Zero calibration method and device based on extended-range power generation system, vehicle and medium

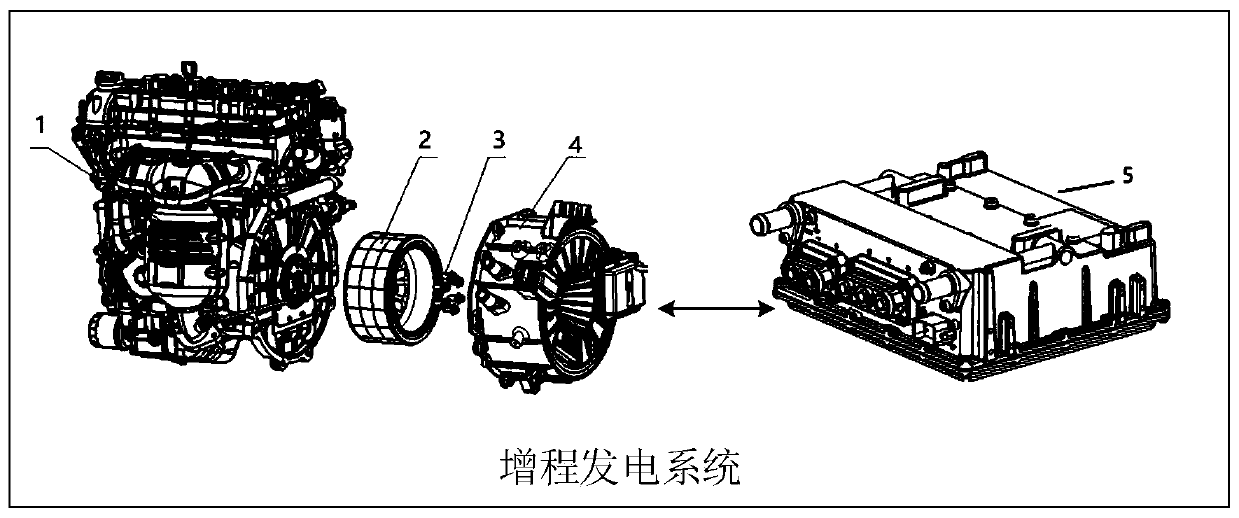

A power generation system and zero-position calibration technology, applied in measurement devices, electric vehicles, vehicle components, etc., can solve problems such as inability to be easily modified, time-consuming installation, deviation of current signal and magnetic field signal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

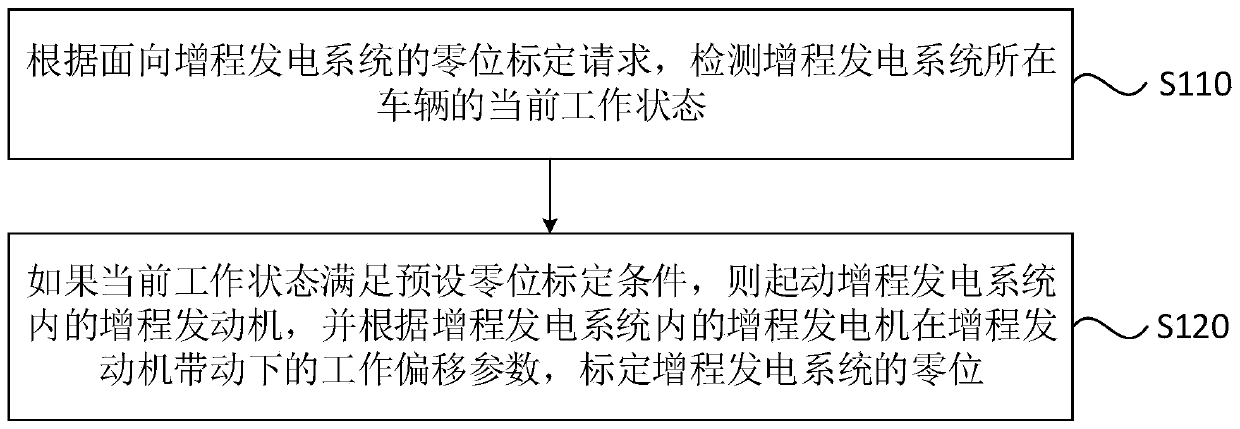

[0029] figure 2 It is a flow chart of a zero calibration method based on a range-extending power generation system provided by Embodiment 1 of the present invention. This embodiment is applicable to any vehicle that uses a range-extending power generation system as a power source. A zero calibration method based on a range-extending power generation system provided in this embodiment can be performed by a zero calibration device based on a range-extending power generation system provided in an embodiment of the present invention, and the device can be implemented by means of software and / or hardware. And integrated in the vehicle that executes the method, the vehicle may be an extended-range vehicle.

[0030] Specifically, refer to figure 2 , the method specifically includes the following steps:

[0031] S110. Detect the current working state of the vehicle where the range-extended power generation system is located according to the zero calibration request for the range-...

Embodiment 2

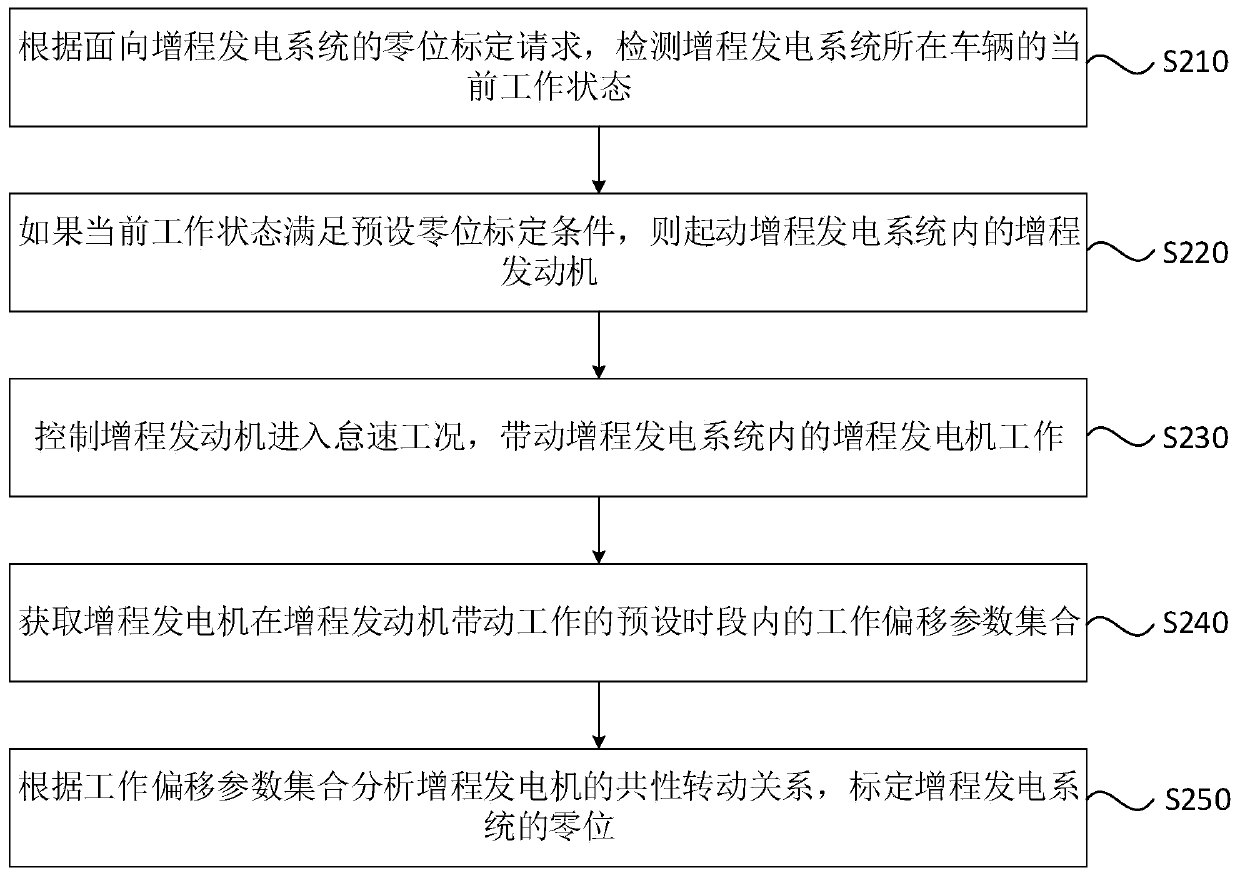

[0046] image 3 It is a flow chart of a zero calibration method based on a range-extending power generation system provided by Embodiment 2 of the present invention. The embodiments of the present invention are optimized on the basis of the foregoing embodiments. Optionally, this embodiment mainly explains in detail the specific calibration process of the zero position on the range-extending power generation system.

[0047] Specifically, see image 3 , the method of this embodiment may specifically include:

[0048] S210. Detect the current working state of the vehicle where the range-extending power generation system is located according to the zero calibration request for the range-extending power generation system.

[0049] S220, if the current working state satisfies the preset zero calibration condition, start the range-extending engine in the range-extending power generation system.

[0050] S230, controlling the range-extending engine to enter the idling condition,...

Embodiment 3

[0063] Figure 4 A functional block diagram of a zero calibration system based on a range-extending power generation system provided by Embodiment 3 of the present invention. This embodiment is applicable to any situation of performing zero calibration on a range-extending power generation system installed in a vehicle. Such as Figure 4 As shown, the system may include: a vehicle 30 equipped with a range-extending power generation system and an offline detection terminal 31 .

[0064] Specifically, the offline detection terminal 31 generates a zero calibration request for the extended-range power generation system according to the zero calibration trigger operation performed by professionals for the extended-range power generation system, and sends it to the vehicle 30 equipped with the extended-range power generation system. After the vehicle 30 receives the zero calibration request sent by the offline detection terminal 31, it executes the zero calibration method based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com