Ground transportation track installation method

A technology of transportation track and installation method, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of loose contact and fit, inability to correct, and failure to meet the quality requirements of track installation, so as to avoid installation deviation and increase installation operations Difficulty, simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

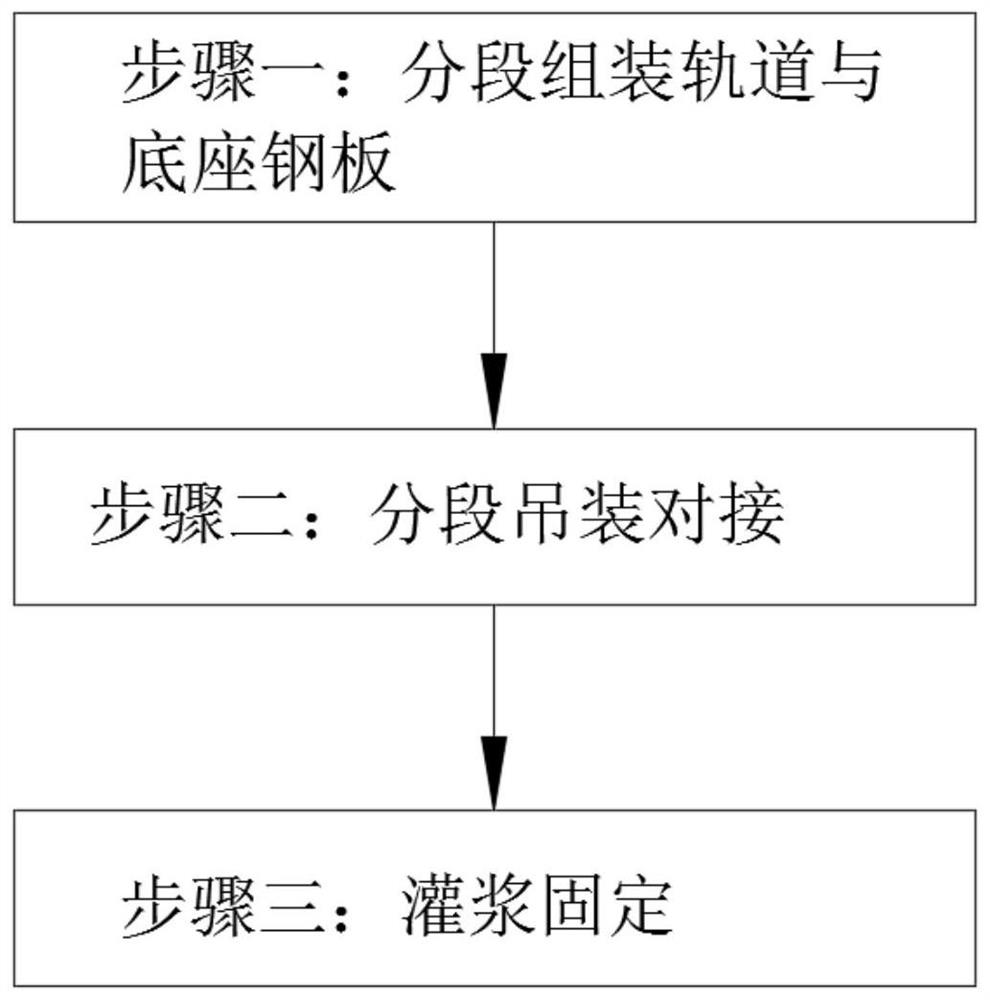

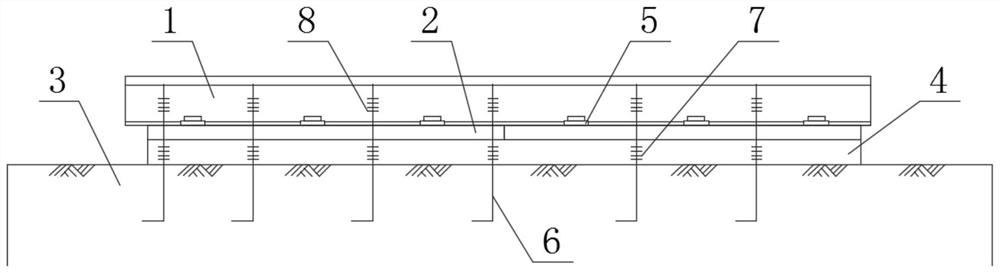

[0022] Embodiment one: if figure 1 As shown, the process flow of the ground transportation track installation method includes the following steps:

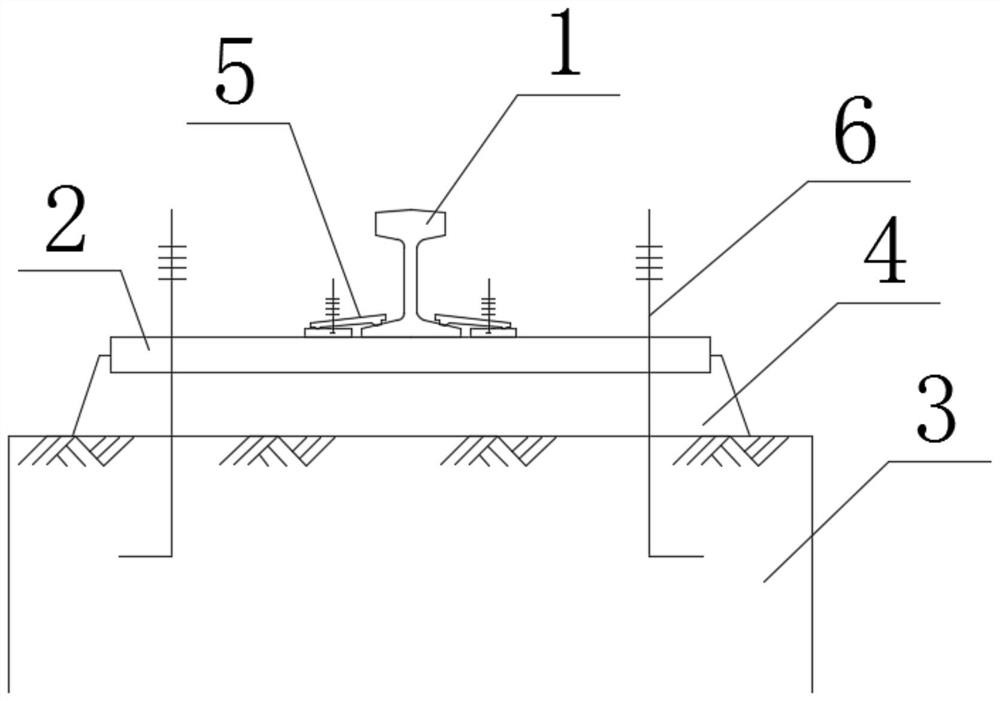

[0023] Step 1: Assemble the track and the base plate in sections. The length of the single track used is 12m, and the length of each base plate is 2m. The width of the base plate is selected according to the actual design requirements. The six base steel plates are grouped into one group, and the six base steel plates of the same group are laid on the flat ground to form a section of 12m in length, and the measurement is made on the six base steel plates in each group that are 12m long. Mark the installation position of the track by setting out the line. When measuring the line, you can choose to reserve a position of 0.5-1.0 meters long at one end of the 12m length, and hang the track on each group of base steel plates to align with the marked track installation position, because in the measurement Reserve a 0.5-1.0 meter long p...

Embodiment 2

[0026] Embodiment 2: The process flow of the ground transportation track installation method includes the following steps:

[0027] Step 1: Assemble the track and the base steel plate in sections. The length of the single track used is 12m, and the length of each base steel plate is 1.2m*2m. Follow the laying method of the base steel plate on the track foundation, and carry out the five base steel plates as a group. In groups, the five base steel plates of the same group are laid out on the flat ground with a width of 1.2m in order to form a section of 10m long, and the set-out marks are measured on the five base steel plates laid out in each group to form a 10m long track installation Position, hoist the track on each group of base steel plates and align with the marked track installation position, each end of the track extends 1m from the edge of the 10m long base steel plate spread; then use a rail clamp to fix the track on the base steel plate ;The rail pressure device inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com