A frame-type electromagnet rapid automatic assembly system

A frame-type electromagnet and automatic assembly technology, which is applied to assembly machines, devices for coating liquid on the surface, metal processing equipment, etc., can solve the problems of electromagnet quality degradation, quality cannot be guaranteed, and cannot be used normally, so as to prevent Installation deviation, compact structure, and the effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

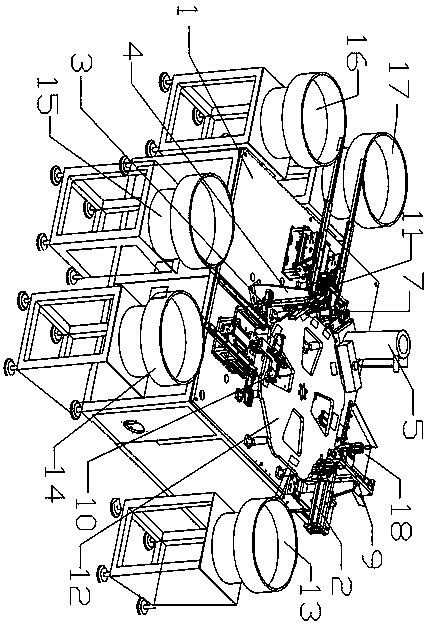

[0032] Such as figure 1 Shown, embodiment 1 of the present invention is:

[0033] A frame-type electromagnet rapid automatic assembly system, including a frame 1, an electric control device is arranged under the frame 1, a main turntable 12 is arranged on the frame 1, and a plurality of square tubes for fixing are arranged on the upper part of the main turntable 12 The lower part of the main turntable 12 is provided with a cam splitter for controlling the rotation of the main turntable 12, and the periphery of the main turntable 12 is provided with a square tube feeding device 2, an iron core winding feeding device 10, a guide Rod feeding device 3, glue dispensing device for bonding the iron core winding to the square tube 4, spring feeding device 11, top cover feeding device 7, welding device for welding the top cover and the upper wall of the square tube 5 and finished product receiving device 9 and above-mentioned each device is all provided with photoelectric sensor; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com