Special-shaped steel tube reinforcing ring installing and fixing structure and method

A special-shaped steel pipe and fixed structure technology, which is applied in the direction of auxiliary equipment, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of welding quality and production efficiency, large amount of assembly welding engineering, unqualified external dimensions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

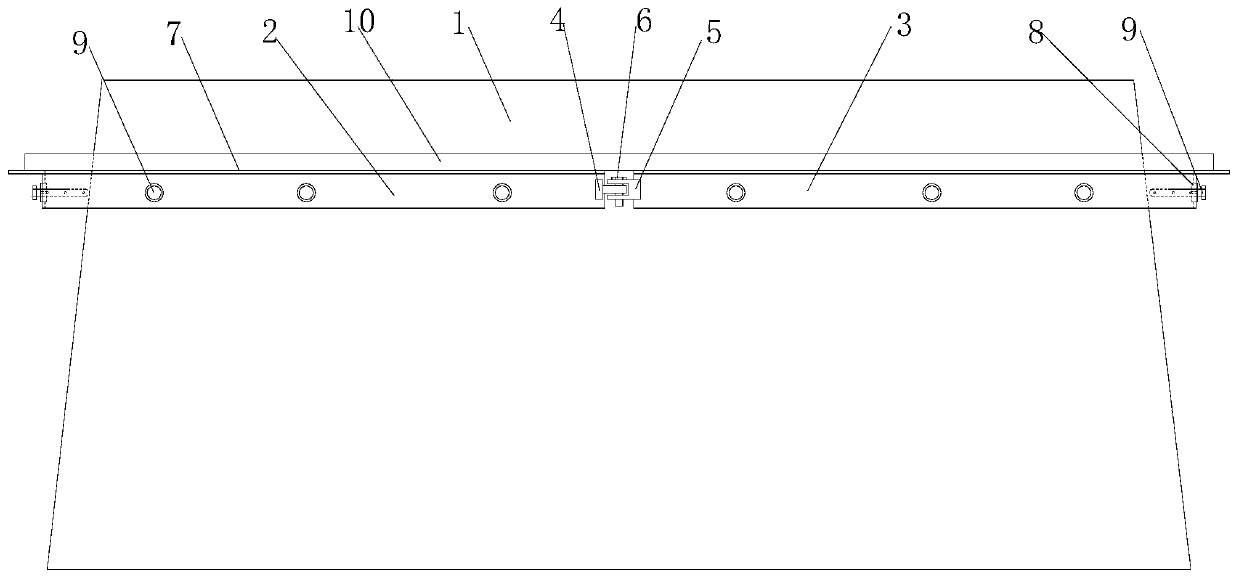

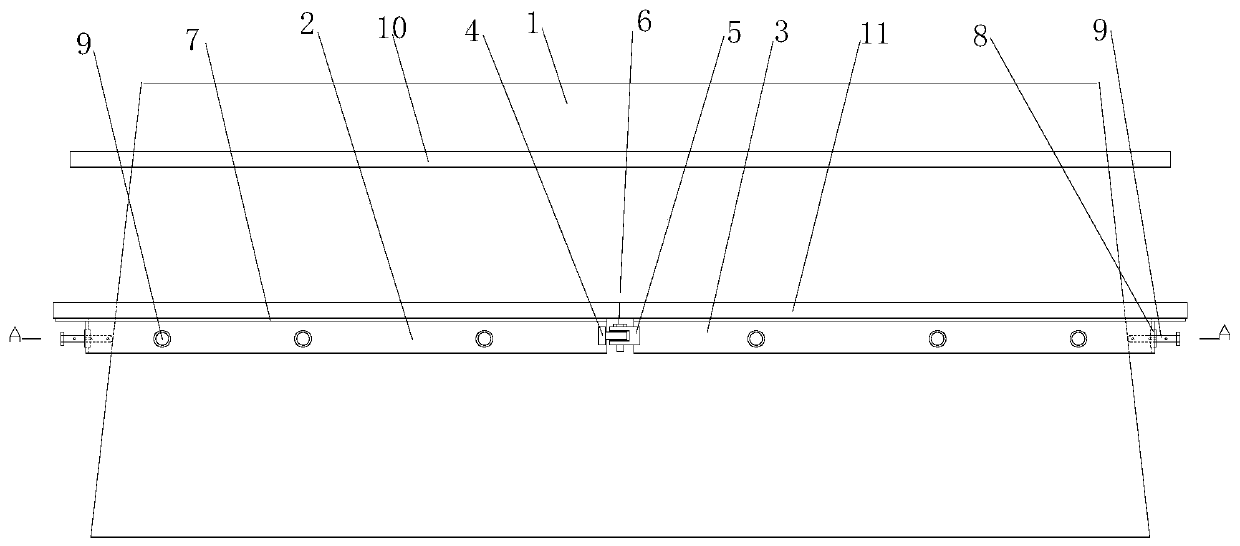

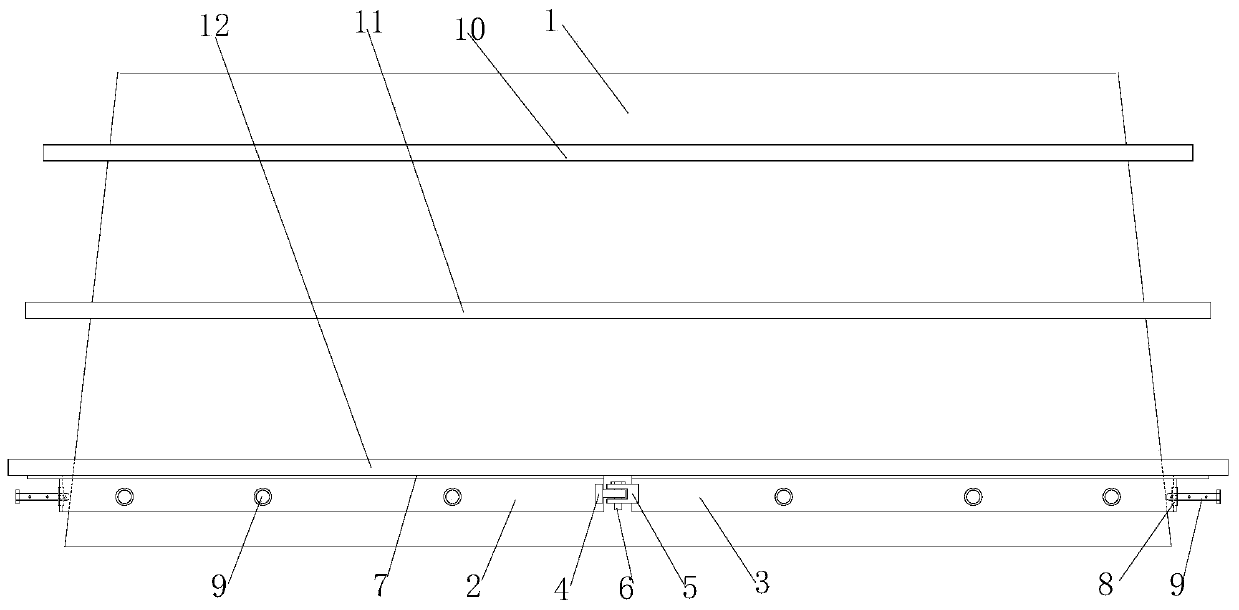

[0072] like Figure 1 to Figure 13 As shown, a special-shaped steel pipe stiffening ring installation and fixing structure according to the present invention, the special-shaped steel pipe 1 is a truncated conical steel pipe, including a vertical support ring frame set on the special-shaped steel pipe 1 and a plurality of uniformly arranged on the special-shaped steel pipe 1 The installation and adjustment mechanism 8 on the side wall of the vertical support ring frame is a hollow structure. The support positioning mechanism 9 passes through the installation adjustment mechanism 8 and abuts against the outer wall of the special-shaped steel pipe 1. The vertical support ring frame includes the first vertical support Half ring frame 2 and the second vertical support half ring frame 3 that cooperates with the first vertical support half ring frame 2, the tops of the first vertical support half ring frame 2 and the second vertical support half ring frame 3 are all set There is a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com