Detection tool for automobile pillar hinges

A column and hinge technology, applied in the field of product inspection, can solve the problems of high inspection cost, installation deviation, and affecting the inspection quality of automobile column hinges, and achieve the effect of ensuring installation requirements, avoiding installation deviation, and improving inspection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

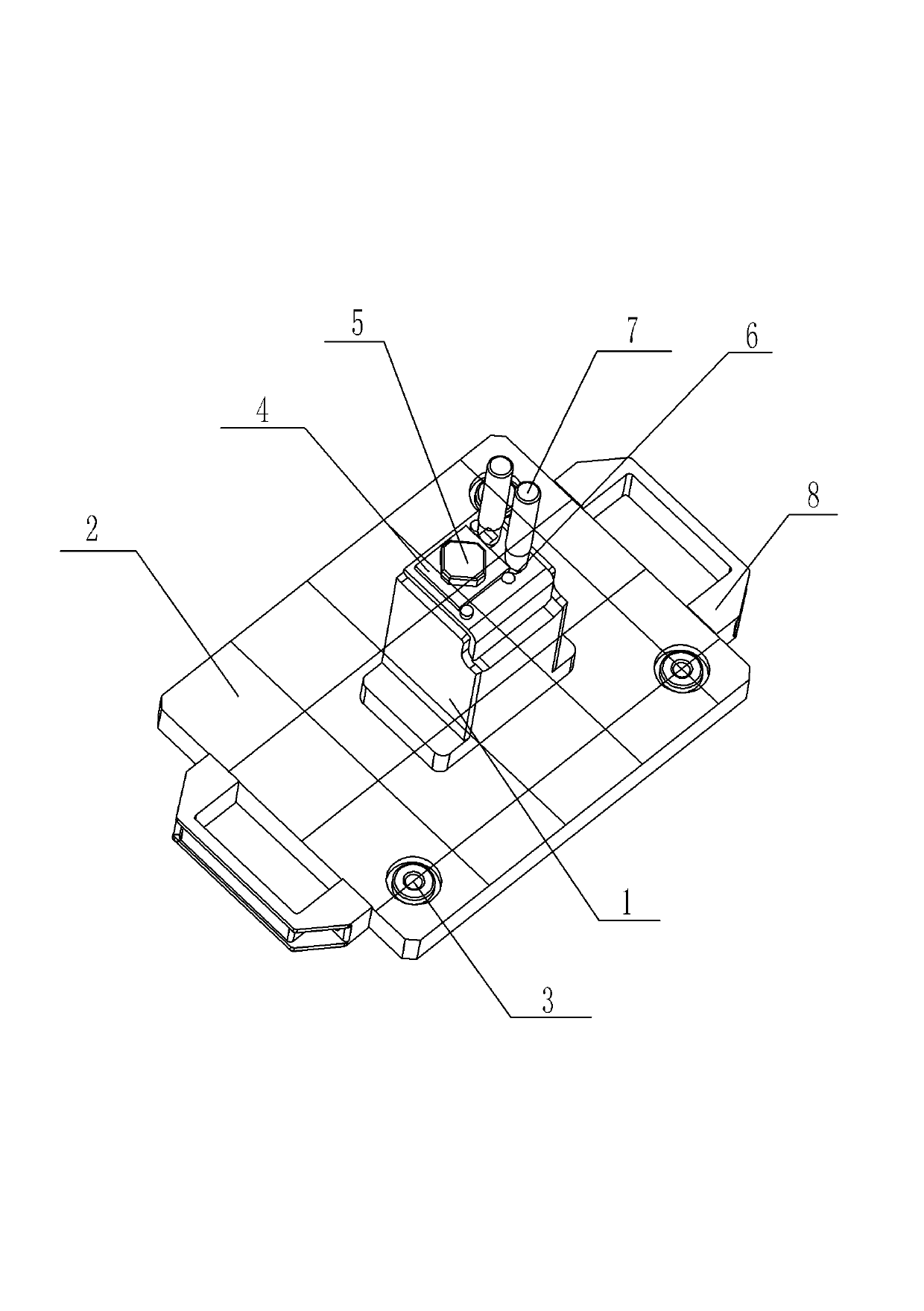

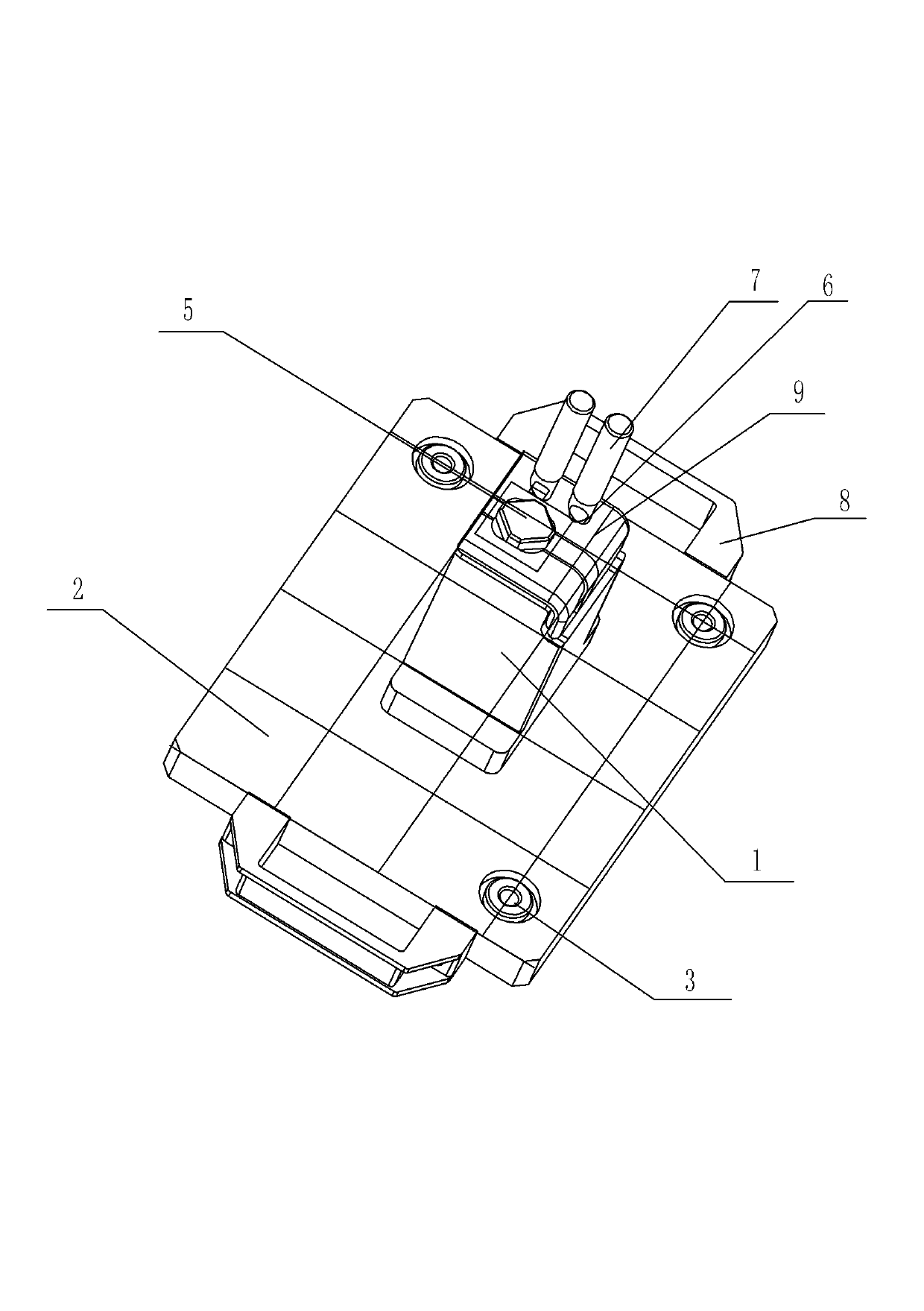

[0009] See figure 1 , figure 2 , a detection tool for the hinge of an automobile column, including a simulation block 1 matched with the hinge of the automobile column, the simulated block 1 is set on a fixed seat 2 with vehicle body coordinates, the fixed seat 2 is provided with a handle 8, and the fixed seat 2 Positioning sleeve 3 is arranged on the top, and positioning surface 4 is provided on the corresponding automobile pillar hinge 8 on the simulation block 1, and the diamond-shaped positioning pin 5 that cooperates with automobile pillar hinge 9 and two corresponding to automobile pillar hinge mounting holes are arranged on the positioning surface 4. Detection pin guide hole 6, detection pin 7 is respectively arranged on the detection pin guide hole, automobile column hinge 9 is placed on the simulation block 1, and the product is fixed on the simulation block positioning surface 4 by the rhombus positioning pin 5, because the simulation block according to The actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com