A method and system for crushing based on oblique shearing

A cutting angle and raw material technology, applied in the field of data analysis, can solve problems such as low crushing efficiency, reduced frontal strike efficiency, and impact on crushing effects, and achieve the effect of increasing shear frequency and improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

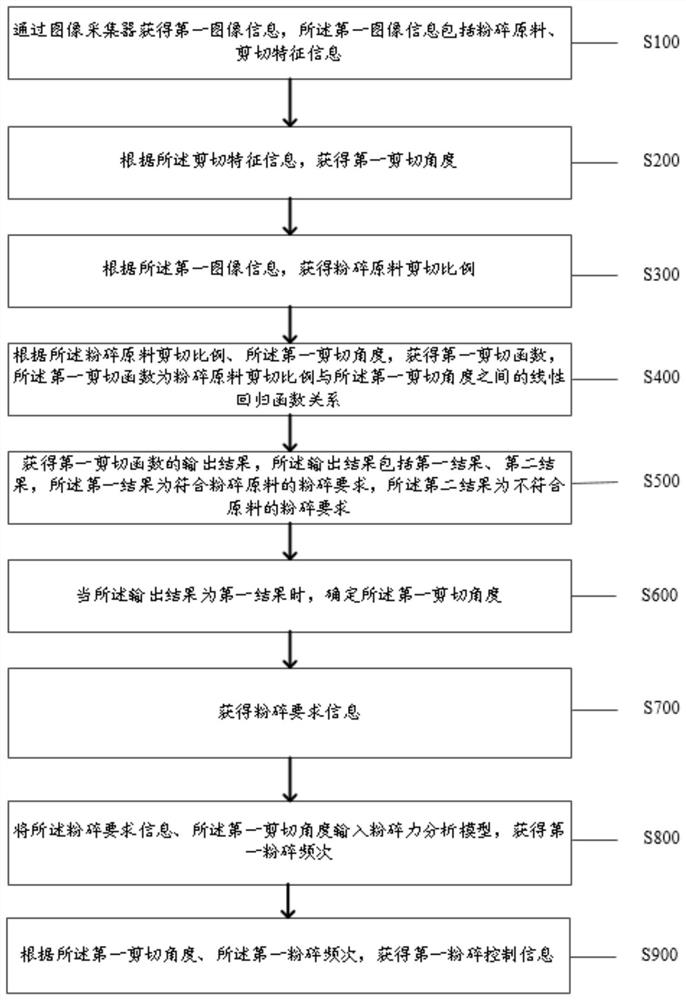

[0031] Such as figure 1 As shown, the present application provides an oblique shear blow pulverization method, the method being applied to a striking pulverizing control device, the device comprising an image collector, the method comprising::

[0032] Step S100 obtains the first image information through the image collector, the first image information comprising a comminuted material, a shear characteristic information;

[0033]Specifically, by mounting the pulverizing control device in the pulverizer, the cutting device in the pulverizer, the pulverizer, the first image information is pulverized in the pulverizer, and the shear device is cut in the pulverizer. The image acquisition in the process can include a plurality of image information for one or a continuous process. In the first image information, the angle of the hammer setting can be exhibited, and the effect of shearing of the raw material is made, how much shear is made to the raw material. That is, the pulverized sh...

Embodiment 2

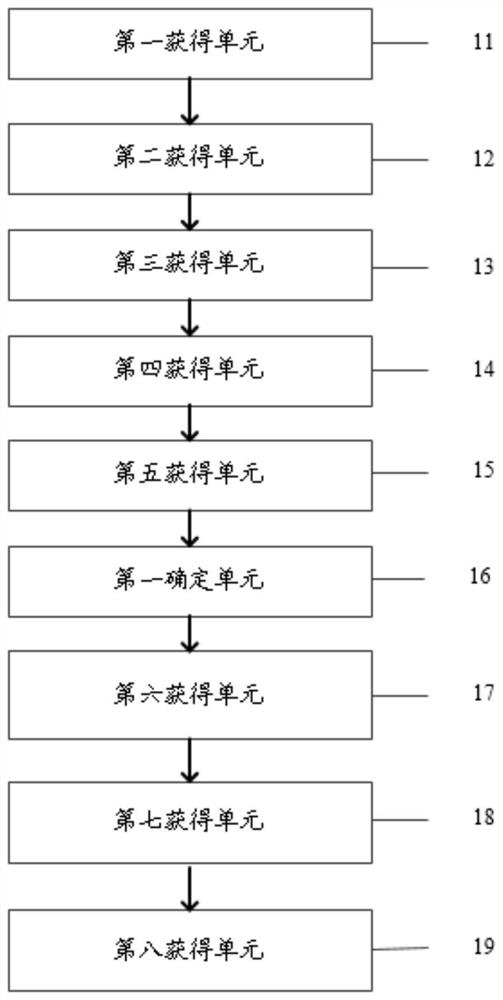

[0059] Based on the inventive conception based on the oblique shear method in the foregoing embodiment, the present invention also provides a blow crushing system based on oblique shear, such as figure 2 As shown, the system includes:

[0060] The first obtaining unit 11, the first obtaining unit 11 is configured to obtain a first image information through the image collector, the first image information including a pulverized raw material, a shear feature information;

[0061] The second obtaining unit 12, the second obtaining unit 12 is used to obtain a first shear angle according to the shear feature information;

[0062] The third obtaining unit 13, the third obtaining unit 13 is used to obtain a shear ratio of a pulverized raw material according to the first image information;

[0063] The fourth obtaining unit 14, the fourth obtaining unit 14 is configured to obtain a first shear function according to the pulverized raw material shear ratio, the first shear function, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com