Curtain wall structure with lamp grooves and construction method thereof

A construction method and curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of small size of anodized aluminum plate, difficult construction, unevenness, etc., and achieve the effect of refined construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

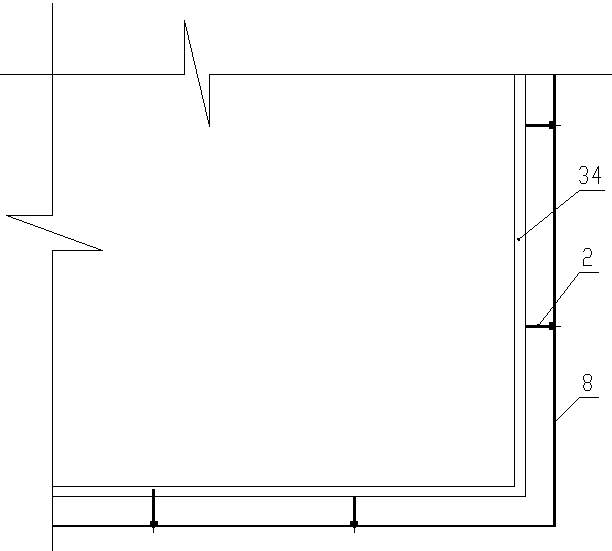

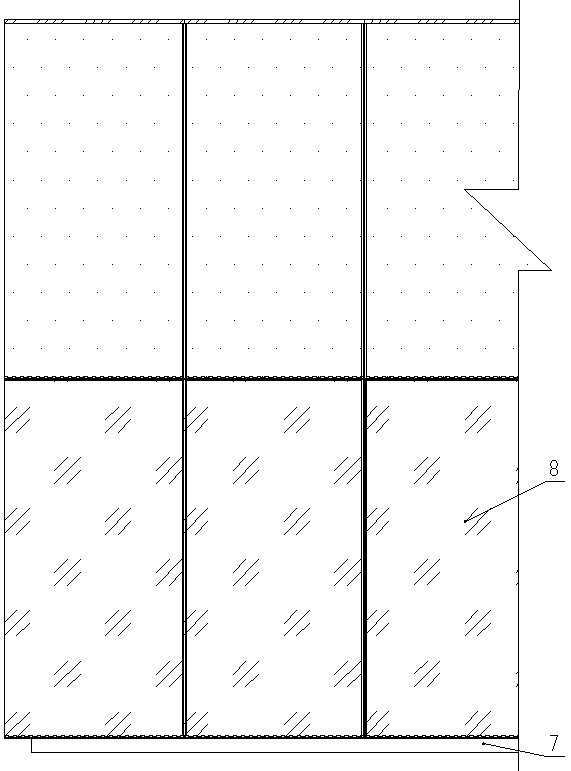

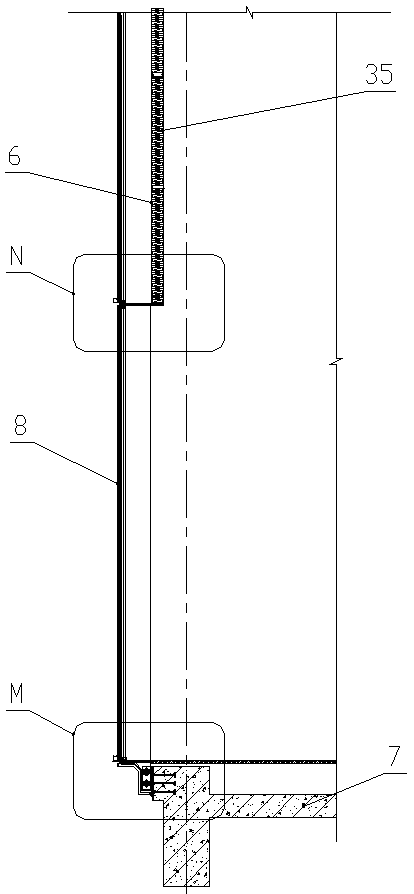

[0069] Such as Figure 1-Figure 12 As shown, the curtain wall structure with light grooves of the present invention includes a moisture-proof structure 1 at the root of the curtain wall, a T-shaped steel column 2, a beam 3, a foundation embedded part 4, an anodized aluminum plate 6, and a thermal insulation positioning structure 35. After the foundation embedded part 4 Part of it is pre-buried in the concrete foundation 7, and the T-shaped steel columns 2 are vertically arranged and evenly arranged along the outer sides of the building 34. The inner parts of the T-shaped steel columns 2 are respectively connected with the main steel structure and the main steel structure arranged on the concrete foundation 7 through the first installation component. The part of the foundation embedded part 4 protruding from the concrete foundation 7 is fixedly connected, the beam 3 is provided with several layers between two adjacent T-shaped steel columns 2 along the height direction, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com