Descaler

A descaling machine and driving device technology, applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of potential safety hazards, increased labor intensity, and insufficient cleaning, so as to save time, reduce labor intensity, and clean up thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

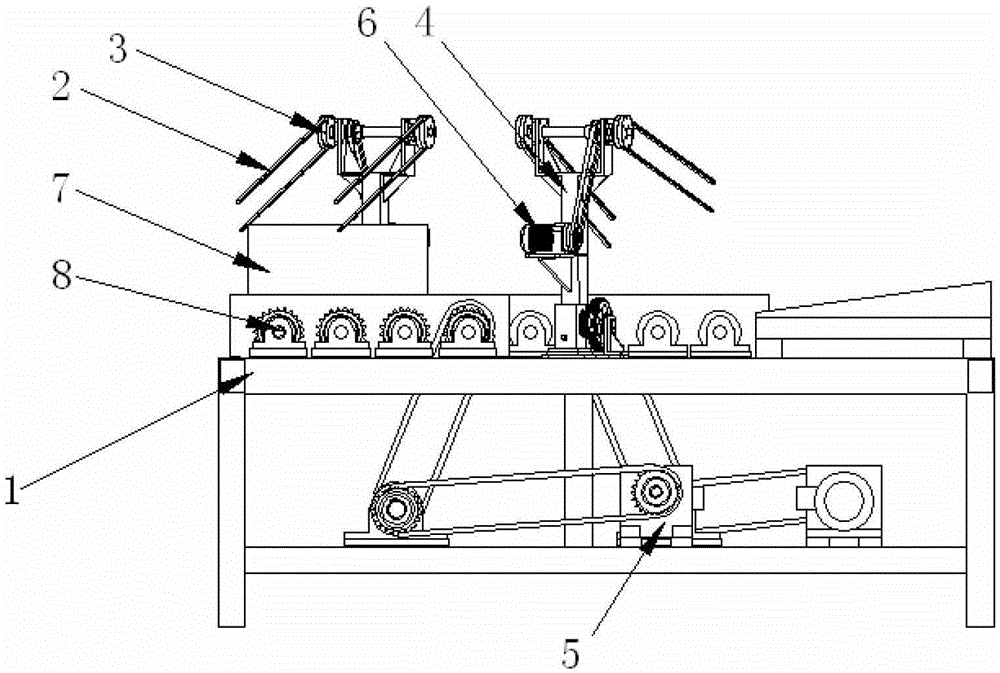

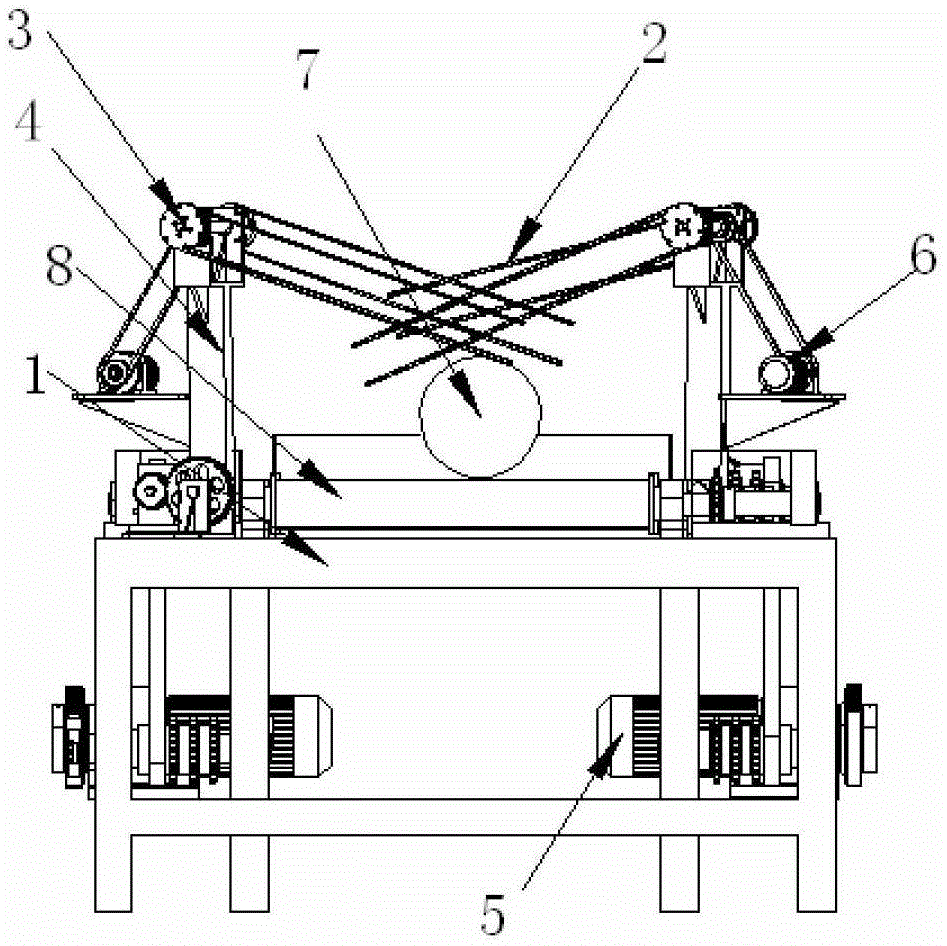

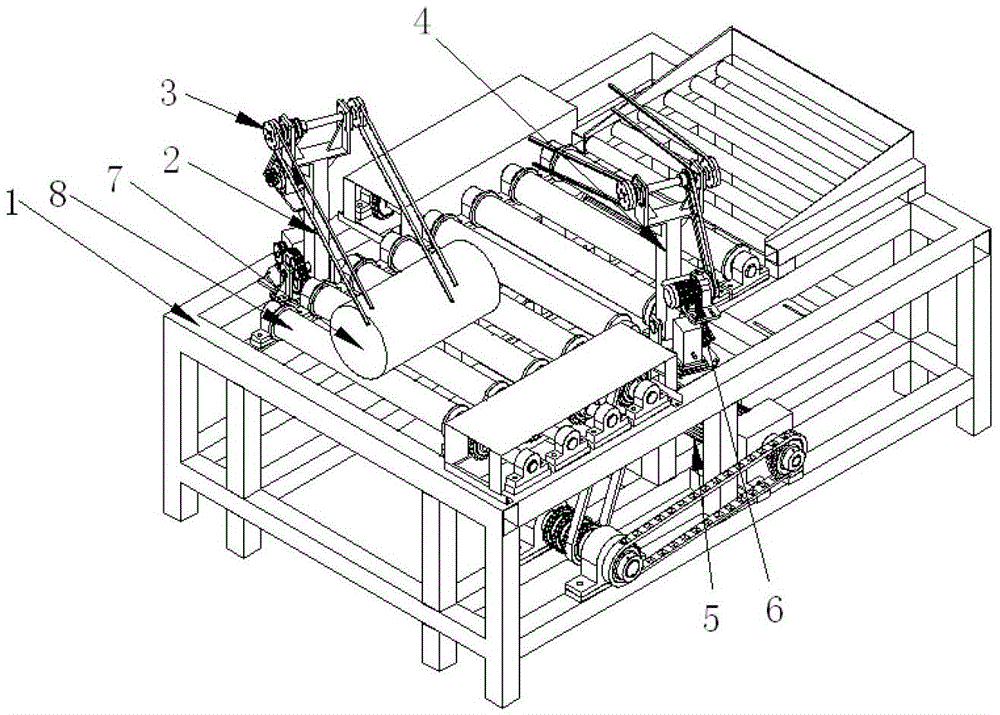

[0017] Embodiment: A descaling machine, comprising a workbench 1, a pumping chain 2, a pumping chain driving device 3, a support frame 4, a conveying device 8, and first and second driving devices, the conveying device 8 is positioned on the workbench 1 , The conveying device 8 can drive the blank 7 to linearly reciprocate along the conveying direction, the support frame 4 is fixed on the worktable 1, the pumping chain driving device 3 is positioned on the support frame 4, and the pumping chain driving device 3 is located directly above the conveying device 8. One end of the whipping chain 2 is fixed on the whipping chain driving device 3, and the whipping chain driving device 3 can drive the whipping chain 2 and the other end to beat the surface of the blank 7 on the conveying device 8. The first and second driving devices drive the conveying device 8 and the whipping chain respectively Drive the device 3 to move, the high-temperature blank 7 is discharged through the heating f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com