Impact hammer for hydraulic drilling rig

A technology of hydraulic drilling rig and impact hammer, which is applied in drilling equipment, earthwork drilling, driving devices for drilling in boreholes, etc., and can solve the problems of fast impact frequency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

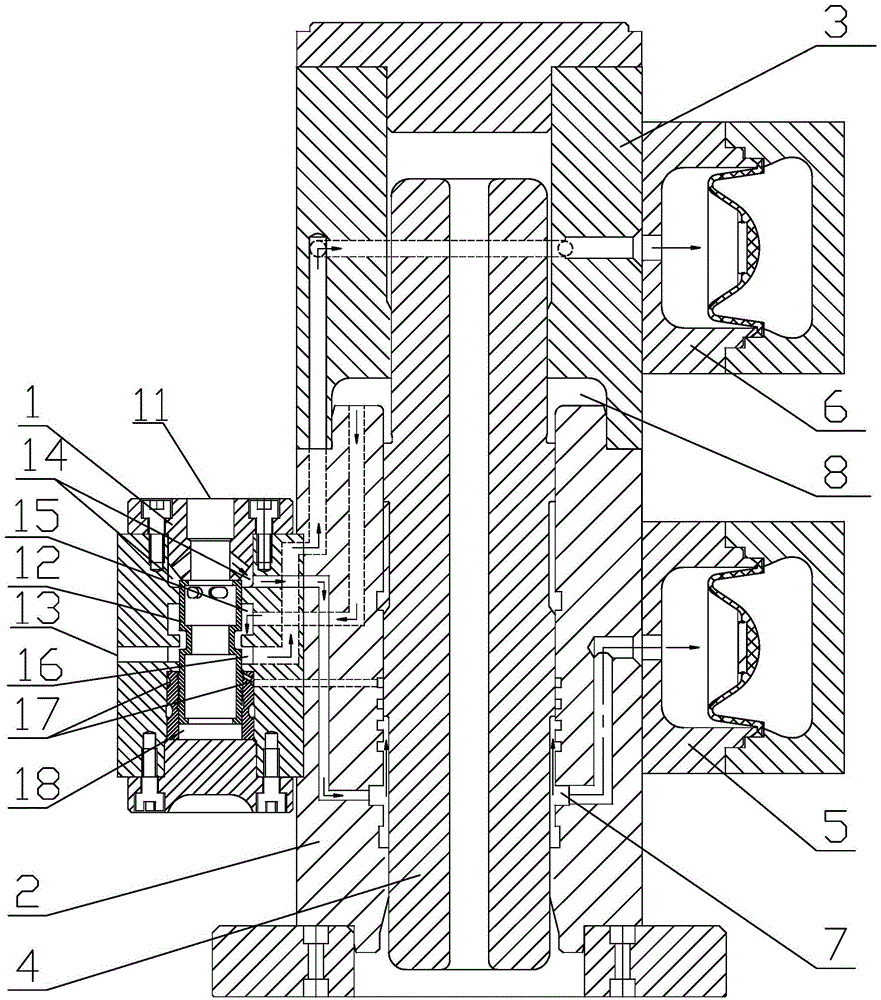

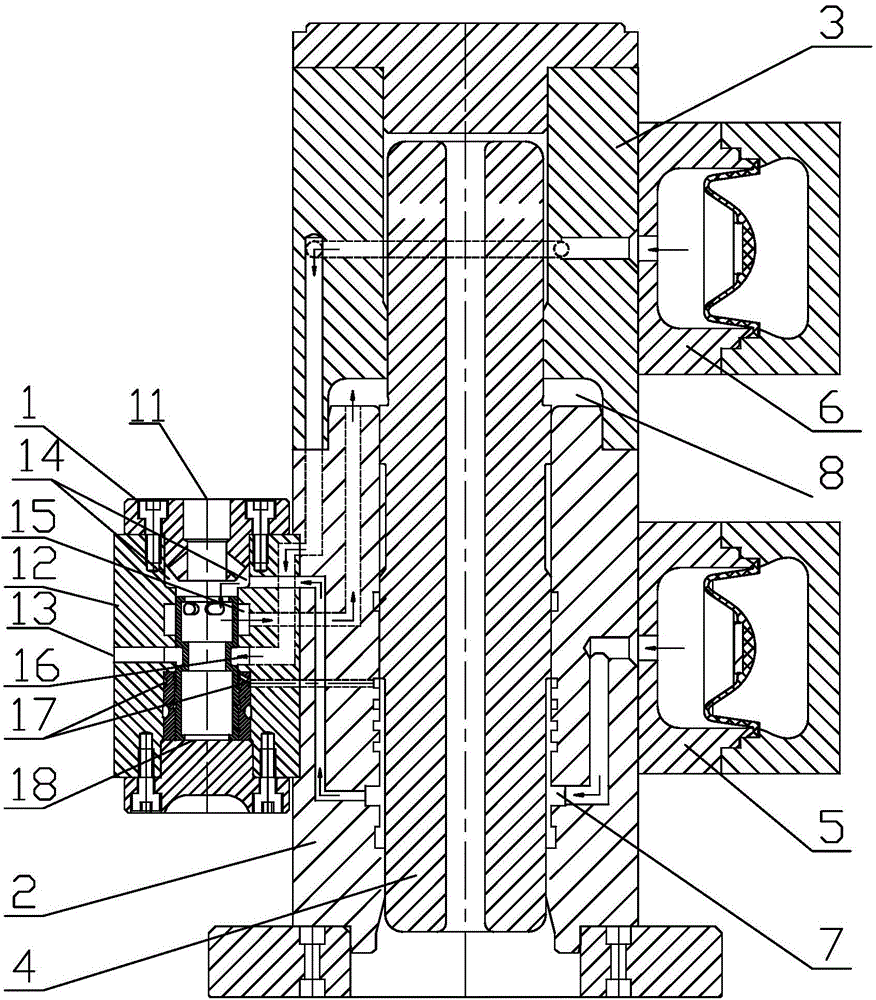

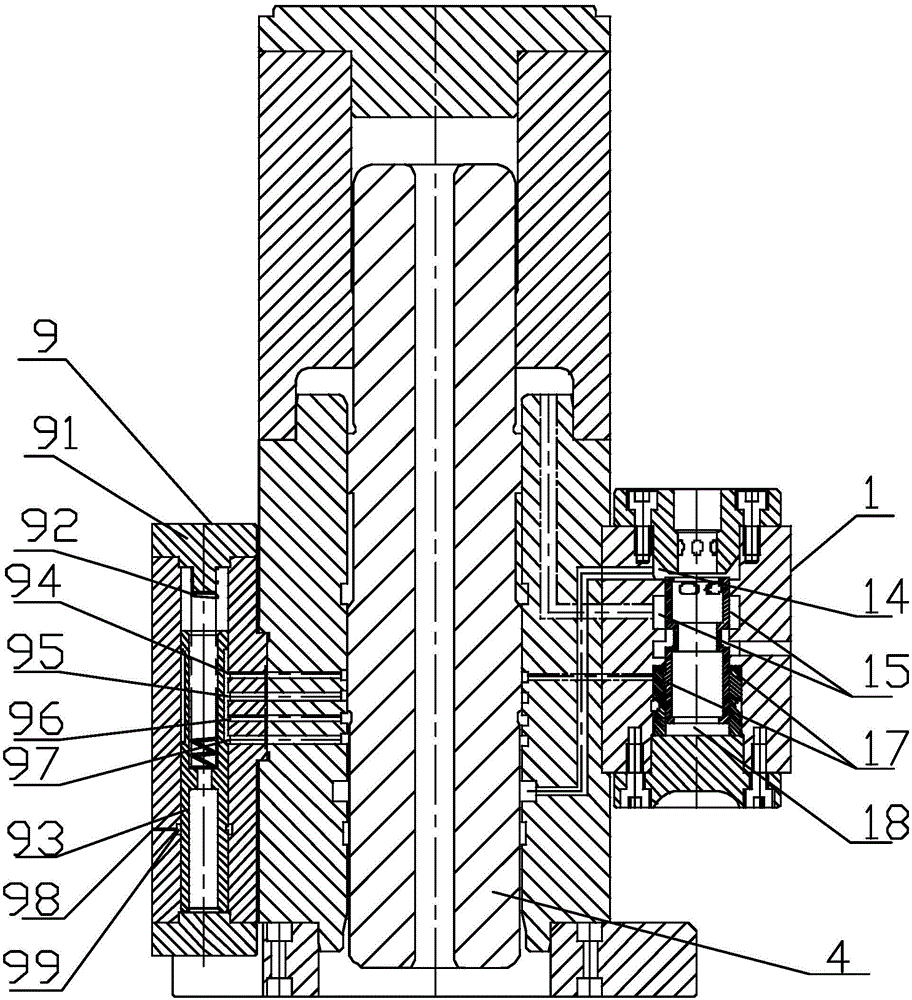

[0013] Below in conjunction with accompanying drawing, will illustrate the specific embodiment of hydraulic drilling rig impact hammer.

[0014] Such as figure 1 and figure 2 As shown, a hydraulic drill impact hammer includes a limit group 1, a spool 12, a front base 2, a piston 4, a front buffer 5, a rear buffer 6 and a rear base 3, and the limit group 1 is installed On the front base 2, one end of the front base 2 is installed on the rotary base of the power head of the hydraulic drilling rig, and the other end is clamped with the rear base 3, and the piston 4 is installed on the front base 2 and the In the inner cavity of the rear base 3, the front buffer 5 is installed on the front base 2, the rear buffer 6 is installed on the rear base 3, and the limiting group 1 includes a valve Body and valve core 12, the valve body is provided with an oil inlet 11 and an oil outlet 13, the valve core 12 is installed in the valve body, a first oil is provided between the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com