Floating valve bracket structure of steam turbine

A support structure, floating technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of high manufacturing cost, increase the flow loss of airflow pipeline, reduce steam quality and other problems, achieve simple structure, advanced design, guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

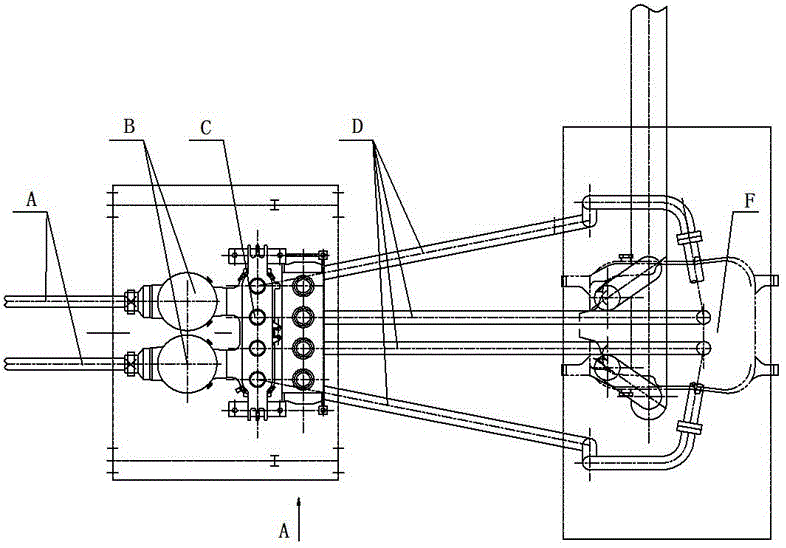

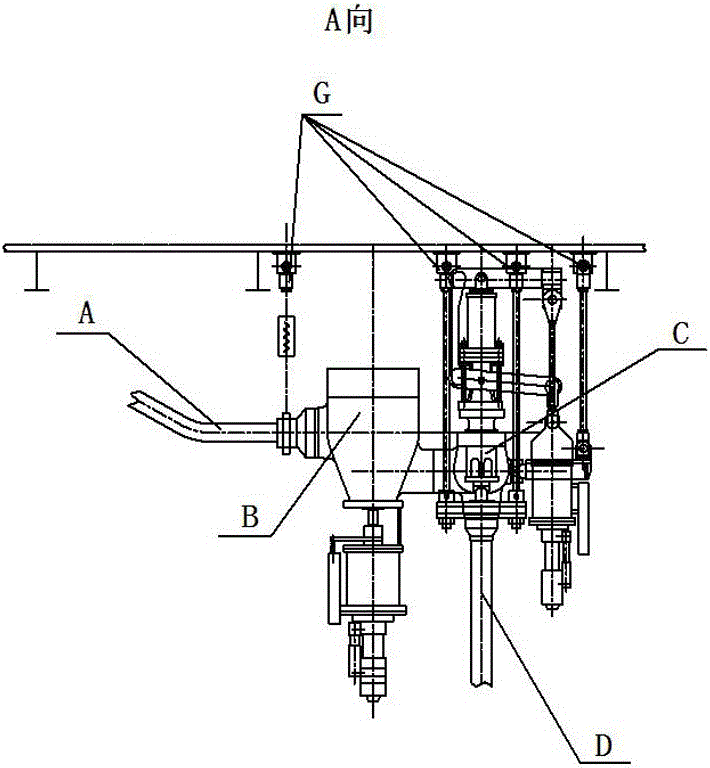

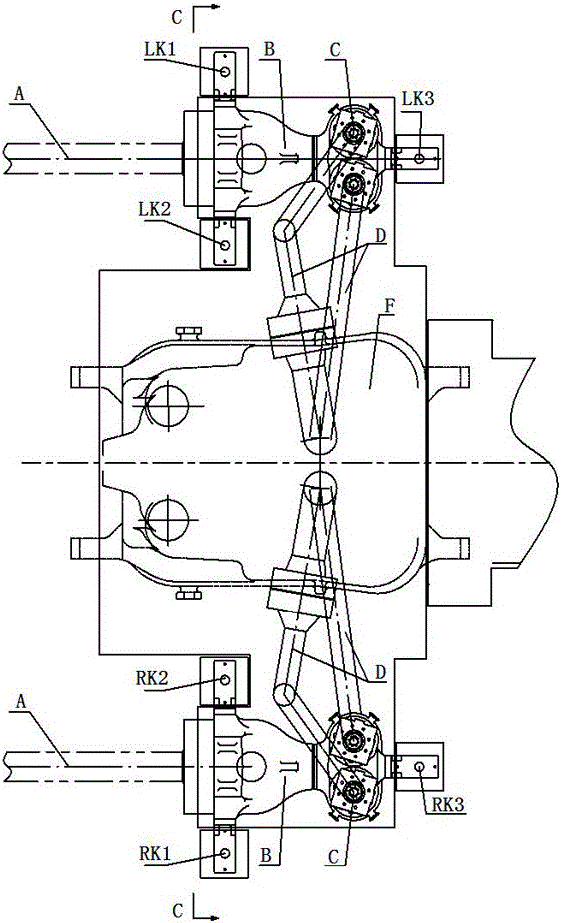

[0030] Such as image 3 , Figure 4 Shown: The high-pressure main steam valve B of a 350MW supercritical steam turbine unit is arranged on the operating platforms on both sides of the high-pressure cylinder F, and each high-pressure main steam valve B is supported by three floating valve bracket structures of steam turbines; on the left side of the high-pressure cylinder F The high-pressure main steam valve B is supported by the left floating support structures LK1 to LK3 respectively; the high-pressure main steam valve B on the right side of the high-pressure cylinder F is supported by the right floating support structures RK1 to RK3 respectively. The total weight of the valve including valve core, insulation layer, oil motor, etc. is about 30T. After the calculation of the piping system, it is determined that the load of the 2 fulcrums of the valve support plate is 112KN, the stiffness is 1800N / mm, the thermal displacement in the direction of sky and earth is 3.5mm downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com