Brightness and chrominance correction coefficient generation device and brightness and chrominance correction method for LED (light emitting diode) display screen

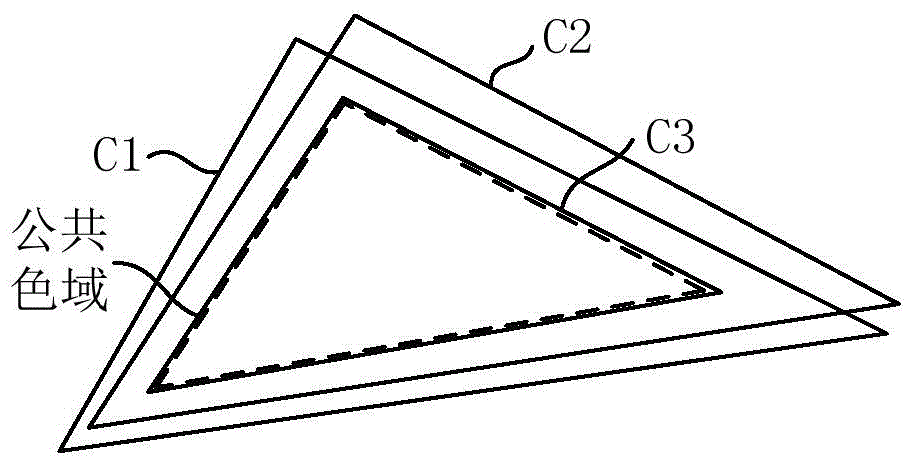

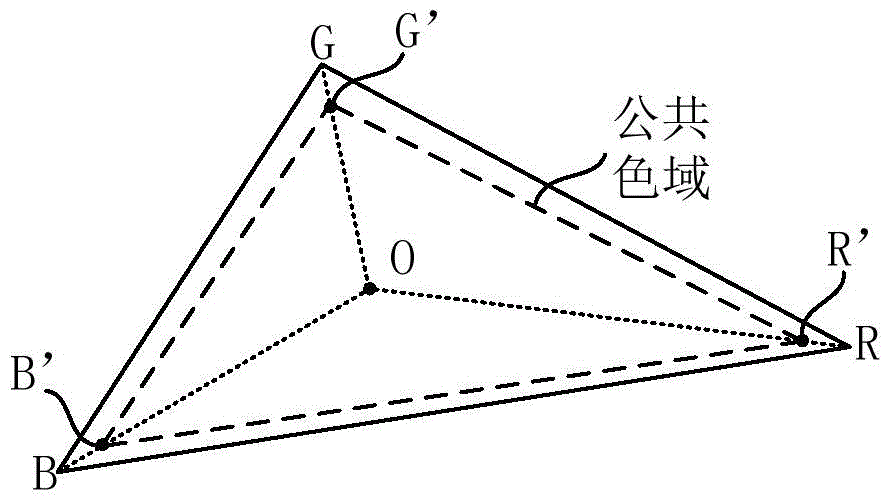

A technology of LED display and calibration method, applied in static indicators, instruments, etc., can solve the problems of decreased color brightness, excessive sacrifice of batch brightness and chromaticity, and small public color gamut.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

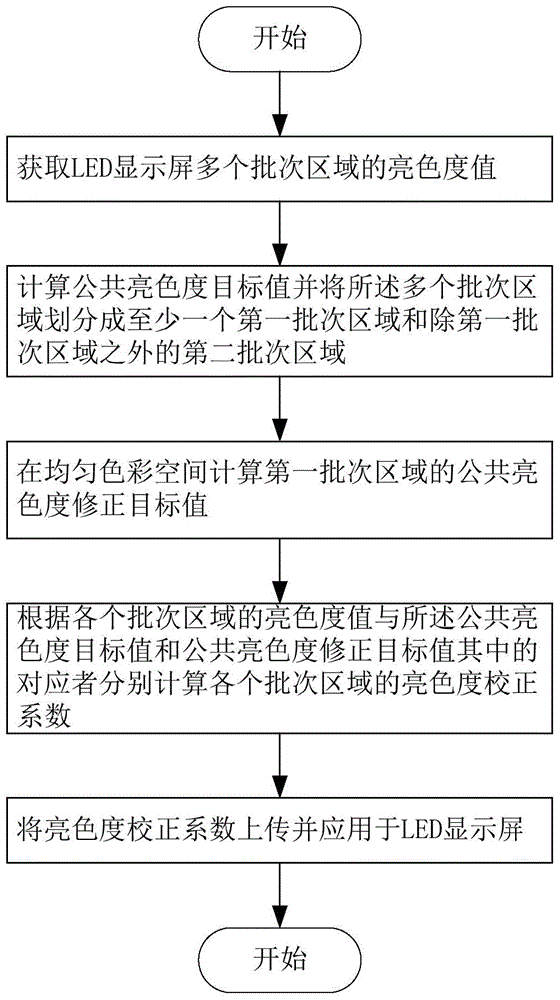

[0036] See figure 2 , which is a flowchart of a method for correcting brightness and chromaticity of an LED display screen based on a uniform color space provided by an embodiment of the present invention. This embodiment aims at the problem that the current commonly used multi-batch LED display screen (that is, the LED display screen using multiple batches of LEDs) correction method may cause the brightness and color vividness of the LED display screen to drop too much. Color space calculations generate luminance and chroma correction coefficients that are closer to human perception. The following will combine figure 2 The specific implementation method is described in detail as follows:

[0037] (1) Obtain the brightness and chromaticity values of multiple batch areas of the LED display. In this embodiment, the acquisition method of the brightness and chromaticity values of each batch area may be: using a camera or a chromaticity meter to collect the brightness and ...

no. 2 example

[0053] See figure 2 , this embodiment aims at the problem that the current commonly used multi-batch LED display screen (that is, the LED display screen using multiple batches of LEDs) correction method may cause the brightness and color vividness of the LED display screen to drop too much. Based on the CIE- Lab color space calculation generates brightness and chroma correction coefficients that are closer to human perception. The following will combine figure 2 The specific implementation method is described in detail as follows:

[0054] (1) Obtain the brightness and chromaticity values of multiple batch areas of the LED display. In this embodiment, the brightness and chromaticity value of each batch area is the brightness and chromaticity measurement value on the CIE-XYZ non-uniform color space, and its acquisition method can be: utilize the camera or chromaticity meter to collect the LED display screen each batch area The luminance and chromaticity information is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com