Polyimide flexible flat heat pipe

A polyimide flexible, flat heat pipe technology, applied in the field of heat transfer, can solve the problems of poor flexibility of metal materials and difficulty in adapting to the heat dissipation requirements of curved surfaces, and achieve the effects of avoiding burning out, increasing the maximum heat dissipation power, and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

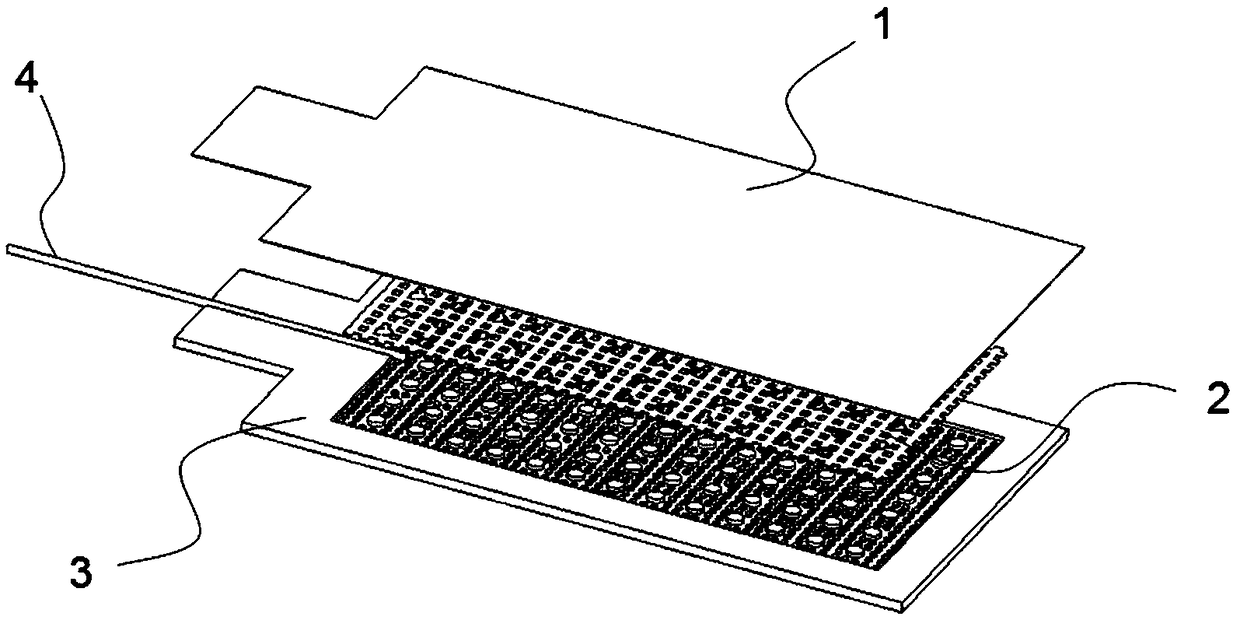

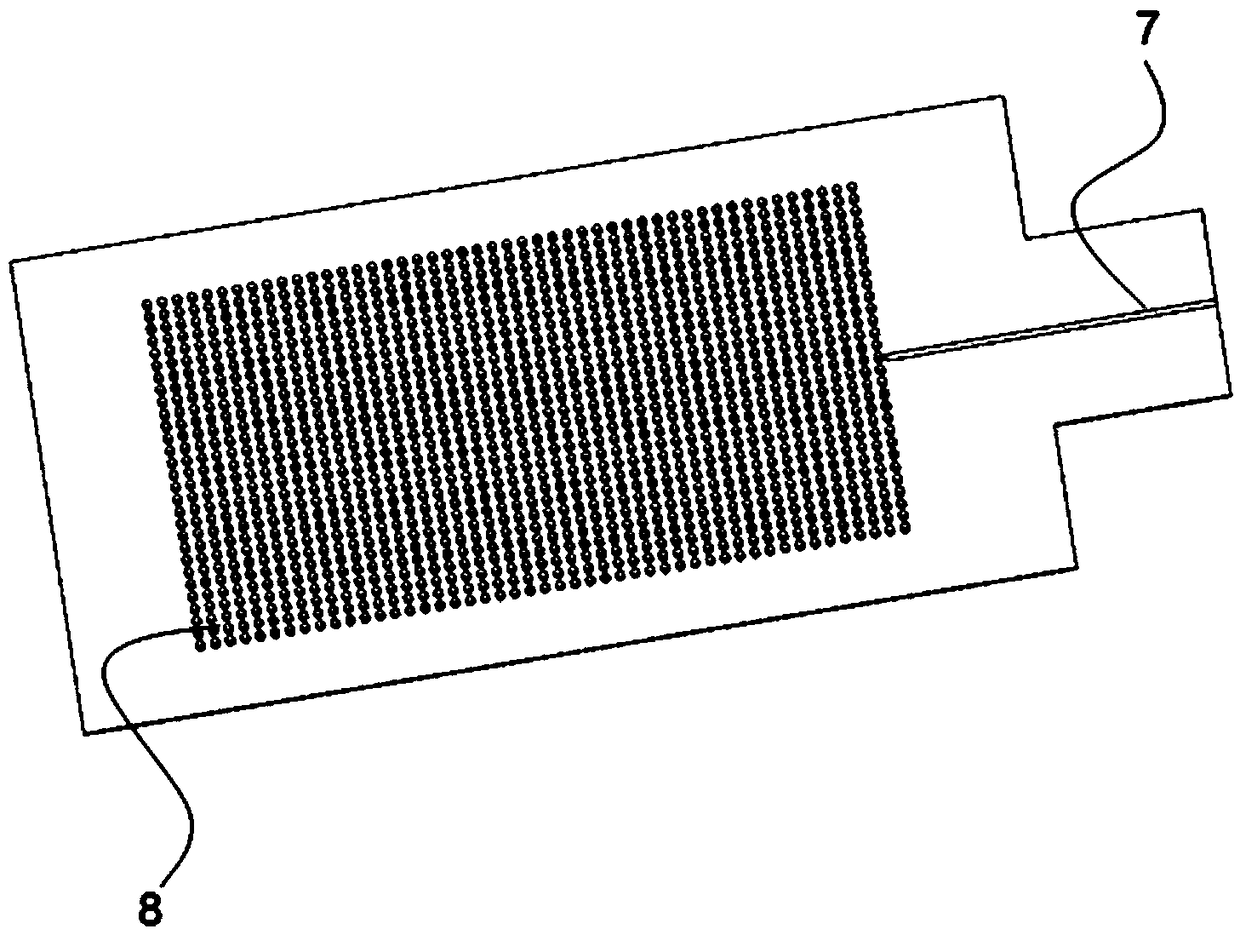

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

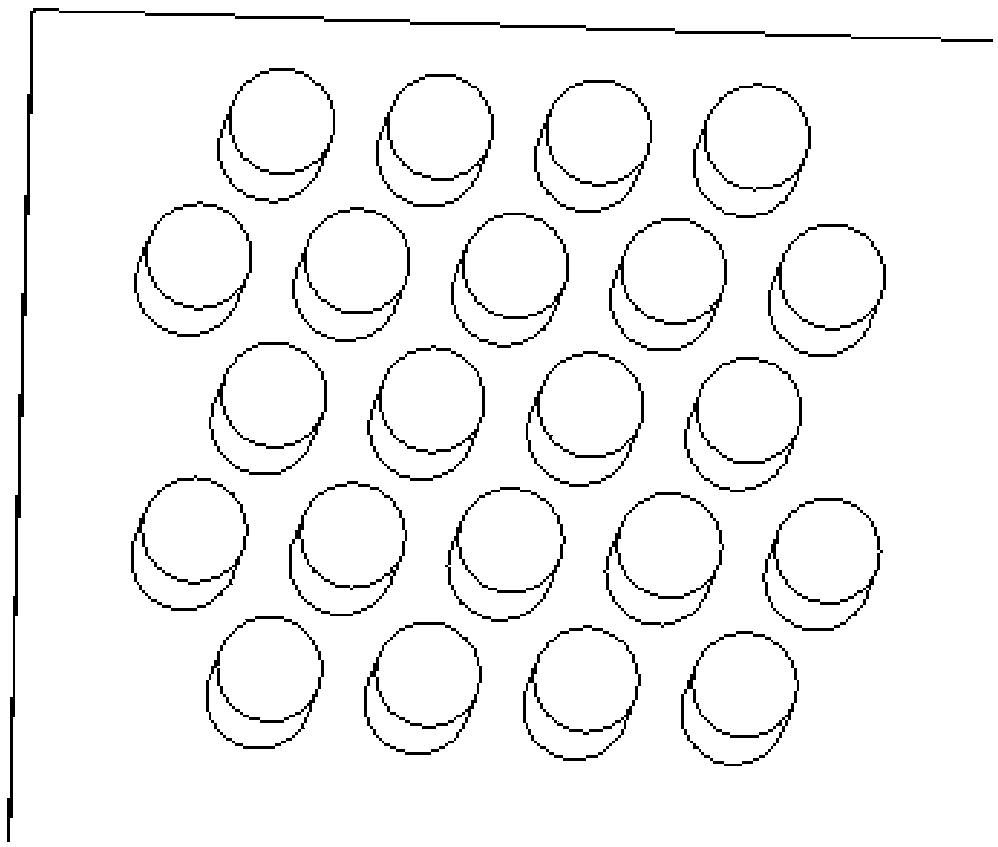

[0025] like Figure 1-5 As shown, the copper column array of the present invention has two types, the array with lower height and smaller diameter arranged in a rectangle, that is, the micro-copper column array 6 as a capillary structure; the array with a higher height and a larger diameter arranged in a rectangle, that is, support The copper column array 5 serves as a space support to provide steam channels.

[0026] Wherein, the liquid-absorbing core of the present invention is a composite structure of microcopper column array 6 and copper grid 2, microcopper column array 6 is closely connected with the upper surface of lower shell plate 3, and copper grid 2 is closely connected with microcopper column array 6. Connected and run through the supporting copper column array 5, the supporting copper column array 5 is arranged between each array of the micro co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com