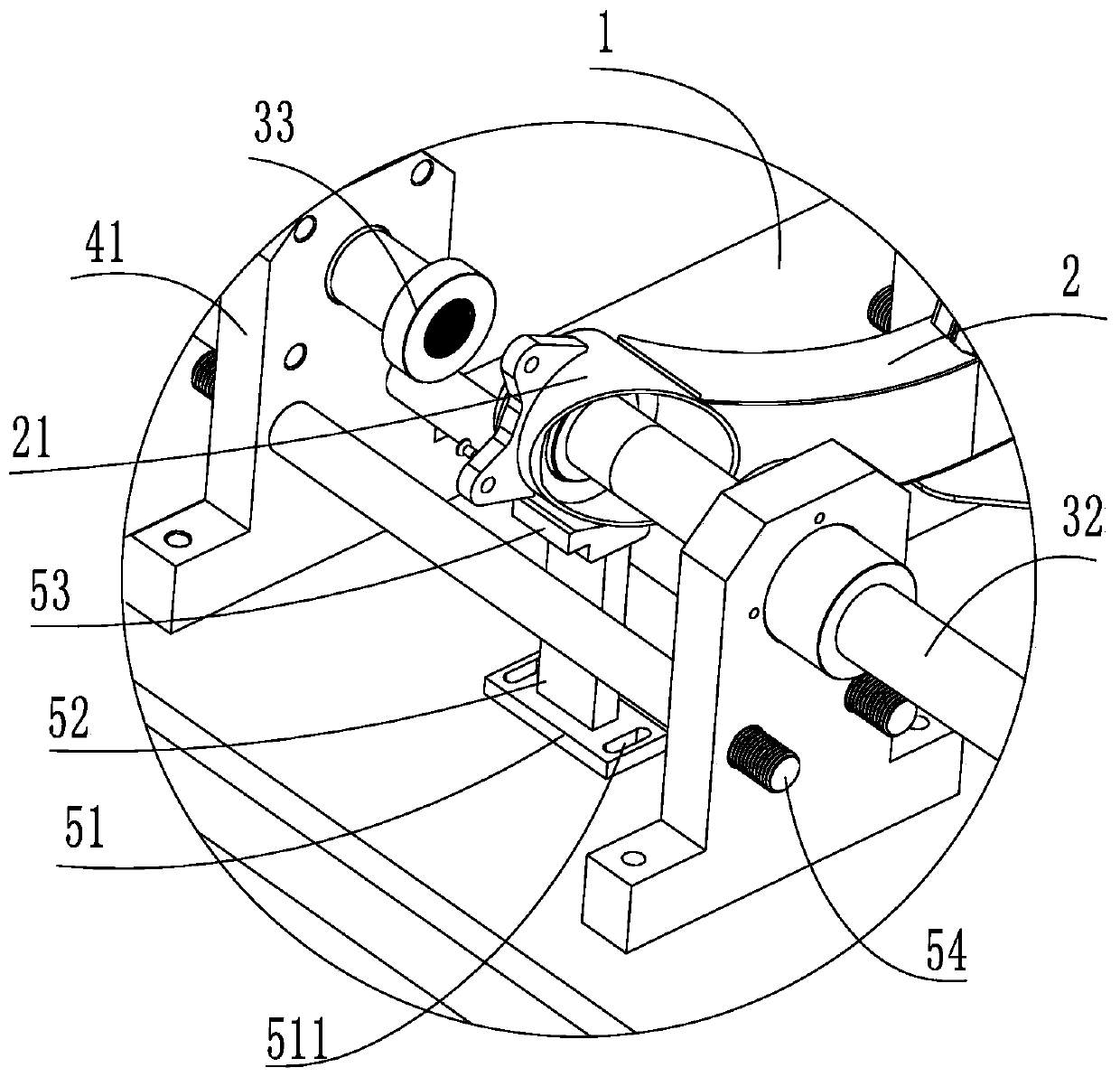

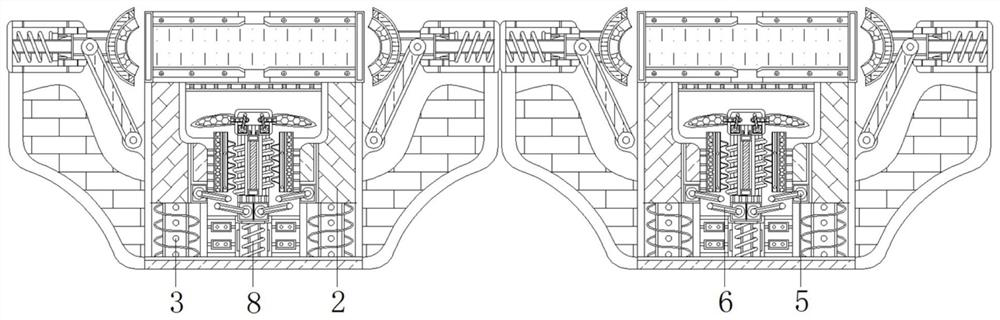

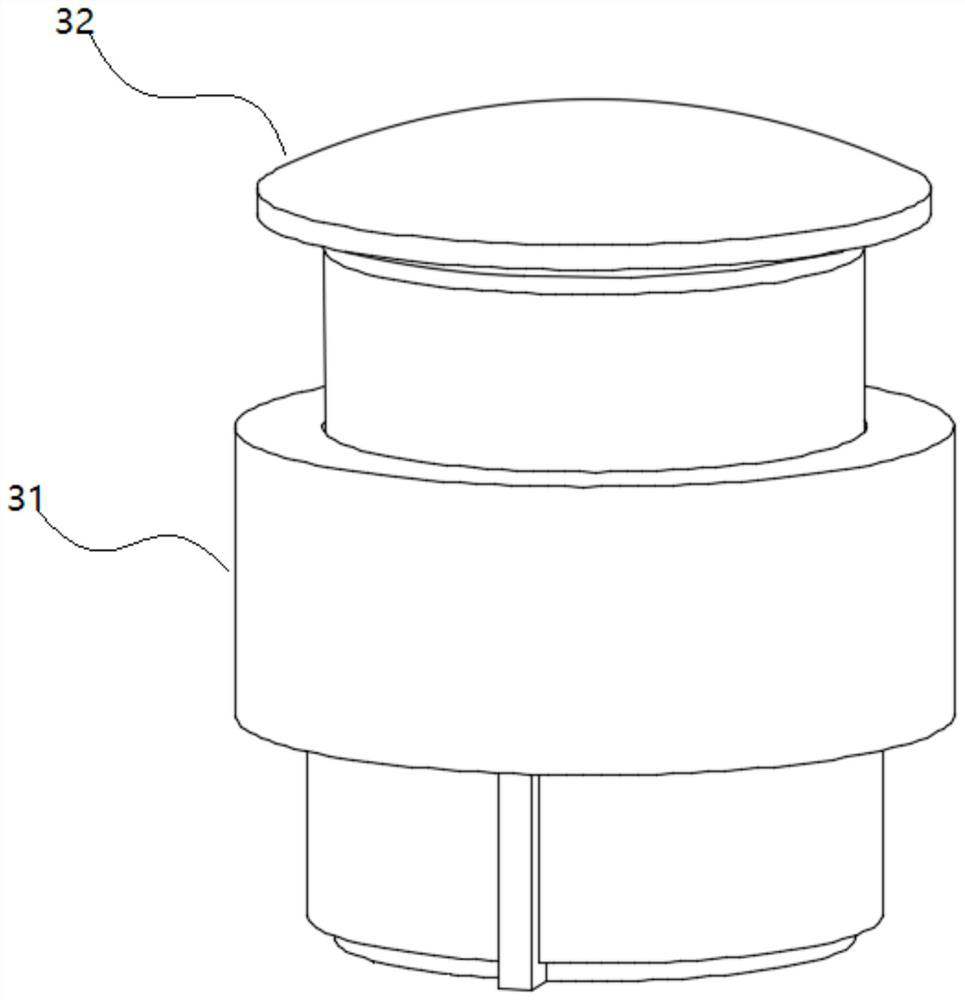

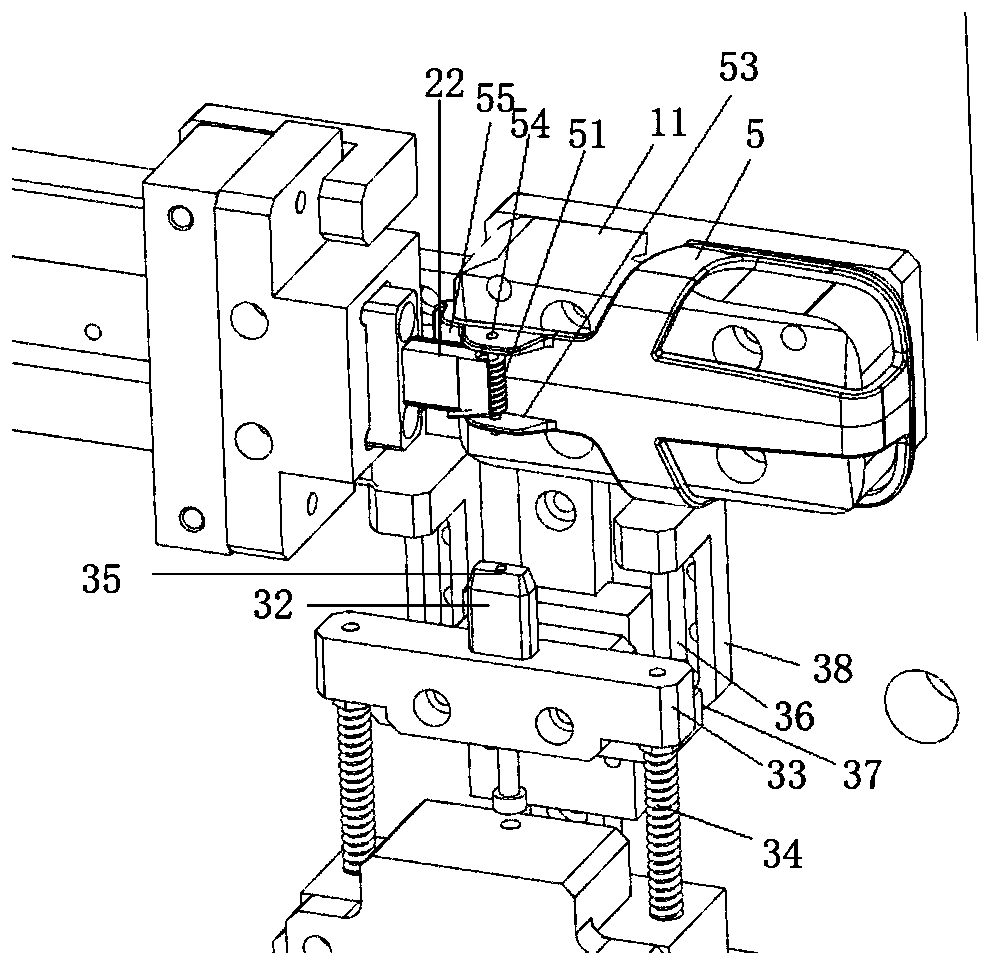

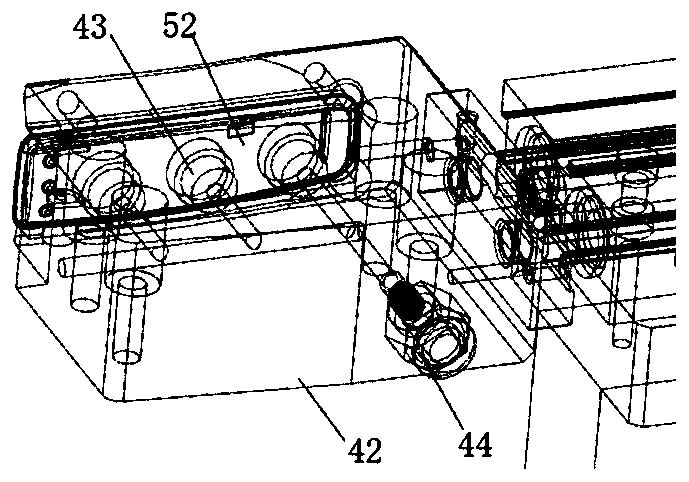

Jig box for railway fastener bulk vehicle

ActiveCN111702733AAvoid missing partsAvoid installation deviationRail fastenersWork tools storageBulk storageFastener

The invention discloses a jig box for a railway fastener bulk vehicle. The jig box comprises an assembly jig box and a bulk storage jig box, wherein the assembly jig box comprises an assembly groove,the assembly groove comprises a side low groove formed in one side of the bottom and used for accommodating a stop block to fix the stop block, a low groove formed in the other side of the bottom andused for accommodating a base plate to fix the base plate, and side arc grooves formed in the two sides and used for accommodating elastic strips to fix the elastic strips; the bulk storage jig box comprises a bulk storage groove, the bulk storage groove comprises a tooth groove engaged with the side wall of the assembly jig box, a bottom arc groove used for accommodating the elastic strips to fixthe elastic strips and a middle arc groove formed in the middle of the bottom arc groove and used for accommodating a gasket to fix the gasket, and when the side wall of the assembly jig box is inserted into the tooth groove, the elastic strips can be tightly attached to the side arc groove and the bottom arc groove at the same time. Complete set assembling and complete set transferring of railway fasteners can be achieved, and the industrial efficiency and the operation quality are remarkably improved.

Owner:BAOJI CSR TIMES ENG MACHINERY

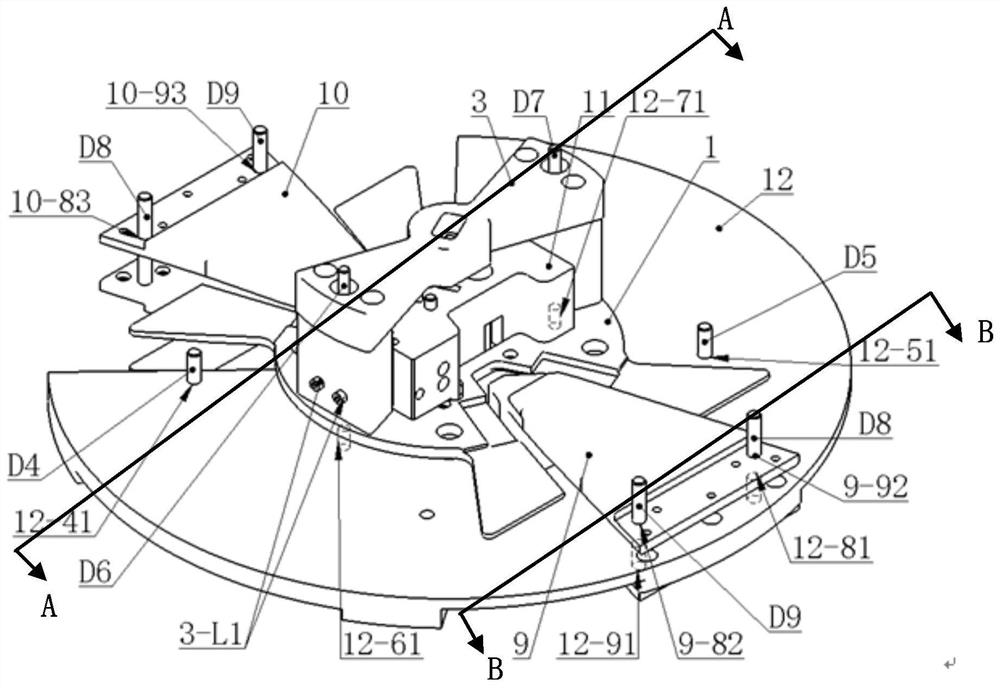

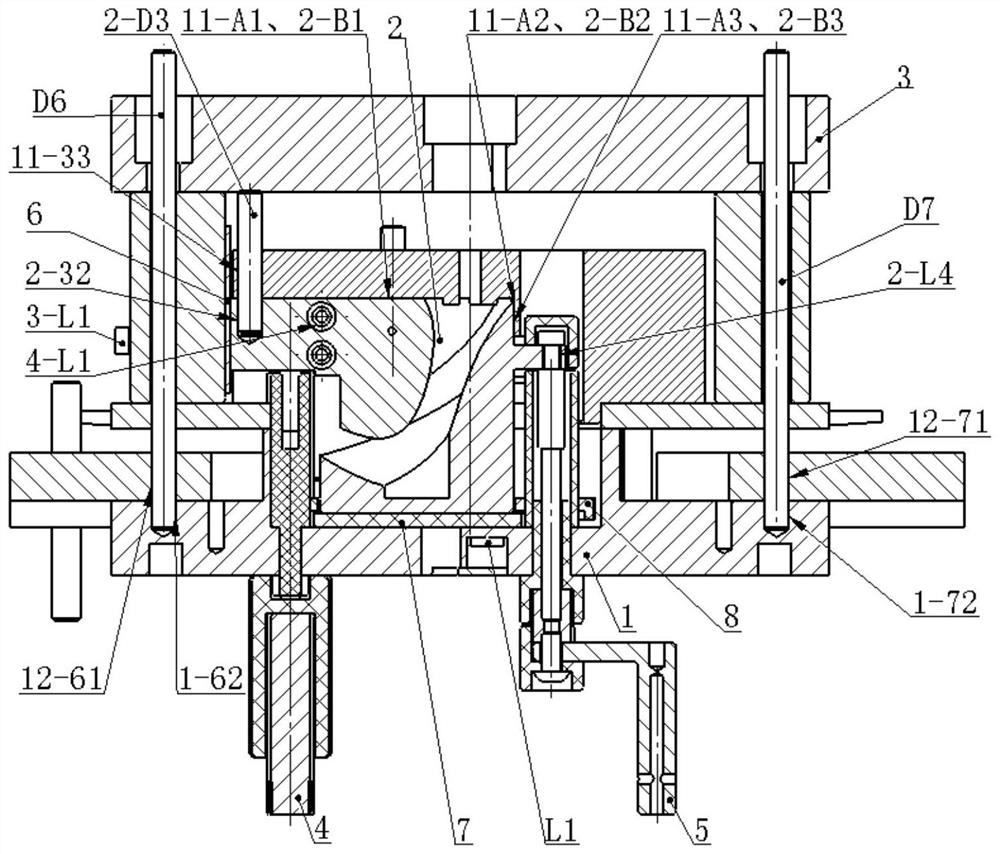

Tool for central area of BNCT accelerator and use method

The invention discloses a tool and method for a central area of a BNCT accelerator. The deflection plate tool is used for fine positioning of a spiral deflection plate, and comprises a part, used for absolute positioning of the spiral deflection plate, of the tool and a part, used for relative positioning of the spiral deflection plate, of the tool; and the part, used for relatively positioning the spiral deflection plate, of the tool comprises relative positioning in the height direction, relative positioning in the front-back direction and relative positioning in the left-right direction between an upper deflection plate and a lower deflection plate. The invention further discloses an absolute positioning method of the deflection plate tool for the height and the horizontal direction of the lower deflection plate. According to the absolute positioning method of the deflection plate tool for the height direction and the horizontal direction of the upper deflection plate, positioning is conducted through pin holes, pins and precise positioning faces which are precisely matched on the tool, installation deviation caused by the amount of installation holes and machining errors is avoided to the maximum extent, and the unexpected effect is achieved. The tool is simple to operate, easy to implement, lower in cost and high in precision.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

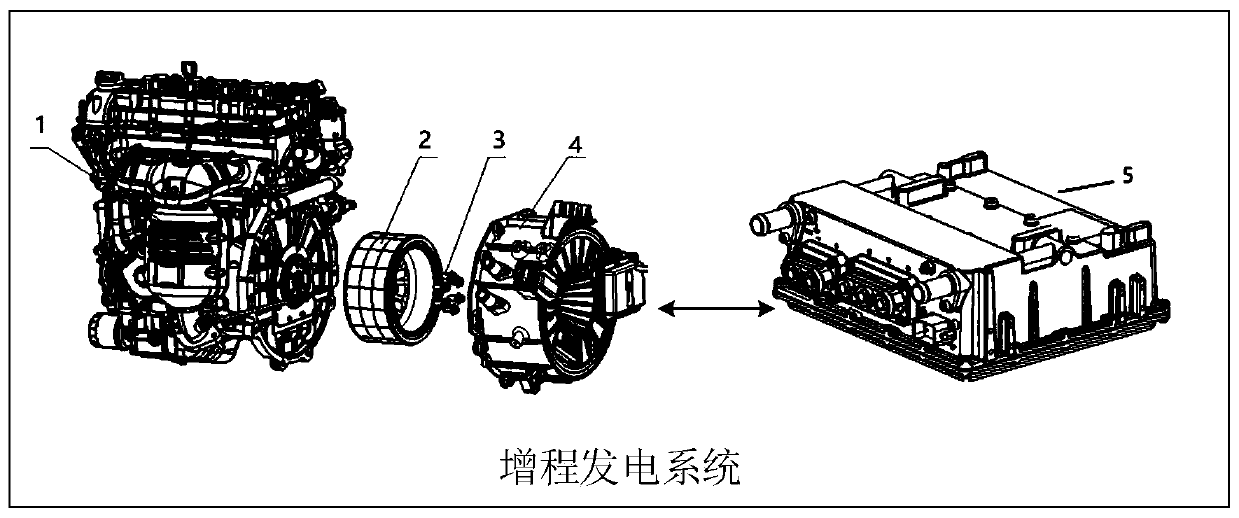

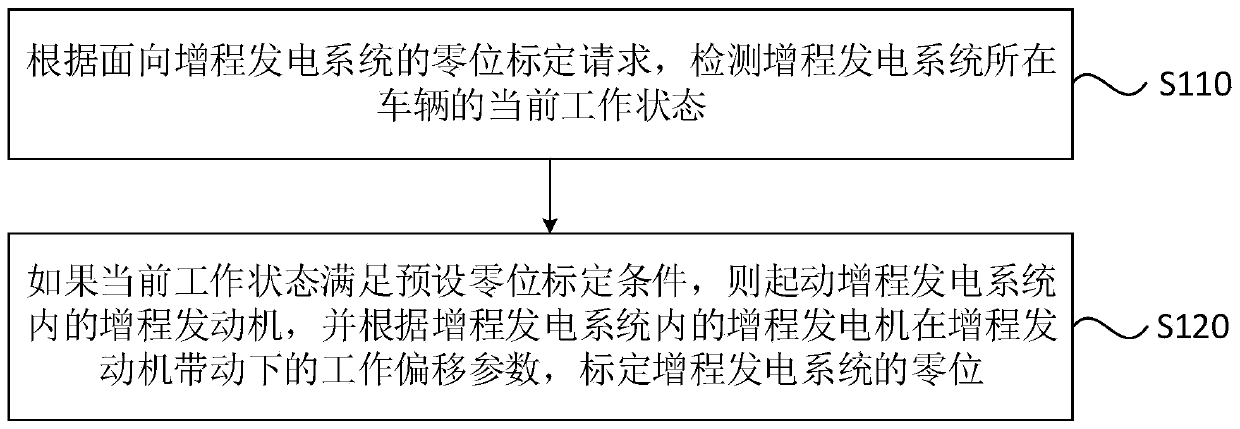

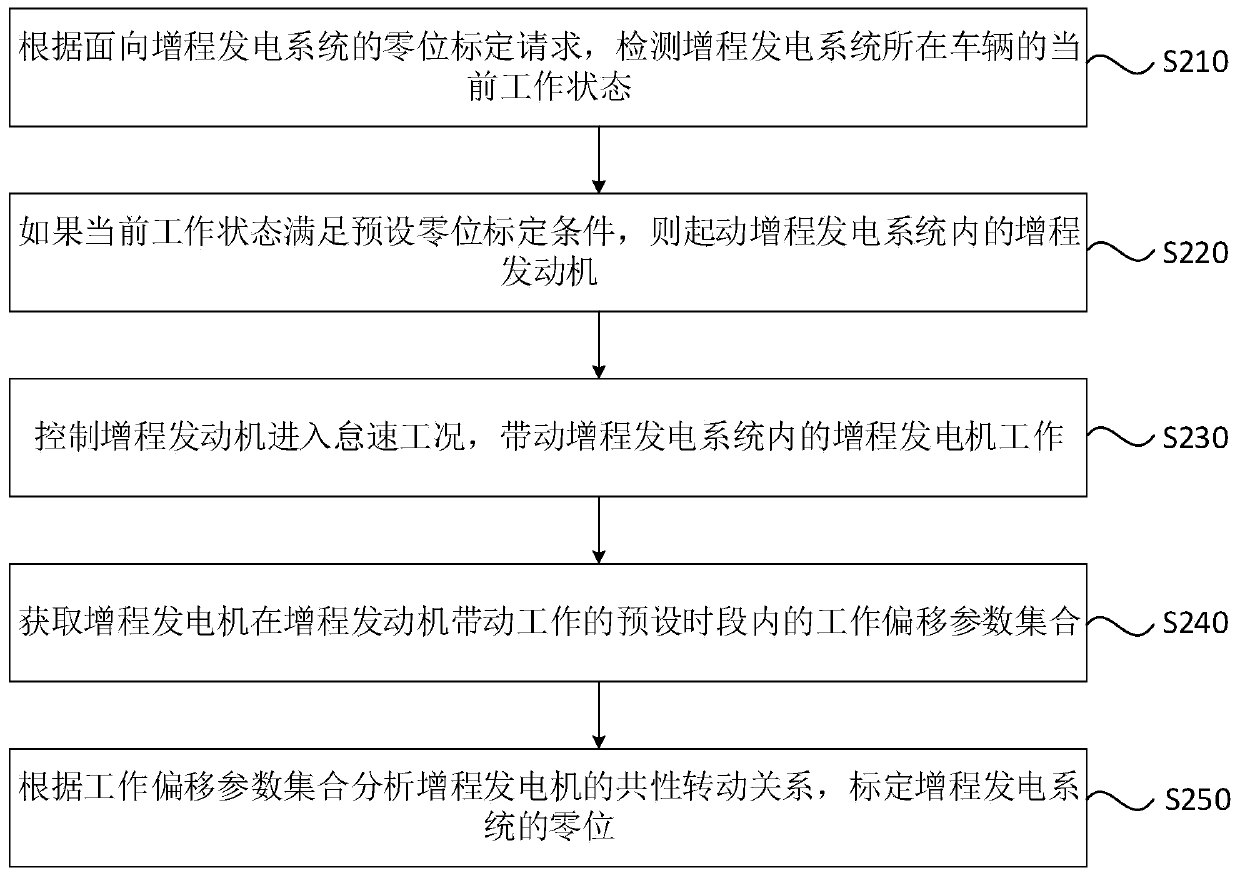

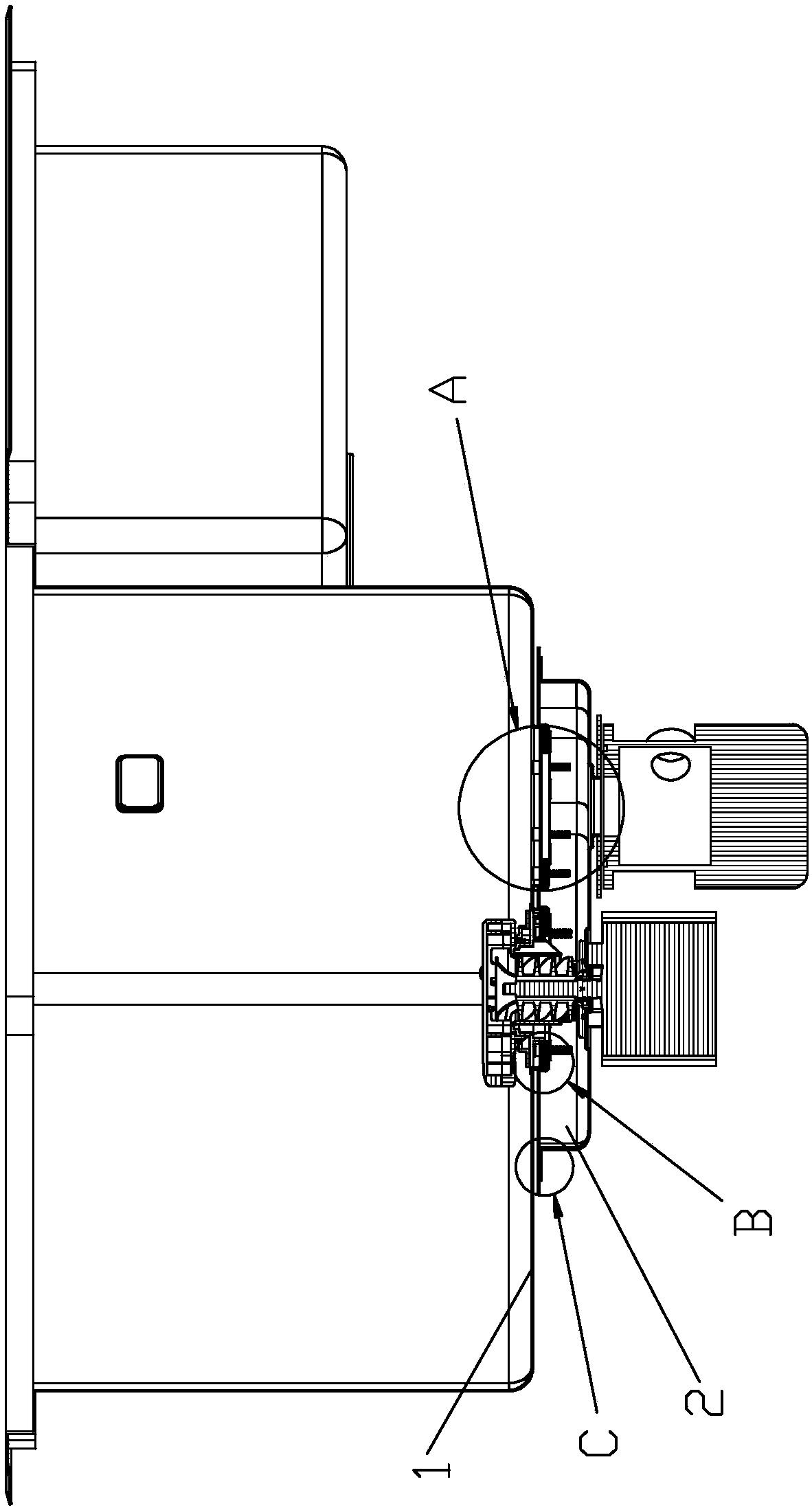

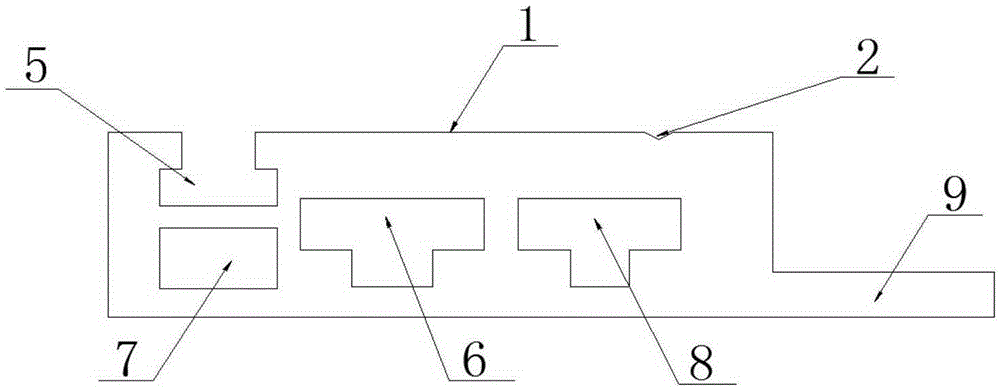

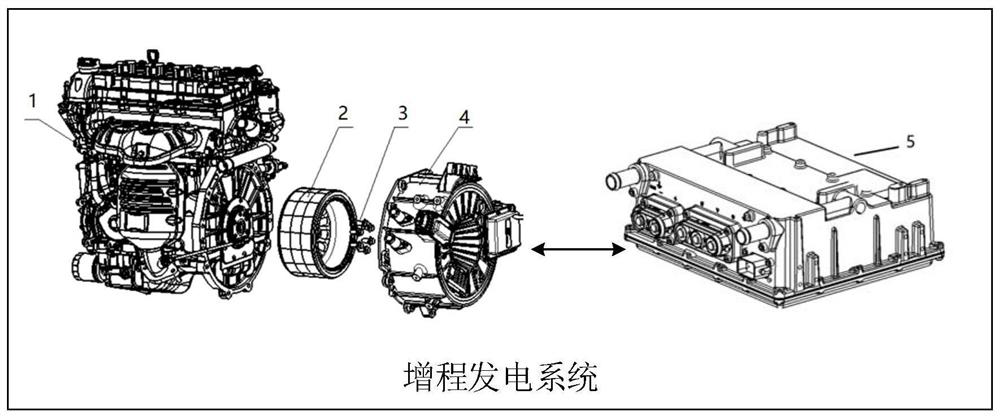

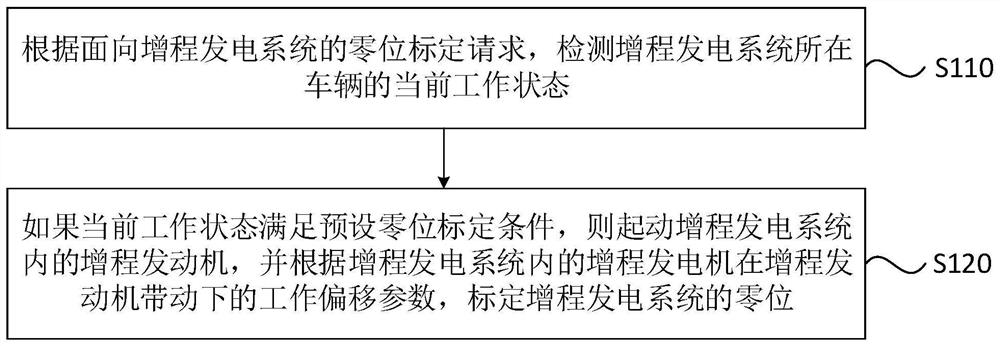

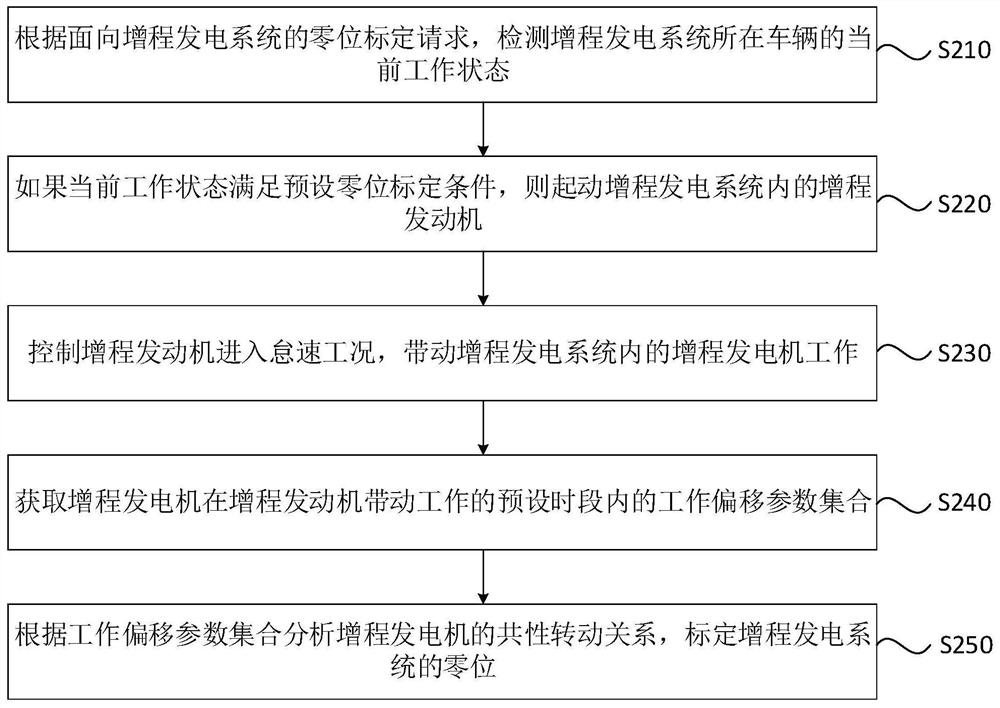

Zero calibration method and device based on extended-range power generation system, vehicle and medium

ActiveCN111426289AImprove assembly efficiencyAvoid installation deviationVehicular energy storageDynamo-electric machine testingControl engineeringControl theory

The embodiment of the invention discloses a zero calibration method and device based on an extended-range power generation system, a vehicle and a medium. The method comprises the steps of detecting acurrent working state of a vehicle where the extended-range power generation system is located according to a zero calibration request for the extended-range power generation system; and if the current working state meets a preset zero calibration condition, starting an extended-range engine in the extended-range power generation system, and calibrating the zero position of the extended-range power generation system according to a working offset parameter of the extended-range power generator in the extended-range power generation system under the driving of the extended-range engine. The embodiment of the invention provides a technical scheme, the automatic calibration of a zero position on the extended-range power generation system is realized; the corresponding zero position does not need to be manually adjusted and recorded when the extended-range power generation system is assembled, the assembly efficiency of the extended-range power generation system is improved, meanwhile, theinstallation deviation of the extended-range power generation system when the zero position is manually adjusted is avoided, the accuracy of zero position calibration on the extended-range power generation system is guaranteed, and the power supply performance consistency of the extended-range power generation system is improved.

Owner:上海元城汽车技术有限公司

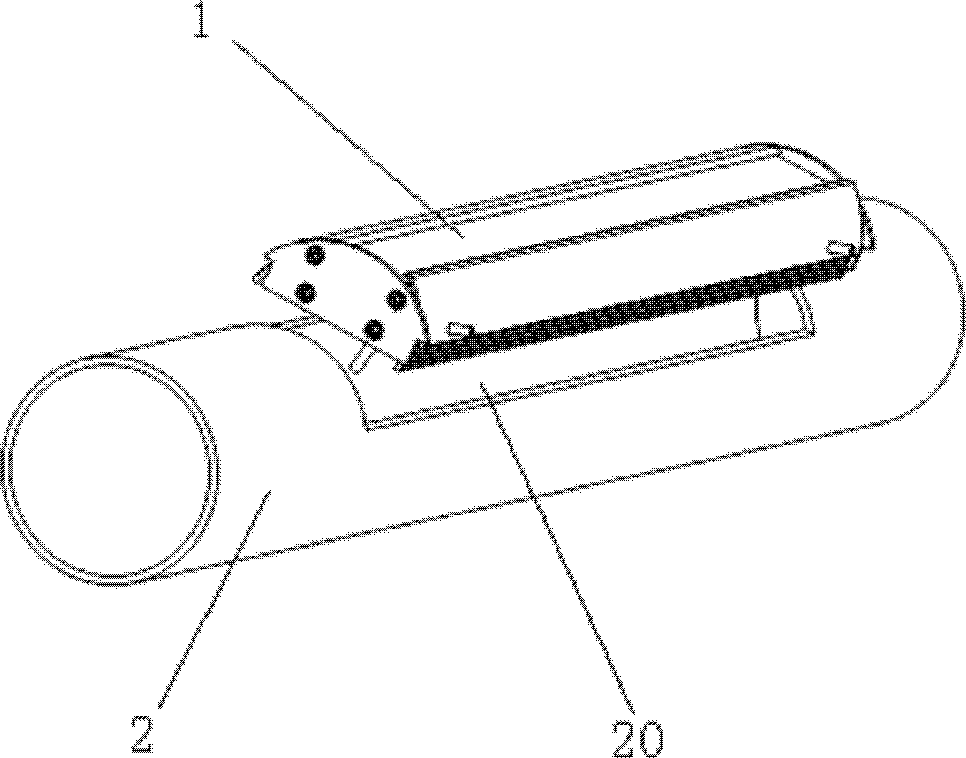

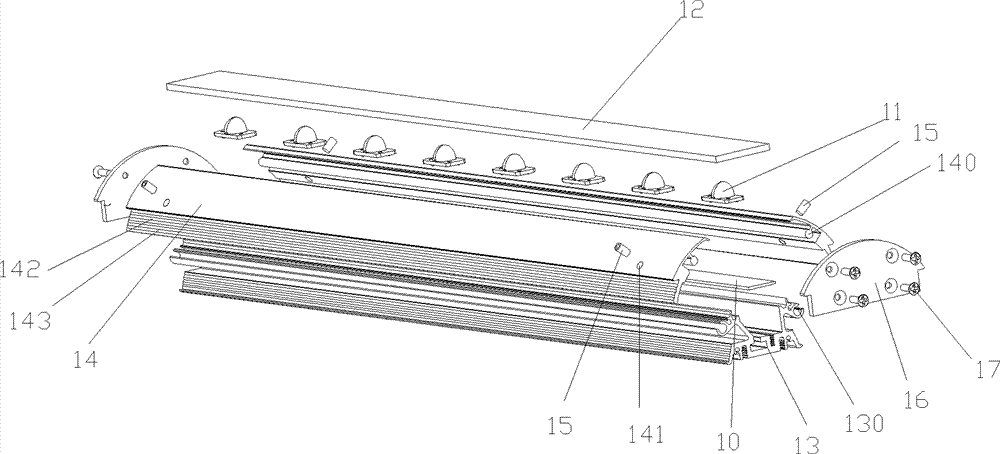

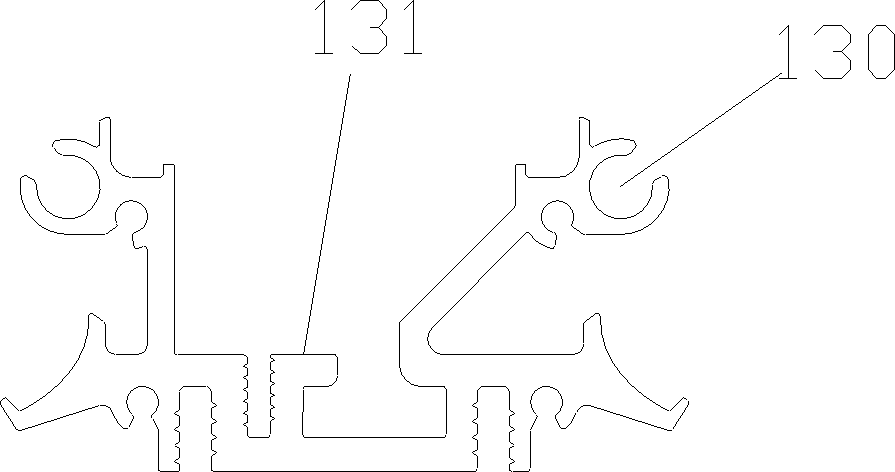

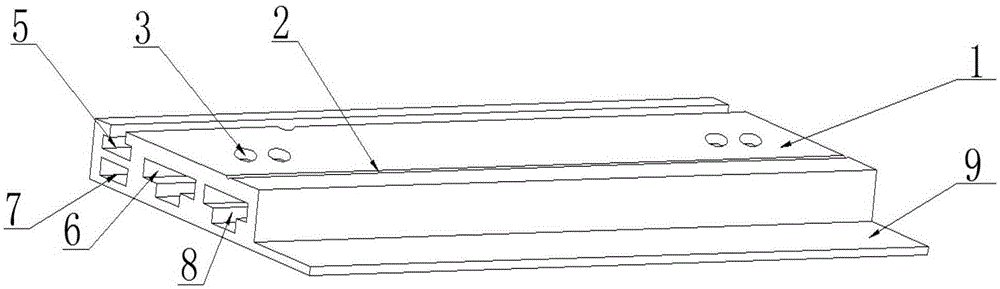

Installing structure of guardrail lamp

ActiveCN102506352BAvoid installation deviationEasy to operateLighting applicationsLight fasteningsStructural engineeringSurface plate

Owner:SHANGHAI SANSI ELECTRONICS ENG +3

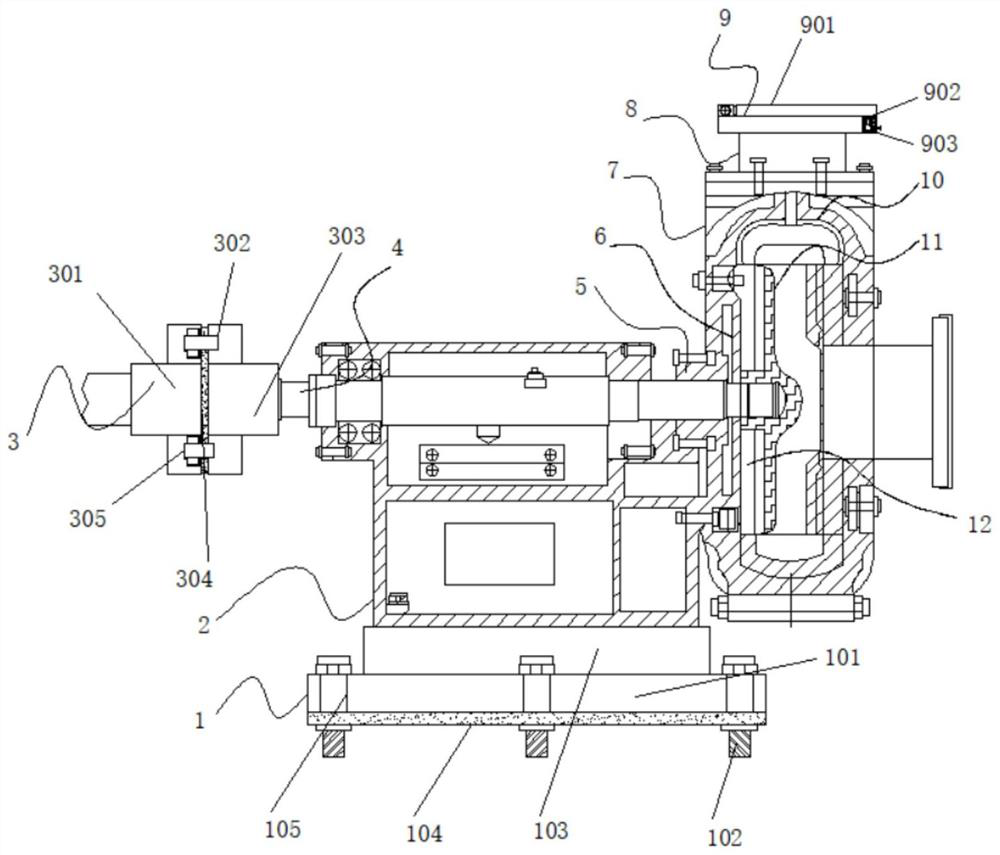

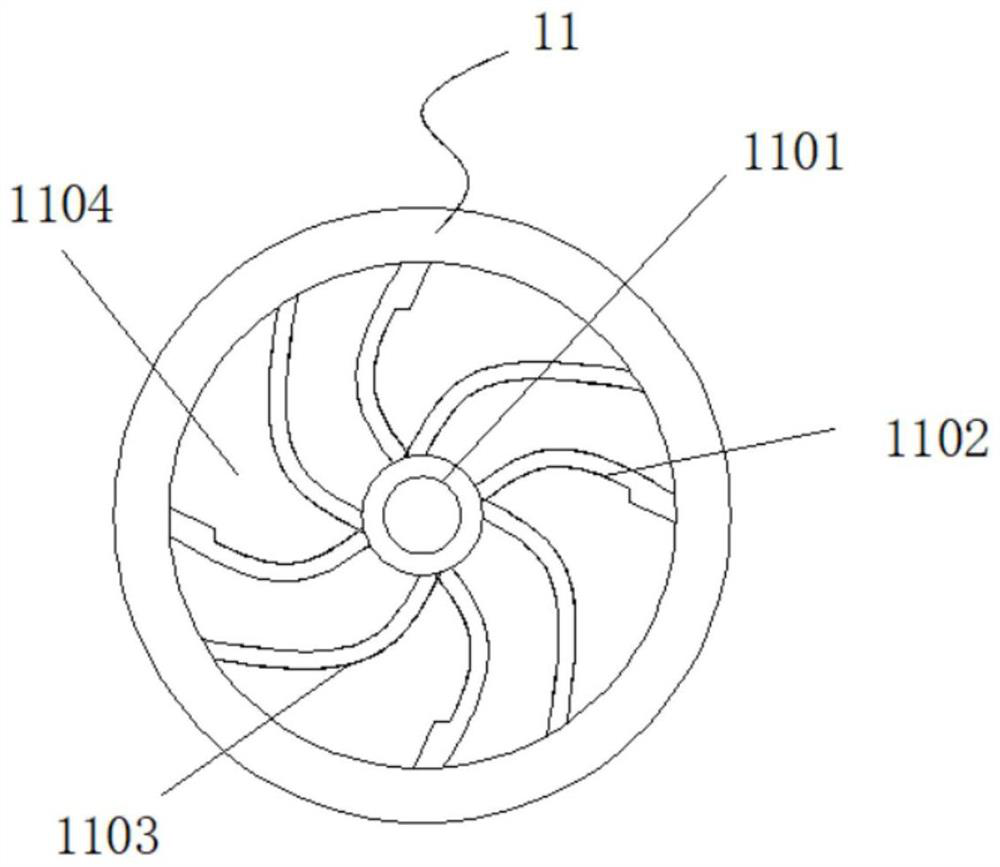

Wear-resistant and corrosion-resistant rubber lining slurry pump

InactiveCN112049804AReduce workloadQuick connectionSpecific fluid pumpsPump componentsImpellerEngineering

The invention discloses a wear-resistant and corrosion-resistant rubber lining slurry pump, and particularly relates to the technical field of slurry pumps. The wear-resistant and corrosion-resistantrubber lining slurry pump comprises a bracket and a pump body, wherein a fixed mounting structure is arranged at the bottom end of the bracket, a bearing is arranged inside the top end of the bracket,a rapid connecting structure is arranged on one side of the bearing, the pump body is arranged on the other side of the bearing, and the top end of the pump body is fixedly connected to a short pipe.According to the wear-resistant and corrosion-resistant rubber lining slurry pump, a packing box, a water sealing ring and an auxiliary impeller are arranged, so that during use, in order to ensure the sealing performance of the wear-resistant and corrosion-resistant rubber lining slurry pump, the packing box and the auxiliary impeller are arranged inside the pump body, under the action of the packing box and the auxiliary impeller, the sealing performance of the pump body is effectively guaranteed, moreover, the pressure generated by the auxiliary impeller can prevent liquid from flowing outduring operation, the water sealing ring is arranged between the packing box and the auxiliary impeller, the water sealing ring and the packing box are matched with each other so that external air can be prevented from entering, meanwhile, external impurities can be prevented from entering, and the use efficiency of the wear-resistant and corrosion-resistant rubber lining slurry pump is improved.

Owner:SANLIAN PUMP IND CO LTD

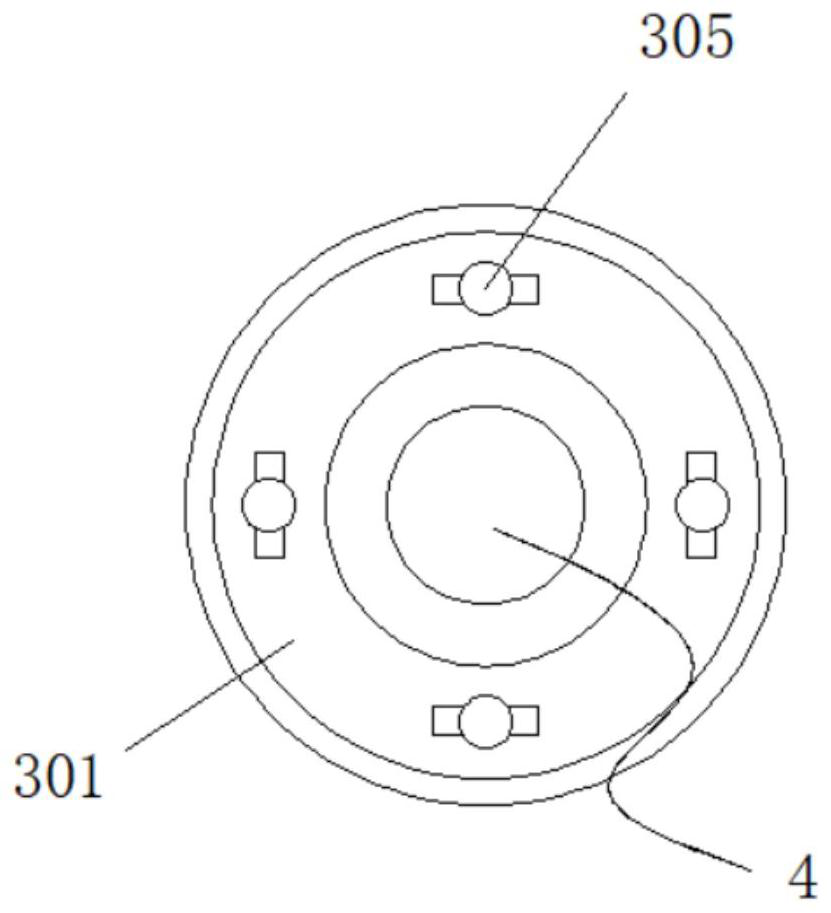

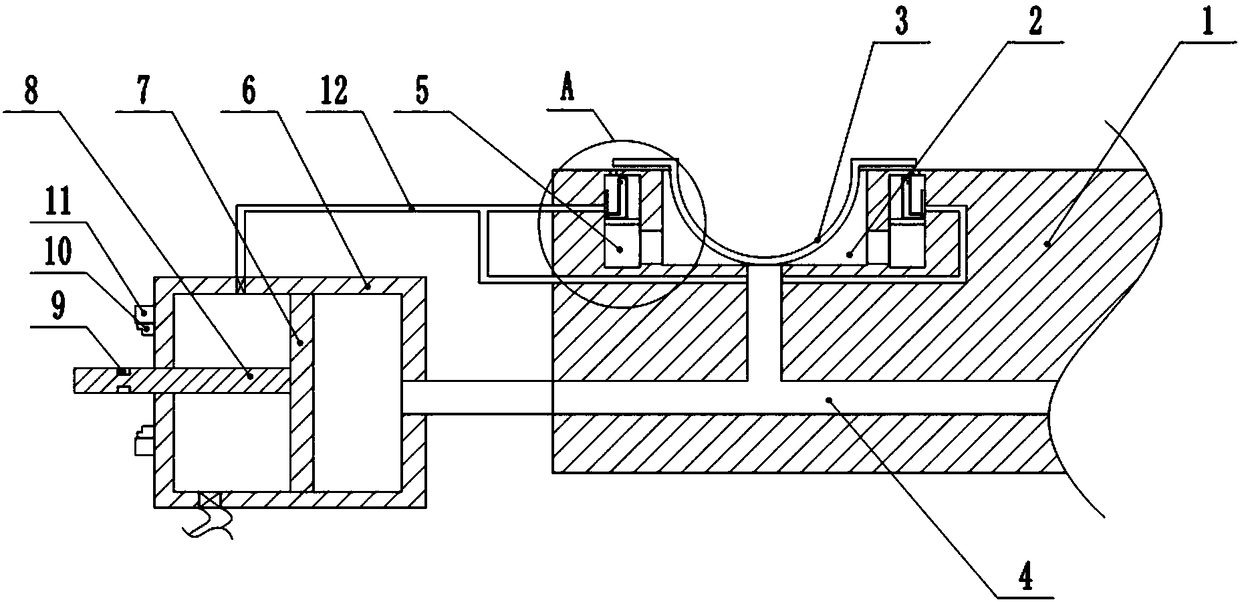

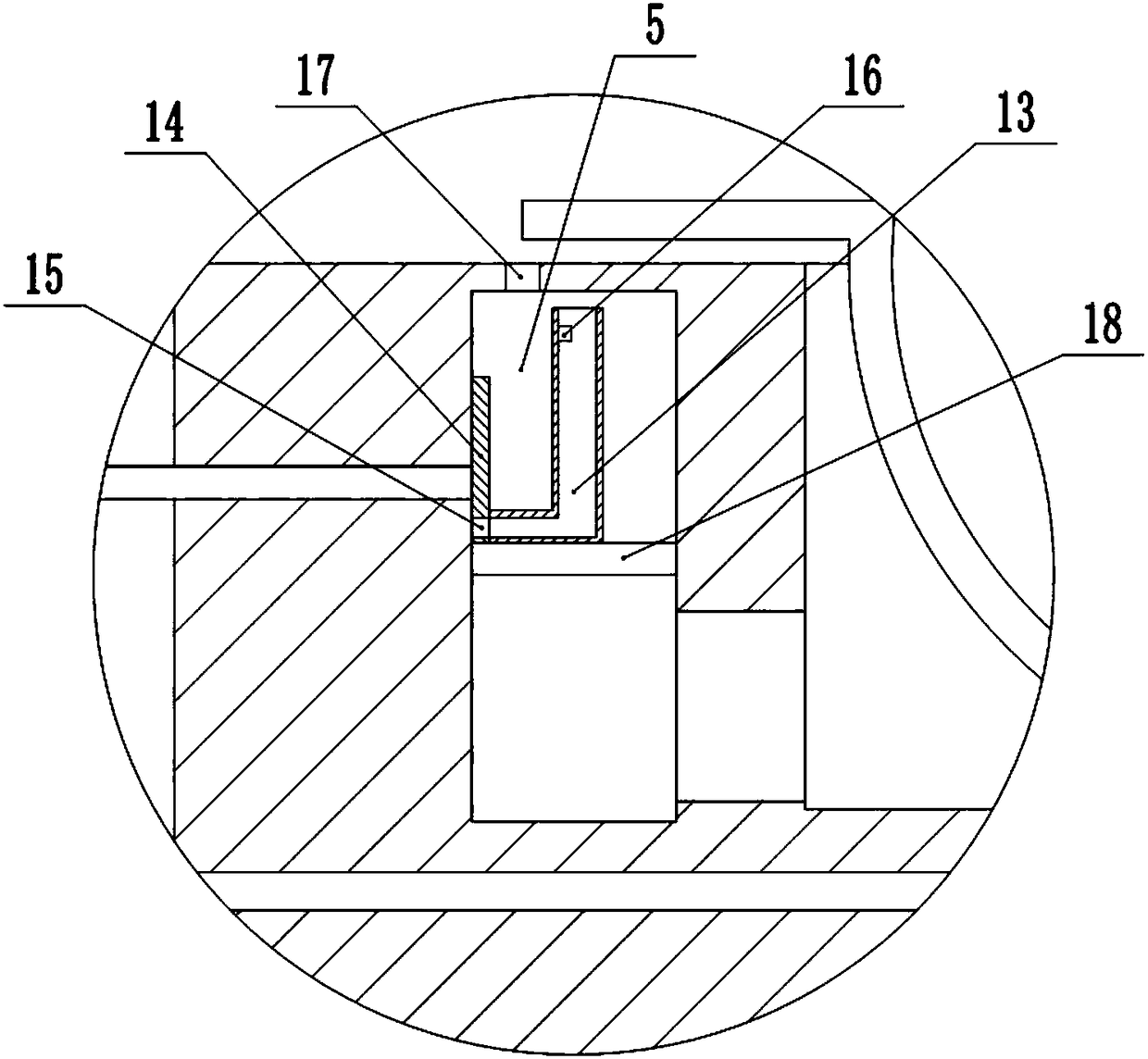

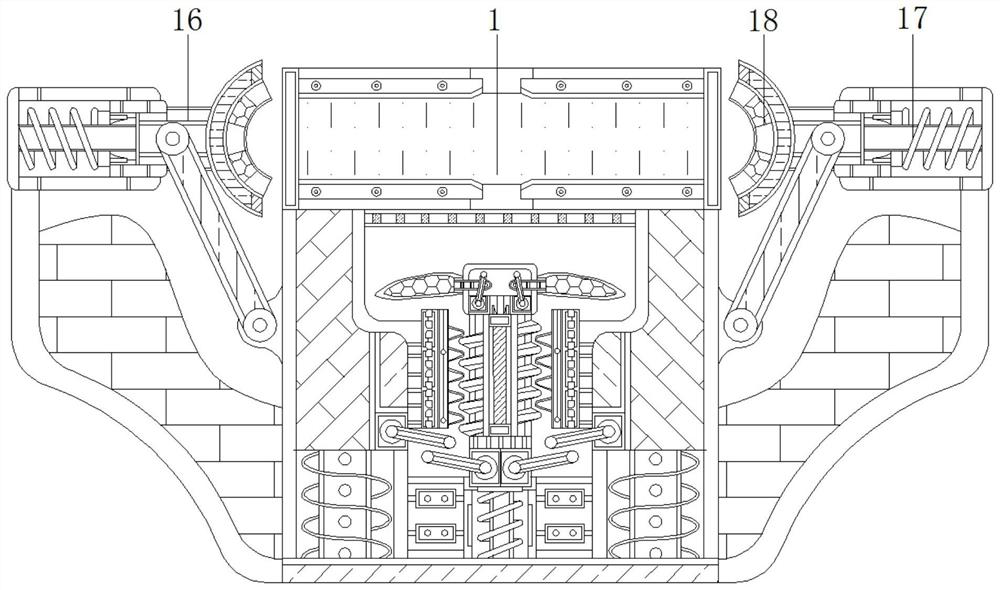

A steam turbine floating valve support structure

ActiveCN105888745BSolve support problemsSimple structureMachines/enginesEngine componentsAgricultural engineeringSteam turbine

The invention discloses a steam turbine floating valve support structure, which is characterized in that it includes an adjusting screw, a valve support plate, a support rod, a sleeve, a spring cover plate, a spring bottom plate and a combined spring; The top of the valve bracket structure, its upper part is connected with the valve support plate, and its bottom is connected with the top of the strut; the strut is installed in the sleeve, and its bottom is in contact with the bottom block on the bottom of the sleeve; the upper end of the sleeve is welded on On the inner wall of the spring cover plate, the sleeve passes through the combined spring, and the bottom of the sleeve is placed in the center hole of the spring bottom plate and there is a certain gap with the spring bottom plate; the bottom of the sleeve is welded with a pad, and the bottom block is placed directly on the On the cushion block; the combined spring is located between the spring cover plate and the spring bottom plate, and tie rod bolts are arranged at the four corners of the spring bottom plate and the spring cover plate. The invention has simple structure, advanced and novel design, and effectively solves the problem of valve support arranged on both sides of the cylinder.

Owner:DONGFANG TURBINE CO LTD

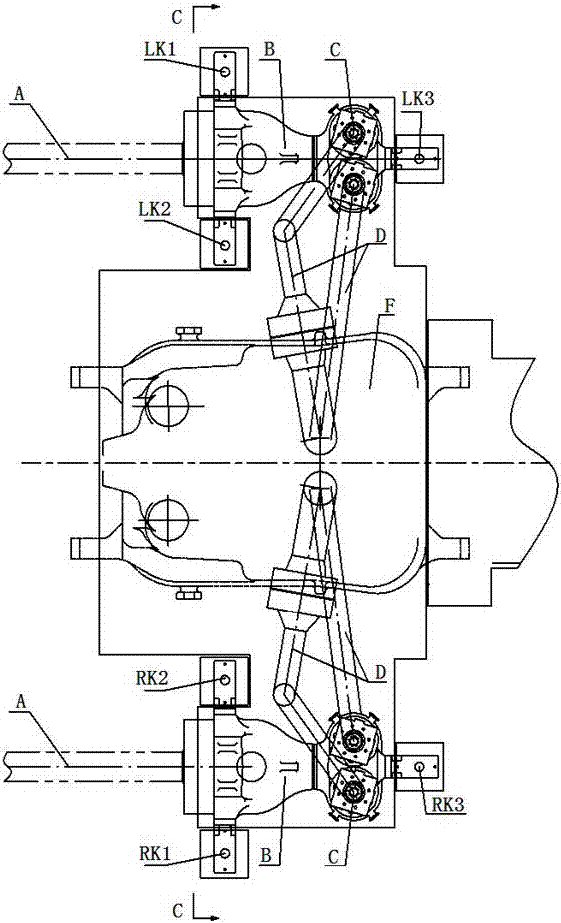

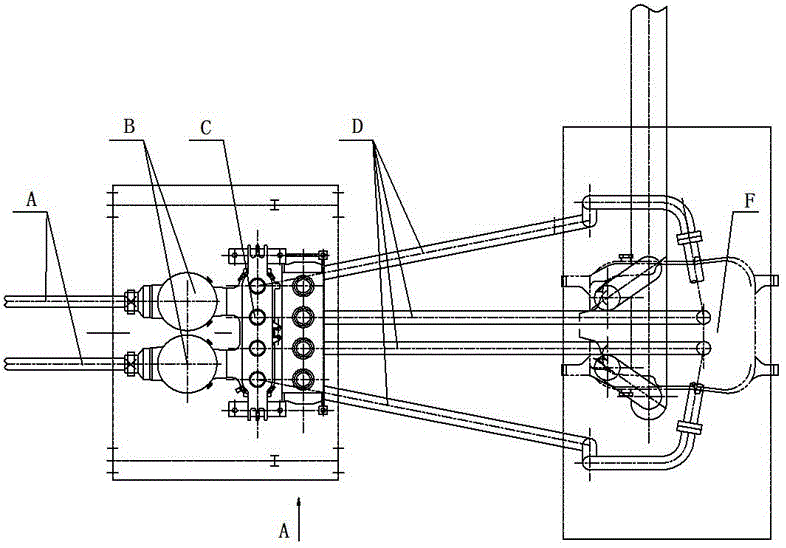

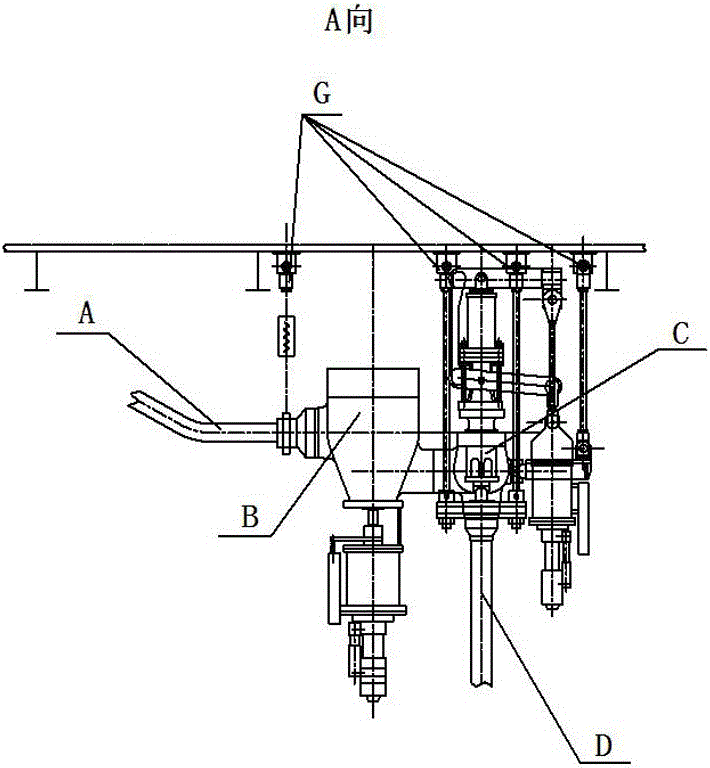

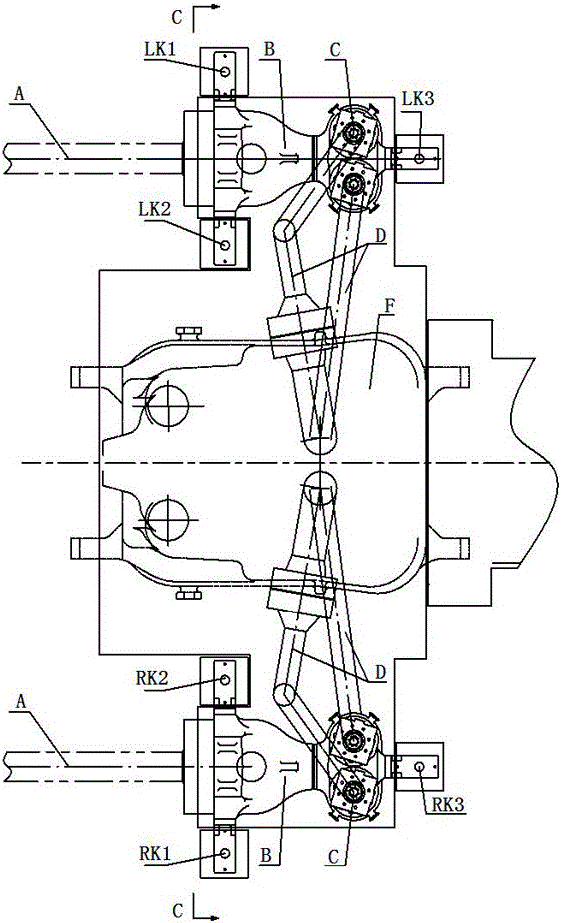

Floating valve bracket structure of steam turbine

ActiveCN105888745ASolve support problemsSimple structureMachines/enginesEngine componentsAgricultural engineeringSteam turbine

The invention discloses a floating valve bracket structure of a steam turbine. The floating valve bracket structure of the steam turbine comprises an adjusting screw, a valve support plate, a strut, a casing pipe, a spring cover plate, a spring bottom plate and a combined spring. The adjusting screw is arranged at the top of a floating bracket, the upper part of the adjusting screw is connected with the valve support plate, and the bottom of the adjusting screw is connected with the top of the strut; the strut is installed in the casing pipe, the bottom of the strut is in contact with a bottom block on the bottom of the casing pipe, the upper end of the casing pipe is welded on the inner wall of the spring cover plate, the casing pipe penetrates the combined spring, and the bottom of the casing pipe is arranged at the position of a central hole in the spring bottom plate and has a certain gap relative to the spring bottom plate; a cushion block is welded on the bottom of the casing pipe, and the bottom block is directly arranged on the cushion block; the combined spring is positioned between the spring cover plate and the spring bottom plate, and stay bolts are arranged on the four corners of the spring bottom plate and the spring cover plate. The floating valve bracket structure of the steam turbine has a simple structure, is advanced and novel in design, and effectively solves the problem of valve supports arranged on both sides of a cylinder is effectively solved.

Owner:DONGFANG TURBINE CO LTD

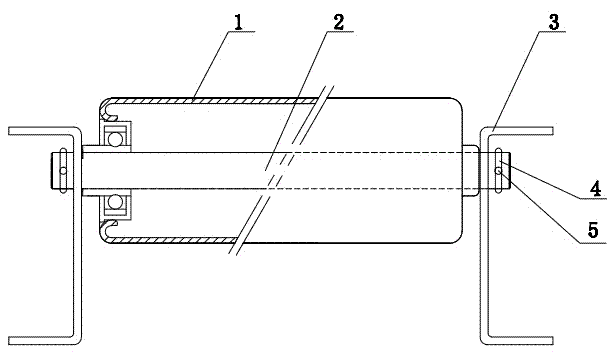

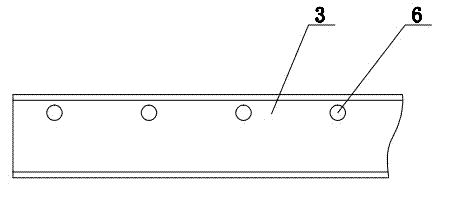

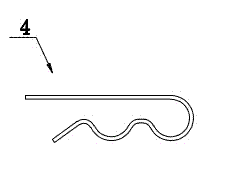

Simple installation structure of unpowered roller shaft

InactiveCN102295146AImprove reliabilityImprove installation efficiencyRollersEngineeringMechanical engineering

Owner:WUXI JIESI LOGISTICS EQUIP

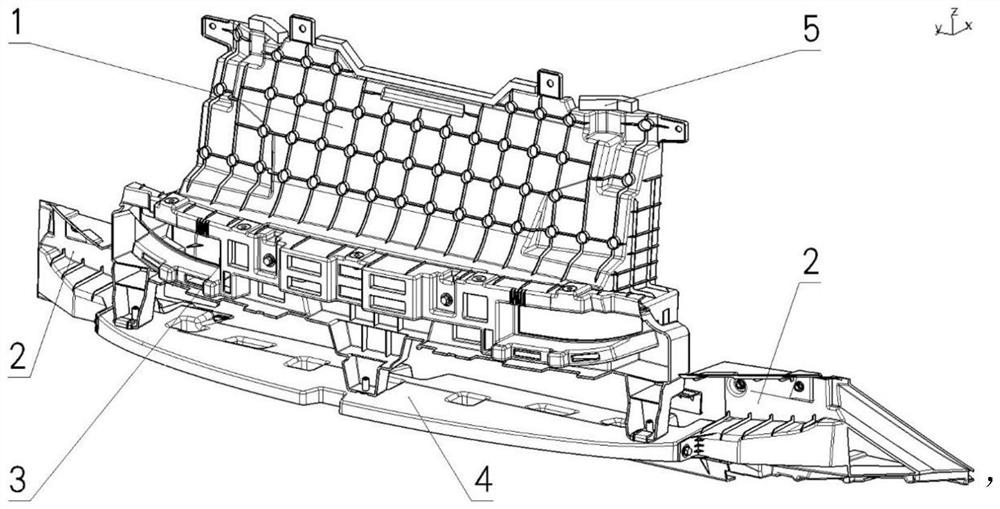

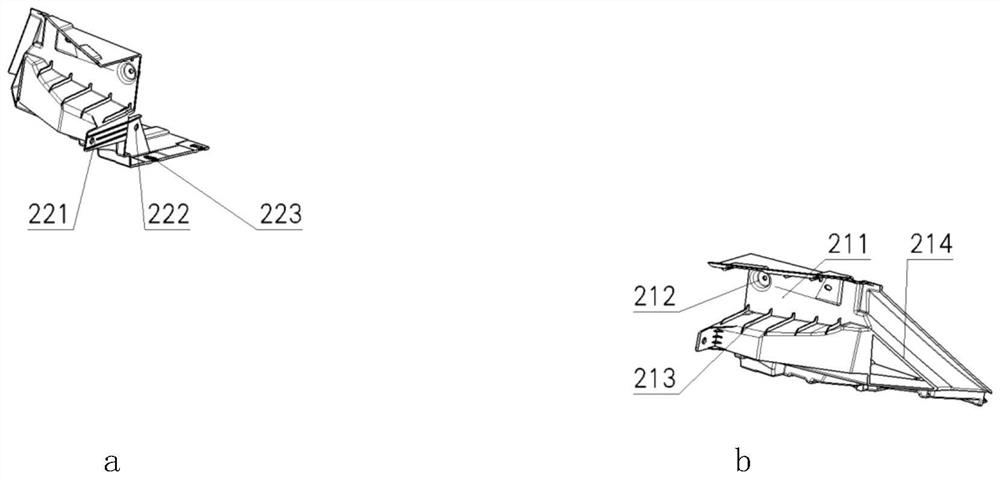

Air deflector structure of pure electric vehicle

PendingCN114407642AAvoid turbulenceGuaranteed heat exchange effectPedestrian/occupant safety arrangementVehicular energy storageHeat managementAir volume

The invention discloses an air deflector structure of a pure electric vehicle, which belongs to the technical field of automobile structures and comprises an air deflector main body, two side air deflectors, a front bumper accessory and a bottom air deflector. The air deflector body guides fresh air flowing from the middle grating and the lower grating to flow upwards through the arc face of the air deflector body and enters the cooling module. The side air guide plates gather air from incoming flows on the two sides of the grating, and the air inlet amount is increased. The bottom air guide plate can guide air flowing from the lower grating into the cooling module and can prevent heat from flowing back from the bottom of the cabin. Due to the cambered surface and inclined arrangement of the air deflector main body, the problem that the air inlet amount of a cooling module is low due to the fact that a grid on a pure electric vehicle is closed can be effectively solved; the bottom air guide plate combines the requirements of heat management and pedestrian protection, has the functions of air guide and shank protection, not only prevents idling heat backflow, reduces the air inlet temperature of the condenser, reduces high-speed leakage, reduces wind resistance in a cabin, but also has the function of protecting pedestrian safety.

Owner:CHINA FIRST AUTOMOBILE

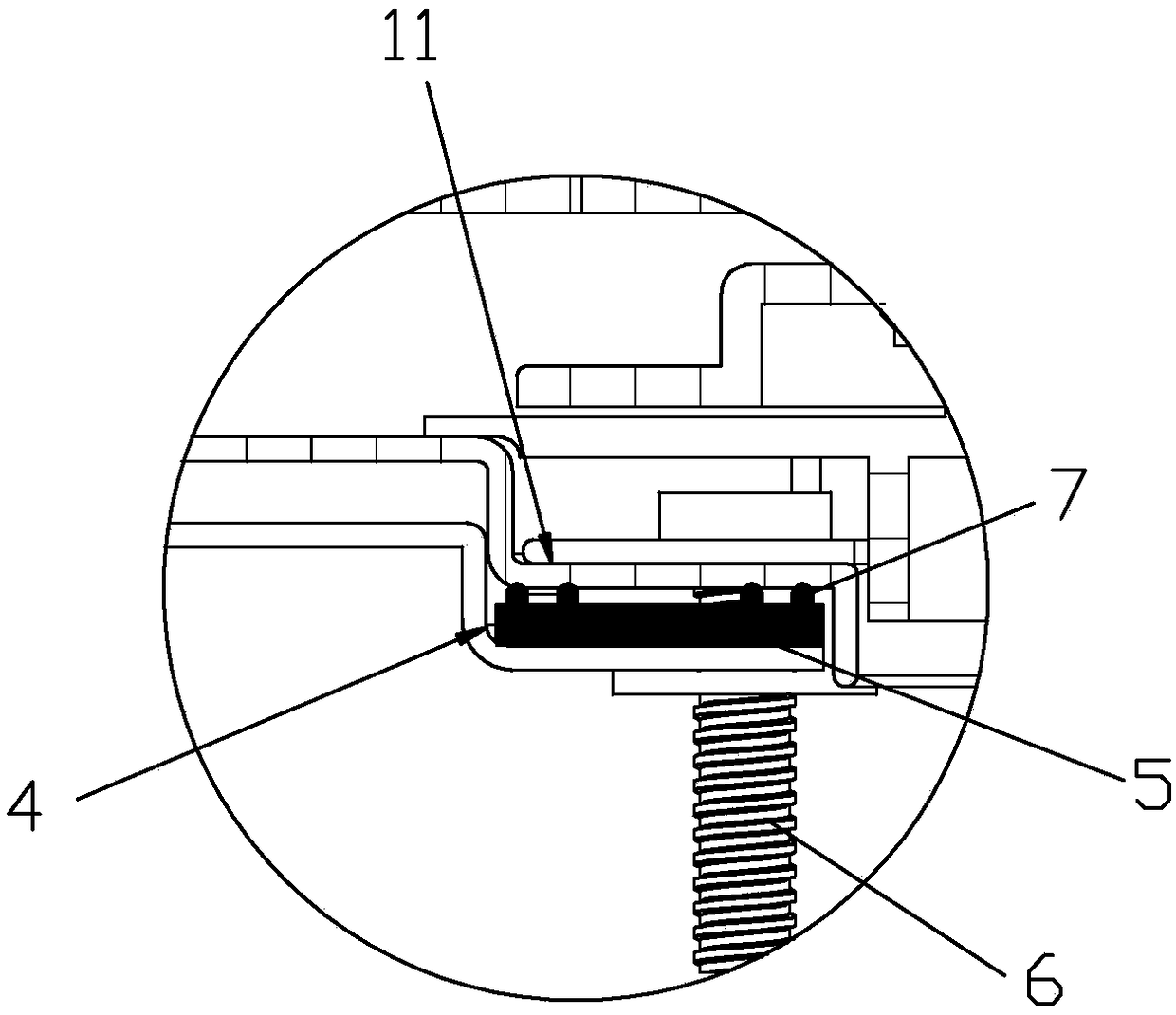

Water containing mechanism of water sink

PendingCN108309196APlay the role of waterproofSolve the problem that cannot be cleaned and affects the cleaning effectTableware washing/rinsing machine detailsWater storage tankEngineering

The invention discloses a water containing mechanism of a water sink. The water containing mechanism comprises a water sink, wherein a water storage tank cover is arranged at the bottom of the water sink; a groove is formed in the water storage tank cover; the groove is provided with a sealing ring; the sealing ring is connected with the water sink; the water sink is provided with a screw rod; thescrew rod penetrates through the sealing ring and is in threaded connection with the water storage tank cover. By adopting the water containing mechanism, the problems that impurities and water scaleaccumulated in a conventional water storage tank of a water sink dish washer cannot be cleaned and the cleaning effect is affected, can be solved.

Owner:嵊州市中天利电子电器厂

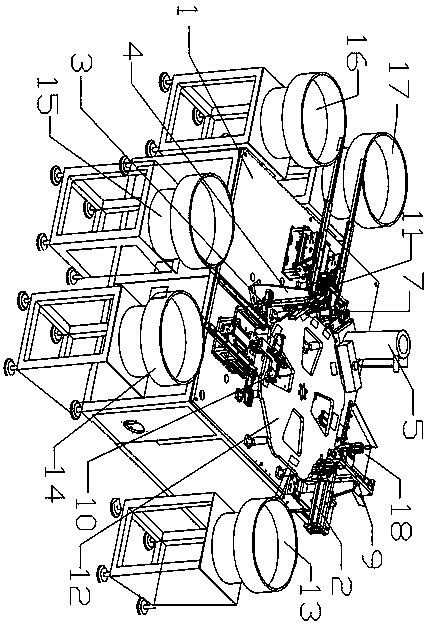

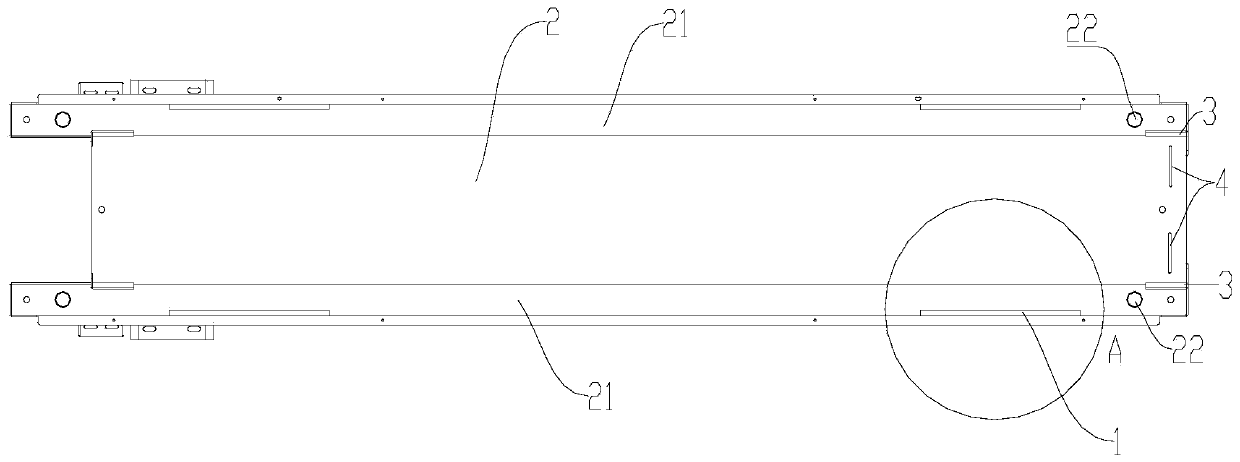

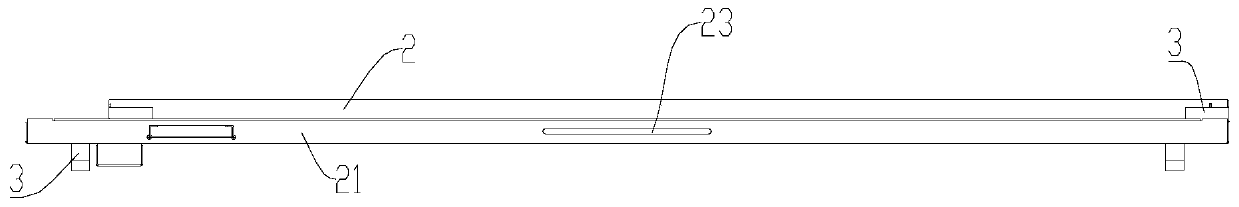

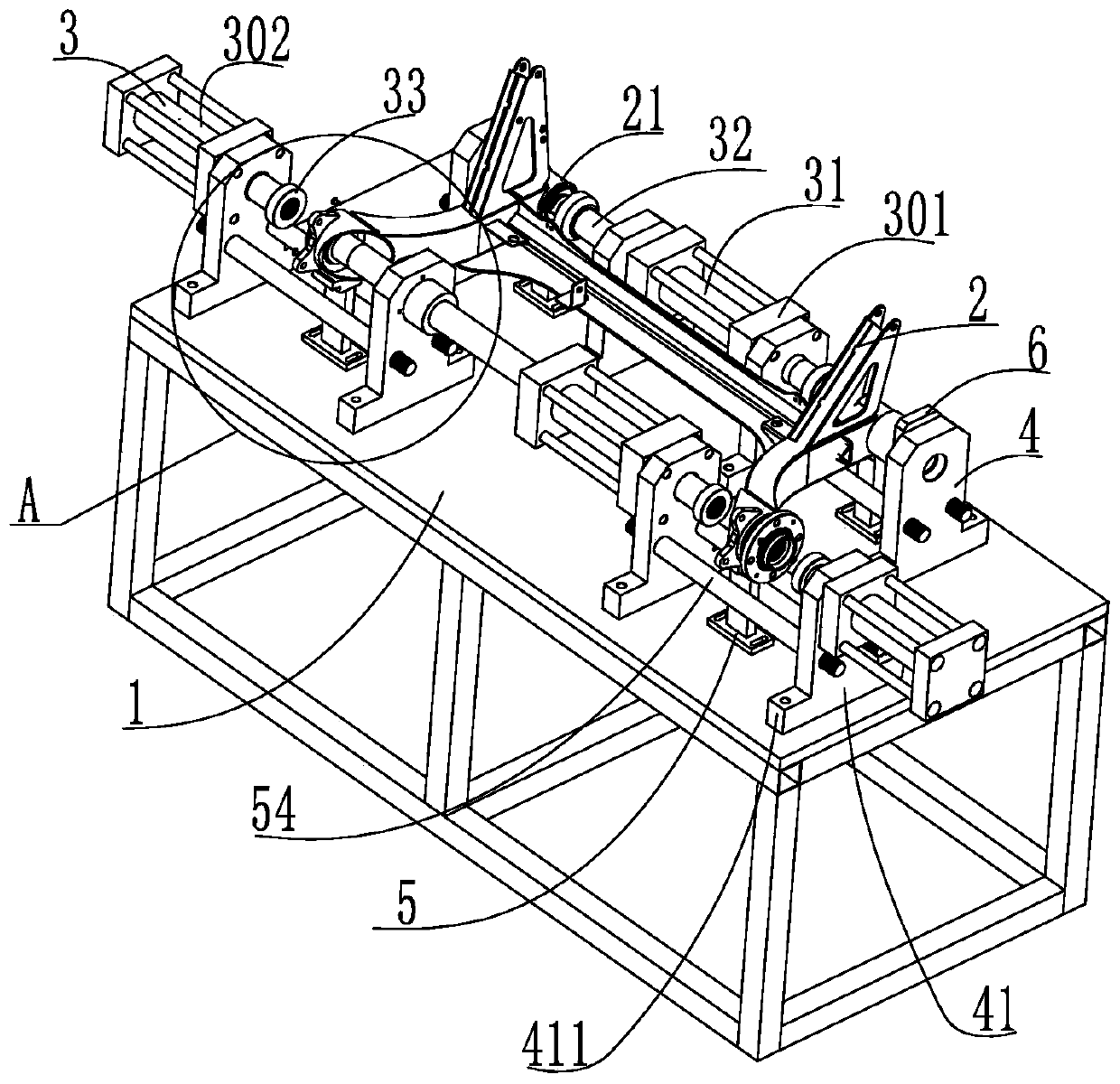

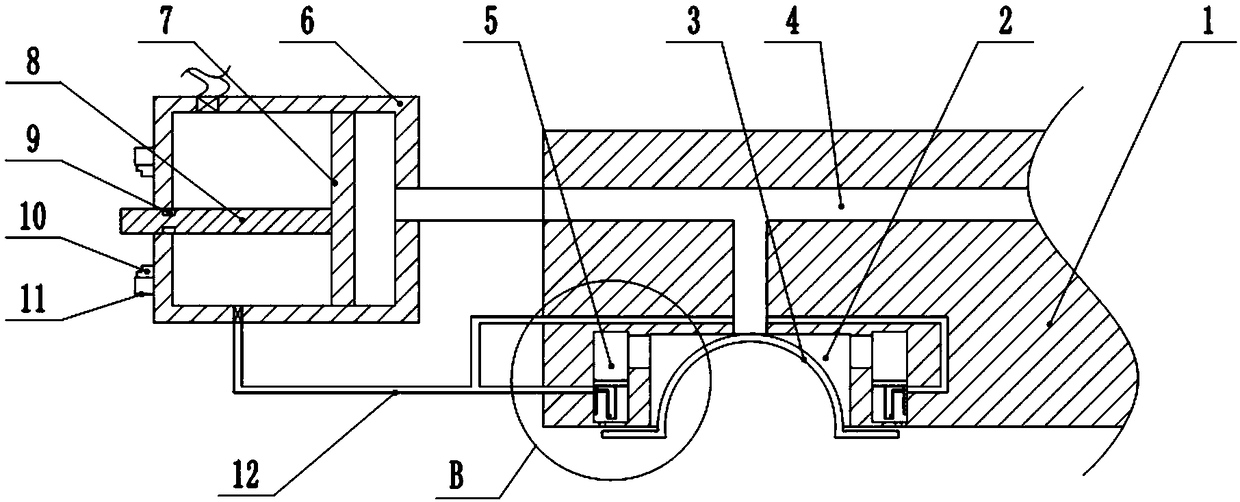

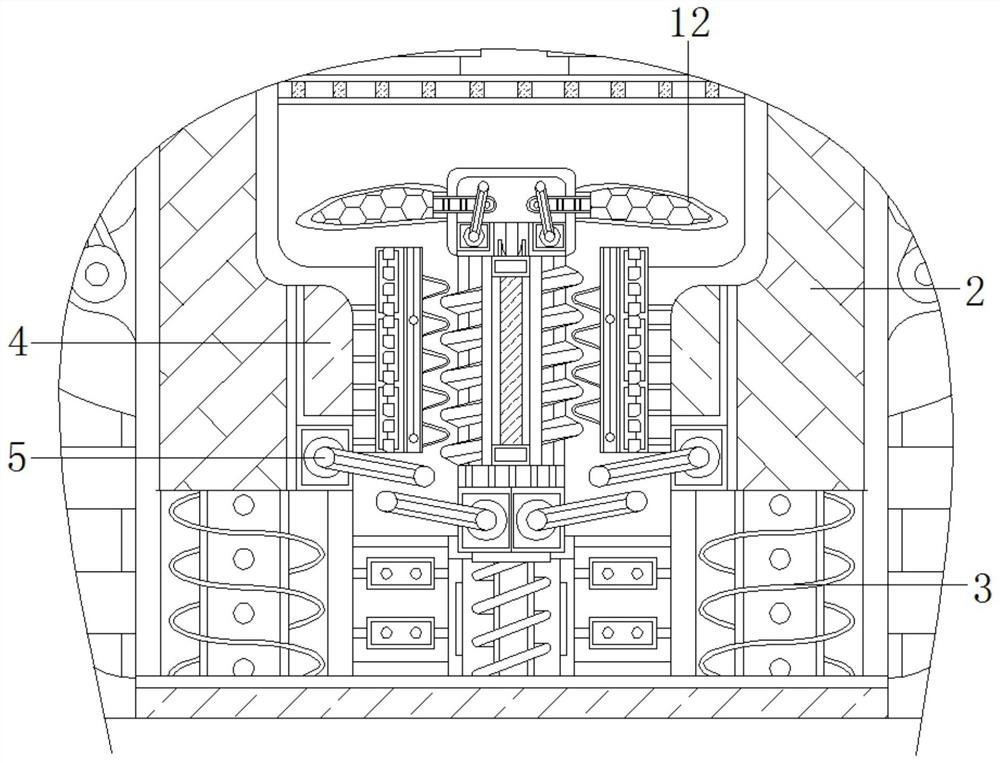

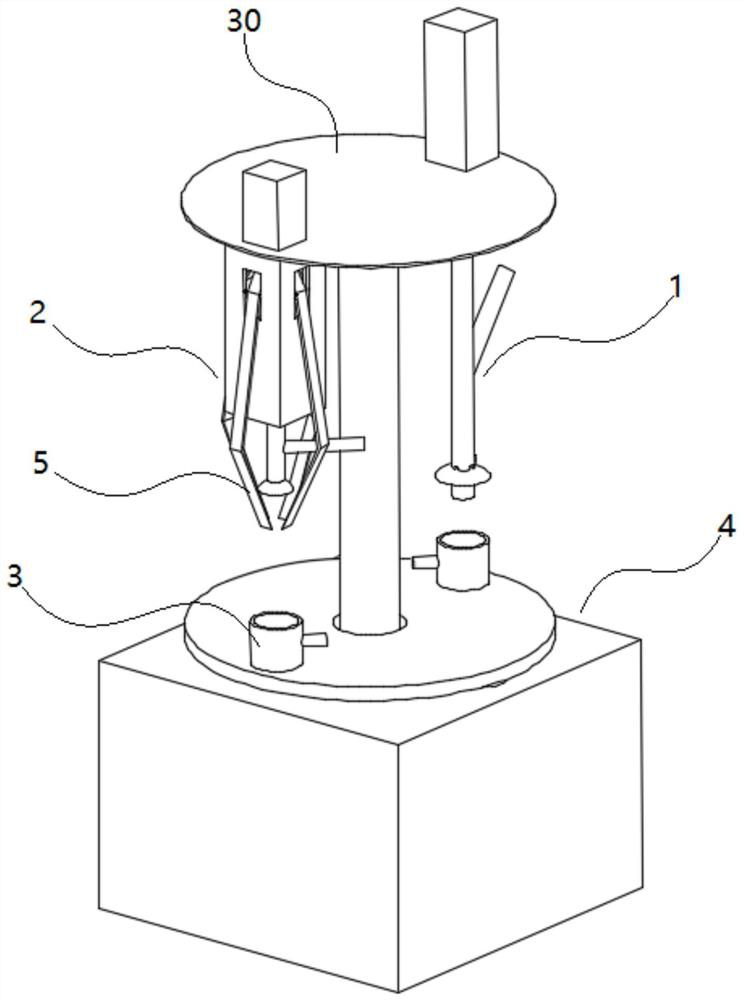

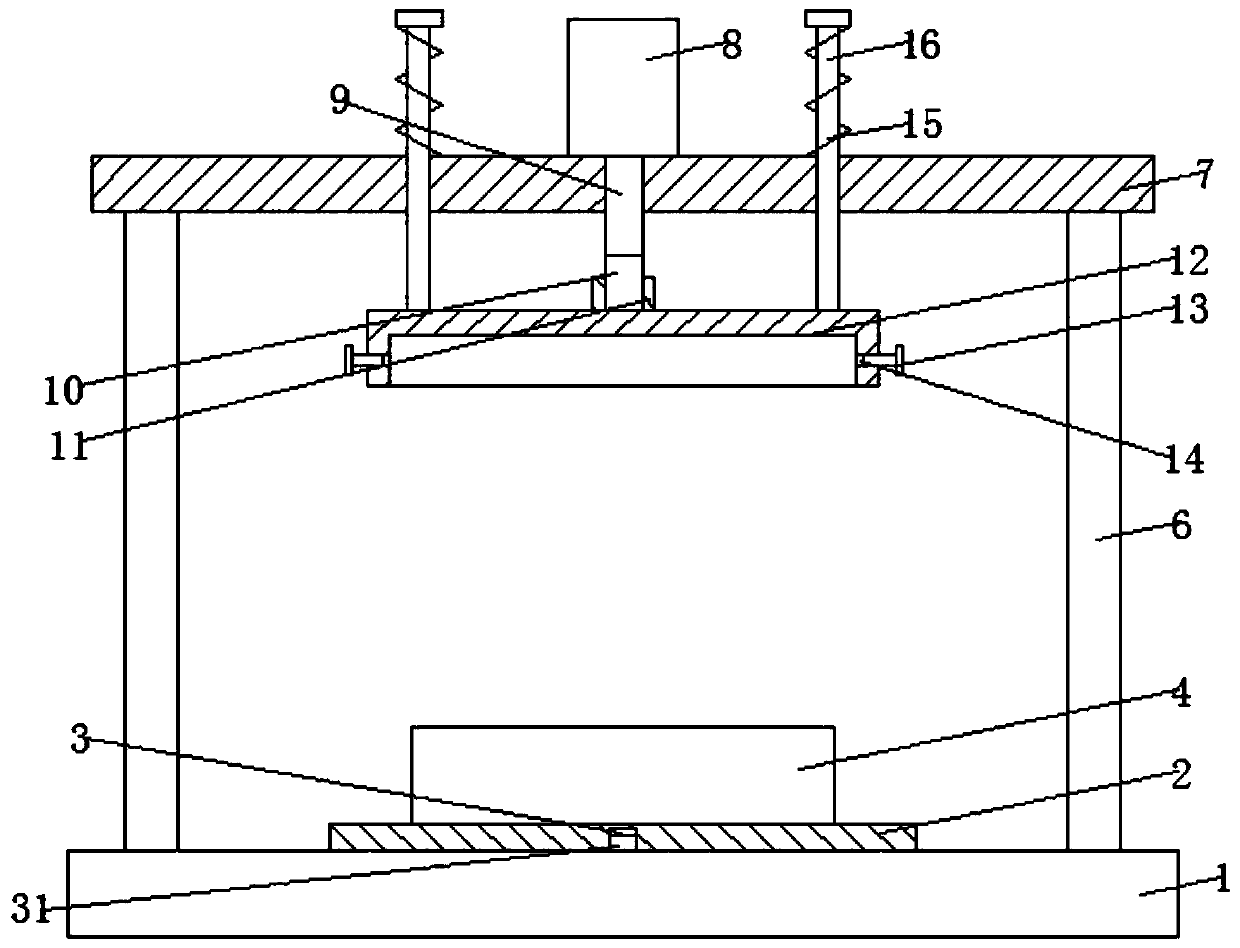

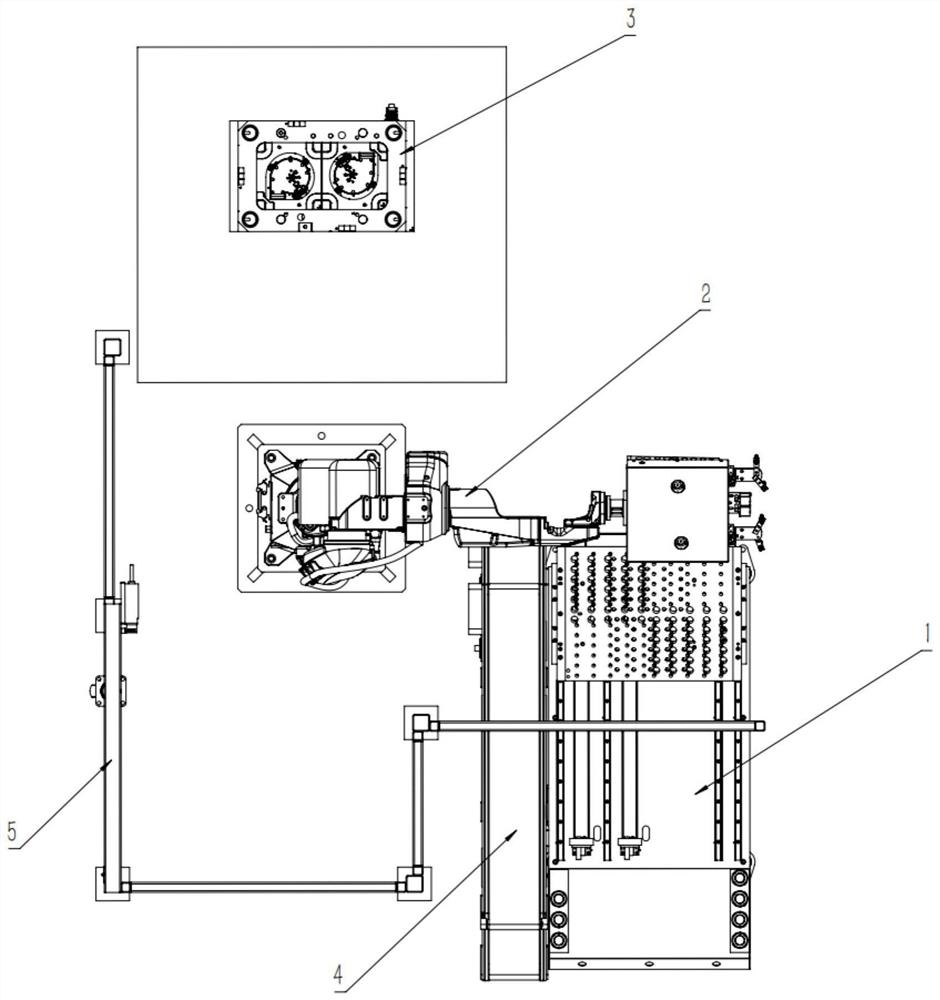

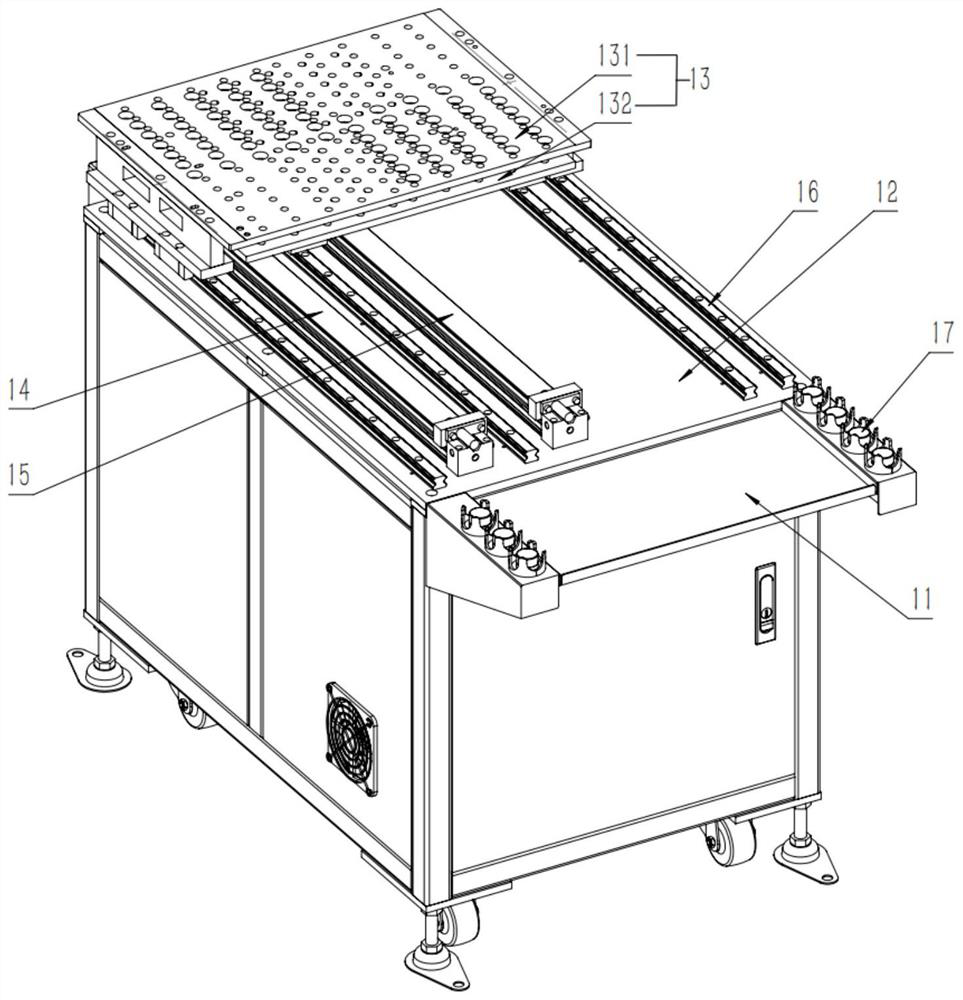

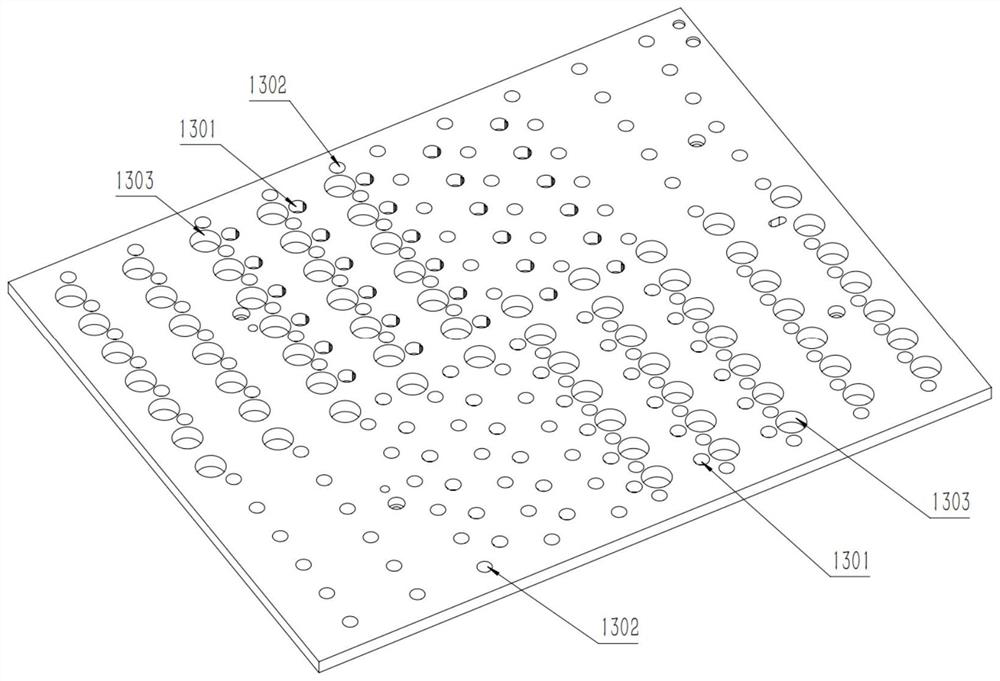

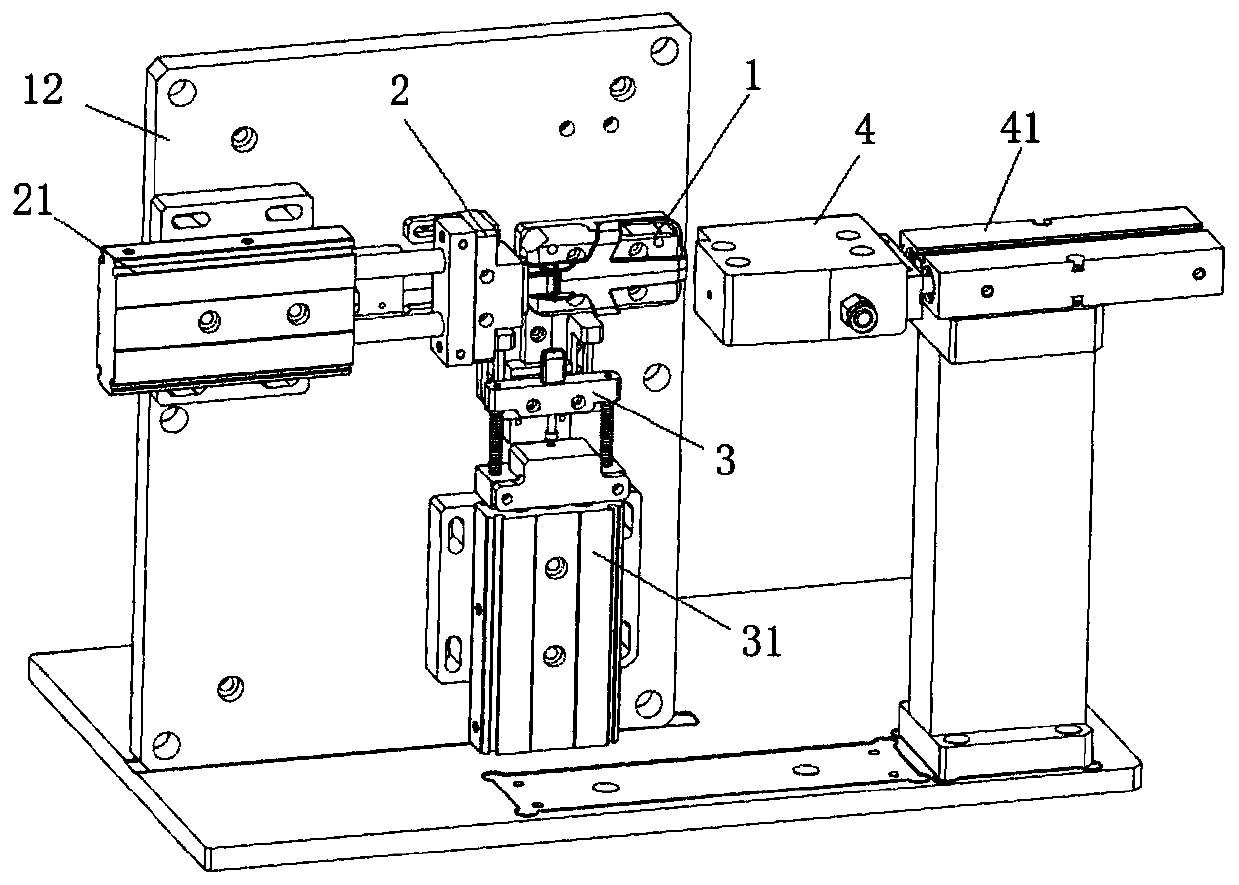

A frame-type electromagnet rapid automatic assembly system

ActiveCN108098338BAvoid installation deviationCompact structureLiquid surface applicatorsAssembly machinesEngineeringElectric control

The invention relates to a frame-type electromagnet rapid automatic assembling system. The frame-type electromagnet rapid automatic assembling system comprises a rack, electric control equipment is arranged below the rack, the rack is provided with a main rotating disc, and the upper portion of the main rotating disc is provided with a plurality of positioning seats; the periphery of the main rotating disc is sequentially provided with a square tube feeding device, an iron core winding feeding device, a guide rod feeding device, a dispensing device, a spring feeding device, a top cover feedingdevice, a welding device and a finished product receiving device in the rotating direction of the main rotating disc; the side face of the spring feeding device is further provided with a winding detecting device and a defective recovery device; and a photoelectric sensing sheet is further arranged at the outer edge, close to the positioning seats, of the main rotating disc. According to the frame-type electromagnet rapid automatic assembling system, a frame-type electromagnet is assembled in a fully-mechanized mode, iron core winding and guide rod mounting deviation are prevented, and the assembling quality is improved; the round main rotating disc is used, the structure is compact, the working process is shortened, and the assembling efficiency is improved; and the winding detecting device and the defective recovery device are matched for operation so as to inspect the quality of iron core winding and remove defectives, and the situation that the defectives flow into the market in amixing mode is avoided.

Owner:陈志伟

Head-up displayer, adjustment method of head-up displayer, mobile terminal and computer readable medium

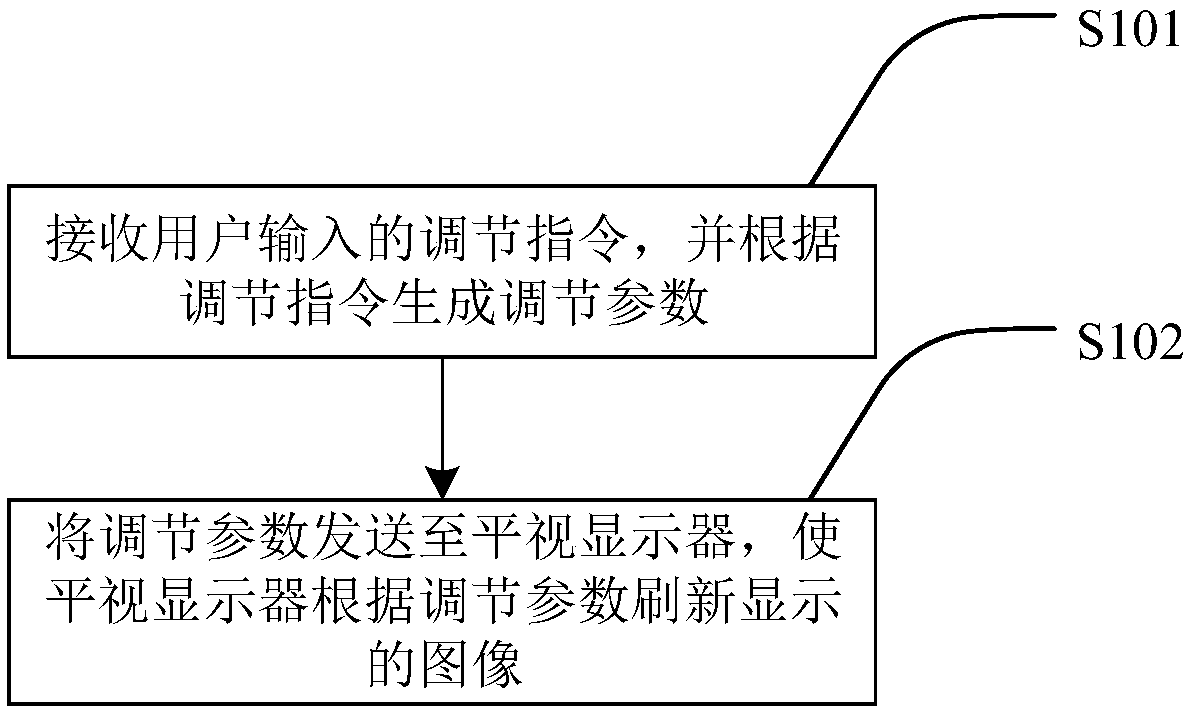

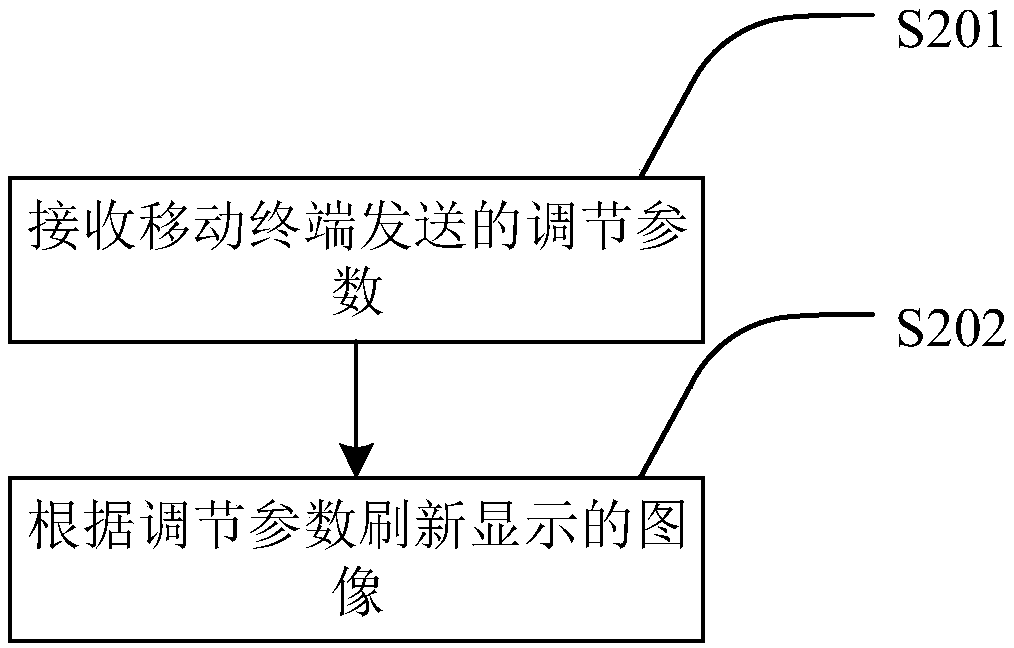

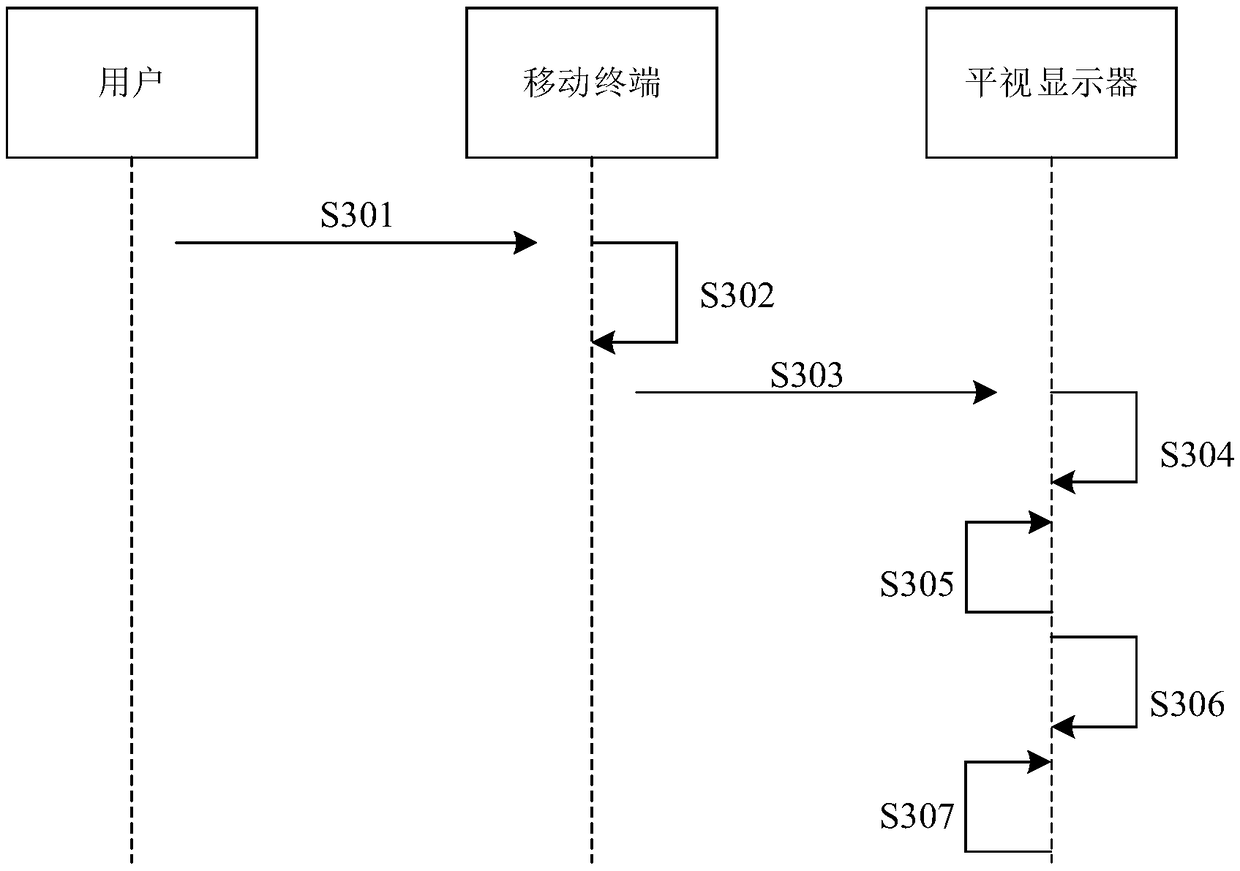

InactiveCN108829365AIncrease visual comfortResolve visual discomfortDigital output to display deviceOptical elementsGraphicsHead-up display

The embodiment of the invention provides a head-up displayer, an adjustment method of the head-up displayer, a mobile terminal and a computer medium and belongs to the technical field of optical projection. The method comprises the steps that an adjustment instruction input by a user is received, and an adjustment parameter is generated according to the adjustment instruction; the adjustment parameter is sent to the head-up displayer, and the head-up displayer refreshes a displayed virtual image according to the adjustment parameter. According to the method, the problems are solved that in thevirtual image displaying process of the head-up displayer, due to design, structures, installation errors and the like, distortion, inclination, position problems, size problems, fuzzy problems and the like of pictures are caused, and accordingly the visual sense of an observer is uncomfortable; therefore, the user can conveniently and quickly adjust the display state of the virtual image of thehead-up displayer according to his / her visual sense habits, and the visual comfort feeling of the user is improved.

Owner:ZHEJIANG CRYSTAL OPTECH

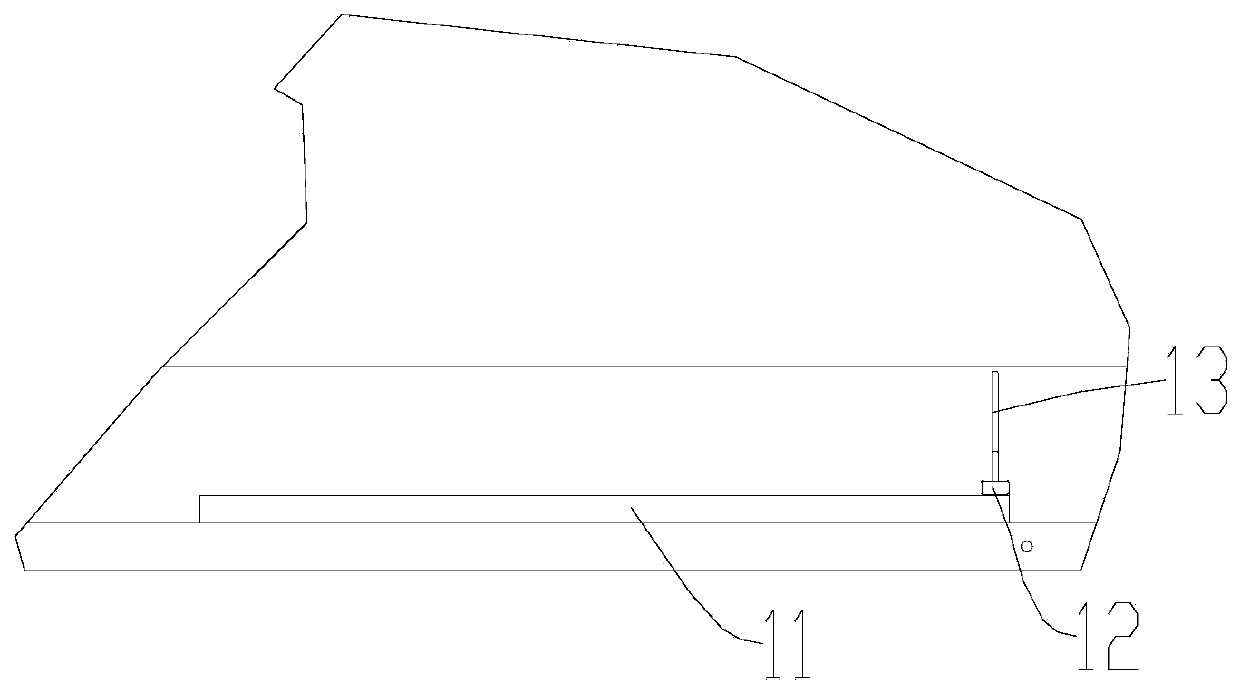

Detection tool for automobile pillar hinges

InactiveCN102997783AAvoid installation deviationImprove detection qualityMechanical measuring arrangementsBlock matchInstallation Error

The invention provides a detection tool for automobile pillar hinges, effectively avoids installation errors of detected automobile pillar hinges, improves quality in detecting the automobile pillar hinges and meets the requirements of the automobile pillar hinges for subsequent installation. The detection tool is characterized by comprising a simulation block matching with an automobile pillar hinge. The simulation block is disposed on a holder provided with automobile body coordinates. A positioning sleeve is disposed on the holder. The simulation block is provided with a positioning surface corresponding to the automobile pillar hinge. A positioning pin matching with the automobile pillar hinge and a detection pin guide hole corresponding to an automobile pillar hinge mounting hole are arranged on the positioning surface. A detection pin is disposed in the detection pin guide hole.

Owner:WUXI MACHINE MACHINERY MFG

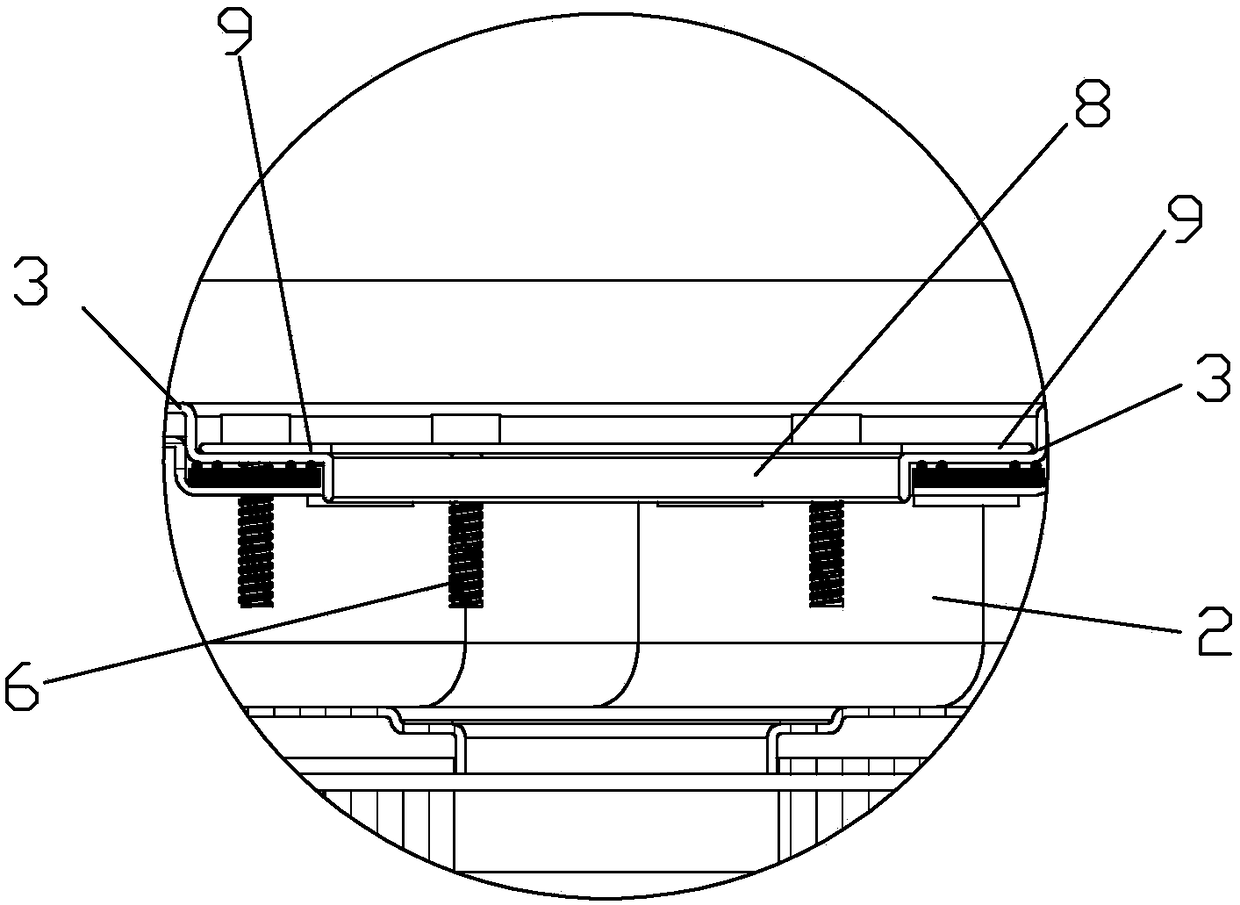

Anti-icing structures, water-containing plate, compressor and air conditioner

PendingCN110500760AGuaranteed safe operationSave man hoursCondensate preventionLighting and heating apparatusReciprocating motionWater flow

The invention provides anti-icing structures, a water-containing plate, a compressor and an air conditioner and relates to the technical field of air conditioners and aims at solving the technical problem that the inner part of the water-containing plate is iced to influence the operation of a unit. The anti-icing structure comprises reciprocating anti-icing parts; by using the anti-icing parts, water positioned at the anti-icing position forms flowing water or is removed; the anti-icing parts comprises sliding rails, sliding blocks and push plates; the water-containing plate comprises a platebody; grooved water receiving parts are arranged on two sides of the plate body; the anti-icing structures are arranged in the water receiving parts; the side walls of the water receiving parts are also provided with water level limiting holes; the plate body is provided with mounting limit holes and mounting baffles; the mounting baffles and the plate body form an integrally forming structure; the compressor comprises the water-containing plate; and the air conditioner comprises the compressor. The anti-icing structures are used for preventing water in the water-containing plate from icing,so that safe operation of the unit is ensured; by using limiting baffles and the mounting limit holes, the work time is saved, the operation is convenient and simple, and mounting errors are reduced;and the limiting baffles and the water-containing plate form an integrated structure, so that the dimensional precision of the baffles is improved.

Owner:GREE ELECTRIC APPLIANCES INC

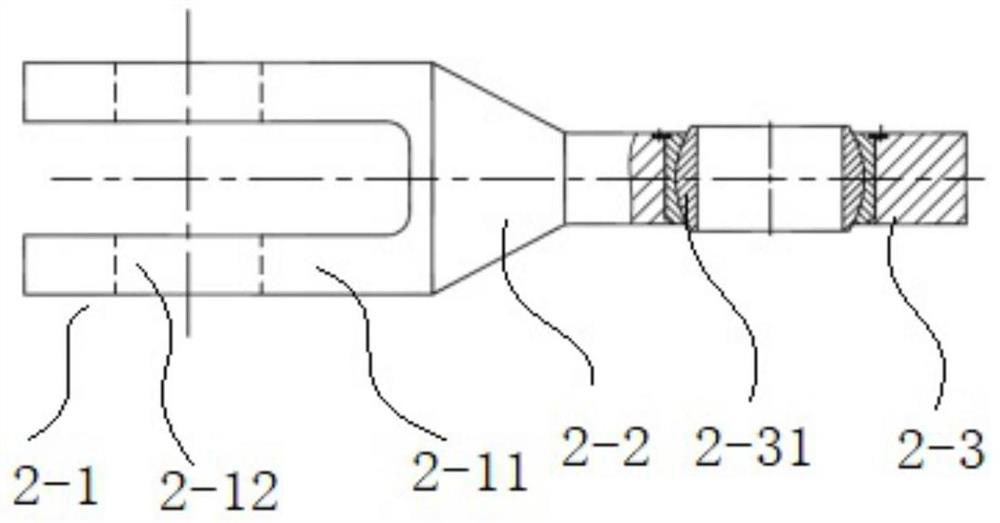

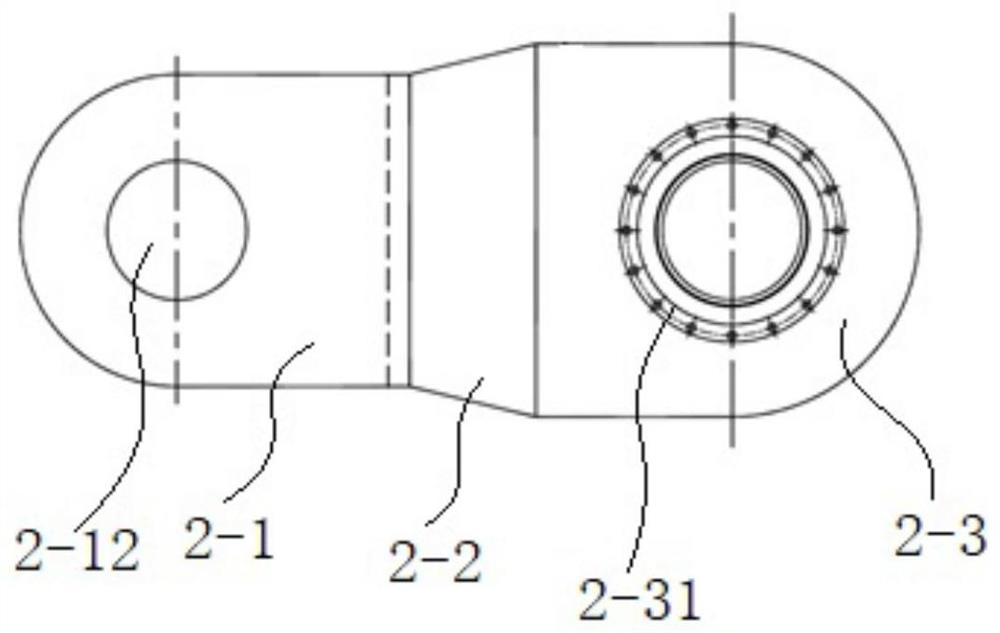

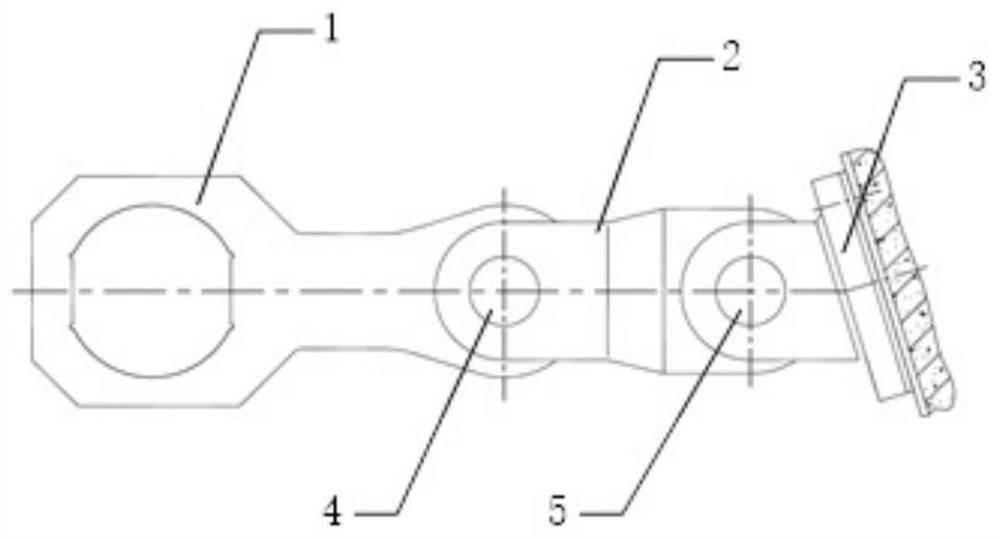

Integrated supporting assembly and transverse supporting structure for nuclear power steam generator

InactiveCN112682676ASimple structureAvoid damaging effectsNuclear energy generationStands/trestlesNuclear powerMechanical engineering

The invention relates to the technical field of supports and hangers of steam generators, and specifically relates to an integrated supporting assembly and a transverse supporting structure for a nuclear power steam generator. The integrated supporting assembly comprise a device connecting part, a middle connecting part and a wall body connecting part which are integrally connected. The device connecting part is a U-shaped hinge joint. Pin holes are formed in two symmetrical clamping arms of the U-shaped hinge joint correspondingly. The whole wall body connecting part is in a plate shape, a spherical hinge hole is formed in the wall body connecting part, and a spherical hinge is arranged in the spherical hinge hole. The two ends of the middle connecting part are connected with the closed end of the U-shaped hinge joint and one end of the wall body connecting part correspondingly. The central axes of the two pin holes are parallel to the central axis of the spherical hinge hole. Compared with the prior art, the supporting assembly is integrally manufactured and formed, and the influence of part damage caused by local stress concentration and the like of combined components under the huge load is avoided; a high-strength material is adopted, and enough strength is achieved; and the transverse supporting structure of the steam generator is formed by conducting connection in a hinged mode, factors, such as operation space, are fully considered, and debugging and overhauling are facilitated.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

A multi-station synchronous rear axle bearing pressing equipment

ActiveCN108637645BImprove processing efficiencyImprove work efficiencyVehicle componentsMetal working apparatusPillow block bearingStructural engineering

The invention discloses a multi-station synchronous rear axle bearing press-fitting device. The device comprises a workbench and a rear axle die, the rear axle die comprises a plurality of bearing seats, the bearing seats are internally provided with to-be-pressed bearings, at least one side of the two axial side faces of each bearing seat is provided with a pressure applying oil cylinder, each pressure applying oil cylinder comprises an oil cylinder shell and a piston rod, pressure applying blocks attached to the side faces of the to-be-pressed bearings are arranged at the ends, facing outwards, of the piston rods, the piston rods are coaxial with the to-be-pressed bearings, the axis of each to-be-pressed bearing is parallel to the working upper plane of the workbench, a limiting assemblyand a positioning assembly for positioning the rear axle die are arranged on the workbench, and the pressure applying oil cylinders are fixed on the limiting assembly. The device has the advantages that when re-machining is carried out after pre-positioning, fixing of the rear axle die is completed by the pressure applying oil cylinders and the pressure applying blocks, the machining space is enlarged, positioning and machining are convenient, the machining precision of the to-be-pressed bearings and the bearing seats is improved, the to-be-pressed bearings are prevented from being eccentricto the bearing seats, the plurality of to-be-pressed bearings can be synchronously machined through the pressure applying oil cylinders, so that the working efficiency of bearing press-fitting is improved.

Owner:HANGZHOU RONG DA INTELLIGENT MFG TECH CO LTD

Device for mounting mobile phone button elastic pieces

PendingCN108480817AAvoid installation deviationImprove installation efficiencyGas flame welding apparatusEngineeringSlide plate

The invention belongs to the field of electronic product processing, in particular to a device for mounting mobile phone button elastic pieces. The device comprises a positioning mechanism, a gas welding mechanism and a driving mechanism. The positioning mechanism comprises a positioning plate. The gas welding mechanism comprises multiple welding cavities formed around each positioning groove. A sliding plate is slidably connected in each welding cavity. The bottoms of the welding cavities are correspondingly communicated with the positioning grooves. Liquid outlet holes communicated with thewelding cavities are formed in the portions, at the tops of the welding cavities, of the positioning plate. A gas welding wire is placed on the portion, above the corresponding sliding plate, in eachwelding cavity. Gas inlet holes communicated with the welding cavities are formed in the positioning plate. A baffle for blocking the corresponding gas inlet hole is arranged on each sliding plate. Through holes capable of being communicated with the gas inlet holes are correspondingly formed in the bottoms of the baffles. An L-shaped pipe is fixedly connected to each sliding plate. The L-shaped pipes are filled with acetylene gas. The driving mechanism comprises a piston cylinder. A piston is slidably connected in the piston cylinder. The piston is fixedly connected with a driving rod. By theadoption of the scheme, the problems of time-consuming and labor-consuming manual installation are solved.

Owner:重庆金茂联合电子有限公司

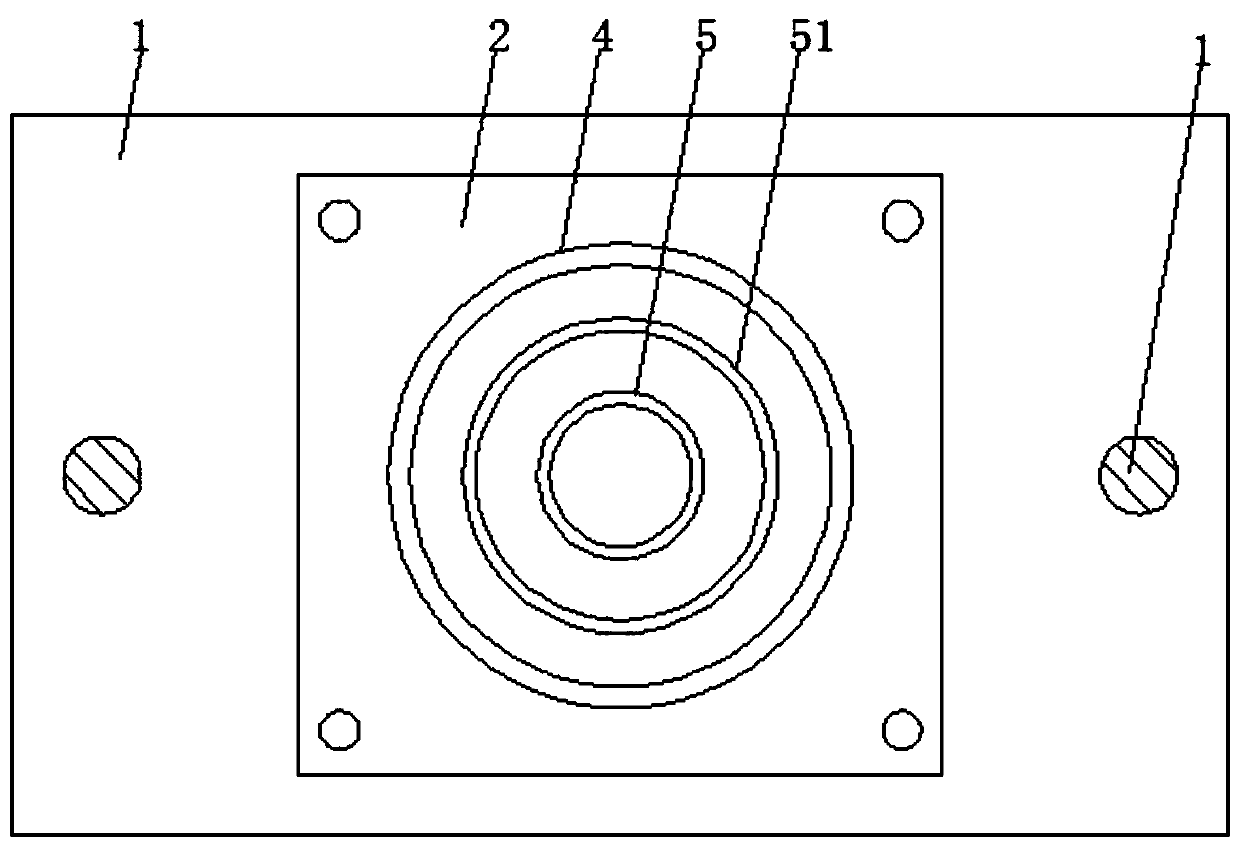

Self-centering auxiliary equipment for mounting bearing rubber seat of central air conditioner

PendingCN113954380AQuality improvementAvoid installation deviationCleaning using gasesBearing unit rigid supportStructural engineeringFan blade

The invention relates to the technical field of central air conditioners, and discloses self-centering auxiliary equipment for mounting a bearing rubber seat of a central air conditioner. The self-centering auxiliary equipment comprises a mounting seat, a supporting seat is fixedly connected to the bottom of the mounting seat, a supporting spring is movably connected to the bottom of the supporting seat, a connecting plate is fixedly connected to the right side of the supporting seat, the bottom of the connecting plate is fixedly connected with an extrusion rod, the bottom of the extrusion rod is movably connected with a transmission rod, and the right end of the transmission rod is fixedly connected with a rotating seat. The bearing rubber seat is placed in the mounting seat, so that the supporting spring is compressed to deform to drive the supporting seat to move, the supporting seat moves to drive a cleaning rotating rod to move together, at the moment, the cleaning rotating rod moves downwards and rotates at the same time, so that negative pressure fan blades are driven to rotate to suck impurities existing in bearing beads, and the effects that the impurities existing in the bearing beads are automatically removed in the assembling process, and the quality of the bearing rubber seat is improved are achieved.

Owner:李岩

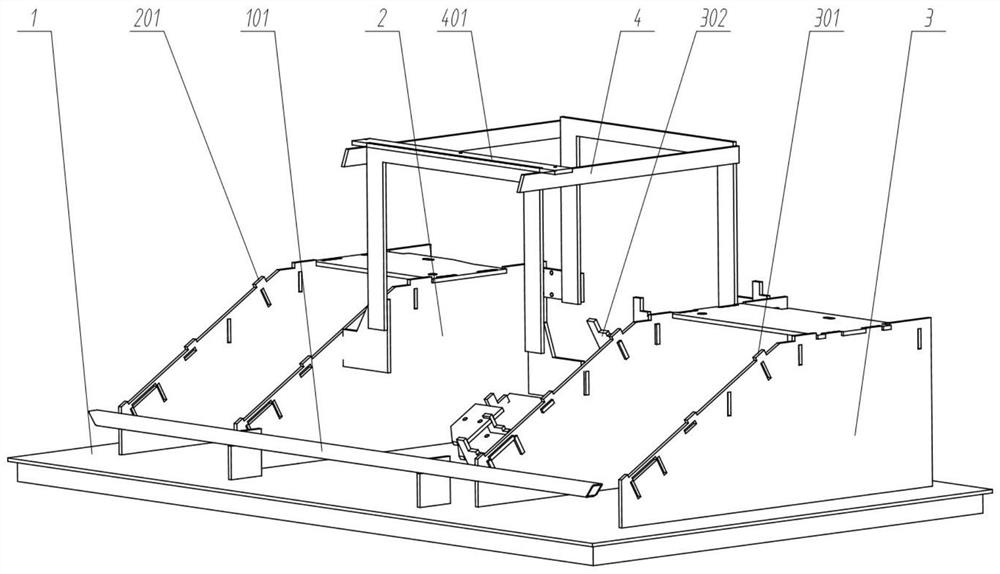

Special vehicle rear floor assembly welding tool

InactiveCN112496632APrevent movementPrevent deviationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention provides a special vehicle rear floor assembly welding tool, belongs to the technical field of welding tools, and aims at solving the problems that an existing special vehicle rear floorassembly welding tool cannot guarantee the welding precision of a special vehicle rear floor assembly, small displacement can be generated when the special vehicle rear floor assembly is welded, andwelding deviation can be caused. The special vehicle rear floor assembly welding tool comprises a base; the left side of the upper portion of the base is fixedly connected with a group of left side welding bracket; the right side of the upper portion of the base is fixedly connected with a group of right side welding bracket; the right side of the left side welding bracket is fixedly connected with a group of top welding bracket; and the top welding bracket is fixedly connected to the left side of the right side welding bracket. According to the special vehicle rear floor assembly welding tool, positioning is achieved through installation of the special vehicle rear floor assembly, the installation deviation of the special vehicle rear floor assembly is prevented, and the special vehicle rear floor assembly is fixed by limiting the special vehicle rear floor assembly, so that the welding deviation caused by movement during welding of the special vehicle rear floor assembly is avoided.

Owner:十堰嘉路车业有限公司

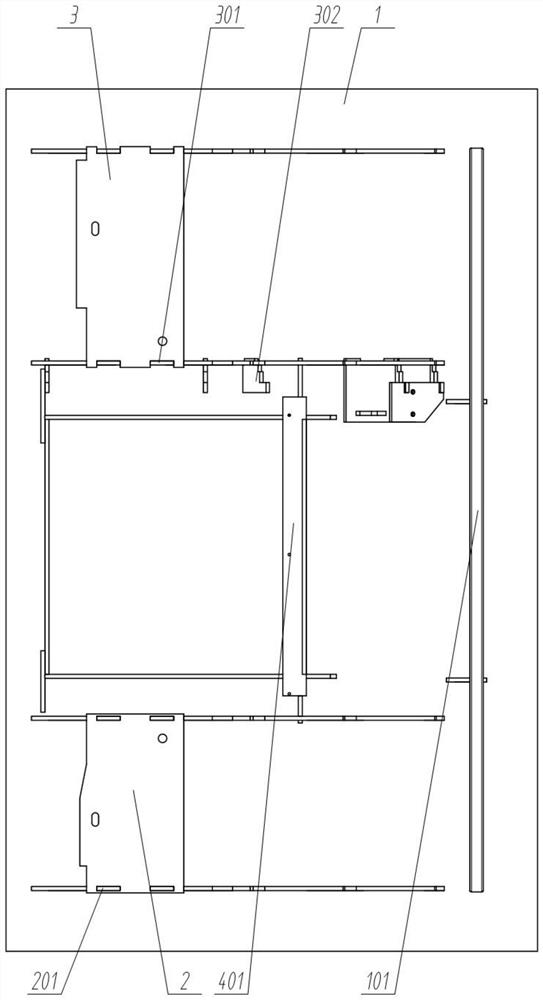

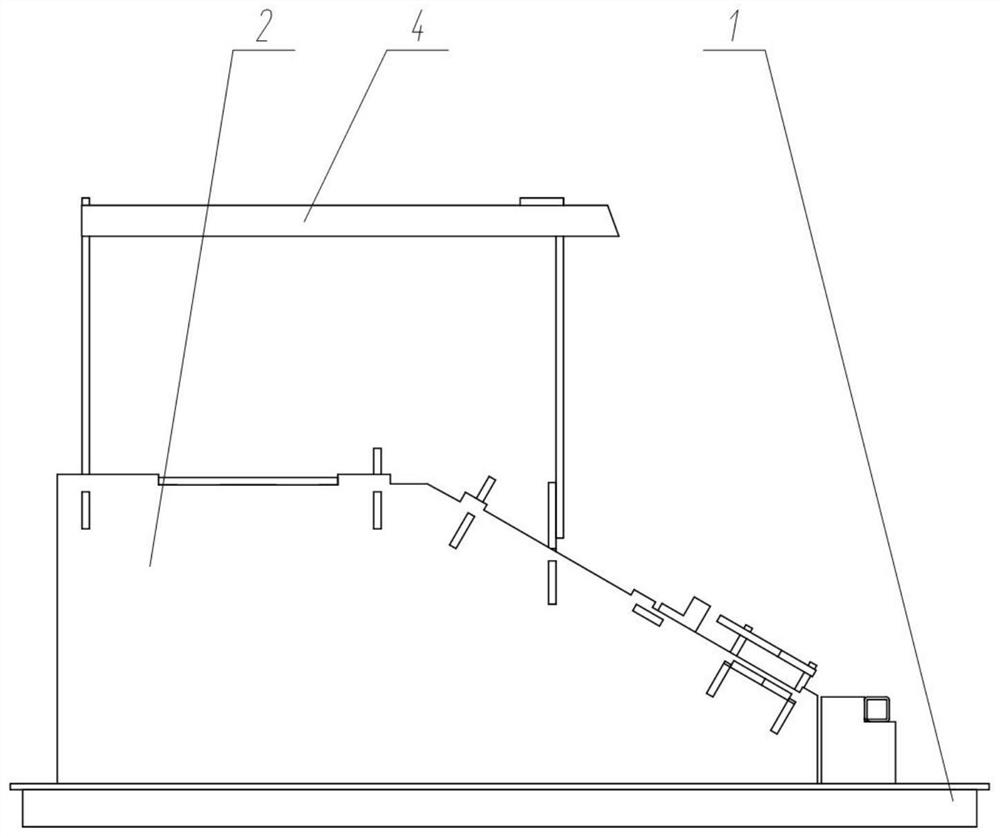

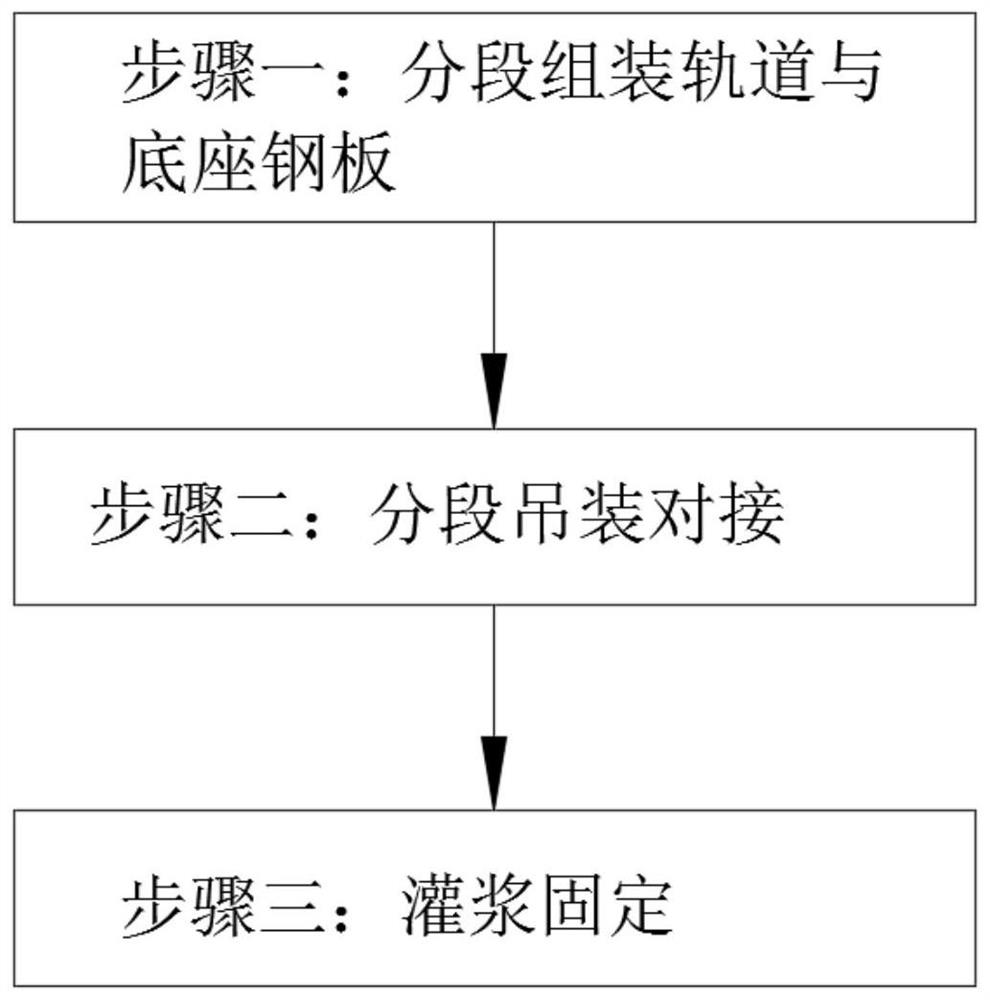

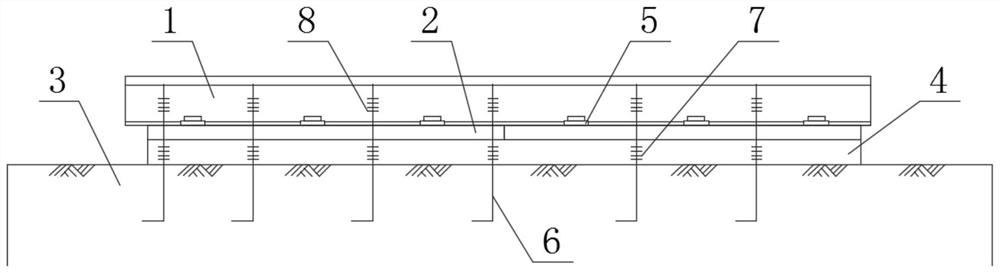

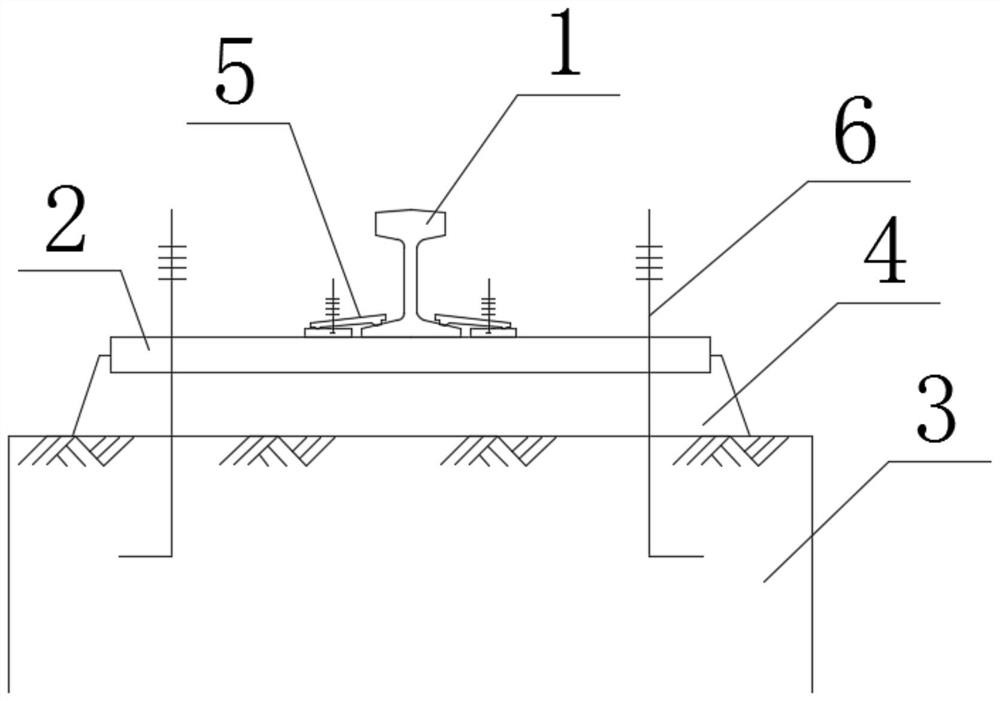

Ground transportation track installation method

ActiveCN110172878BAchieve correctionAvoid installation deviationRailway track constructionButt jointArchitectural engineering

The invention belongs to the technical field of ground track mounting construction, and discloses a ground transportation track mounting method. The ground transportation track mounting method comprises the steps that 1, tracks and base steel plates are assembled in a segmented mode, specifically, the base steel plates are grouped and sequentially laid on the flat ground, the ends of the adjacentbase steel plates in the same group are arrayed and laid in a closely-attached mode, surveying and setting-out are conducted on all the groups of base steel plates, the track mounting positions are marked on all the groups of base steel plates, in each group, the tracks are hoisted on the base steel plates to be aligned with the marked track mounting positions, then the tracks are fixed to the base steel plates, heat deformation of the base steel plates in the machining process is corrected through the rigidity of the tracks while fixing is conducted, thus the track steel plates are closely attached to the bottom faces of the tracks, and after completion, assembled segments of the tracks and the base steel plates are formed in all the groups; 2, hoisting and butt joint are conducted in a segmented mode; and 3, grouting fixing is conducted. According to the ground transportation track mounting method, the track mounting sequence is changed, deformation correction of the base steel plates is conducted through the rigidity of the tracks, and thus the mounting error caused by deformation of the base steel plates can be reduced.

Owner:CHINA HUAYE GROUP +1

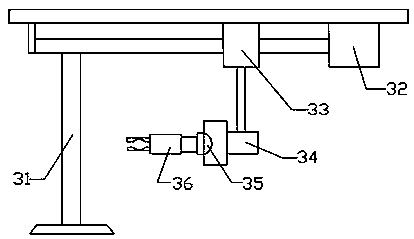

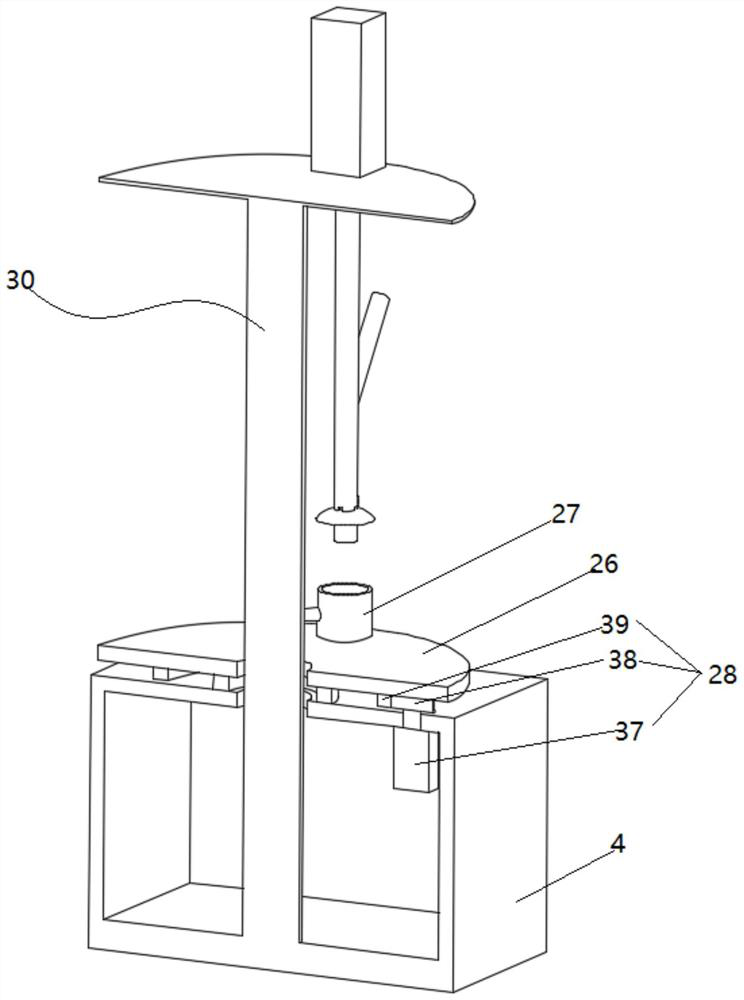

Probiotic beverage production equipment

The invention discloses a probiotic beverage production equipment. The probiotic beverage production equipment comprises a filling mechanism, a pressure head mounting mechanism, a bottle cap clamping mechanism and a base, wherein the bottle cap clamping mechanism is rotationally mounted on the base; the filling mechanism and the pressure head mounting mechanism are fixedly mounted on the base through mounting supports; and the filling mechanism and the pressure head mounting mechanism are matched with the bottle cap clamping mechanism. According to the probiotic beverage production equipment, probiotic powder is injected into a bottle cap through the filling mechanism, a pressing head is mounted in the bottle cap through the pressing head mounting mechanism, and a complete bottle cap type probiotic package is formed; and a guiding assembly is rotationally mounted in the pressing head mounting mechanism, and the pressing head is guided by the guiding assembly, so that the pressing head is conveniently mounted in the bottle cap, the mounting deviation between the pressing head and the bottle cap caused by equipment errors is prevented, the equipment outage rate is reduced, and the packaging efficiency of the probiotic powder of the equipment is improved.

Owner:浙江迈亚塔菌检智能科技有限公司

Assembly tool for automobile gearbox oil filter

PendingCN111421323AEasy to limitConvenient card connectionMetal working apparatusControl engineeringStructural engineering

The invention discloses an assembly tool for an automobile gearbox oil filter, and belongs to the field of assembly tools. The assembly tool includes a base, wherein the upper end of the base is fixedly connected with a bottom plate through bolts, the upper end of the bottom plate is fixedly connected with a shell sleeve, the upper end of the bottom plate is fixedly connected with a coarse filterelement sleeve, the upper end of the bottom plate is fixedly connected with a fine filter element sleeve, and the left side and the right side of the upper end of the base are respectively and fixedlyconnected with supporting rods, the upper ends of the supporting rods are fixedly connected with a crossbeam, the upper end of the crossbeam is fixedly connected with an air cylinder, an air cylinderrod of the air cylinder is fixedly connected with a threaded block, and the threaded block is rotatably connected with a threaded sleeve through threads. Through the arrangement of the shell sleeve,the coarse filter element sleeve and the fine filter element sleeve, a shell, a coarse filter element and a fine filter element are conveniently limited, and the phenomenon of installation deviation is avoided; a fixed seat is pressed downwards by the air cylinder rod, so that the fixed seat drives a upper end cover to be clamped to the shell conveniently, the tightness between the installation isincreased; and moreover, through the arrangement of a spring, the buffer capacity is increased, and the damage to the shell during extrusion is reduced.

Owner:RUIAN TRANSTAR AUTOMOTIVE TECH CO LTD

Lamp border profile

InactiveCN105402691AEasy to disassembleBeautiful frameProtective devices for lightingLight fasteningsEngineering

Owner:CHONGQING BEACON OPTOELECTRONICS TECH

Zero calibration method, device, vehicle and medium based on extended-range power generation system

ActiveCN111426289BImprove assembly efficiencyAvoid installation deviationVehicular energy storageDynamo-electric machine testingControl engineeringControl theory

Owner:上海元城汽车技术有限公司

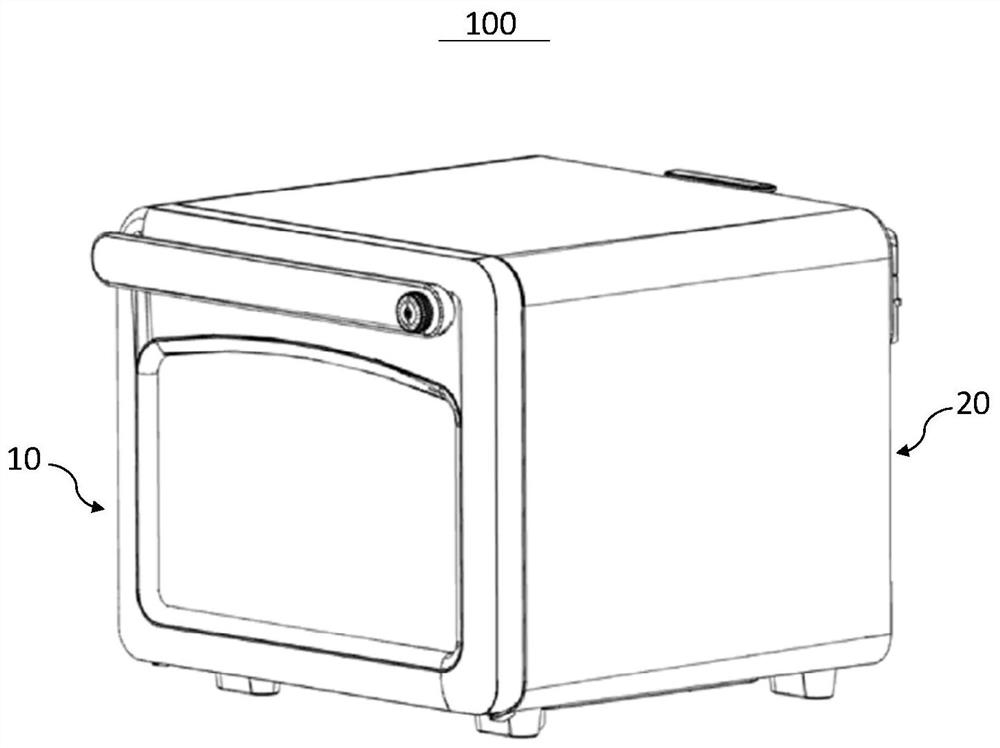

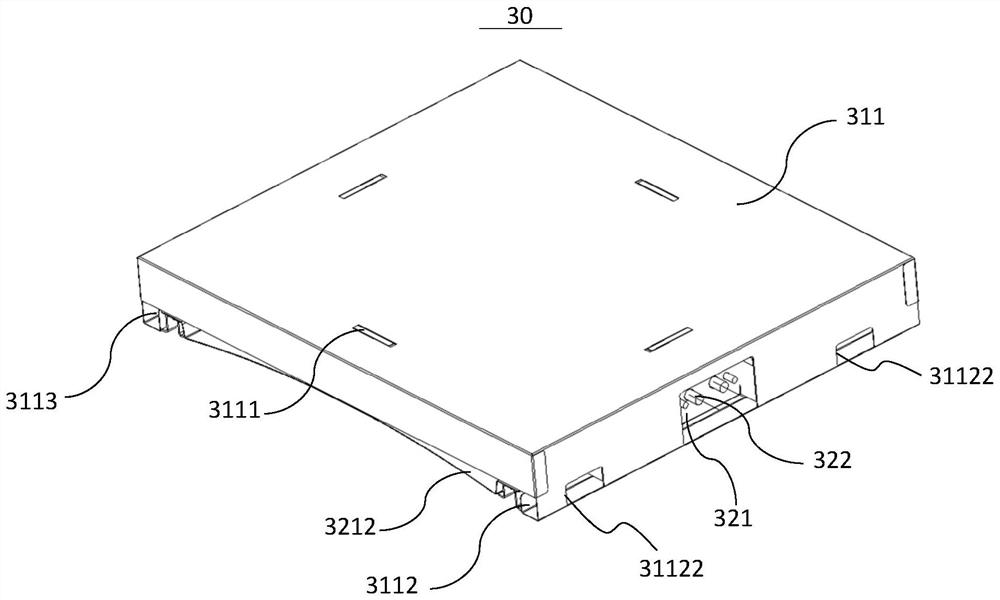

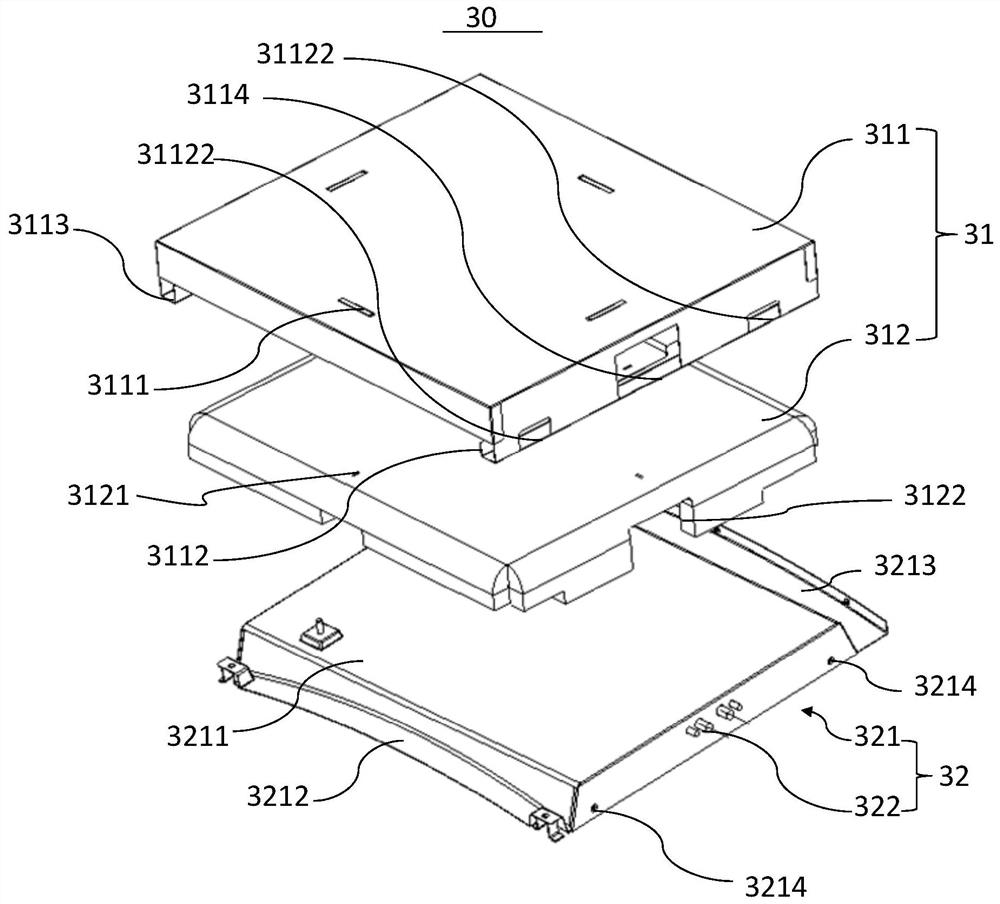

Heating assembly and cooking device with same

ActiveCN111466784BAchieve installationAvoid installation deviationCooking utensils shields/jacketsSteam cooking vesselsThermodynamicsProcess engineering

The invention discloses a heating assembly and a cooking device with the same. The heating assembly includes a heating module and a heat insulation module. The heating module includes a heating pipe and a heating pipe cover. The heating pipe cover cooperates with the cooking device. The heating pipe is arranged on the heating pipe cover. Inside, the heat insulation module includes a heat shield and a heat shield, the heat shield cooperates with the heat pipe cover, and the heat shield is fixedly connected to the heat shield and sandwiched between the heat shield and the heat pipe cover. By cooperating the heat shield with the heat pipe cover, the heat shield is sandwiched between the heat pipe cover and the heat shield, thereby realizing the installation of the heat shield. Since the heat insulating part is fixed on the heat shield, the heat shield is positioned and installed on the outside of the heat pipe cover, thereby realizing the positioning and installation of the heat insulating part, avoiding the installation deviation of the heat insulating part, and ensuring the heat insulation effect. In addition, the heat insulating part is fixed with the heat shield and then assembled with the heat pipe cover, which facilitates the assembly process, thus effectively improving the installation efficiency and reducing the manufacturing cost of the product.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

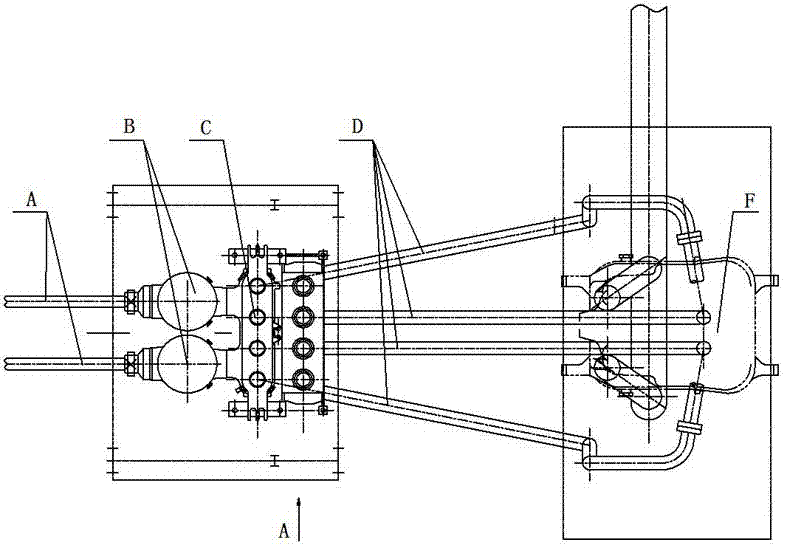

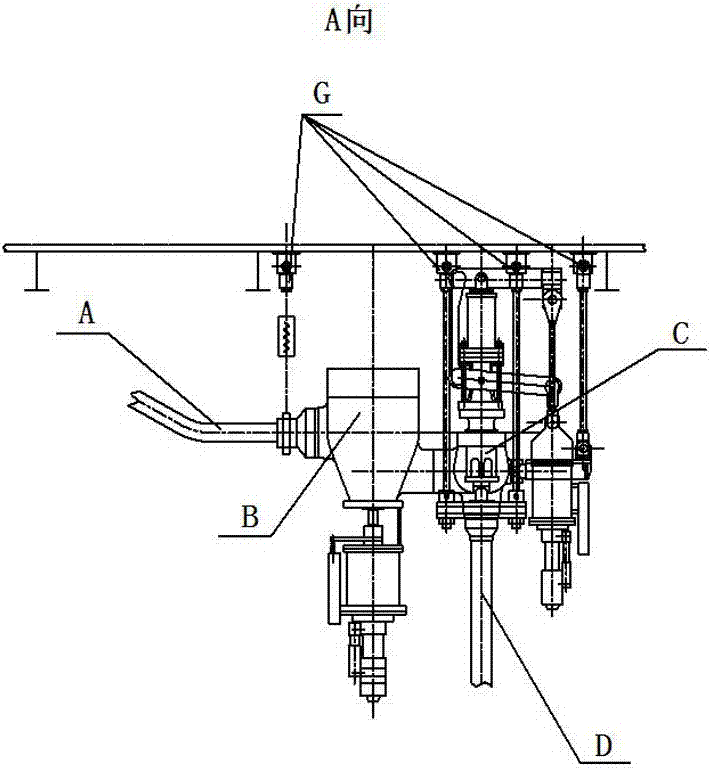

Fan shell injection molding equipment and method of automatically embedded copper piece

PendingCN113977850APrecise positioningAvoid installation deviationCoatingsRobot handInjection moulding

The invention provides (a) fan shell injection molding equipment and method of an automatically embedded copper piece, and relates to the technical field of fan shell injection molding. The fan shell injection molding equipment comprises a feeding system, a carrying system, an injection molding system and a discharging system, the feeding system comprises a material placing area, a workbench and a material sliding table plate; a plurality of materials can be placed on the material sliding table plate; the carrying system comprises a mechanical arm, a multifunctional clamping jaw is arranged at the tail end of the mechanical arm, the multifunctional clamping jaw comprises a base plate, and two material clamping devices are fixed to the base plate; a plurality of positioning columns are distributed on the lower surface of the base plate, and two mold locking devices are arranged on the lower surface of the base plate; the multifunctional clamping jaw achieves reciprocating carrying among the feeding system, the injection molding system and the discharging system; and the injection molding system comprises an injection mold, and the upper surface is further provided with a positioning hole and a mold locking groove. According to the technical scheme, the installation precision of the copper piece is high, the phenomenon that the surface is scratched due to installation inclination is avoided, and the product precision and quality are guaranteed.

Owner:苏州博宇科技有限公司

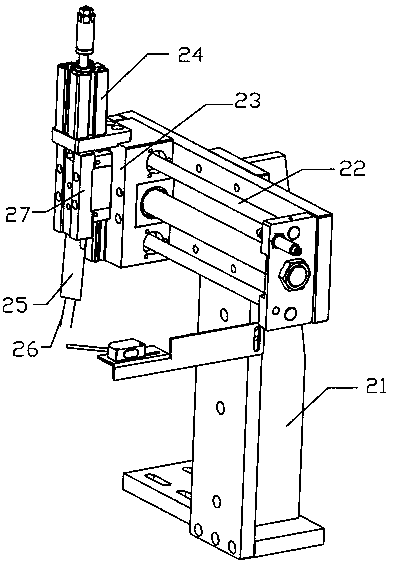

Portable dovetail clamp assembling device

PendingCN109968000AInhibit sheddingAvoid installation deviationAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a portable dovetail clamp assembling device which comprises a product positioning jig, a spring assembling structure and a PIN assembling structure corresponding to the productpositioning jig, and a clamping plate copying positioning structure, wherein the product positioning jig comprises a positioning table copying a handle; the spring assembling structure comprises a transverse push air cylinder and a positioning block; the positioning block is positioned at the end part of the transverse push air cylinder and is corresponding to a spring; the PIN assembling structure comprises a jacking air cylinder below the positioning table and a jacking block; the jacking block is arranged at the top of the jacking air cylinder and inserts a PIN into a PIN hole site in an elastic jacking manner; and the clamping plate copying positioning structure comprises a side pushing air cylinder, a fixed block at the end part of the side pushing air cylinder, and an adsorption device arranged in the fixed block and used for adsorbing a clamping plate. The portable dovetail clamp assembling device improves the product assembling efficiency.

Owner:昆山泰德兴自动化设备有限公司

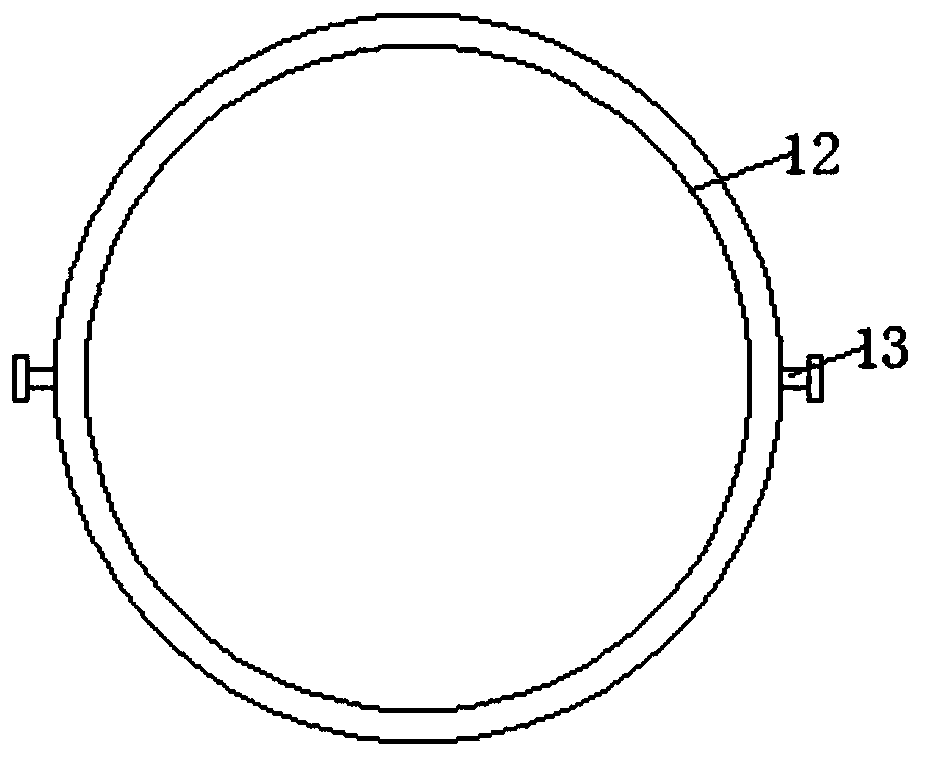

Special-shaped steel tube reinforcing ring installing and fixing structure and method

ActiveCN110449821AEasy to useImprove general performanceWelding/cutting auxillary devicesHydro energy generationButt jointWeld seam

The invention discloses a special-shaped steel tube reinforcing ring installing and fixing structure and method. The structure comprises a vertical supporting ring frame arranged on a special-shaped steel tube in a sleeving mode and a plurality of installation adjusting mechanisms, the installation adjusting mechanisms are evenly arranged on the side wall of the vertical supporting ring frame andare of a hollow structure, and supporting and positioning mechanisms penetrate through the installation adjusting mechanisms and are in butt-joint with the outer wall of the special-shaped steel tube.The method comprises the steps that firstly, three reinforcing ring positioning lines are drawn; secondly, a special-shaped steel tube reinforcing ring installing and fixing device is manufactured; thirdly, a first reinforcing ring is installed and fixed; fourthly, the special-shaped steel tube reinforcing ring installing and fixing device is loosened and disassembled; fifthly, a second reinforcing ring is installed and fixed; sixthly, a third reinforcing ring is installed and fixed; and seventhly, the special-shaped steel tube reinforcing ring installing and fixing device is disassembled. According to the special-shaped steel tube reinforcing ring installing and fixing structure and method, one installing and fixing structure is used for achieving installing and fixing of three reinforcing rings with different inner diameters, the positioning precision and the construction efficiency are high, installation deflection of the reinforcing rings is avoided, the welding quality of reinforcing ring butt-joint seams and angle welding seams is facilitated, and the labor intensity of workers can be effectively relieved.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

A unit assembly installation method for special-shaped arc-shaped grg decorative panels

ActiveCN104763123BEnsure data flowImprove machining accuracyCovering/liningsEngineeringSurface shape

The invention belongs to the technical field of installing building decoration boards, and specifically relates to a unit assembling type installation method of an irregular arc-shaped GRG decoration board. The method comprises the following steps: setting the arc and making a template by a computer; processing a GRG decoration board according to the size set by the computer; firstly installing a variable arc GRG unit decoration board by taking a variable arc position as a benchmark through connection manners such as hanging, buckling and bolting; the installing a standard GRG unit decoration board; and then processing the joint and painting the surface after finished installing all the GRG decoration boards. In this installation method, enough installation cavities are not needed to be preserved between the body structure and the GRG decoration board; the installation of the GRG decoration board can be finished directly outside the framework structure. Being a green construction, the bolt connecting manner provides a convenience for the later maintenance. Templates are made two times in the installation process to control the arc of installing the variable arc GRG decoration board, so as to ensure the installation arc of the GRG decoration board to be in consistency with the on-site arc, and to ensure the overall smoothness.

Owner:SUZHOU KELIDA BUILDING & DECORATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com