A unit assembly installation method for special-shaped arc-shaped grg decorative panels

An installation method and a technology of decorative panels, which are applied in building construction, covering/lining, construction, etc., can solve problems such as overall unevenness, and achieve the effect of high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

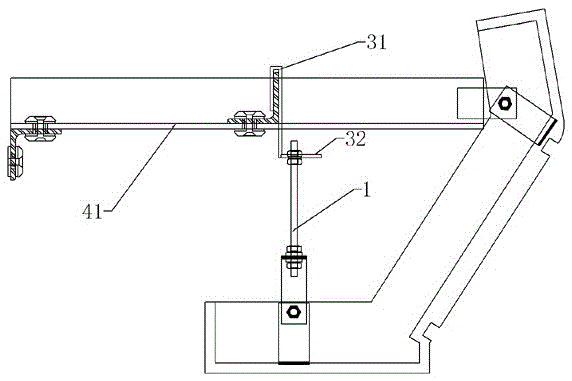

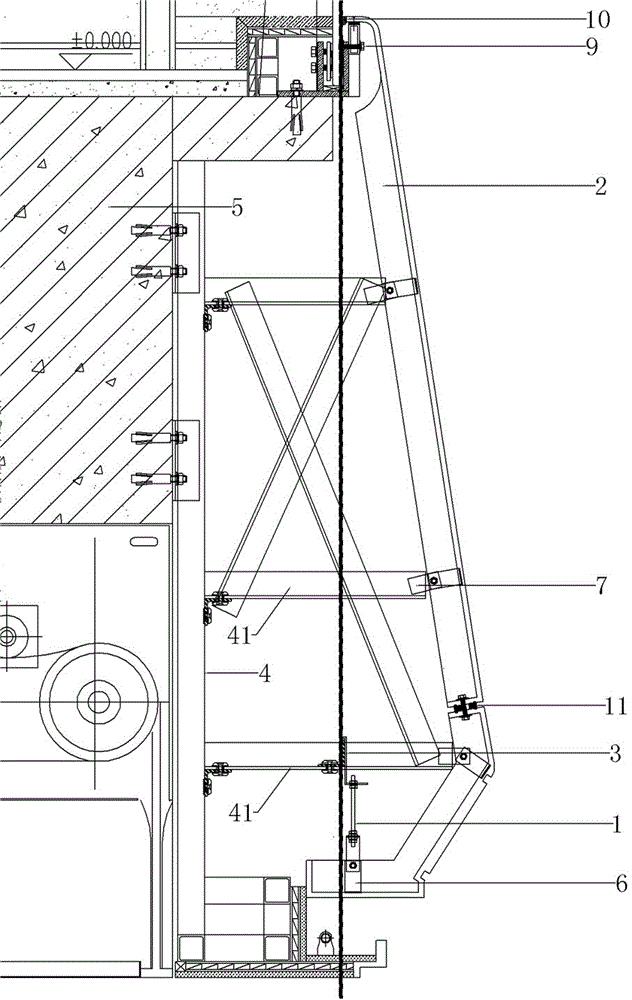

[0035] This embodiment 1 provides a unit assembly installation method for special-shaped arc-shaped GRG decorative panels, including the following steps:

[0036] S1: On-site setting out to determine the size of the GRG decorative panel installation surface, based on the variable arc position, according to the site size, computer drawing to close the special-shaped arc surface, determine the size of the variable arc GRG decorative panel and standard GRG decorative panel, so that the overall curved surface data is smooth ; and each variable arc GRG decorative panel and standard GRG decorative panel is an independent unit plate.

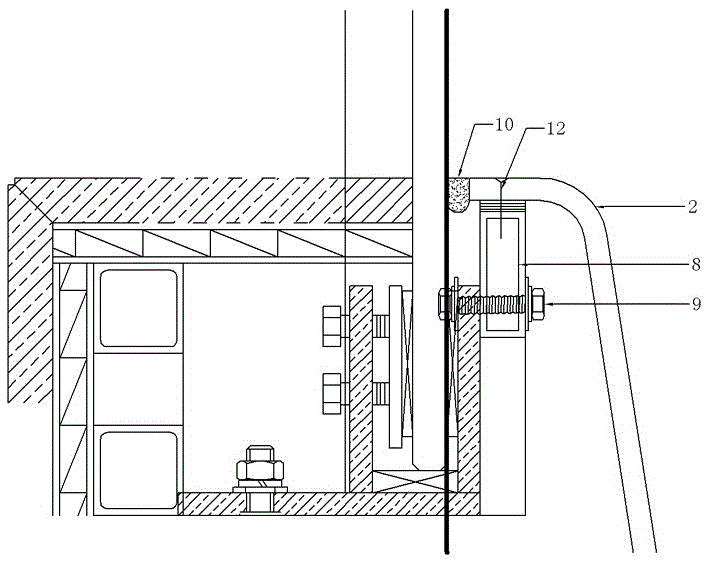

[0037] S2: According to the size of the computer, the template of the variable arc position GRG unit veneer is made with a splint. With this template, the variable arc GRG unit veneer 2 is processed first, and then the standard GRG unit veneer is processed; the original laying-out on site is corrected according to the computer size, and the The finishe...

Embodiment 2

[0055] This embodiment provides a unit assembly installation method for special-shaped arc-shaped GRG decorative panels. The difference from Embodiment 1 is that in step S3, the skeleton structure 4 is straightened through the adjustable oblong holes on the bending members. After straightening, use splints to make a formwork that matches the processing size of the GRG unit veneer at the variable arc position, that is, the secondary formwork, and when installing the variable arc GRG unit veneer, first temporarily place it up and down on the skeleton structure 4 at the variable arc position Install the manufactured template, and then install the hooking device 3 on the skeleton structure 4 at the two adjacent variable arc positions, connect the hooking device 3 with one end of the hanging part 1 by means of bolts, and connect the other end of the hanging part 1 with the back of the GRG unit veneer panel The embedded parts 6 are connected, and the arc of the GRG unit decorative pa...

Embodiment 3

[0058] This embodiment provides a unit assembly installation method for special-shaped arc-shaped GRG decorative panels. The difference from Embodiment 1 is that in step S3, before completing the installation of all standard GRG unit decorative panels, a standard GRG unit is reserved For the veneer space, the standard GRG unit veneer with the size of the reserved space is reprocessed on site, so that the size of the last standard GRG unit veneer processed on site matches the vacant position on site, and then the last GRG unit veneer is installed to Complete the installation of the entire GRG veneer. Through on-site secondary processing of the size of the last standard GRG unit veneer, certain installation deviations during the installation process can be avoided, so as to ensure that the radian of the special-shaped arc-shaped GRG veneer in the shared space is consistent with the construction site, making the GRG veneer as a whole Fluency of installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com